Page 1

X8 MIG Welder

OPERATING MANUAL

Page 2

Contents

1 Read first.................................................................................................................... 4

1.1 Symbols..................................................................................................................................................................................... 4

2 X8 MIG Welder.......................................................................................................... 8

2.1 System introduction............................................................................................................................................................. 8

2.1.1 Introduction to WeldEye for welding procedure and qualification management....................... 9

2.2 System structure..................................................................................................................................................................10

2.2.1 X8 Power Source.................................................................................................................................................11

2.2.2 X8 Wire Feeder....................................................................................................................................................15

2.2.3 X8 MIG Guns........................................................................................................................................................ 20

2.2.4 Control Pad............................................................................................................................................................22

2.3 Installation..............................................................................................................................................................................25

2.3.1 Before installation...............................................................................................................................................25

2.3.2 Power Source installation................................................................................................................................ 26

2.3.3 Wire Feeder installation...................................................................................................................................34

2.3.4 Cables installation...............................................................................................................................................50

2.3.5 Control Pad installation....................................................................................................................................55

2.3.6 Welding gun installation..................................................................................................................................59

2.3.7 Lifting X8 MIG Welder......................................................................................................................................78

2.3.8 Purchasing and managing welding software.......................................................................................... 79

2.3.9 Optional accessories..........................................................................................................................................79

2.4 Operation............................................................................................................................................................................... 84

2.4.1 X8 MIG Welder control devices....................................................................................................................84

2.4.2 Preparing welding system for use.............................................................................................................101

2.4.3 How to use welding system........................................................................................................................ 110

2.5 Troubleshooting................................................................................................................................................................ 166

2.5.1 Error codes..........................................................................................................................................................170

2.6 Maintenance....................................................................................................................................................................... 170

2.6.1 Daily maintenance............................................................................................................................................171

2.6.2 Periodic maintenance of power source and wire feeder..................................................................173

2.6.3 Service workshops........................................................................................................................................... 174

2.7 Technical data.................................................................................................................................................................... 174

2.7.1 X8 Power Source 400 A / 400AMV....................................................................................................... 174

2.7.2 X8 Power Source 500 A / 500AMV....................................................................................................... 176

2.7.3 X8 Power Source 600 A / 600AMV....................................................................................................... 178

2.7.4 X8 Cooler.............................................................................................................................................................180

2.7.5 X8 Wire Feeder..................................................................................................................................................180

2.7.6 X8 Control Pad..................................................................................................................................................181

2.7.7 X8 MIG Gun 200-g.......................................................................................................................................... 182

2.7.8 X8 MIG Gun 300-g.......................................................................................................................................... 183

2.7.9 X8 MIG Gun 400-g.......................................................................................................................................... 184

2.7.10 X8 MIG Gun 420-w....................................................................................................................................... 185

2.7.11 X8 MIG Gun 520-w....................................................................................................................................... 186

2.7.12 X8 MIG Gun 600-w....................................................................................................................................... 187

2.7.13 X8 MIG Gun WS 420-w...............................................................................................................................189

ii

Page 3

2.8 Ordering codes..................................................................................................................................................................190

2.9 Disposal of unit.................................................................................................................................................................193

iii

Page 4

X8 MIG WELDER 1.1 Symbols

1 Read first

Kemppi takes special care in informing its customers about the safety of our products. We also mind the

environment and aspire to disposing of our products according to specified European Directives.

1.1 Symbols

Items in the manual that require particular attention, to minimize damage and personal harm, are indicated

with a three-level notification and warning system.

Convention Used for

Note:

Note text here.

Caution:

Caution text here.

Warning:

Warning text here.

Gives the user a piece of information of particular importance.

Describes a situation that may result in damage to the equipment or

system.

Describes a potentially dangerous situation that may result in personal

damage or fatal injury.

Kemppi symbols

Table 1: Kemppi symbols used in this documentation

Symbol Description

CE mark

EMC Class A

This symbol indicates that the waste of electrical and electronic equipment

must not be disposed as unsorted municipal waste and must be collected

separately. Contact an authorized representative of the manufacturer for

information concerning the decommissioning of your equipment.

Coolant input

OPERATING MANUAL | EN 4

©

KEMPPI | 2018-09-28

Page 5

X8 MIG WELDER 1.1 Symbols

Symbol Description

Coolant output

Gas input

Gas output

High voltage

#

'

8

!

Protective earth

1-MIG

DPulse MIG

Carbon arc gouging

MIG

MMA

5

Pulse MIG

%

OPERATING MANUAL | EN 5

©

KEMPPI | 2018-09-28

Page 6

X8 MIG WELDER 1.1 Symbols

Symbol Description

DProcess

WiseRoot+

,

WiseThin+

*

WiseFusion

+

WiseSteel

E

ŕ

P

S

R

T

WisePenetration+

Creep Start

Hot Start

Upslope

Crater Fill with Downslope

Crater Fill with Downlevel

U

OPERATING MANUAL | EN 6

©

KEMPPI | 2018-09-28

Page 7

X8 MIG WELDER 1.1 Symbols

Symbol Description

2T

Ö

4T

Õ

WP Switch

W

Touch Sense Ignition

Ɔ

O

User manual

OPERATING MANUAL | EN 7

©

KEMPPI | 2018-09-28

Page 8

X8 MIG WELDER 2.1 System introduction

2 X8 MIG Welder

These instructions describe the use of Kemppi's X8 MIG Welder, the top-class welding system for demanding

industrial use. The system consists of a power source, wire feeder, welding gun, Control Pad and various

welding software components and connectivity to Kemppi cloud services. Read the instructions through

carefully.

Disclaimer

While every effort has been made to ensure that the information contained in this guide is accurate and

complete, no liability can be accepted for any errors or omissions. Kemppi reserves the right to change the

specification of the product described at any time without prior notice. Do not copy, record, reproduce or

transmit the contents of this guide without prior permission from Kemppi.

2.1 System introduction

X8 MIG Welder is a multi-process welding equipment intended for demanding professional use in general or

heavy fabrication. The welding system is suitable for various MIG/MAG processes (MIG, 1-MIG, Pulse, DPulse,

WiseRoot+, WiseThin+ ) as well as MMA welding and gouging, cladding and brazing.

1. X8 Power Source 400/500/600

• Includes all the software, welding programs and memory channels for the welding system

• Connects to one or two X8 Wire Feeders

2. X8 Wire Feeder

• Operates with several wire spool types (some of which require an adapter)

• Connects to an external wire drum

OPERATING MANUAL | EN 8

©

KEMPPI | 2018-09-28

Page 9

X8 MIG WELDER 2.1 System introduction

• Contains a control panel for basic adjustment of welding parameters, memory channels and settings

3. X8 MIG Gun 200/300/400-g, 420/520/600-w, X8 MIG Gun WS 420-w

• Connects to the wire feeder with Kemppi Gun Adapter

• Gas-cooled models feature a rotating, changeable neck

• Remote control for selecting memory channels and adjusting settings (optional)

• Ergonomic pistol grip handle

4. X8 Cooler (optional)

• Optionally included in the power source delivery

• Can also be purchased separately

• Essential for welding with a current over 400 A

5. Control Pad

• Wireless remote interface for operating X8 MIG Welder

6. Interconnection Cable 70/95-w/-g (several options)

• Bundle of cables connecting the wire feeder to the power source

• Transfers the welding current, control signals, shielding gas and coolant from the power source to the

wire feeder

7. X8 Wheel Set (several options)

• The wheel set is included in the power source delivery

• The gas cylinder cart is optionally included in the power source delivery

8. My Fleet web service

• Cloud-based service for viewing and managing various information about your X8 MIG Welder

• Provides manufacturer's validation certificate

9. WeldEye (optional)

• Cloud-based service for creating and managing digital WPS documents and other welding-related

information

In addition:

• Several accessories (optional)

• Several welding software products (optional)

2.1.1 Introduction to WeldEye for welding procedure and qualification

management

Welding procedure and qualification management

WeldEye for Welding procedure and qualification management is a cloud-based tool for creating, managing

and storing various welding-related documents and qualification certificates. WeldEye is an end-to-end

solution for handling pWPS, WPQR and WPS documents as well as welder qualification certificates. The

software contains procedure and certificate templates to match all major welding standards. Together with its

integrated drawing tool, WeldEye is swift and easy to use.

