Page 1

KENCO ENGINEERING COMPANY

P.O. BOX 470426, TULSA, OK 74147-0426

PHONE: (918) 663-4406 FAX: (918) 663-4480

http://www.kenco-eng.com e-mail: info@kenco-eng.com

KENCO Loop Powered Magnetostrictive Transmitter

KMD SERIES – Operation and Installation Manual

Table of Contents

__________________________________________________________________________________________

Section Page

1. INTRODUCTION 2

2. PRODUCT DESCRIPTION 2

Mounting Instructions / Transmitter Dimensions 3

3. TRANSMITTER FEATURES 4

4. PRINCIPLE OF MAGNETOSTRICTION 4

5. TRANSMITTER SPECIFICATIONS 5

6A. ELECTRICAL CONNECTIONS AND WIRING PROCEDURES 6

6B. NOTES FOR ELECTRICAL CONNECTIONS 7

6C. LOOP RESISTANCE VS. POWER SUPPLY 8

6D. RECOMMENDED SAFETY BARRIERS FOR INTRINSICALLY 8

SAFE INSTALLATIONS

7. SYSTEM CHECK 9

8. MAINTENANCE 9

9. UNITS OF MEASURE FOR KMD TRANSMITTER 9

10. CALIBRATION PROCEDURES USING FRONT PANEL DISPLAY 10

11. OTHER SETTINGS AVAILABLE ON LCD PANEL DISPLAY 11

12. ADJUSTMENTS FOR TRANSMITTER VIA 11-13

HART‚ COMMUNICATIONS

Page 2

1. INTRODUCTION

____________________________________________________________

KENCO is pleased to update its loop powered magnetostrictive

transmitter with the latest innovations in magnetostrictive

technology, as well as adding new features to the product offering.

The KENCO KMD Series magnetostrictive transmitter is designed

solely for use with the KENCO magnetic liquid level indicator, the

Magna-Site. The transmitter electronically monitors the location of

the magnetic float within the Magna-Site gauge housing, providing

an output in a unit of measure as a % of span or a 4-20 mA output.

The KMD series also incorporates HART® communications and a

visual display as part of the standard offering.

2. PRODUCT DESCRIPTION

_____________________________________________________________

KENCO transmitters electronically monitor the location of the

magnetic float within the Magna-Site gauge housing, providing an

output in a unit of measure as a % of span or a 4-20 mA output. The

transmitter is available up to a length of 300 inches. Zero and span

may be adjusted by using the HART® communications protocol or it

may be manually calibrated using the keypad display inside of the

explosion proof housing. These transmitters operate within a process

temperature range of – 40°F to 300°F. Field replaceable electronics

are potted and encapsulated. KENCO transmitters are available as

standard with NEMA 4X/7 explosion-proof housings. These housings

feature an industrial epoxy coating for corrosion resistance. All

KENCO level transmitters use non-contacting, magnetostrictive

technology. This simple design ensures no scheduled maintenance or

re-calibration – ever. Accurate, non-contact float location sensing is

achieved with absolutely no wear to any of the sensing elements.

