Page 1

KENCO ENGINEERING COMPANY

P.O. BOX 470426 TULSA, OK 74147-0426 ● PHONE: (918) 663-4406 FAX: (918) 663-4406

www.kenco-eng.com e-mail: info@kenco-eng.com

MODEL KMVR, KMVU, KHVR, AND KHVU GAUGE VALVES

INSTALLATION / OPERATION INSTRUCTIONS

GENERAL DESCRIPTION

Kenco Flat Glass Gauge Valves are simple, rugged instruments engineered and constructed throughout to give you

accurate liquid level readings for the life of the vessel. We offer a complete range of valves suitable for most applications.

Like any instrument, Kenco gauge valves must be installed, operated, and maintained with reasonable care and due

regard for the application, and the environment.

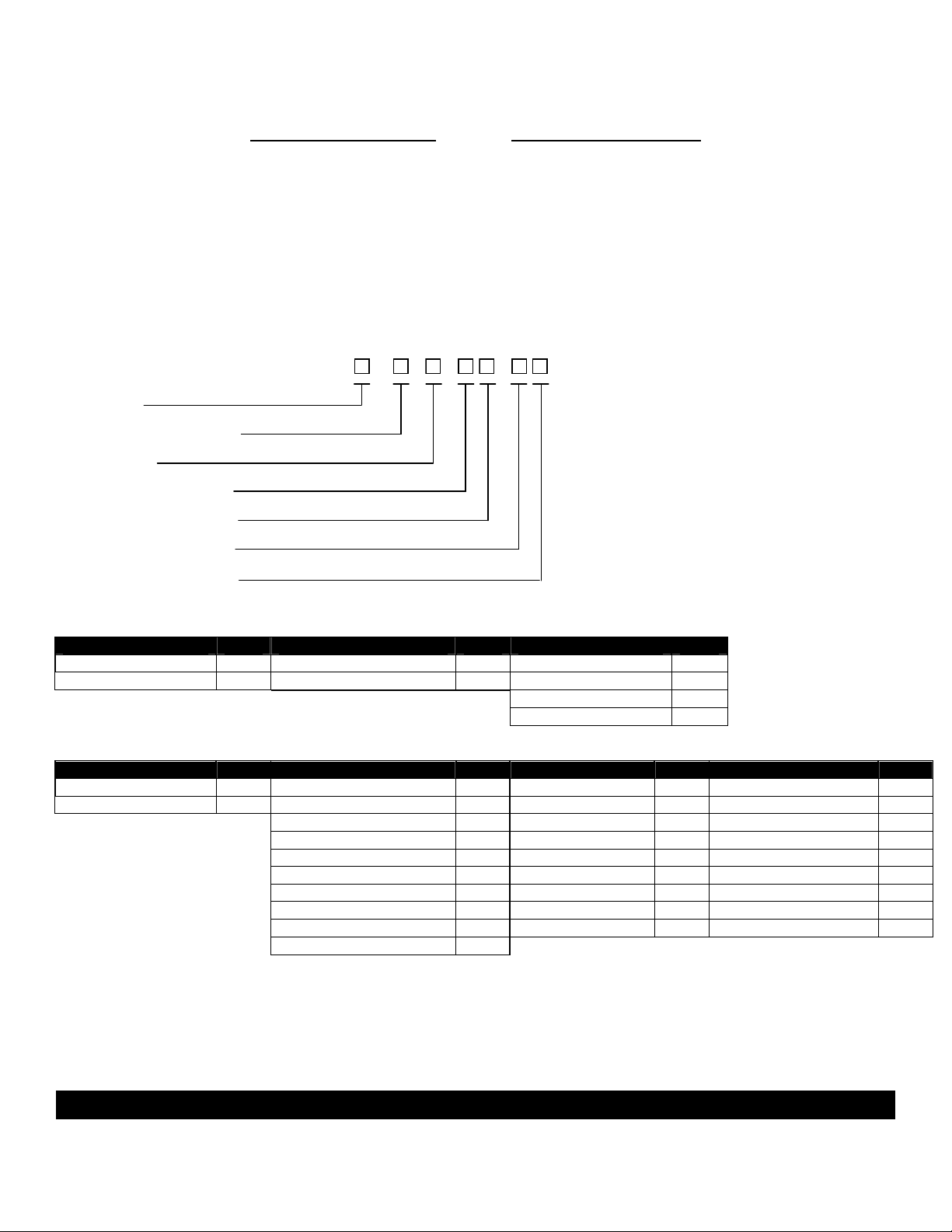

MODEL CONFIGURATOR

K

Valve Type

Gauge Connection Style

Construction

Gauge Connection Size

Gauge Connection Type

Vessel Connection Size

Vessel Connection Type

Valve Type Gauge Connection Style Valve Construction

Type Code Style Code Construction Code

Medium Pressure M Rigid R

High Pressure H Union U

Size Code Type Code Size Code Type Code

1/2" 50 NPTF N 1/2" 50 Union (NPTM) M

3/4" 75 Union (NPTM) M 3/4" 75 Union (NPTF) W

Union (NPTF) W 1" 1 Socketweld (Male) T

Socketweld (Male) T 1-1/2" 15 150# ANSI Flange A

150# ANSI Flange A 2" 2 300# ANSI Flange B

300# ANSI Flange B 3" 3 600# ANSI Flange C

600# ANSI Flange C 4" 4 900# ANSI Flange D

900# ANSI Flange D 6" 6 1500# ANSI Flange E

1500# ANSI Flange E 8" 8 2500# ANSI Flange F

2500# ANSI Flange F

Gauge Connection Size/Type Vessel Connection Size/Type

INSPECTION & DELIVERY

Upon receiving the valves, check all components carefully for damage incurred in shipping. Notify the shipping company

immediately of any such damage, and request a damage inspection. Confirm that the valve model number and

pressure/temperature ratings (located on the nameplate) match the application conditions. Also, confirm that the valve

materials are compatible with the process media and the environmental conditions.

CAUTION – Kenco valves are not to be used with lethal substances as defined by ASME Section VIII.