The software enables you to keep track of qualification certificates and their expiration dates, and to easily

extend their validity. Revision history helps you track the changes made to the documents. With a flexible

search functionality, you can easily find the welding procedures, personnel, and certificates you need. You

OPERATING MANUAL | EN 9

©

KEMPPI | 2018-09-28

Page 10

X8 MIG WELDER 2.2 System structure

can print out documents or, for example, a list of welders with a certain qualification certificate. Attachments

can be added to any document.

Discover WeldEye – universal welding management software

WeldEye is your primary tool and storage space for keeping your welding-related documents in order.

There is even more to WeldEye than welding document management. WeldEye is a universal solution for

managing welding production. Fitting any size and type of organization that performs welding within the

requirements of international welding standards like ISO, ASME and AWS, WeldEye provides control in all

processes - including welding procedures, welder and inspector qualifications, documentation, reporting and

administration. Most importantly, you get 100% traceability for every weld you ever make.

WeldEye's modular structure is based on various useful functions that serve the needs of wide-ranging

industries and welding-related tasks:

Welding procedures

Includes the digital library and management of pWPS, WPQR and WPS templates according to the most

important welding standards.

Personnel and qualifications

Includes the management and renewal processes of all personnel - welders and inspectors - qualification

certificates.

Quality management

Includes quality verification functionalities with digital WPS and qualification compliance control against

automatically collected digital welding data.

Welding management

Includes document register functionalities and features for comprehensive welding project

documentation and management.

For more information on the full system and other modules, see www.weldeye.com.

2.2 System structure

The parts of X8 MIG Welder are in close co-operation with each other. The information transfer is efficient

and quick, and the different functions, for example, the use of displays, follow the same principles.

Caution:

Do not modify the welding equipment in any way, except for the changes and adjustments covered

in the manufacturer’s instructions.

OPERATING MANUAL | EN 10

©

KEMPPI | 2018-09-28

Page 11

X8 MIG WELDER 2.2 System structure

5

7

1

6

42 3

Figure 1: A chart of the connections between the different parts of X8 MIG Welder

2.2.1 X8 Power Source

This section describes the structure of X8 Power Source.

Front

1. Indicator panel

2. Transportation handle

OPERATING MANUAL | EN 11

©

KEMPPI | 2018-09-28

Page 12

X8 MIG WELDER 2.2 System structure

6

2

3

3

2

4

4

8

5

5

9

7

10

1

11

12

3. USB connector

Connect a USB memory stick to upload the welding procedures (WPS) or Wise features to the power

source or update firmware if a wireless connection is unavailable.

4. Control Pad connector

Connect Control Pad to the power source with a cable to charge its battery or to use it in wired mode.

5. Front panel

6. Front panel latch

Pull to open the front panel and reveal the coolant container.

7. Coolant circulation button

Press to pump the coolant through the system.

Rear

1. Transportation handle

2. Welding current cable connectors (positive pole)

3. Earth return cable connectors (negative pole)

4. Measurement cable connectors

Connectors for wire feeder 1 on the left, wire feeder 2 on the right side of the power source.

5. Control cable connectors

Connectors for wire feeder 1 on the left, wire feeder 2 on the right side of the power source.

6. Ethernet connector

7. Power switch

8. Coolant outlet hose connector

9. Coolant inlet hose connector

10. Rear panel

11. Mains cable

OPERATING MANUAL | EN 12

©

KEMPPI | 2018-09-28

Page 13

X8 MIG WELDER 2.2 System structure

12. Strain relief holder

Indicator panel

1. Power indicator

The LED is green when the unit is on.

2. Voltage Reduction Device (VRD) indicator

The LED is green when VRD is switched on and the no-load voltage is under 35 V.

The LED blinks red when VRD is switched on and the no-load voltage is above 35 V.

The LED is off when VRD is switched off or during welding.

Note:

VRD is in use with MMA and Gouging modes only.

3. Overheat indicator

The LED is yellow when the unit is overheating.

Caution:

If the power source overheats, a thermal cutoff switches the unit off and does not allow it to be

used until it has cooled down.

4. Kemppi cloud connection

The LED is blue when the wire feeder or power source is connected to Kemppi cloud services.

The LED blinks blue when the wire feeder or power source is connecting to Kemppi cloud services.

5. Coolant level warning

The LED is yellow when the coolant level is too low.

6. Coolant temperature warning

The LED is yellow when the cooler is overheating.

Caution:

OPERATING MANUAL | EN 13

©

KEMPPI | 2018-09-28

Page 14

X8 MIG WELDER 2.2 System structure

7

1

4

2

3

65

If the coolant liquid overheats, a thermal cutoff switches the welding system off and does not

allow it to be used until the coolant liquid has cooled down.

7. Coolant circulation warning

The LED is green when the coolant circulation is working normally.

The LED is red when there is a problem in the coolant circulation.

The LED blinks green and red in turns when the circulation of the coolant liquid has been obstructed too

long.

Caution:

If the circulation of the coolant liquid is obstructed, a thermal cutoff switches the welding system

off. Check and fix the error before using the welding system again.

If the error was caused in an unsuccessful filling of the cooler, refill the cooler. In other cases, the

error disappears automatically in 30 seconds.

8. Wireless pairing button

To pair the wire feeder or power source with Control Pad, press the button. If the power source is

connected to wire feeder(s), the wire feeder(s) pairs with Control Pad. If the power source is not

connected to a wire feeder, the power source pairs with Control Pad.

The LED is blue when the wire feeder or power source is wirelessly connected to Control Pad.

The LED blinks blue when the wire feeder or power source is pairing with Control Pad.

Interconnection cable

1. Shielding gas hose

2. Coolant inlet hose

3. Coolant outlet hose

4. Welding current cable

5. Control cable

OPERATING MANUAL | EN 14

©

KEMPPI | 2018-09-28

Page 15

X8 MIG WELDER 2.2 System structure

6. Measurement cable

7. Strain relief pin

2.2.2 X8 Wire Feeder

This section describes the structure of X8 Wire Feeder.

Main parts

1. Top cover

Caution:

Keep the wire feeder top cover closed during welding to reduce the risk of injury or an electric

shock. Keep the top cover closed also at other times to keep the wire feeder insides clean.

2. Handle

Caution:

The handle is only intended for short distance manual carrying. Use Wire Feeder Hanger for

Boom for lifting or hanging the wire feeder.

3. Top cover latch

4. Cable cabinet door

5. Cable cabinet latch

6. Control panel

7. Strain relief

8. Strain relief latch

9. Gun holder mount

OPERATING MANUAL | EN 15

©

KEMPPI | 2018-09-28

Page 16

X8 MIG WELDER 2.2 System structure

15

12

13

14

1011

Figure 2: The warning sticker inside the wire feeder

10. Wire spool

11. Wire spool locking cover

12. Feed rolls

13. Pressure handle

14. Wire guide

15. Inside control buttons

OPERATING MANUAL | EN 16

©

KEMPPI | 2018-09-28

Page 17

X8 MIG WELDER 2.2 System structure

5

6

2

1

4

3

5

6

2

1

4

3

Control panel

The control panel on the front of the wire feeder enables easy control of the wire feeder's basic features.

Although Control Pad is the main control of the welding system, you can also use the wire feeder control

panel or the welding gun remote control.

The wire feeder control panel parts are:

1. Locking button

Press and hold for 2 seconds to lock or release the display and buttons.

2. Channel button

The button lights up blue, when the view is activated.

OPERATING MANUAL | EN 17

©

KEMPPI | 2018-09-28

Page 18

X8 MIG WELDER 2.2 System structure

3. Settings button

The button lights up orange, when the view is activated.

4. Left control knob

5. Right control knob

6. Left and right button

For more information on the use and features of the control panel, see Wire feeder views on page 96.

Control buttons on the inside

The wire feeder has control buttons inside the wire cabinet.

1. Wire retract button

Drive the filler wire backward with arc off.

2. Gas test button

Test the shielding gas flow, or flush out the remainder of the previous gas.

3. Wire inch button

Drive the filler wire forward with arc off.

Interconnection cable connectors

OPERATING MANUAL | EN 18

©

KEMPPI | 2018-09-28

Page 19

X8 MIG WELDER 2.2 System structure

1. Welding current

Supplies current from the power source to the wire feeder.

2. Shielding gas

Supplies shielding gas to the welding gun.

3. Measurement

Supplies the welding parameters measured during welding.

4. Control

Supplies data and operating voltage to the wire feeder.

5. Coolant outlet and inlet

Circulates coolant to and from the welding gun.

For information on the installation of the cables, see Cables installation on page 50.

External component connectors

1. Kemppi Gun Adapter

Connects to the welding gun.

Note:

The wire feeder is supplied with Kemppi Gun Adapter.