Page 3

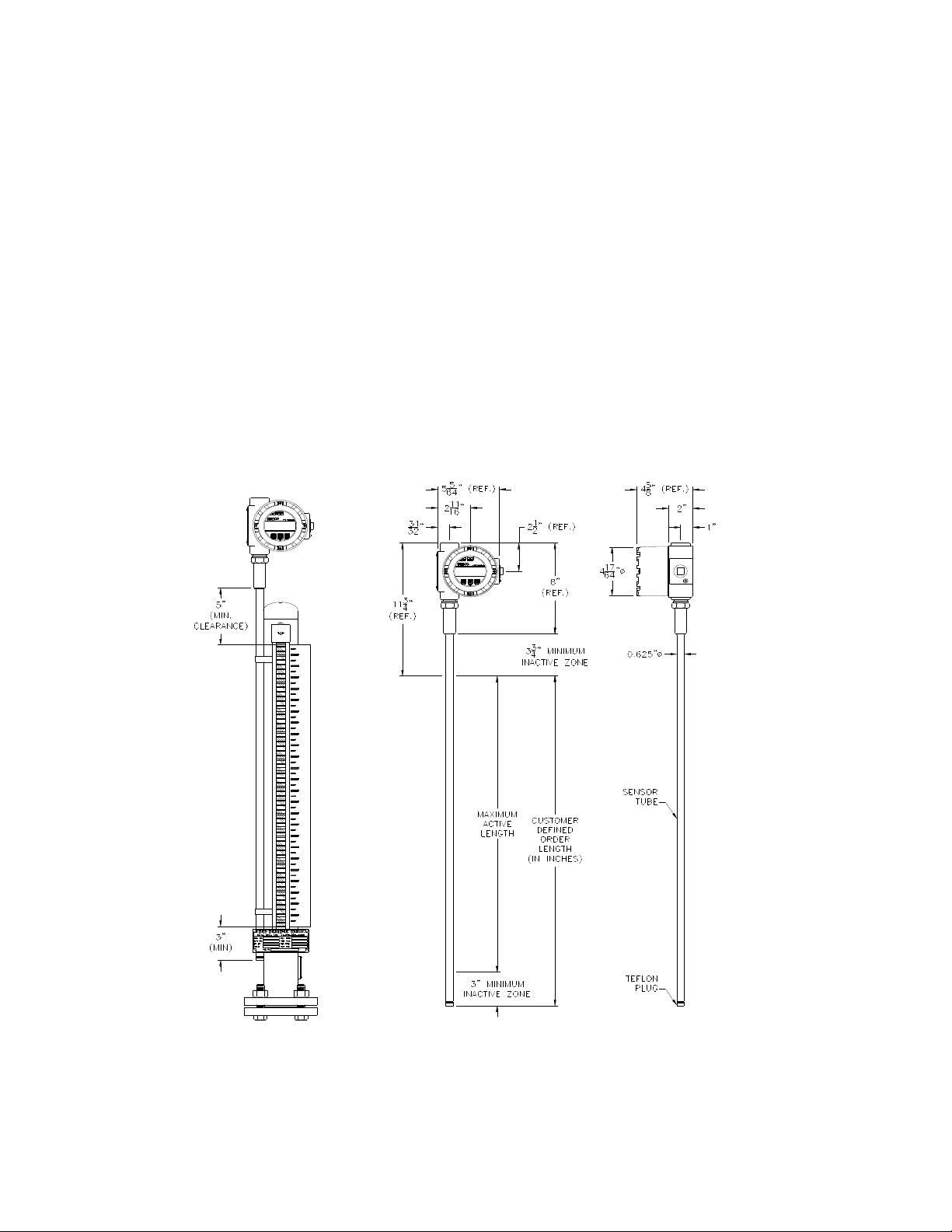

Mounting Instructions / Transmitter Dimensions

________________________________________________________________________________________________

The KMD Transmitter is mounted directly to the housing of the MagnaSite. In a typical application, the magnetic flag assembly is attached to

the gauge housing chamber with hose clamps which have been welded to

the back of the flag assembly, typically 180° from the flanged or threaded

connections to the tank. Install the transmitter at least 90° to the right or

the left of the flag assembly (your choice) by placing the outer pipe of the

transmitter body adjacent to the gauge housing. Tighten the hose clamp of

the flag assembly around the outer pipe of the transmitter. Allow for the

inactive zone of 3 inches at the bottom of the transmitter by placing

transmitter bottom 3 inches below the zero setting. Your application will

allow for 5 inches of clearance at the top of the outer pipe. See dimensional

information below.

Note: In a typical application, KENCO adds 2 inches to the order length so

that the customer has additional mounting flexibility. Units are factory

calibrated with the additional 2 inches at the top of the gauge, bringing the

total inactive zone at the top to 7”.