V

-

-

Page 1

-

Carbon Steel C

Stainless Steel Wetted W

All Stainless Steel A

Special X

Page 2

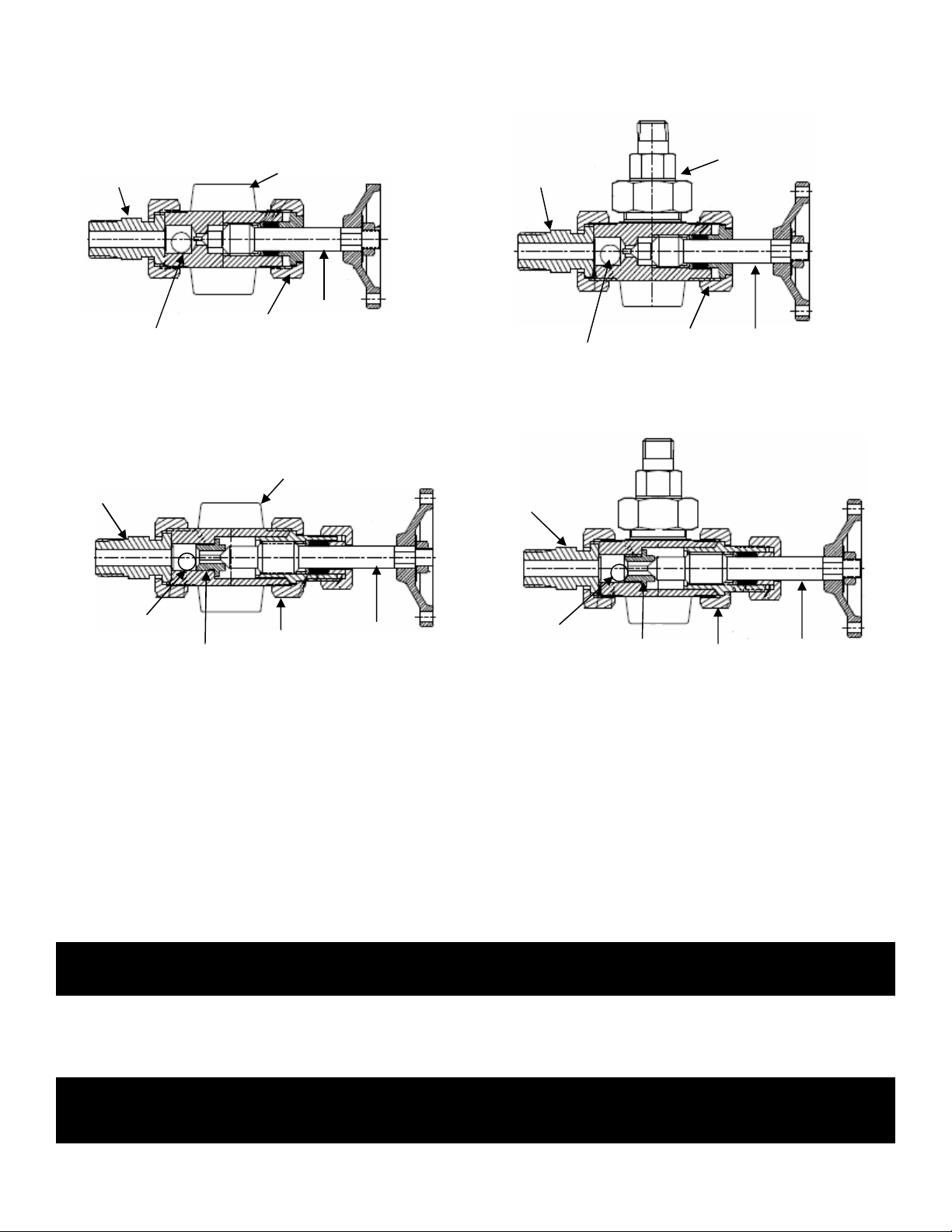

VALVE CONSTRUCTION

Model KMVR

Valve

Model KMVU Valve

Valve Stem

Vessel Connection

Vessel Connection

Valve Stem

Model KHVR

Valve

Model KHVU

Valve

Valve Stem

Vessel Connection

Valve Seat

Vessel Connection

Valve Stem

Valve Seat

Adjustable Union

Adjustable Union

BEFORE YOU INSTALL THE GAUGE VALVES

Consider the following:

OPERATION

For protection during shipping, the packing gland is loosened and the stem is in the open position. Adjust the stem and

packing after installation. Do not tighten the packing any more than is needed to stop leakage. Slowly open the valves

carefully, and wait until the gauge is fully warmed up before completely opening the valves. Kenco

Ball Check

Ball Check

Renewable

• To avoid imposing piping strains on the valves, connect and mount the valves so that they do not support the

piping.

• Support brackets should be considered for gauges over four feet in length or over 100 pounds in weight,

especially when the gauge is exposed to vibration. These support brackets will prevent overloading the

connecting valves and piping and prevent damage to the gauge from excessive vibration.

• Always provide shutoff valves between the gauge and vessel. Kenco automatic ball check valves are

recommended to provide protection against physical injury and loss of product if glass breakage should occur.

These valves also provide a means to isolate the gauge for maintenance.

CAUTION – Rapid opening of connecting valves can cause glass breakage and / or possible injury to

personnel. Gauges should be brought into service slowly.

CAUTION – While the valves are in operation they must be in their fully open position. A partially open valve

will prevent the automatic ball checks from seating, which could result in physical injury to

personnel and loss of product.

Integral

Bonnet

Fixed Gauge

Connection

Fixed Gauge

Connection

Union

Bonnet

Adjustable Union

Adjustable Union

Ball Check

Page 2

Ball Check

Renewable

Integral

Bonnet

