Page 1

KENCO ENGINEERING COMPANY

K

- - -

P.O. BOX 470426 TULSA, OK 74147-0426 ● PHONE: (918) 663-4406 FAX: (918) 663-4406

www.kenco-eng.com e-mail: info@kenco-eng.com

MODEL KMR, KMT, KHR, AND KHT FLAT GLASS GAUGES

INSTALLATION / OPERATION INSTRUCTIONS

GENERAL DESCRIPTION

Kenco Flat Glass Gauges are simple, rugged instruments engineered and constructed throughout to give you accurate

liquid level readings for the life of the vessel. We offer a complete range of gauges suitable for most applications. Like

any instrument, Kenco flat glass gauges must be installed, operated, and maintained with reasonable care and due regard

for the application, and the environment, if they are to give accurate readings over a long life.

This instruction sheet covers medium and high pressure gauges, as well as, large chamber gauges. Weld Pad gauges

are covered in a separate instruction sheet. Contact Kenco if you need the Weld Pad sheet.

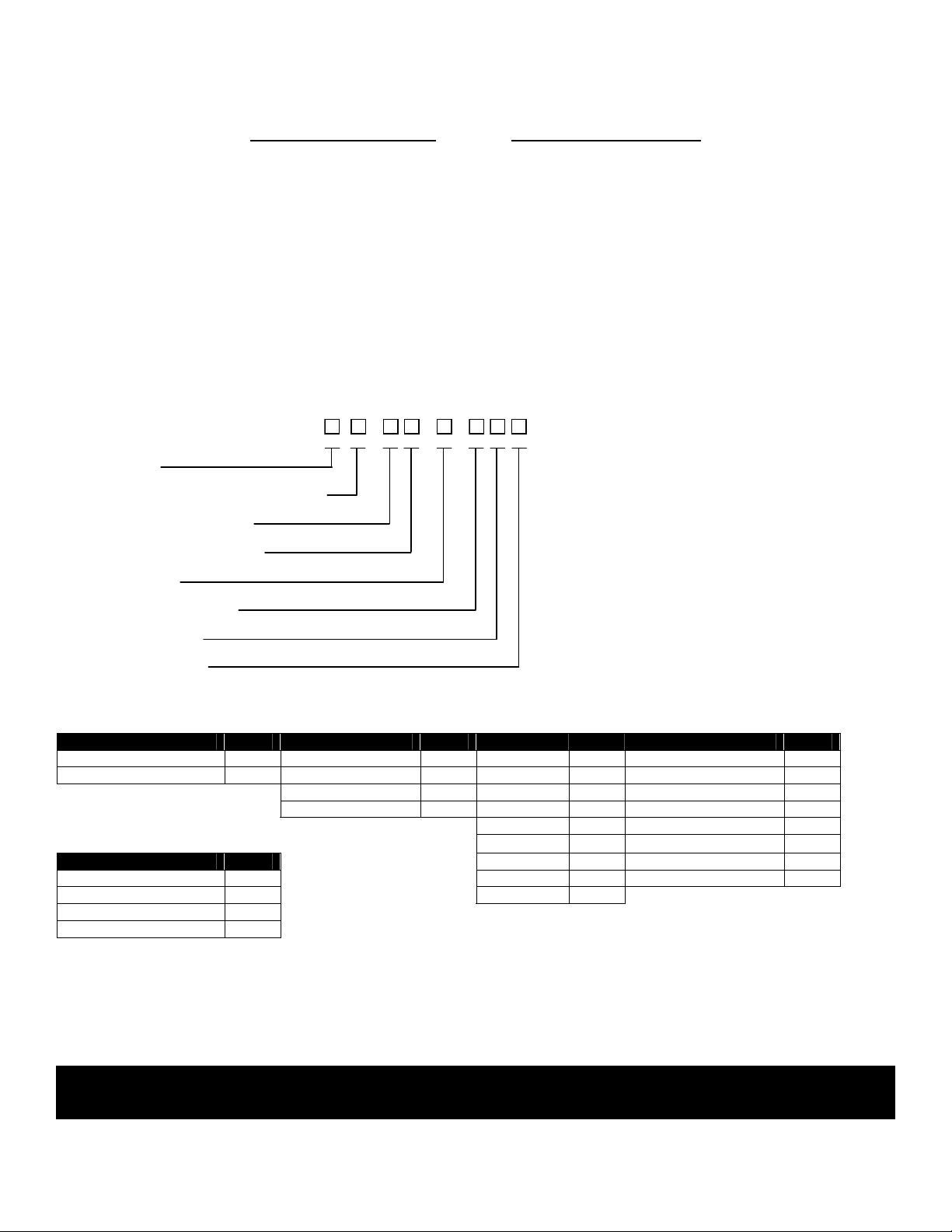

MODEL CONFIGURATOR

Gauge Type

Style (R – Reflex; T- Transparent)