9999 999999 9999

9999 999999 9999

Page 4

3. TRANSMITTER FEATURES

____________________________________________________________________________________________________________________

• CSA approved explosion-proof enclosure

• Digital Display for zero and span settings and readout

• Readout is updated every 3 seconds

• Readout available as a % of span, a 4-20 mA output or any unit of

measure

• Adjustments may be made using a HART ® hand held communicator

• Repeatability is .005% full span or .005 inches

• Temperature range: - 40°F to 300°F (call KENCO for higher temperature

requirements)

• No maintenance required

• Immune from electrical and mechanical noise

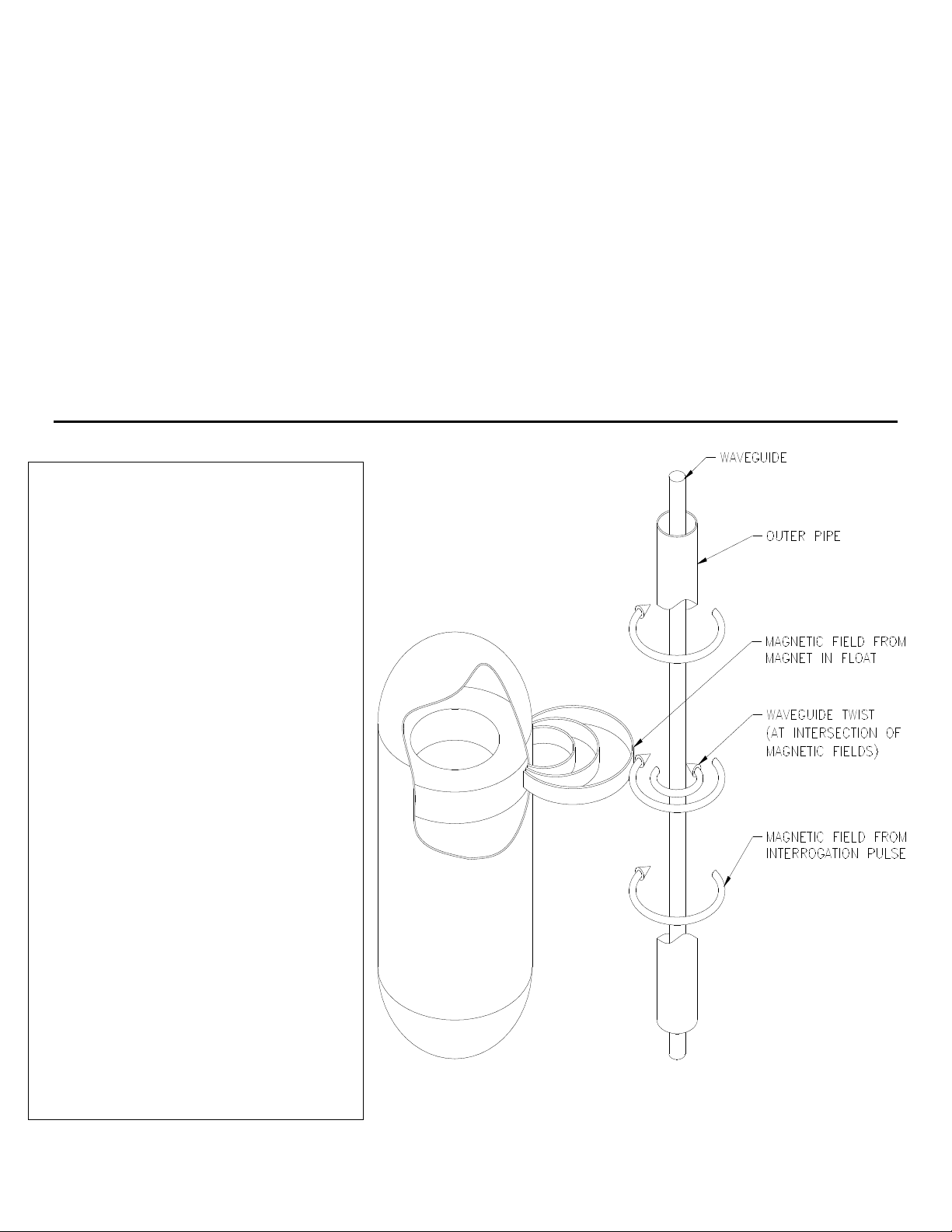

4. PRINCIPLE OF MAGNETOSTRICTION

The level transmitter is composed of 2

concentric members. The outermost

member is a protective 316 stainless

chamber that withstands aggressive

environments. Inside of the chamber

is the waveguide, a formed element

constructed of a proprietary

magnetostrictive material.

