Page 1

KENCO ACCU-RATE PUMP SETTING GAUGE®

INSTALLATION AND OPERATING INSTRUCTIONS

Install pipe fittings into gauge by rigidly clamping the END PLATE that is to have piping

installed. Tighten the pipe fittings into the threaded connection of this END PLATE.

GLASS SIGHT TUBE will BREAK if the END PLATE is not HELD RIGIDLY to eliminate

any TWISTING.

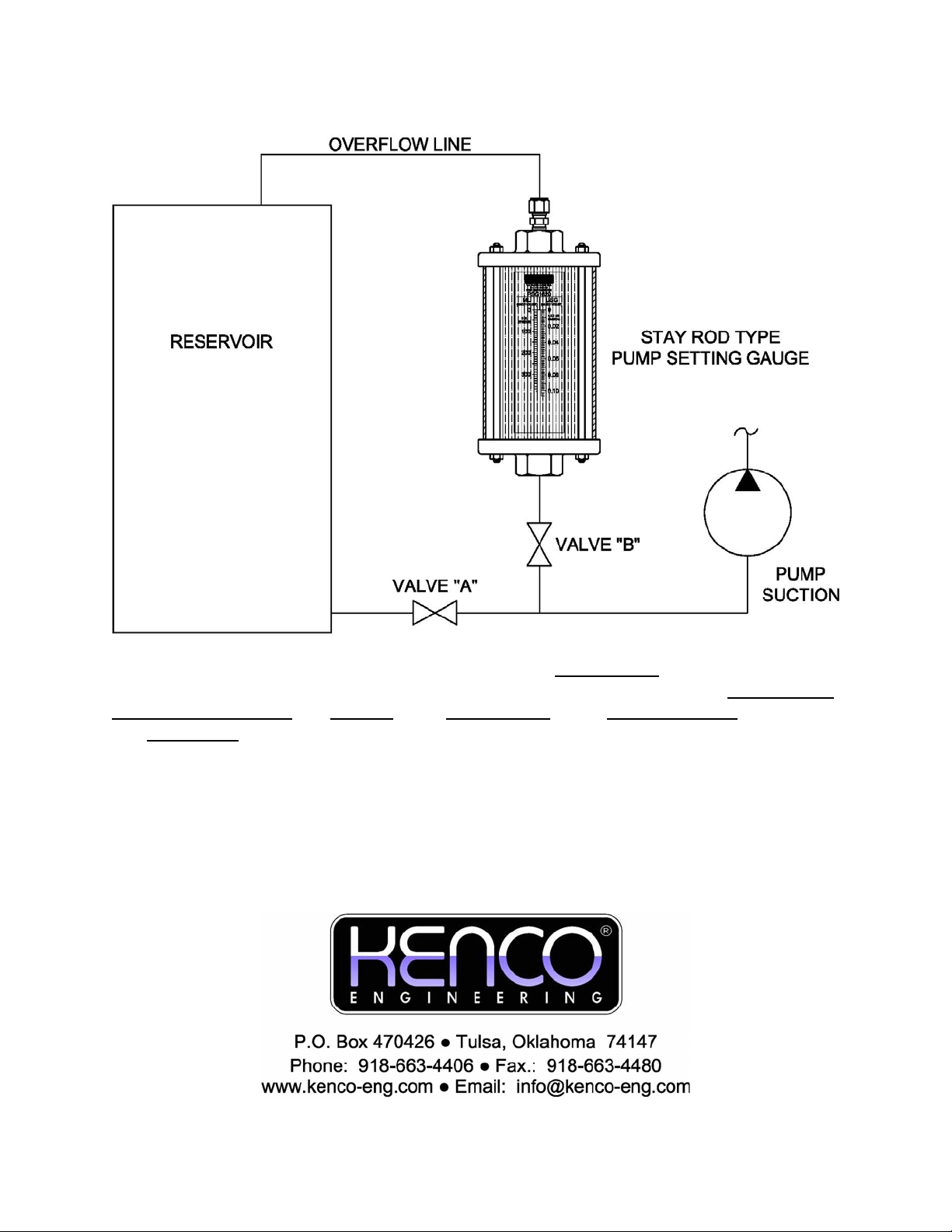

GAUGE MUST BE INSTALLED SO GRAVITY WILL FILL THE GAUGE.

To check pumping rate, open VALVE “B” to fill the pump setting gauge. When the

gauge is filled, close VALVE “A” for one minute and note the level in the gauge at the

beginning of the test and at the end of the test. Count the number of marks on the rate

scale that the level dropped. This is the pump rate.