Sections – (1 through 9)

Glass Size – (1 through 9)

Construction

Connection Location

Connection Size

Connection Type

Gauge Type Connection Location Connection Size Connection Type

Material Code Gauge Code Size Code Type Code

Medium Pressure M End E ½” 50 NPTF N

High Pressure H Side (Right) R ¾” 75 Socketweld (Female) S

Side (Left) L 1” 1 150# ANSI Flange A

Back B 1½” 15 300# ANSI Flange B

2” 2 600# ANSI Flange C

Construction

Material Code

Carbon Steel C 6” 6 2500# ANSI Flange F

Stainless Steel Wetted W 8” 8

All Stainless Steel A

Special X

INSPECTION & DELIVERY

Upon receiving the gauge, check all components carefully for damage incurred in shipping. Notify the shipping company

immediately of any such damage, and request a damage inspection. Confirm that the gauge model number and

pressure/temperature ratings (located on the nameplate) match the application conditions. Also, confirm that the gauge

materials are compatible with the process media and the environmental conditions around the gauge.

CAUTION – Kenco Gauge Glasses are not to be used for indicating the level of lethal substances as defined

by ASME Section VIII.

3” 3 900# ANSI Flange

4” 4 1500# ANSI Flange E

D

Page 1

Page 2

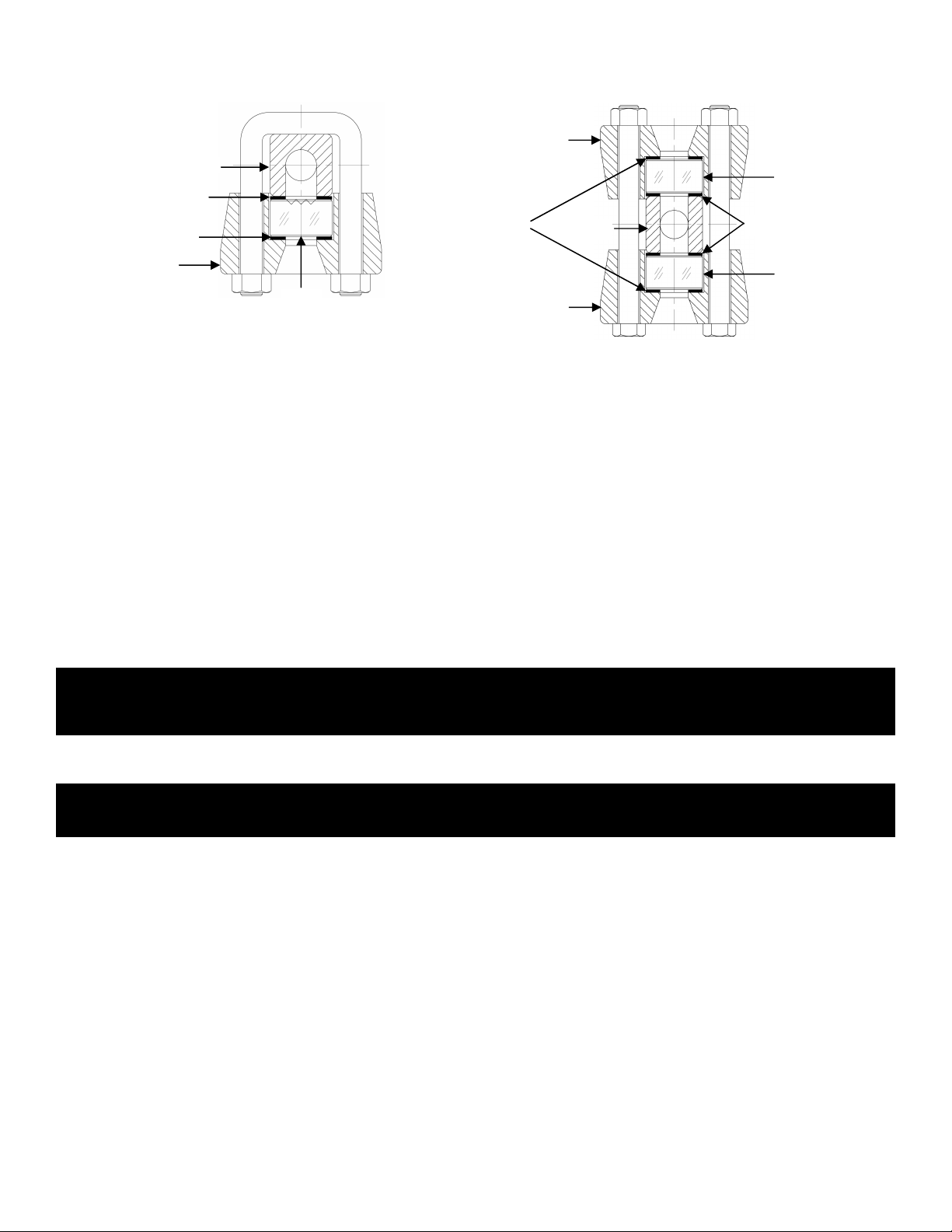

GAUGE CONSTRUCTION

Glass

Chamber

Gasket

Cover

Glass

Cover

Glass

BEFORE YOU INSTALL THE GAUGE

Consider the following:

• To avoid imposing piping strains on the gauge chamber, connect and mount the gauge so that it does not support

• Differential thermal expansions between the vessel and gauge can impose severe mechanical loads on the

• Support brackets should be considered for gauges over four feet in length or over 100 pounds in weight,

• Always provide shutoff valves between the gauge and vessel. Kenco automatic ball check valves are

• Bolt torque is vital to the proper operation of a flat glass gauge. Because gaskets compress over time, bolt torque

CAUTION – Gauges should always be isolated from the process system by closing the upper and lower

OPERATION

CAUTION – Rapid opening of connecting valves can cause glass breakage and / or possible injury to

Always warm up the gauge slowly when it is used with a vessel containing a hot fluid. Slowly open the shutoff valves

carefully, and wait until the gauge is fully warmed up before completely opening the valves. Kenco Gauges use tempered

glass, designed to withstand thermal shock. However, additional loads that you cannot measure are imposed on the

glass during installation. Resistance to thermal shock is reduced accordingly. This procedure also applies to cold fluids.

During system shutdown, it is best to leave the shutoff valves open so that as the gauge cools it depressurizes along with