Union Gauge

Connection

Union Gauge

Connection

Union

Bonnet

Page 3

MAINTENANCE

CAUTION – Prior to any disassembly of valves, first be sure that the valves are relieved of all internal

pressure, and that the temperature is ambient, and has been drained and/or purged of any fluids.

Failure to do this may result in a sudden release of pressure and/or physical injury to personnel.

CAUTION – When the gauge glass fails causing the ball checks to seat, closing the valve will allow fluid to

flow from the vessel during that period when the stem pin pushes the ball check off its seat and

before the stem has contacted the seat. Personnel can be injured if they don’t realize what is

happening. Fires could result if hazardous liquids are involved.

A. Replace Stem Packing

Close valves and drain fluid. Disengage packing gland nut and pull the packing gland out of stuffing box. Remove

and discard old packing and insert new packing. Put the packing gland and packing gland nut into position, and

tighten the nut. The packing gland nut should be tightened enough to stop leakage around the stem without causing

excessive binding of the stem during operation.

Packing

Gland

Packing

Packing Gland

Nut

B. Replace Valve Seat (KHVR & KHVU Valves Only)

Close valves and drain fluid. Disengage the sleeve nut from the valve body and remove the stem, sleeve, sleeve

nut, packing gland, and packing gland nut as a unit from the valve (see page #4 for details). Use a standard 5/8”

socket wrench to remove the seat. Before replacing the seat, apply lubricant (Molykote “G” or equivalent) to the

threads to prevent seizure of the seat to the valve body. Tighten the seat well, to prevent leakage. Replace the

stem unit in the valve body and tighten the sleeve nut.

WARNING –During system shutdown, it is best to leave shutoff valves open. The equipment then cools and

depressurizes along with the rest of the system. Keeping valves closed during shutdown can

trap high pressure liquid in the valves.

Page 3

Page 4

Valve Seat

Stem

Sleeve Nut

Packing Gland

Renewable

Packing Gland

Nut

Sleeve

Page 4

Loading...

Loading...