2. Subfeeder

Provides control to optional SuperSnake subfeeder or a motorized welding gun.

3. Remote control

Connects to remote control devices (Control Pad). Supplies power and data connection with 12 V voltage.

4. Voltage sensing

Connects to the welding piece and measures arc voltage in real time.

5. Coolant outlet

Delivers cold coolant to the welding gun.

6. Coolant inlet

Receives heated coolant from the welding gun.

OPERATING MANUAL | EN 19

©

KEMPPI | 2018-09-28

Page 20

X8 MIG WELDER 2.2 System structure

13

108

65 7 9

4

3

11212

1

2.2.3 X8 MIG Guns

Gas-cooled gun

1. Gas nozzle

2. Insulating bush

3. Contact tip

4. Contact tip adapter

5. Neck

6. Neck tightener

7. Work light

Press the trigger lightly to switch on the light.

8. Handle cover plate

Covers the handle if the remote control is not used.

9. Trigger

10. X8 Gun Remote Control

The remote control is an optional accessory.

11. Trigger on the pistol grip handle

OPERATING MANUAL | EN 20

©

KEMPPI | 2018-09-28

Page 21

X8 MIG WELDER 2.2 System structure

12. Pistol grip handle

Quick to attach and detach.

13. Kemppi Gun Connector

Water-cooled gun

1. Gas nozzle

2. Insulating bush

3. Contact tip

4. Contact tip adapter

5. Neck

6. Work light

Press the trigger lightly to switch on the light.

7. Handle cover plate

Covers the handle if the remote control is not used.

8. Trigger

9. X8 Gun Remote Control

The remote control is an optional accessory.

10. Trigger on the pistol grip handle

11. Pistol grip handle

Quick to attach and detach.

12. Kemppi Gun Connector

13. Coolant inlet hose

14. Coolant outlet hose

OPERATING MANUAL | EN 21

©

KEMPPI | 2018-09-28

Page 22

X8 MIG WELDER 2.2 System structure

6

7

8

9

5

4

1

2

4

3

6

7

8

9

5

4

1

2

4

3

2.2.4 Control Pad

This section describes the structure of Control Pad.

1. Power button

The button lights up orange, when you switch Control Pad on.

2. Left control knob

3. Right control knob

4. Left and right button

When the button lights up green, you can press the button to confirm an action.

5. Display

6. View buttons

7. Channel button

The button lights up blue, when the view is activated.

8. Menu button

The button lights up white, when the view is activated.

9. Settings button

The button lights up orange, when the view is activated.

OPERATING MANUAL | EN 22

©

KEMPPI | 2018-09-28

Page 23

X8 MIG WELDER 2.2 System structure

14

10

11

12

13

10. NFC reader

11. Barcode reader

12. ON/OFF button for NFC and barcode readers

The button also acts as a shortcut button for reading a barcode in any Control Pad view.

13. Loop for the carrying strap

14. Hook

When you connect or disconnect the charger, Control Pad shows you the charge level.

OPERATING MANUAL | EN 23

©

KEMPPI | 2018-09-28

Page 24

X8 MIG WELDER 2.2 System structure

When Control Pad is charging, green leds on the left side of the display indicate ongoing charging. The

lowest led turns red when the charge level is low.

OPERATING MANUAL | EN 24

©

KEMPPI | 2018-09-28

Page 25

X8 MIG WELDER 2.3 Installation

17

16

15

18

15. Charger cable port

A stopper shields the charger cable port.

16. Micro USB port

A cover shields the micro USB port and the USB cable port.

17. USB cable port

18. Combo cable port

Combo cable port transfers both data and power. A stopper shields the combo cable port.

2.3 Installation

Perform this installation procedure to prepare your X8 MIG Welder for use.

Read the instructions carefully and follow them closely.

2.3.1 Before installation

Make sure to acknowledge and follow the local and national requirements on installation and the use of high

voltage units.

Before installation, check the contents of the packages and make sure the parts are not damaged.

Before you remove the power source completely from its packaging, install the wheel set.

Before you install the power source on the site, see the following requirements regarding the mains cable

type and fuse rating.

Warning:

The mains cable must be installed by an authorized electrician.

OPERATING MANUAL | EN 25

©

KEMPPI | 2018-09-28

Page 26

X8 MIG WELDER 2.3 Installation

Warning:

Provided that the public low voltage short circuit power at the point of common coupling is higher

than or equal to 5.1 MVA, this equipment is compliant with IEC 61000-3-11 and IEC 61000-3-12 and

can be connected to public low voltage systems. It is the responsibility of the installer or user of the

equipment to ensure, by consultation with the distribution network operator if necessary, that the

system impedance complies with the impedance restrictions.

Table 2: Cable type and fuse rating requirements

High voltage version (380-460V) Multi-voltage version (220-230/380-460V)Unit amperage

Cable type Fuse rating Cable type Fuse rating

400 A 6 mm

500 A 6 mm

600 A 6 mm

2

2

2

25 A - -

32 A 16 mm

35 A 16 mm

2

2

63 A

63 A

2.3.2 Power Source installation

For power source cable connections, see Installing interconnection cable and Installing or replacing mains

cable. For operating the power source, see Preparing welding system for use.

2.3.2.1 Installing wheels

To have turning wheels in the front and the back, install the front wheel assembly to the front of the unit.

To have fixed wheels in the front, install the rear wheel assembly to the front of the unit. See also Installing

optional gas cylinder cart.

Proceed as follows:

Install the rear wheels:

Remove the packaging from the sides but leave the power source resting on the pallet.

1.

OPERATING MANUAL | EN 26

©

KEMPPI | 2018-09-28

Page 27

X8 MIG WELDER 2.3 Installation

1 2 3 4

Push the rear axle through the opening in the bottom of the rear side of the unit and set the axle in the

2.

middle.

Slide the two wheel spacers (1) onto the axle.

3.

Slide the two wheels (2) onto the axle.

4.

Slide the two washers (3) onto the axle.

5.

Slide the two retaining rings (4) on the axle, until they lock into the groove on the axle.

6.

Install the front wheels:

Push the front axle through the opening in the bottom of the front side of the unit and set the axle in

7.

the middle.

OPERATING MANUAL | EN 27

©

KEMPPI | 2018-09-28

Page 28

X8 MIG WELDER 2.3 Installation

21

Max. 20 Nm

Place the transportation handle over the ridge in the wheel assembly and align the holes in the wheel

8.

assembly with the ends of the axle.

Attach the front wheel assembly to the end of the axle with a bolt (1) and washer (2) from both sides.

9.

When the wheels are attached, lift the power source off the pallet.

10.

OPERATING MANUAL | EN 28

©

KEMPPI | 2018-09-28

Page 29

X8 MIG WELDER 2.3 Installation

Note:

If your setup includes X8 Gas Cylinder Cart, proceed to Installing optional gas cylinder cart.

2.3.2.2 Installing optional gas cylinder cart

To transport a larger gas cylinder with the power source, install X8 Gas Cylinder Cart. For detailed

instructions, see X8 Gas Cylinder Cart Mounting Instructions. If your setup does not include the gas cylinder

cart, proceed to Installing optional X8 Cooler.

Remove the packaging from the sides but leave the power source resting on the pallet.

1.

Attach a wheel set to the front of the unit.

2.

• To have turning wheels in the front and the back, install the front wheel assembly to the front of the

unit.

For more information, see Installing wheels on page 26.

• To have fixed wheels in the front, install the rear wheel assembly to the front of the unit.

For more information, see Installing wheels on page 26.

Attach the gas cylinder cart to the rear of the unit:

Push the axle through the opening in the bottom of the rear side of the unit.

3.

OPERATING MANUAL | EN 29

©

KEMPPI | 2018-09-28

Page 30

X8 MIG WELDER 2.3 Installation

4321

Attach the wheel set of the gas cylinder cart to the axle with a bolt (1) and washers (2, 3, 4) from both

4.

sides.

Insert cover plugs to the open ends of the wheel set.

5.

OPERATING MANUAL | EN 30

©

KEMPPI | 2018-09-28

Page 31

X8 MIG WELDER 2.3 Installation

3 2 1

Place the upper part of the gas cylinder cart on the wheel set, and push it down until the claw fastens

6.

over the transportation handle.

Attach the upper part of the gas cylinder cart to the wheel set with two bolts (1) and washers (2, 3) from

7.

both sides.

Attach the bottom of the gas cylinder cart to the wheel set with six bolts (1) and washers (2, 3).

8.