the rest of the system. Keeping valves closed during shutdown can trap high pressure liquid in the gauge. For high

pressure / temperature applications a viewing system of mirrors should be used to protect personnel from physical injury

in the event of glass breakage.

Gauges should be isolated periodically and bolt torque checked to prevent leaks. This is especially important on gauges

used in intermittent operation, or varying service conditions. When putting a gauge into service always check for leaks

and be certain the shutoff valves are fully open with all vents and drains closed before leaving the site.

Reflex Gauge (Model KMR & KHR)

Cushion

Cover

the piping.

gauge, especially if the vessel contains hot or cryogenic liquids. To prevent these, install an expansion loop

between the gauge and vessel, or use a reasonably long run of piping.

especially when the gauge is exposed to vibration. These support brackets will prevent overloading the

connecting valves and piping and prevent damage to the gauge from excessive vibration.

recommended to provide protection against physical injury and loss of product if glass breakage should occur.

These valves also provide a means to isolate the gauge for maintenance.

should be checked before the gauge is installed (see MAINTENANCE). Bolt torque should also be checked after

the first few hours of operation.

isolation valves, and draining the gauge to relieve pressure before doing any torque or

maintenance checks.

personnel. Gauges should be brought into service slowly.

Transparent Gauge (Model KMT & KHT)

Cushion

Chamber

Gasket

Page 2

Page 3

CAUTION – While the gauge glass is in operation, the shutoff valves must be fully open. A partially open

valve will the automatic ball checks from seating, which could result in physical injury to

personnel and loss of product.

MAINTENANCE

The following is a step-by-step procedure for maintaining your Kenco Flat Glass Gauges:

A. Inspection of Glass:

Look at the glass regularly for any signs of clouding or scratching. In new processes, the glass should be inspected

daily until the need fro replacement becomes apparent. This will help establish the routine inspection / maintenance

cycle.

To examine for scratches, shine a very bright concentrated light (e.g. MagLight) at a 45° angle. Anything that

glistens brightly should be inspected closely. Any scratch which catches your fingernail, any star-shaped or

crescent-shaped mark which glistens is cause for replacement. If inner (process side) surface appears cloudy or

roughened and will not respond to cleaning procedures (next section), is an indicator of chemical attack and, if

severe, is cause for replacement.