A pulse is induced in the waveguide by

the momentary interaction of 2

magnetic fields, one from an electric

current pulse launched along the

waveguide and the other from the

magnets inside the float. This

interaction produces a strain pulse

that travels along the waveguide. The

location of the magnet inside the float

is determined by measuring the

elapsed time between the launching of

the electronic pulse and the detection

of the strain pulse that travels along

the waveguide. The location of the

magnet inside the float is determined

by measuring the elapsed time between

the launching of the electronic pulse

and the detection of the strain pulse by

the sensor head. The time period

measurement is used to produce an

output reading of the float location.

Page 5

5. TRANSMITTER SPECIFICATIONS

________________________________________________________________________________________________________________________

Parameter Specifications

Level Output

Measured Variable Liquid Level (as determined by location of magnetic float)

Full Range 18” to 300”

Non-Linearity Full Span 0.020 F.S. or 1/32”, whichever is greater

Repeatability 0.01% F.S. or 1/32”, whichever is greater

Sensor Operating Temp. - 40°F to 300°F

Transmitter Loop

Input Voltage Range 10.5 to 36.1 VDC

Reverse Polarity Protection Series Diodes

Safety Approval CSA Certified Explosion Proof C1.I, Grps. B, C, D C1.II Grps E, F, G

Division 1, NEMA 4X

CSA Certified Intrinsically Safe (when installed with I.S. Barriers)

C1. I, Grps A, B, C, D; C1. II, Grps, E, F, G. Division 1, NEMA 4X

Calibration

Zero Adjust Range Anywhere within the active length

Span Adjust Range Full scale more than or equal to 0.5” from zero

Environmental

Electronics Operating Temp. - 30°F to 160°F

Humidity 0 to 100% Relative Humidity

Materials/Outer Pipe 316 Stainless Steel

Field Installation

Mounting 3/4” NPT fitting or flange mounting

Wiring 2 wire connection, shielded cable or twisted pair to screw terminals

through a 3/4” NPT conduit opening

Display

Measured Variables Liquid Level

Update Rate: 3 seconds

Size: 0.5”

Number of digits: 16

Measurement: % of span, a 4-20 mA output or any unit of measure

HART® Communications

Method of Communication Frequency Shift Keying (FSK) conforms with Bell 202 Modem

Standards with respect to baud rate and digital “1” and “0” frequencies

Baud Rate 1200 bps

Digital “0” Frequency 2200 Hz.

Digital “1” Frequency 1200 Hz.

Data Byte Structure 1 Start Bit, 8 Data Bits, 1 Odd Parity Bit, 1 Stop Bit

Digital Process Structure Rate Poll//Response Model 2.0 per second

Page 6

6A. ELECTRICAL CONNECTIONS AND WIRING PROCEDURES

___________________________________________________________________________________________________________________

A typical intrinsically safe connection for the KMD Transmitter includes protective safety

barriers, a power supply, and a reading or monitoring device.

Non-Hazardous Locations (Intrinsically Safe):

Hazardous Location:

A typical explosion-proof connection for the KMD Transmitter includes a power supply

and a reading or monitoring device connected via an explosion-proof conduit.

HART® Communications Inside Display Module:

9999 999999 9999

Page 7

6B. NOTES FOR ELECTRICAL CONNECTIONS

_____________________________________________________________________________________________________________

1. For intrinsically safe installations, wiring shall be installed in accordance with the

country in use. Example given: Canadian Electrical Code, Part 1, National Electric

Code ANSI/NFPA 70 Article 504-30.