The gas cylinder cart bottom has two alternative settings (the lower setting described in the figure). The

higher setting gives a better ground clearance, but you must lift the gas cylinder higher.

OPERATING MANUAL | EN 31

©

KEMPPI | 2018-09-28

Page 32

X8 MIG WELDER 2.3 Installation

3 2 1

Max. 20 Nm

Place the gas cylinder on the cart.

9.

Fasten the straps in the cart around the gas cylinder.

10.

2.3.2.3 Installing optional X8 Cooler

If your setup does not include X8 Cooler, you can skip these instructions.

Caution:

X8 Cooler must be installed by authorized service personnel. Do not open the covers of X8 Power

Source.

OPERATING MANUAL | EN 32

©

KEMPPI | 2018-09-28

Page 33

X8 MIG WELDER 2.3 Installation

64 5

1

3

2

1. Front panel

2. Front panel latch

3. Coolant circulation button

4. Cooler

5. Coolant container

6. Connectors for the liquid cooling unit

Proceed as follows:

Detach the two screws in the front panel of the power source.

1.

OPERATING MANUAL | EN 33

©

KEMPPI | 2018-09-28

Page 34

X8 MIG WELDER 2.3 Installation

Pull the front panel outwards from the lower edge.

2.

Remove the lower left cover from the rear of the power source.

3.

Push the cooler inside the power source from the opening in the front.

4.

Note:

Do not use force, but make sure the connectors on the cooler and the power source are

properly connected.

Fill the coolant container with applicable coolant solution. For more information, see Filling cooler on

5.

page 103.

Attach the two screws in the front panel of the power source.

6.

2.3.2.4 Installing or replacing mains cable

The power source is supplied with a 5-meter mains cable without a plug installed.

Warning:

The mains cable must be installed by an authorized electrician.

For high voltage versions, install the 6 mm2 cable. For multi-voltage versions, install the 16 mm2 cable.

The mains cable includes the following wires:

1. Brown: L1

2. Black: L2

3. Grey: L3

4. Yellow-green: Protective earth

2.3.3 Wire Feeder installation

This chapter describes the wire feeder installation.

For wire feeder cable connections, see Installing interconnection cable. For information on operating the

wire feeder, see Wire feeder control panel on page 96.

Caution:

Welding quality and efficiency are greatly dependent on the consumable parts used on the wire

line. These include the wire guide tubes, feed rolls, wire liners, gas nozzles and contact tips. Always

ensure that you are using the correct consumable parts suitable for the filler wire size and material.

For more information, visit Kemppi consumable kit selection site at kitselect.kemppi.com.

2.3.3.1 Installing wire feeder

The installation of the Wire Feeder Rotating Plate and Double Wire Feeder Rotating Plate is identical, as is

installing one or two wire feeders.

Install the wire feeder on the power source with a Wire Feeder Rotating Plate. To install two wire feeders, use

a Double Wire Feeder Rotating Plate.

Note: To set up the system for double wire feeder configuration, you need certain assembly parts.

For more information, see Double wire feeder assembly parts.

Proceed as follows:

OPERATING MANUAL | EN 34

©

KEMPPI | 2018-09-28

Page 35

X8 MIG WELDER 2.3 Installation

Place the wire feeder rotating plate or double rotating plate on top of the power source, with the orange

1.

claw at the rear of the unit.

Pull the release lever at the front of the wire feeder rotating plate, and turn the top sideways to allow

2.

access to the bottom half.

Attach the bottom of the wire feeder rotating plate to the power source with four screws (1) and

3.

washers (2).

OPERATING MANUAL | EN 35

©

KEMPPI | 2018-09-28

Page 36

X8 MIG WELDER 2.3 Installation

2

1

5 Nm

With the control panel facing the same way as the power source front panel, place the wire feeder in the

4.

corresponding grooves on the wire feeder rotating plate.

Slide the wire feeder from front to back until the bar in the back of the unit locks to the orange claw at

5.

the back of the wire feeder rotating plate.

2.3.3.2 Installing welding gun holder

Install the welding gun holder to either side of the wire feeder.

OPERATING MANUAL | EN 36

©

KEMPPI | 2018-09-28

Page 37

X8 MIG WELDER 2.3 Installation

121

2

Proceed as follows:

Install the welding gun holder mount to the wire feeder with 2 screws going to the corresponding holes

1.

on the wire feeder upper cover hinge.

Attach the welding gun holder to the mount with 2 screws.

2.

2.3.3.3 Replacing feed rolls

Replace the feed rolls when the material and diameter of the filler wire changes.

Proceed as follows:

Open the top cover and lift the pressure handle.

1.

OPERATING MANUAL | EN 37

©

KEMPPI | 2018-09-28

Page 38

X8 MIG WELDER 2.3 Installation

Push the collars on the mounting pins of the feed rolls up to pull the mounting pins off.

2.

OPERATING MANUAL | EN 38

©

KEMPPI | 2018-09-28

Page 39

X8 MIG WELDER 2.3 Installation

Note:

The mounting pins are different: The drive rolls' mounting pins have a circular mark on the

top, while the pressure rolls' mounting pins have no marks. The pressure rolls' mounting pins

have central axles attached to them, so the drive and pressure rolls' mounting pins cannot be

confused with each other.

Pull the drive rolls upwards (1) and the pressure rolls out of their slots (2).

3.

OPERATING MANUAL | EN 39

©

KEMPPI | 2018-09-28

Page 40

X8 MIG WELDER 2.3 Installation

1

2

Select the feed rolls according to the tables below.

4.

Wire feed rolls, plastic

Filler wire

material

Fe, Ss (Al, Mc,

Feed roll profile Filler wire

diameter (mm)

V-groove

0.6 W001045 W001046

Fc)

0.8−0.9 W001047 W001048

1.0 W000675 W000676

1.2 W000960 W000961

Feed roll

identification

Drive roll code Pressure roll

code

OPERATING MANUAL | EN 40

©

KEMPPI | 2018-09-28

Page 41

X8 MIG WELDER 2.3 Installation

Wire feed rolls, plastic

1.4 W001049 W001050

1.6 W001051 W001052

2.0 W001053 W001054

2.4 W001055 W001056

Fc, Mc (Fe) V-groove,

knurled

1.0 W001057 W001058

1.2 W001059 W001060

1.4−1.6 W001061 W001062

2.0 W001063 W001064

2.4 W001065 W001066

U-groove

1.0 W001067 W001068Al (Fc, Mc, Ss,

Fe)

1.2 W001069 W001070

OPERATING MANUAL | EN 41

©

KEMPPI | 2018-09-28

Page 42

X8 MIG WELDER 2.3 Installation

Wire feed rolls, plastic

1.6 W001071 W001072

Wire feed rolls, metal

Filler wire

material

Fe, Ss (Al, Mc,

Fc)

Feed roll profile Filler wire

diameter (mm)

V-groove

0.8−0.9 W006074 W006075

1.0 W006076 W006077

Feed roll

identification

See the text on

the roll

Drive roll code Pressure roll

code

1.2 W004754 W004753

1.4 W006078 W006079

Fc, Mc (Fe) V-groove,

knurled

1.0 W006080 W006081

1.2 W006082 W006083

1.4−1.6 W006084 W006085

2.0 W006086 W006087

Al (Fc, Mc, Ss,

U-groove

Fe)

Place the feed rolls back to their places. Align the cut on a drive roll's bottom with the pin on the drive

5.

1.0 W006088 W006089

1.2 W006090 W006091

1.6

W006092 W006093

shaft.

Reattach the mounting pins to lock the drive and pressure rolls to their places. Align one of the cuts on

6.

the bottom of the pressure rolls' mounting pin with the stud on the mount.

Lower the pressure handle on the feed rolls and close the top cover.

7.

OPERATING MANUAL | EN 42

©

KEMPPI | 2018-09-28

Page 43

X8 MIG WELDER 2.3 Installation

2

1

2.3.3.4 Replacing wire guides

The wire feed mechanism includes two wire guide tubes. Replace them when the filler wire diameter grows

or the material changes.

1. Inlet tube

Pull out the inlet tube and insert a new one. There is no additional locking.

2. Middle tube

A metal piece locks the middle wire guide tube in its place. Turn the piece aside to free the middle wire

guide tube for replacement. Turn it back to lock down the new middle wire guide tube.

2.3.3.5 Changing wire spool

Note:

Install the welding gun to the wire feeder before installing the wire spool.

Caution:

If you change the filler wire to a different diameter or material, change the feed rolls accordingly.