58270

(12-22-11)

Page 2

KENCO ACCU-RATE PUMP SETTING GAUGE®

Model PSG0180, PSG0404, PSG0720, PSG1620 and PSG2880

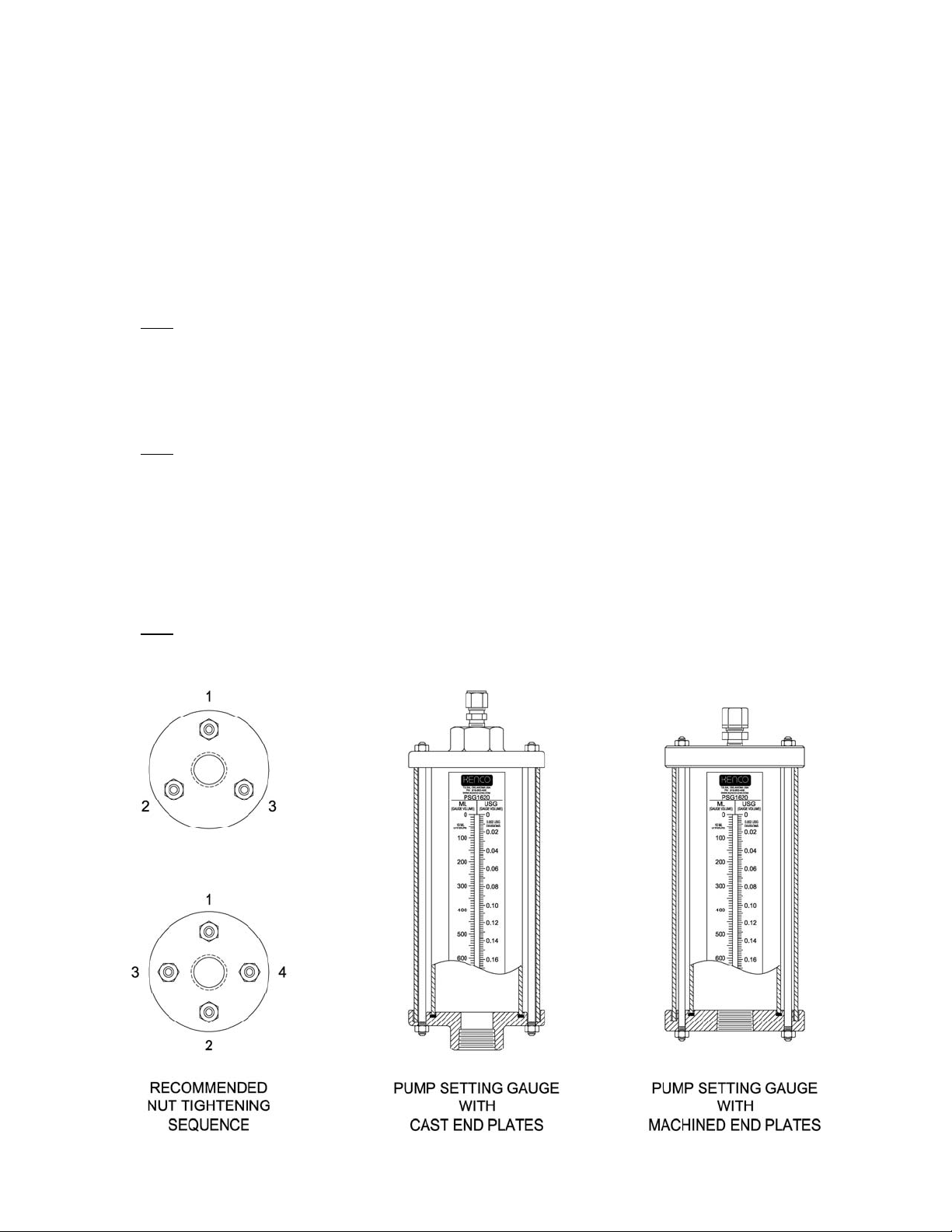

Sight Tube Installation Instructions

1. Apply a small amount of blue thread locking compound onto threads of one end of each stay rod and thread hexagon

nut onto that end until approximately 1/8” of rod is projecting through nut.

2. Inspect seal grooves in gauge end plates to ensure that they are free of any foreign materials which might interfere

with seal.

3. Anchor lower end plate with seal groove side up.

4. Insert seal into groove in lower end plate.

5. Place sight tube shield in lower end plate.

6. Wipe off ends of sight tube.

7. Lower sight tube, with zero mark on scale at top, into sight tube shield until lower end of sight tube is centered in

groove on top of seal in lower end plate.

Note

8. Rotate sight tube so scale is visible between stay rod holes in end plate.

9. Insert seal into groove in upper end plate.

10. Carefully place upper end plate onto upper end of sight tube shield and sight tube.

11. Rotate upper end plate so stay rod holes in upper end plate are lined up with stay rod holes in lower end plate.

12. Ensure that upper end of sight tube is centered in seal groove in upper end plate.

Note

13. Compress all parts now in place together by pushing down on upper end plate with the palm of your hand.

14. Insert stay rods through holes in upper end plate and into and through holes in lower end plate.

15. While holding all parts securely in place, apply a small amount of blue thread locking compound onto threads of each

stay rod on lower end of gauge and install hexagon nuts hand tight.

16. Closely inspect sight tube to ensure that ends are still centered within seal grooves in end plates and carefully adjust

its position at this time if necessary.

17. Using recommended tightening sequence illustrated below, tighten lower hexagon nut on each stay rod a 1/4 turn at

a time.

Note

: It is very important that sight tube is centered in groove because if edge of sight tube is outside of

groove, permanent damage to sight tube will occur.

: It is very important that sight tube is centered in groove because if edge of sight tube is outside of

groove, permanent damage to sight tube will occur.

: Hexagon nuts on gauges with three stay rods to be tightened to 40 inch pounds of torque and hexagon

nuts on gauges with four stay rods to be tightened to 50 inch pounds of torque. If a torque wrench is not readily

available, tighten hexagon nuts 1 to 1-1/2 turns beyond hand tight.

58270

(12-22-11)

Loading...

Loading...