2. Shielded twisted cable of 24 AWG or heavier should be used. Cable capacitance

shall be less than 30 PF per foot.

3. Control room equipment should not use or generate more than 250 V RMS.

4. For FMRC and CSA approved transmitters barriers must be FMRC and CSA

approved.

5. The connection between the earth ground terminal of FMRC or CSA entity approved

safety barriers and system earth ground must be less than 1 ohm.

6. Safety barriers are FMRC and CSA entity approved safety barriers used in an

approved configuration where transmitter Vmax is greater than barrier Voc and

transmitter Imax is greater than barrier Isc.

7. Transmitter Ci plus total cable capacitance for each loop must not exceed barrier Ca.

transmitter Li plus total cable inductance for each loop must not exceed barrier La

(see note 10).

8. Transmitter enclosure shall be grounded to earth ground through the provided

ground lug in the enclosure.

9. Parameters for each loop entity:

• Vmax = 36v

• Imax = 118 mA

• Ci = 0

• Li = 200 µH

10. HART® communicator must be connected in accordance with manufacturers’ I.S.

installation instructions (FM and CSA approved procedures must be followed).

11. Use only NRTL listed and CSA certified dust-tight seal for Class II and Class III

hazardous locations.

12. CSA file number is LR 81728.

13. Do not use plugged housing entry (at top of enclosure) for termination of conduit.

14. In high humidity areas, use a breather type conduit sealing fitting to minimize

moisture intrusion.

15. Safety recommendations: Always follow applicable local and national electrical

codes and observe polarity when making electrical connections. Never make

electrical connections to the transmitter with power turned on. Make sure that no

wire strands are loose or sticking out of the terminal block connections, which could

short and cause a problem. Make sure that no wire strands, including shield, are in

contact with the electronic module enclosure. The electronics module enclosure is

grounded through internal circuitry and electrically isolated from the explosion proof

enclosure.

Page 8

6C. LOOP RESISTANCE VS. POWER SUPPLY

______________________________________________________________________________________________________________

6D. RECOMMENDED SAFETY BARRIERS FOR INTRINSICALLY

SAFE INSTALLATIONS

____________________________________________________________________________________________________________

NOTES:

1. When selecting barrier types, the electrical specifications for the transmitter are:

• Vmax = 36.1 Vdc

• Imax = 118 mA

• Ci = 0.0 µF

• Li = 0.0 µHy

2. KENCO recommends the following safety barrier:

• Stahl Model Number 9001/01-280-100-10

SAFE OPERATING

POWER

INSUFFICIENT OPERATING POWER

EXCESS OPERATING POWER

Page 9

7. SYSTEM CHECK AND ALARM SETTINGS

______________________________________________________________________________________________________________

System Check

After completing the wiring, the system is ready to be checked out. Apply power to the unit.

Using a DC voltmeter, measure the voltage at Loop 1 connection. The voltage must be

> 10.5 v. If the voltage level is too low, shut down the system. Check for shorts, power supply

voltage, and excessive loop resistance. Refer to the safe operating chart on the previous page,

which shows the relationship between loop resistance and operating voltage.

To test Loop 1 on a bench, move the magnetic float (or a magnet) along the operational range of

the transmitter body. If functioning properly, the output current will change as the float moves.

An output range of less than 4 mA or greater than 20 mA could indicate a problem.

Alarm Settings

When a fault condition is detected by the internal microprocessor, the 4 to 20 mA current will

go to the current selected. If in the 4 mA alarm mode when a fault is detected, the output will

be continuous at 3.8 + 0.1 mA. If in the 20 mA alarm mode when a fault is detected, the

output will be continuous at 21.5 + 0.2 mA.

8. MAINTENANCE

_____________________________________________________________________________________________________________

Removal of Electronic Puck

The transmitter is designed so that the user may remove the electronics module for any reason,

including repair or replacement. Use the instructions below to remove the electronics module:

1. Remove power from transmitter.

2. Remove cover from explosion-proof housing.

3. Gently pull out the electronic puck by raising equally on all sides of the round

puck.