Proceed as follows:

Remove the wire spool:

OPERATING MANUAL | EN 43

©

KEMPPI | 2018-09-28

Page 44

X8 MIG WELDER 2.3 Installation

Open the top cover latch.

1.

Lift the top cover up.

2.

Cut and file the tip of the filler wire.

3.

Note:

The sharp cut tip of the filler wire may cause damage to the wire liner, if not filed.

Press Wire retract to pull back the remaining filler wire from the welding gun.

4.

Push the wire spool locking cover aside.

5.

Lift the wire spool from the wire feeder.

6.

Loosen and pull the wire spool brake halves apart.

7.

Install a new wire spool:

OPERATING MANUAL | EN 44

©

KEMPPI | 2018-09-28

Page 45

X8 MIG WELDER 2.3 Installation

Attach the wire spool brake halves to the new wire spool by pushing them together inside the wire

8.

spool. Tighten if necessary.

Note:

The spool brake is equipped with an optional wire tensioning feature, which keeps the wire feed

steady in short repeated welds and with heavy wire spools. To enable wire tensioning, attach

the spool brake hub to the wire spool so that the tightening knob is on the right, seen from the

front.

Lower the wire spool to its socket.

9.

Note:

Ensure that the wire spool is facing the right direction, the filler wire running from the top of the

spool to the feed rolls.

Lift the pressure handle off of the feed rolls.

10.

Install the filler wire:

OPERATING MANUAL | EN 45

©

KEMPPI | 2018-09-28

Page 46

X8 MIG WELDER 2.3 Installation

Release the pressure arms to move the feed rolls apart. This opens a gap between the feed rolls.

11.

Release the filler wire end from the spool and cut off any deformed section so that the end is straight.

12.

Note:

Ensure that the filler wire does not spill from the spool when it is released.

File the tip of the filler wire smooth.

13.

Caution:

Sharp edges on the filler wire tip may damage the wire liner.

Guide the filler wire through the inlet tube (A) and middle wire guide tube (B) to the outlet, which feeds

14.

the filler wire to the welding gun. Push the filler wire by hand inside the gun so that the wire reaches the

wire liner (about 20 cm).

Close the pressure arms so that the filler wire is locked between the feed rolls. Ensure that the filler wire

15.

sits in the feed roll grooves.

Lower the pressure handle on the feed rolls.

16.

Adjust the pressure of the feed rolls with the pressure adjustment wheels. The pressure is the same for

17.

both feed roll pairs.

The graduated scales on the pressure handle indicate the pressure applied to the feed rolls. Adjust the

pressure of the feed rolls according to the table below.

OPERATING MANUAL | EN 46

©

KEMPPI | 2018-09-28

Page 47

X8 MIG WELDER 2.3 Installation

Filler wire material Feed roll profile Filler wire diameter (mm) Adjustment (x100N)

Fe/Ss solid V-groove 0.8−1.0

≥ 1.2

1.5−2.0

2.0−2.5

Metal and flux cored V-groove, knurled ≥ 1.2 1.0−2.0

Self-shielded V-groove, knurled ≥ 1.6 2.0−3.0

Aluminium U-groove 1.0

1.2

1.4

≥ 1.6

0.5 1.0

1.0−1.5

1.5−2.0

2.0−2.5

Caution:

Excessive pressure flattens the filler wire and may damage coated or cored filler wires. Excessive

pressure also unnecessarily wears the feed rolls and increases gearbox load.

Press Wire inch to drive the filler wire to the welding gun's contact tip. To speed up the wire feed speed,

18.

turn the left control knob on the control panel.

Note:

The control panel shows how much the filler wire has run.

OPERATING MANUAL | EN 47

©

KEMPPI | 2018-09-28

Page 48

X8 MIG WELDER 2.3 Installation

Finalize the installation:

Select the shielding gas and attach the gas cylinder to the wire feeder.

19.

Press Gas test to flush the former shielding gas from the system.

20.

Note:

You can also use this button to test that the gases flow through the system properly.

Close the top cover.

21.

Wire spools

X8 MIG Welder has three different wire spool hub options available for different wire spools:

A. Standard spool

B. Spool hub for the small wire spool

Attach the extension pieces to the standard spool halves.

C. Spool hub for the wire spool with a large center hole

All parts are delivered with the wire feeder.

Loosen and pull the spool halves to detach them.

OPERATING MANUAL | EN 48

©

KEMPPI | 2018-09-28

Page 49

X8 MIG WELDER 2.3 Installation

2.3.3.6 Attaching interconnection cable to strain relief

To ease the installation of the interconnection cable and to prevent any unnecessary strain on the cable

connectors, attach both ends of the interconnection cable bundle to a strain relief.

Proceed as follows:

Attach the strain relief holder to the transportation handle at the rear of the power source. Fasten the

1.

strain relief holder with a bolt from below.

Take the power source end of the interconnection cable and insert the strain relief pin to the strain relief

2.

holder.

Note:

If the wire feeder is detached from the power source, insert the strain relief pin to the holder

from below.

Note:

If the wire feeder is on the power source, insert the strain relief pin to the holder from above.

OPERATING MANUAL | EN 49

©

KEMPPI | 2018-09-28

Page 50

X8 MIG WELDER 2.3 Installation

Insert the supplied locking pin through the hole in the strain relief pin.

3.

Route the cable bundle from the back of the power source and attach the strain relief in the other end of

4.

the cable to the left-hand side of the wire feeder. For more information, see .

2.3.4 Cables installation

For a detailed description of the power source and wire feeder cabling, see Installing interconnection cable.

For a full overview of the cabling, see Cabling diagram.

2.3.4.1 Installing interconnection cable

Install the interconnection cable first to the the wire feeder and then to the power source.

Proceed as follows:

OPERATING MANUAL | EN 50

©

KEMPPI | 2018-09-28

Page 51

X8 MIG WELDER 2.3 Installation

Connect the interconnection cable to the wire feeder:

Lift the cable cabinet latch to reveal the connectors.

1.

Connect the welding current cable to the wire feeder. Push the cable as far as it goes and turn the

2.

connector clockwise to tighten the cable to its place.

Caution:

Tighten the welding current cable as much as you can by hand. If the welding current cable

connection is loose, it may overheat.

Push the shielding gas hose towards the shielding gas hose connector base until it locks down.

3.

Attach the strain relief to the slot on the wire feeder.

4.

Lock the strain relief latch to secure the strain relief.

5.

Connect the control cable to the connector. Rotate the collar clockwise to lock it in place.

6.

Connect the measurement cable to the connector. Rotate the collar clockwise to lock it in place.

7.

If you have the optional cooler, pull the cover over the cooling water hoses' slot to remove it.

8.

OPERATING MANUAL | EN 51

©

KEMPPI | 2018-09-28

Page 52

X8 MIG WELDER 2.3 Installation

Connect the cooling water hoses to the slot.

9.

Close and lock the cable cabinet door.

10.

Note:

When connecting the cables to the wire feeder, route the cables neatly so that the cable cabinet

door closes properly.

Connect the interconnection cable to the power source:

OPERATING MANUAL | EN 52

©

KEMPPI | 2018-09-28

Page 53

X8 MIG WELDER 2.3 Installation

Connect the welding current cable to the plus (+) side connector (1) on the power source.

11.

The interconnection cable crosses from the wire feeder to the power source connector diagonally.

Note:

If two wire feeders are connected to a power source, connect the interconnection cable upright:

from the wire feeder on the left to the connector (1) on the left.

Connect the earth return cable to the minus (-) side connector (2).

12.

Connect the measurement cable to the measurement cable connector (4).

13.

Connect the control cable to the control cable connector (3) on the same side as the measurement

14.

cable.

If the water cooler is present, use the red connector (5) for the hose that goes to the cooler.

15.

If the water cooler is present, use the blue connector (6) for the hose that comes from the cooler.

16.

If you need shielding gas, connect the shielding gas hose to the gas cylinder.

17.

The power source can be connected to two wire feeders at the same time.

Caution:

Ensure that you have connected and tightened all the cables properly.

2.3.4.2 Cabling diagram

Connect the interconnection cables to power source and wire feeder. The figure below shows the cables with

colors to facilitate the identification.

OPERATING MANUAL | EN 53

©

KEMPPI | 2018-09-28

Page 54

X8 MIG WELDER 2.3 Installation

Figure 3: Interconnection cabling for power source and wire feeder

Table 3: Color codes

Welding current cable

Shielding gas hose

Control cable

Measurement cable

Coolant input and output hoses

OPERATING MANUAL | EN 54

©

KEMPPI | 2018-09-28

Page 55

X8 MIG WELDER 2.3 Installation

Earth return cable

2.3.5 Control Pad installation

This chapter describes the control pad installation.