B. Cleaning of Glass

Keep glass clean using commercial glass cleaners (e.g. Windex, Bon-Ami). If these don’t seem to work, a dilute

solution of Hydrochloric (muriatic) acid can be used. Observe safety rules when handling these dangerous

chemicals. Cleaning should be done without removing the glass. This may require recirculation of cleaning

materials if the process side of the glass is not accessible. Never use harsh abrasives, wire brushes, metal

scrapers, or other things which could scrape the glass.

CAUTION – DO NOT attempt to clean the glass while the gauge is in operation.

C. Receiving and Storing Glass

Upon receiving replacement glass inserts, inspect containers and glass inserts for shipping damage. Keep glass in

original box until ready for use. If glass is to be inspected, unwrap and re-wrap carefully, avoiding bumping or sliding

polished face across any other object (including table tops).

D. Disassembly

Prior to any disassembly of the gauge, first be sure that the gauge is relieved of all internal pressure, and that the

gauge is at ambient temperature. Loosen end bolts first, working from opposite ends toward the center.

CAUTION – Failure to relieve pressure may result in a sudden release of internal pressure, which can cause

physical injury, and/or glass breakage..

E. Reassembly Guidelines

NOTE: See the section on “GAUGE CONSTRUCTION” for the location any parts discussed below.

Kenco gauges use molded borosilicate glass, tempered to increase its bending resistance. This glass has a low

coefficient of expansion and is more resistant to thermal shock than other glasses. Nevertheless, like any glass it is

much stronger in compression than it is in tension. You should be careful not to impose any bending on the glass, or

set up any local stresses. The following points should be observed to insure long life:

• Check with the Maintenance Supervisor or Engineer for the proper glass to be used in the gauge. Check

box and glass labels or marking against the gauge pressure and temperature ratings.

• The glass, gaskets, cushions, and bolts should not be reused, even when they appear in perfect condition.

Replace with new parts. Bolts will stretch when re-torqued, thereby weakening them. Glass deforms under

pressure from the chamber and cover. Even though a used glass may look perfect, it is not as reliable as a

new one. Best practice is to always use a new glass.

• The glass should be seated on a flat surface with a suitable gasket on the seating surface to avoid

subjecting the glass to stress concentrations which result from poor loading. It should be clamped in place

with a flat cover plate that is uniformly loaded, as described in the “Reassembly Procedures” below.

Page 3

Page 4

• The glass should not be in contact with any metal surfaces.

• For transparent gauges used in steam service, use mica shields between the glass and gasket on the

chamber (process) side.

F. Reassembly Procedure

To avoid leakage and undue stresses on the glass, we recommend the following reassembly procedure:

1.) Before reassembly, clean the gauge chamber seats and cover seats thoroughly with a soft metal scraper,

preferably brass. Be sure all burrs and bits of old gasket are removed. Gouged or scarred seats should be

refinished in a milling machine (or you can return the chamber to Kenco for refinishing). Damaged seats cause

low gasket compression and leakage.

2.) Locate the glass centrally in chamber and cover seat, to avoid glass-metal contact at the ends or sides. This is

best done with the gauge horizontal on a bench, If the gauge must be reassembled in a vertical position. Use a

rubber band around the sides and ends of the glass. This will prevent glass-metal contact during assembly.

3.) With a torque wrench, replace the gauge covers as follows:

a.) Clean bolt and nut threads, and apply a light oil to the threads and nut face. For gauges operating at more

than 150°F, use Molykote or a similar molybdenum disulfide lubricant.

b.) Tighten the nuts finger-tight in the sequence shown in the sketch below, and then tighten with a torque

wrench in the same sequence. Tighten the nuts in five-pound stages. This procedure produces even

loading of the glass.

c.) Recommended final torque values.

• KMR & KMT – 32ft./lbs.

• KHR & KHT – 40ft./lbs.

d.) New rubber-bonded gaskets tend to become permanently compressed after a short time in service. This

causes slight leaks or apparent loosening of the bolts. Therefore, re-torque to the original value after the

gauge has been in service for a few hours, using the same sequence as before.

RECOMMENDED SPARE PARTS

Part Commissioning Two Years

Glass 5% 10%

Shields (if used) 5% 10%

Gaskets 5% 10%

Cushions 5% 10%

Bolts/Nuts 5% 10%

12 14

13711 13

248

5 9

6 10

Page 4

Loading...

Loading...