4. Pull electronic puck completely free of connector pins on block cover.

Installation of Electronic Puck

1. Remove power from transmitter.

2. Remove cover from explosion-proof housing.

3. Place electronics puck on top of mating connector pins (2 places) and gently

press down on puck.

4. Press down on puck until connection is made completely.

9. UNITS OF MEASURE FOR KMD TRANSMITTER

_____________________________________________________________________________________________________________

The KMD transmitter can be calibrated to read the following units of measure:

1. mA 4. Feet

2. % of Total Span 5. Centimeters

3. Inches 6. Meters

The unit of measurement must be decided at the time of order placement. Otherwise all

units will be factory set so that the LCD display will readout in 4-20 mA.

Page 10

10. CALIBRATION PROCEDURES USING FRONT PANEL DISPLAY

____________________________________________________________________________________________________________________

The KENCO level transmitter can be bench-calibrated with the display and the three push

buttons. Please follow these procedures:

1. Change the mode of operation from the Run Mode to the Program Mode. To enter the

Program Mode, press any of the following keys: Up, Down or Enter (see diagram

below). Important Note: Upon entering the Program Mode, a one-minute timer is

started. Each time a button is pressed, the timer will be reset. If the operator fails to

press a menu button within one minute, the timer will expire and the display will return to

Run Mode. This automatic timeout feature is incorporated so that the transmitter will

not be inadvertently stuck in Program Mode.

2. Calibrate Level 1? appears on screen. Press Enter.

3. Set Zero? appears on screen. Place magnetic float (or a simple magnet) on outer pipe at

desired zero position. Press Enter key and hold for a one second count. (Unit is

factory set at 3” from end of pipe at the beginning of visual for the flag assembly).

4. Press Enter again.

5. Accept New Value? appears on screen. Press Enter if zero location is acceptable. If

there is a need to reset this zero position, press up or down keys simultaneously to begin

process again from step 2.

6. Calibrate Level 1? reappears on screen. Press Enter.

7. Set Zero? appears on screen. Press down key one time.

8. Set Span? appears on screen. Place magnetic float (or a simple magnet) on outer pipe at

desired span location. Press Enter key and hold for a one second count. (Unit is factory

set at the end of the visual for the flag assembly at the upper end of the gauge.

9. Press Enter again.

10. Accept New Value? appears on screen. Press Enter if span location is acceptable. If

there is a need to reset this zero position, press up or down keys simultaneously to begin

process again from step 7. Calibration is now complete.

11. Once all steps are complete, press all 3 buttons to get out of Program Mode and return to

Run Mode, or allow the Program Mode timer to expire after one minute.

9999 999999 9999

Page 11

11. OTHER SETTINGS AVAILABLE ON LCD PANEL DISPLAY

____________________________________________________________________________________________________________________

Adjust LCD Contrast. This function allows the operator to adjust the brightness of the LCD

readout.

1. Change the mode of operation from the Run Mode to the Program Mode. To enter the

program mode, press any of the following keys: Up, Down, or Enter (see diagram on

previous page).

2. Calibrate Level 1? appears on screen. Press Up or Down key until Adjust LCD

Contrast? appears on screen.

3. Press Enter. LCD Cntrst 0 appears on screen.

4. Using Up and Down keys, you can adjust the brightness of the LCD readout. 0 is the

brightest setting, 3 is the faintest. Press Enter when desired brightness is displayed.

5. Accept? appears on screen. Press Enter. Adjust LCD Contrast function is complete.

6. Once all steps are complete, press all 3 buttons to get out of Program Mode and return to

Run Mode or allow the Program Mode timer to expire after one minute.

Perform LCD Test. This function allows the operator to view all LCD digits available.

Note: Only Level 1 is applicable for the KENCO KMD transmitter. Level 2 and temperature

readings are not applicable.

1. Change the mode of operation from the Run Mode to the Program Mode. To enter the

Program Mode, press any of the following keys: Up, Down or Enter (see diagram on

previous page).

2. Calibrate Level 1? appears on screen. Press Up, or Down key until Perform LCD

Test? appears on screen.