For information on operating Control Pad, see Control Pad on page 84.

2.3.5.1 Wireless connection

Control Pad connects wirelessly to X8 Wire Feeder. If there are two wire feeders in the system, choose which

one to connect to. Control Pad can be connected to X8 Power Source in applications where no wire feeder is

needed, such as stick welding or gouging.

To set up a wired connection between Control Pad and the power source or the wire feeder, see Wired

connection on page 57.

If Control Pad is not connected, you see this info message on the display.

Proceed as follows:

To connect Control Pad wirelessly to a wire feeder or power source:

1.

a) Press the wireless pairing button on the power source indicator panel.

OPERATING MANUAL | EN 55

©

KEMPPI | 2018-09-28

Page 56

X8 MIG WELDER 2.3 Installation

The led on the power source begins to blink when it is searching for Control Pad.

The serial numbers of the nearby available wire feeders or power sources appear on Control Pad's

display.

Note:

When there are wire feeders connected to the welding system, pressing the wireless pairing

button allows you to connect Control Pad to a wire feeder. When there are no wire feeders

connected to the system, Control Pad allows you to connect to a power source.

Figure 4: Connecting to wire feeder Figure 5: Connecting to power source

b) Move focus to select the connection and press the green button.

Note:

OPERATING MANUAL | EN 56

©

KEMPPI | 2018-09-28

Page 57

X8 MIG WELDER 2.3 Installation

The connection list shows the serial numbers of the available wire feeders and a power

source. Check the serial number on the device rating plate.

A connection forms between the wire feeder or power source and Control Pad. The led on the power

source lights up permanently.

Note:

Once you have created the connection, Control Pad tries to reconnect if you take it out of the

connection distance. Select Disconnect on Control Pad to disconnect the connection.

You can also connect Control Pad to the wire feeder through the wire feeder control panel if the wire

2.

feeder is far from the power source.

a) Go to Settings > Wireless devices > Connect.

The wire feeder connects automatically to Control Pad.

If the buttons of the power source and wire feeder are unreachable:

3.

a) Go to Settings > WirelessDevicesAvailable in Control Pad.

b) Move focus to a wire feeder or a power source.

c) Press the green button.

2.3.5.2 Wired connection

Control Pad makes a wired connection with X8 Power Source and X8 Wire Feeder. Connect Control Pad to a

wired connection, when wireless connection is unavailable.

Proceed as follows:

To make a wired connection between Control Pad and the power source:

1.

a) Plug the combo cable to the Control Pad connector of the power source.

The connector is marked with a Control Pad icon.

OPERATING MANUAL | EN 57

©

KEMPPI | 2018-09-28

Page 58

X8 MIG WELDER 2.3 Installation

b) Plug the combo cable to the combo cable port on the bottom of Control Pad.

To make a wired connection between Control Pad and the wire feeder:

2.

a) Plug the combo cable to the remote control connector of the wire feeder.

The connector is marked with a Control Pad icon.

b) Plug the combo cable to the combo cable port on the bottom of Control Pad.

Note:

Use mainly the external charger to charge Control Pad.

2.3.5.3 Suspending Control Pad

Control Pad has a hook, which you can use to suspend it on the welding machine or other suitable place.

Control Pad also has a loop in each corner, which you can use for the carrying strap.

OPERATING MANUAL | EN 58

©

KEMPPI | 2018-09-28

Page 59

X8 MIG WELDER 2.3 Installation

2.3.6 Welding gun installation

2.3.6.1 Preparing and connecting welding gun

X8 MIG Gun has been preassembled by the manufacturer: the wire liner, contact tip and gas nozzle are

premounted. To start using the gun, proceed as follows:

Check that the wire liner, contact tip and gas nozzle are suitable for the job. Change if needed. If your

1.

setup includes a gas-cooled gun, you can also change the neck.

Attach the pistol grip handle, if suitable for the job.

2.

Attach X8 Gun Remote Control, if suitable for the job (optional accessory).

3.

Connect the welding gun to the wire feeder: Push the welding gun connector into the wire feeder gun

4.

adapter, and hand-tighten the collar.

OPERATING MANUAL | EN 59

©

KEMPPI | 2018-09-28

Page 60

X8 MIG WELDER 2.3 Installation

Note:

X8 MIG Guns connect to X8 Wire Feeder with Kemppi Gun Adapter that enables, among other

things, accurate measurement of the actual arc voltage and the usage of the remote control.

Therefore, X8 MIG Guns are only compatible with X8 Wire Feeder.

If your setup includes a water-cooled gun, connect the cooling hoses to the wire feeder. The coolant

5.

inlet hose is marked with blue and the coolant outlet hose with red color.

Dress the sharp filler wire tip before loading to improve wire loading and to lengthen consumables'

6.

lifetime.

Press the Wire inch button to load the filler wire.

7.

OPERATING MANUAL | EN 60

©

KEMPPI | 2018-09-28

Page 61

X8 MIG WELDER 2.3 Installation

Trim the excess filler wire at a slight angle to improve ignition.

8.

Check the gas flow rate.

9.

The welding gun is now ready for use. When not using the gun, keep it in the welding gun holder on the wire

feeder.

2.3.6.2 Replacing consumable parts of welding gun

Select a suitable contact tip, gas nozzle, neck and wire liner according to the job. See also how to change the

feed rolls of the wire feeder accordingly: Replacing feed rolls on page 37.

Standard delivery set of consumable parts

The tables below list the consumable parts that are delivered with the welding gun. To find other compatible

parts for various materials, use Kemppi's Consumable Kit Selector at kitselect.kemppi.com.

Gas-cooled guns

X8 MIG Gun 200-g (3.5m) X8301203500

X8 MIG Gun 200-g (5.0m) X8301205000

X8 MIG Gun 300-g (3.5m) X8301303500

X8 MIG Gun 300-g (5.0m) X8301305000

Contact tip W012132

Contact tip adapter W011483

Gas nozzle W011478

Wire guide tube SP011868

X8 MIG Gun 200-g (3.5m) X8301203500

X8 MIG Gun 300-g (3.5m) X8301305000

Wire liner W012361

X8 MIG Gun 200-g (5.0m) X8301205000

X8 MIG Gun 300-g (5.0m) X8301305000

Wire liner W012362

OPERATING MANUAL | EN 61

©

KEMPPI | 2018-09-28

Page 62

X8 MIG WELDER 2.3 Installation

X8 MIG Gun 400-g (3.5m) X8301403500

X8 MIG Gun 400-g (5.0m) X8301405000

Contact tip W012134

Contact tip adapter W011483

Gas nozzle W011472

Wire guide tube SP011869

X8 MIG Gun 400-g (3.5m) X8301403500

Wire liner W012361

X8 MIG Gun 400-g (5.0m) X8301405000

Wire liner W012362

Water-cooled guns

X8 MIG Gun 420-w (3.5m) X8300423500

X8 MIG Gun 420-w (5.0m) X8300425000

Contact tip W012132

Contact tip adapter W011483

Gas nozzle W011478

Liner guide tube SP011868

X8 MIG Gun 420-w (3.5m) X8300423500

Wire liner W013628

X8 MIG Gun 420-w 5.0m X8300425000

Wire liner W013632

X8 MIG Gun 520-w (3.5m) X8300523500

X8 MIG Gun 520-w (5.0m) X8300525000

Contact tip W012134

Contact tip adapter W011483

Gas nozzle W011472

Liner guide tube SP011869

X8 MIG Gun 520-w (3.5m) X8300523500

Wire liner W013628

X8 MIG Gun 520-w (5.0m) X8300525000

Wire liner W013632

OPERATING MANUAL | EN 62

©

KEMPPI | 2018-09-28

Page 63

X8 MIG WELDER 2.3 Installation

Changing wire liner (gas-cooled gun)

Caution:

Use the correct wire liner. The tip of the filler wire may damage an incorrect liner.

Lay the welding gun cable straight on a flat surface.

1.

Loosen the neck tightener by rotating it half a turn, and remove the neck.

2.

Remove the guide nut from the tip of the sleeve.

3.

Remove the sleeve and pull out the liner. Make sure the cone and the seal slide out with the liner.

4.

OPERATING MANUAL | EN 63

©

KEMPPI | 2018-09-28

Page 64

X8 MIG WELDER 2.3 Installation

1 2

Load the new liner through the welding gun connector as far as it goes. Check that you have pushed the

5.

liner far enough: the liner must be visible at the tip of the gun.

OPERATING MANUAL | EN 64

©

KEMPPI | 2018-09-28

Page 65

X8 MIG WELDER 2.3 Installation

1 2 3

Assemble the cone (1), seal (2) and sleeve (3) (supplied with the new liner) over the liner protruding from

6.

the welding gun connector. Tighten the sleeve as tight as possible with a spanner.

Cut the excessive liner leaving 1 - 2 mm. Use side cutting pliers for spiral liner and carpet knife for DL

7.

Chili liner.

OPERATING MANUAL | EN 65

©

KEMPPI | 2018-09-28

Page 66

X8 MIG WELDER 2.3 Installation

1-2 mm

Attach the guide nut at the tip of the sleeve.

8.

Re-assemble the neck and tighten the neck tightener to secure.

9.

Changing neck (gas-cooled gun)

You can change the neck without tools.

Turn the neck tightener half a turn counter-clockwise to loosen it, and pull the neck out.

1.

OPERATING MANUAL | EN 66

©

KEMPPI | 2018-09-28

Page 67

X8 MIG WELDER 2.3 Installation

Push in the new neck and turn the neck tightener half a turn clockwise to secure it. Make sure you push

2.

the neck deep enough: When the neck is correctly inserted, the groove on the neck is completely hidden

under the neck tightener.

Note:

You can rotate the neck into different positions without loosening the neck tightener.

Changing gas nozzle (gas-cooled gun)

Screw the gas nozzle into its place.

OPERATING MANUAL | EN 67

©

KEMPPI | 2018-09-28

Page 68

X8 MIG WELDER 2.3 Installation

Changing contact tip (gas-cooled gun)

Remove the contact tip.

1.

Replace the contact tip adapter / gas diffuser, if needed. Screw in and hand-tighten the new adapter as

2.

tight as possible (no tool is needed). Make sure there is no gap between the contact tip adapter and the

black plastic bushing.

Note:

It is important to tighten the adapter properly to enable a tight connection of the contact tip to

the gun.

OPERATING MANUAL | EN 68

©

KEMPPI | 2018-09-28

Page 69

X8 MIG WELDER 2.3 Installation

Screw in a new contact tip and tighten it with an appropriate tool. Some thread grooves on the contact

3.

tip remain visible when the contact tip is properly connected to the gun.

Changing wire liner (water-cooled gun)

Caution:

Use the correct wire liner. The tip of the filler wire may damage an incorrect liner.

Lay the welding gun cable straight on a flat surface.

1.

OPERATING MANUAL | EN 69

©

KEMPPI | 2018-09-28

Page 70

X8 MIG WELDER 2.3 Installation

Remove the guide nut from the tip of the sleeve.

2.

Remove the sleeve and pull out the liner together with the cone .

3.

OPERATING MANUAL | EN 70

©

KEMPPI | 2018-09-28

Page 71

X8 MIG WELDER 2.3 Installation

Load the new liner through the welding gun connector as far as it goes The liner should be just visible, a

4.

couple of millimeters from the tip of the gun.

Note:

Make sure the liner is properly inside the contact tip adapter before you cut the liner at the

connector end.

OPERATING MANUAL | EN 71

©

KEMPPI | 2018-09-28

Page 72

X8 MIG WELDER 2.3 Installation

1 2

Assemble the cone (1) and sleeve (2) (supplied with the liner) over the liner protruding from the welding

5.

gun connector. Tighten the sleeve with a spanner to secure.

OPERATING MANUAL | EN 72

©

KEMPPI | 2018-09-28

Page 73

X8 MIG WELDER 2.3 Installation

1-2 mm

Cut the excessive liner leaving 1 - 2 mm. Use side cutting pliers for spiral liner and carpet knife for DL

6.

Chili liner.

Attach the guide nut at the tip of the sleeve.

7.

OPERATING MANUAL | EN 73

©

KEMPPI | 2018-09-28

Page 74

X8 MIG WELDER 2.3 Installation

Changing gas nozzle (water-cooled gun)

Screw the gas nozzle into its place.

Changing contact tip (water-cooled gun)

Remove the contact tip.

1.

OPERATING MANUAL | EN 74

©

KEMPPI | 2018-09-28

Page 75

X8 MIG WELDER 2.3 Installation

Replace the contact tip adapter/gas diffuser , if needed. Screw in and hand-tighten the new adapter as

2.

tight as possible (no tool is needed).

Note:

It is important to tighten the adapter properly to enable a tight connection of the contact tip to

the gun.

Screw in a new contact tip and tighten it properly with a tool. Some thread grooves on the contact tip

3.

remain visible when the contact tip is properly connected to the gun.

OPERATING MANUAL | EN 75

©

KEMPPI | 2018-09-28

Page 76

X8 MIG WELDER 2.3 Installation

2.3.6.3 Installing pistol grip handle

The pistol grip handle is suitable for all X8 MIG Guns. The handle improves the ergonomics of many welding

positions.

To attact the pistol grip handle, align the grooves and pull the handle forward to attach the front side (1),

and then push the handle back to snap-lock it into its place (2).

To detach the pistol grip handle, press the lock button at the back of the handle.

2.3.6.4 Installing remote control

X8 Gun Remote Control is an optional accessory for X8 MIG Gun.

OPERATING MANUAL | EN 76

©

KEMPPI | 2018-09-28

Page 77

X8 MIG WELDER 2.3 Installation

TORX 20

For operation instructions, see Gun remote control on page 99.

Unscrew the two screws that attach the cover to the gun.

1.

Remove the protective cover from the gun by pushing it forwards and lifting it up.

2.

Remove the interface card that covers the connectors.

3.

Note:

Store the interface card in case you want to remove the remote control later. If you remove the

remote control, re-mount the interface and the cover on the gun.

Attach the remote control by pushing it down and backwards into its place so that the connectors align.

4.

OPERATING MANUAL | EN 77

©

KEMPPI | 2018-09-28

Page 78

X8 MIG WELDER 2.3 Installation

Screw in the two screws.

5.

2.3.7 Lifting X8 MIG Welder

If you need to lift X8 MIG Welder, pay special attention to the safety measures. Follow the local regulations.

Warning:

Do not lift the welder with the gas cylinder.

Proceed as follows:

OPERATING MANUAL | EN 78

©

KEMPPI | 2018-09-28

Page 79

X8 MIG WELDER 2.3 Installation

Loop two lifting straps through the handle at the front and two straps through the handle at the back of

1.

the power source.

Caution:

Place the straps as close to the power source as possible.

Lift steadily straight up.

2.

2.3.8 Purchasing and managing welding software

You can purchase Kemppi welding software licenses to X8 MIG Welder. Installed licenses can be viewed with

Control Pad.

For more information, visit www.kemppi.com.

2.3.9 Optional accessories

X8 MIG Welder has several accessories to facilitate its use and improve welding quality.

Wire Drum Kit

To use the wire drum kit, drill a hole at the back of X8 Wire Feeder's transparent cover.

OPERATING MANUAL | EN 79

©

KEMPPI | 2018-09-28

Page 80

X8 MIG WELDER 2.3 Installation

Wire Feeder Hanger for Boom

The wire feeder hanger for boom facilitates welding where it is difficult to bring the full X8 MIG Welder

welding system. The hanger allows more fluent transitions in constricted spaces.

Caution:

Do not hang the wire feeder from the handle. Use the wire feeder hanger for boom instead.

OPERATING MANUAL | EN 80

©

KEMPPI | 2018-09-28

Page 81

X8 MIG WELDER 2.3 Installation

Wire Feeder Counterbalance Arm

The wire feeder counterbalance arm reduces the weight of the cable bundle over the working area.

Proceed as follows:

OPERATING MANUAL | EN 81

©

KEMPPI | 2018-09-28

Page 82

X8 MIG WELDER 2.3 Installation

1. Lock the rotating plate to its position.

2. Adjust the length of the arm. Tighten the screws to lock to position.

3. Turn to adjust the tension of the counterbalance spring.

4. Turn to adjust the damping of the up and down movement.

Wire Feeder Cabinet Heater

The wire feeder cabinet heater prevents moisture from condensing inside the wire feeder cabinet so that the

wire spool stays dry.

Double Wire Feeder Rotating Plate

The double wire feeder rotating plate allows the use of two wire feeders on one power source.

OPERATING MANUAL | EN 82

©

KEMPPI | 2018-09-28

Page 83

X8 MIG WELDER 2.3 Installation

X8 Cable Rack

The cable rack holds the interconnection cable during transportation or storage.