3. Press Enter. All LCD digits are displayed for 10 seconds.

4. Once all steps are complete, press all 3 buttons to get out of Program Mode and return to

Run Mode, or allow the Program Mode timer to expire after one minute.

12. ADJUSTMENTS FOR TRANSMITTER VIA HART®COMMUNICATIONS

_____________________________________________________________________________________________________________________

Refer to the documentation supplied with your specific HART® software package or hand held

communicator for details on performing sensor calibration. Using the HART® interface allows

for calibration of the zero and span without having to remove the unit from the process and

position the magnetic float. The HART® commands 35 and 65 are implemented for this

function. Loop 1 (Zero and Span) is the primary variable.

Calibration set points are given as the absolute displacement from the tip of the sensor. For

example, if the desired zero position is 3 inches, the transmitter will produce 4 mA when the

float is 3 inches from the tip of the transmitter. If the desired span position is 30 inches, the

transmitter will produce 20 mA when the float is 33 inches from the tip of the transmitter.

Page 12

12. ADJUSTMENTS FOR TRANSMITTER (cont’d)

HART® Quick Start

The KMD transmitter can be calibrated using a HART® Model 275 hand-held terminal.

1. Be sure you have the transmitter Loop #1 connected to a load of 250 to 500 ohms.

A unit installed in a control loop is a good example of this loop load. You may also

use a load resistor in the range of the above value.

2. Be sure the transmitter is connected to a clean 24 VDC power supply. Use a linear

supply, as switching types do not provide ripple free power. HART® cannot

tolerate more than a 25 mV voltage ripple.

3. If the unit is installed in a live application, place your automatic controllers in

manual mode and be advised that the output current will change during calibration.

4. Follow safe working procedures as applicable for working on live equipment in a

hazardous location. When safety is secured, remove housing cover.

5. Press the black and black “I/O” button on the HART® terminal. The terminal will

go into self test, then into the main screen. If not connected properly, you will get a

“No device found” message.

6. From the main screen, press keypad #1, “Device Setup”.

7. From the “Device Setup” screen, press key #3, “Basic Setup”.

8. Press key #3, you are now in “Range Values” screen.

9. To Set Low Value: To set low value (4 mA), select key #1, PV LRV (Process

Variable, Lower Range Value). You are now in the PV LRV screen. The current

low value is displayed. Below this value is a highlighted value. Key in the desired

low value (example: 3 inches is shown; if 4 inches is desired, key in 4.). When the

new desired low value is keyed in, press “Enter” (F4) button located below the LCD

display, right. To write the changed lower value to memory, press the “SEND” key

now. Next, you will see two “WARNING” screens that ask if you are sure. If your

new low values are correct, press “OK” for both messages. This action resets the

Lower Range Value, or 4 mA position into the transmitter’s memory.

· Go back to the “Range Values” screen to verify that the new parameters have been

accepted into the transmitter memory.

· You may now exit program mode or continue on to reset the upper value. If you

choose to exit the program mode, replace the calibration jumper to the “ON”

position and return your controllers to automatic.

10. To Set High Value: You should now be in the “Range Values” screen. To set the

20 mA (Upper Range), press key #2. You are now in the “PV URV” (Process

Variable, Upper Range Value) screen. As in the lower value screen, the current

value is displayed with a highlighted number below it. To change the upper value,

key in the desired value. You may use whole numbers or whole numbers and

decimal numbers (40 = 40 inches; 40.5 = 40.50 inches). Whole numbers will be

entered as their decimal equivalents by HART® automatically. Key in the desired

upper range value desired. Press the “Enter” (F4) button.

Caution! Do not enter a high value that exceeds the active length of the sensor!

Page 13

12. ADJUSTMENTS FOR TRANSMITTER (cont’d)

11. You are back in the “Range Values” screen. If the numbers for lower and upper are

correct, press the “Send “ key. You will get a “WARNING!” Press the “OK”

button. You will again get “WARNING!” Press “OK” again.

12. Startup is now complete.

Loading...

Loading...