Note:

This is an alternative accessory for the gas cylinder cart. Both cannot be installed at the same time.

X8 Accessory Tray

The accessory rack holds the small parts and tools needed for welding. Install it on the side of the welding

machine.

OPERATING MANUAL | EN 83

©

KEMPPI | 2018-09-28

Page 84

X8 MIG WELDER 2.4 Operation

2.4 Operation

Follow these operating instructions carefully to have full advantage of your X8 MIG Welder and to minimize

the risk of malfunctions.

2.4.1 X8 MIG Welder control devices

Welding with X8 MIG Welder can be controlled through three different control panels, which offer slightly

different features for adjusting the welding parameters.

The actual features vary according to the functions and usability of the control panel.

2.4.1.1 Control Pad

Control Pad is a window to X8 MIG Welder: Control Pad shows you all the settings and licenses installed in

the welding system.

You can adjust the welding parameters and their values remotely with the one-knob navigation, and connect

Control Pad to any X8 MIG Welder nearby.

Navigation

Above the display, Control Pad has three view buttons. Press these buttons to change the view on Control

Pad's display. Press the Menu button twice to open the View menu.

Use the knobs under the display to move in the display and to adjust the values. When there is a green light

in the center of the knob, the knob also functions as a push button.

OPERATING MANUAL | EN 84

©

KEMPPI | 2018-09-28

Page 85

X8 MIG WELDER 2.4 Operation

Figure 6: The View menu

In the Welding view, adjust the welding power with the left knob and the fine tuning with the right knob. In

most welding processes, this secondary parameter is voltage.

In all other views, move up and down in the menus with the right knob. Press the green button in the center

of the knob to open an item.

If you need to perform a reversing action, such as Cancel or Default, press the green button to accept.

Header and footer

Control Pad's header displays the serial number of the welding machine, the selected wire feeder, and the

name of the user:

There is an instruction on the footer above the knob, when the knob has a specific function. A green circle in

the footer prompts the push of the button on the control knob. The adjustable parameter or value in focus is

highlighted with orange.

OPERATING MANUAL | EN 85

©

KEMPPI | 2018-09-28

Page 86

X8 MIG WELDER 2.4 Operation

Figure 7: Control Pad display with the Adjust

footer

Figure 8: Control Pad display with the Select footer

If the selection of the toggle button comes into effect right away, the footer command is Close. If the change

comes into effect after pressing the green button, the footer command is OK.

Control Pad views

There are three main views on Control Pad display: Channel (memory channels), Welding, and Settings.

Toggle between the views with the view buttons. The View menu inside Welding opens, when you press the

Menu button again in the Welding view.

Figure 9: The Channel button

Figure 10: The Menu button

OPERATING MANUAL | EN 86

©

KEMPPI | 2018-09-28

Page 87

X8 MIG WELDER 2.4 Operation

Figure 11: The Settings button

Welding view

In the Welding view, you can:

• See an overview of the settings of the selected welding program

• Adjust the main parameters (welding power and fine tuning)

Depending on the selected welding process, function and program, some or all of the following information

is shown:

1. Memory channel, its number and the welding program

The first row shows the memory channel's name.

The second row shows the welding program's name, which consists of the filler wire material and

diameter and the shielding gas.

If you have modified the welding settings, the channel number tilts to the right. To save changes, press

and hold the Channel button until the number returns to its normal position.

2. Operation mode of the welding gun (trigger logic)

2T, 4T or WP Switch. For more information, see Trigger logic functions on page 133.

3. Touch sense ignition

Option for smooth ignition with less spatter.

OPERATING MANUAL | EN 87

©

KEMPPI | 2018-09-28

Page 88

X8 MIG WELDER 2.4 Operation

4. Upslope

The selected start and stop logics.

5. Estimated welding current

6. Estimated plate material thickness

7. Wire feed speed

8. Serial number of the power source, wire feeder's number (1 or 2) and user name

9. Welding process

10. Hot start

The selected start and stop logics.

11. Crater fill

The selected start and stop logics.

12. Voltage

13. Voltage/Fine tuning

Adjust the welding power with the left control knob.

Fine tune the secondary welding parameter with the right control knob. The adjustable secondary parameter

varies according to the welding process and function.

The welding power graph shows with grey raster pattern the area, where the selected values result in

globular transfer.

Figure 12: Raster pattern in the wire feed arc

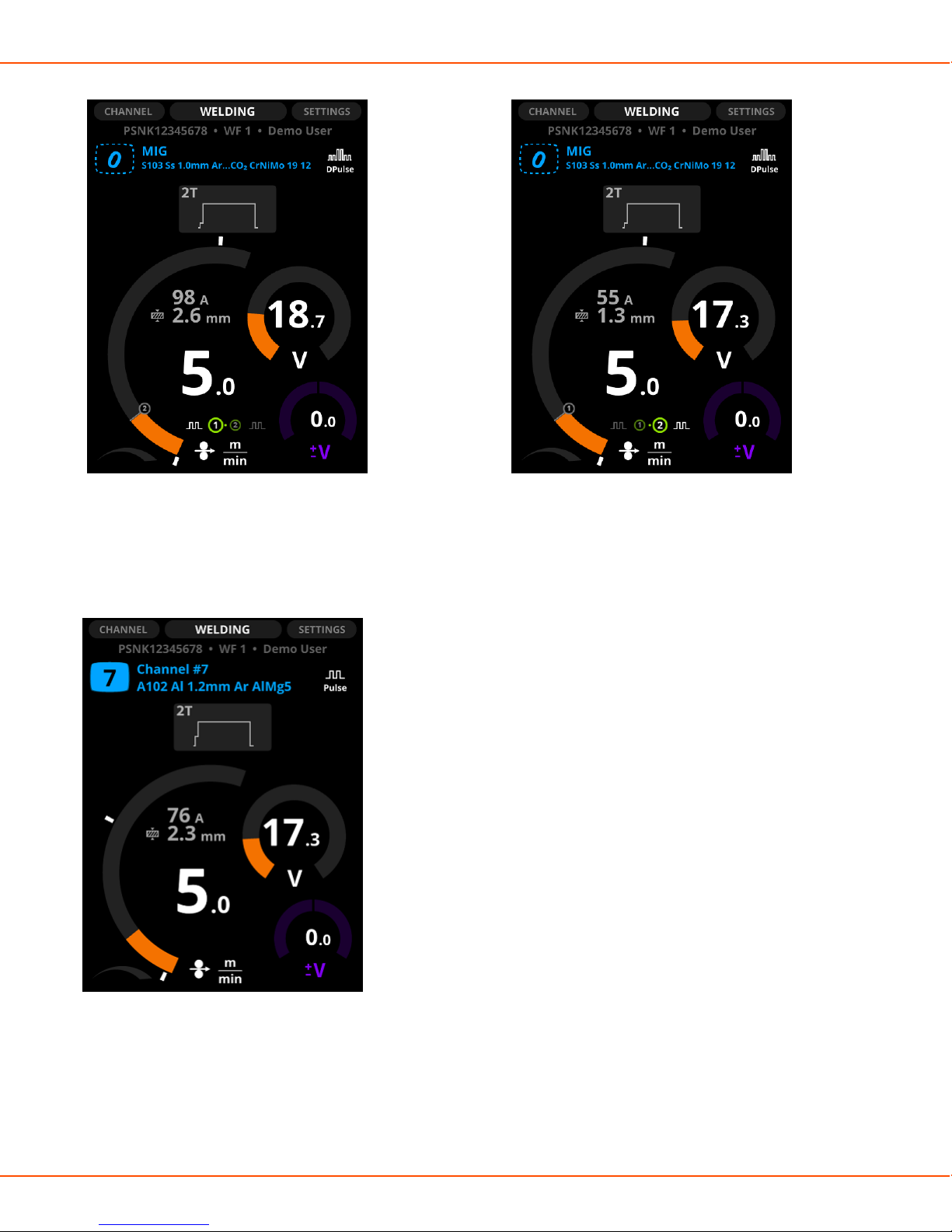

In DPulse, WP Switch and DProcess, you can adjust two value sets: the first level and the second power level.

Press the left green button to toggle between them. Adjust the values with the control knobs. The other

power level is shown with gray line on the wire feed speed diagram.

OPERATING MANUAL | EN 88

©

KEMPPI | 2018-09-28

Page 89

X8 MIG WELDER 2.4 Operation

Figure 13: Toggling DPulse (1) Figure 14: Toggling DPulse (2)

You can specify the minimum and maximum values of the wire feed speed. They are displayed as white

stoppers beside the wire feed speed diagram.