Page 1

1920840

1814

A7 MIG WelderX3 MIG Welder

EN

OPERATING MANUAL

Page 2

2

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

CONTENTS

1. Read rst .................................................................................................3

1.1 General ......................................................................................................3

1.2 About X3 MIG Welder product series .......................................................3

2. X3 MIG Welder structure ..................................................................4

2.1 System introduction ..................................................................................4

2.2 X3 Power Source........................................................................................4

2.3 X3 Wire Feeder ...........................................................................................5

3. Installation .............................................................................................5

3.1 Before use ..................................................................................................5

3.2 Positioning of the machine .......................................................................5

3.3 Distribution network .................................................................................6

3.4 Connecting cables .....................................................................................6

3.4.1 Mains connection ...................................................................................6

3.4.2 Wire feeder connection ...........................................................................7

3.4.3 Earth return cable connection ...................................................................7

3.5 Optional accessories .................................................................................8

3.5.1 Wheel sets.............................................................................................8

3.5.2 Undercarriage ........................................................................................8

3.5.3 Wire feeder mounting plate ......................................................................8

3.5.4 Gas heater .............................................................................................8

4. Operation ...............................................................................................9

4.1 Loading the ller wire ...............................................................................9

4.1.1 Mounting and locking the wire spool .........................................................9

4.1.2 Adjusting the spool brake ........................................................................9

4.1.3 Adjusting the pressure arms .....................................................................9

4.1.4 Feeding the ller wire ............................................................................10

4.1.5 Wire feed mechanism DuraTorque 400 .....................................................10

4.2 Controlling the welding system..............................................................12

4.2.1 Setup panel .........................................................................................12

4.2.2 Starting the power source ......................................................................12

4.2.3 LCD display .........................................................................................12

4.2.4 LED indicators ......................................................................................12

4.2.5 Settings menu parameters .....................................................................13

4.2.6 Wire feeder control panel .......................................................................14

4.3 Selecting shielding gas ...........................................................................14

4.4 Gas test ....................................................................................................14

4.5 Trigger logic and Crater ll function .......................................................14

4.6 Calibrating wire feed speed ....................................................................16

5. Troubleshooting ................................................................................17

6. Maintenance .......................................................................................17

6.1 Regular maintenance ..............................................................................17

6.2 Disposal of the machine .........................................................................17

7. Technical data ....................................................................................18

8. Ordering codes ..................................................................................20

Page 3

3

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

1. READ FIRST

1.1 General

Congratulations on choosing the X3 MIG Welder series

power source. Used correctly, Kemppi products can signicantly increase the productivity of your welding, and

provide years of economical service.

This operating manual contains important information

on the use, maintenance and safety of your Kemppi

product. The technical specications of the device can

be found at the end of the manual.

Please read the manual carefully before using the equipment for the rst time. For your own safety and that of

your working environment, pay particular attention to

the safety instructions in the manual.

For more information on Kemppi products, contact

Kemppi Oy, consult an authorised Kemppi dealer, or visit

the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to

change without prior notice.

Important notes

Items in the manual that require particular attention in

order to minimize damage and harm are indicated by the

symbols below. Read these sections carefully and follow

their instructions.

Note: Gives the user a useful piece of information.

Caution: Describes a situation that may result in dam-

age to the equipment or system.

Warning: Describes a potentially dangerous situation.

If not avoided, it will result in personal damage or fatal

injury.

Disclaimer

While every eort has been made to ensure that the information contained in this guide is accurate and complete,

no liability can be accepted for any errors or omissions.

Kemppi reserves the right to change the specication of

the product described at any time without prior notice.

Do not copy, record, reproduce or transmit the contents

of this guide without prior permission from Kemppi.

1.2 About X3 MIG Welder product series

X3 MIG Welder is a set of inverter-based welding equipment intended for professional use in industrial MIG/MAG

welding applications. It can be connected to a 3-phase

mains power supply.

The X3 MIG Welder contains either a 400- or 500-ampere

X3 Power Source and the X3 Wire Feeder 300 unit for wire

feeding.

The system is equipped with gas type selection buttons.

It automatically presets the welding dynamic characteristic according to your gas selection choice.

Enjoy welding with your Kemppi product!

Page 4

4

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

2. X3 MIG WELDER STRUCTURE

2.1 System introduction

• X3 Power Source

• X3 Wire Feeder 300: The wire feeder can be

installed as stand-alone, or it can be mounted on

top of the power source with an optional X3 Wire

Feeder Mounting Plate.

• X3 Wheel Set / X3 Four Wheel Set (optional). The

power source can be equipped with large rear

wheels and/or a set of turning front wheels.

• P20 undercarriage (optional)

• Power supply for external gas heater

2.2 X3 Power Source

3

1

4 5 6

2

FRONT

1. ON/OFF switch

2. LCD display

3. Fan grill

4. Earth return cable connector ( – )

5. Control cable connection

6. Wire feeder cable connector ( + )

10

8

9

7

BACK

7. Mains cable

8. Power source fuse, 6.3 A

9. Shielding gas heater fuse, 2 A

10. Connector for shielding gas heater

Page 5

5

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

2.3 X3 Wire Feeder

1

2

3

4

5

1. Control panel

2. Welding gun connection

3. Shielding gas connection

4. Control cable connection

5. Welding current cable connection

3. INSTALLATION

3.1 Before use

Always make sure before use that the products have not

been damaged during transportation.

Check also that you have received the components you

ordered and the instruction manuals needed. Product

packaging material is recyclable.

When moving the welding machine, always lift it from

the handle, never pull it from the welding gun or other

cables.

Operating environment

This machine is suitable for both indoor and outdoor

use. Always make sure that the air ow in the machine is

unrestricted. The recommended operating temperature

range is –20…+40 °C.

Please read also the Safety Instructions concerning the

operating environment.

3.2 Positioning of the machine

Place the machine on a sturdy, level surface that is dry

and does not allow dust or other impurities to enter the

machines cooling air ow. Preferably site the machine to

a suitable carriage unit so it is above oor level.

Notes for positioning the machine

• The surface inclination may not exceed

15 degrees.

< 15°

• Ensure the free circulation of the cooling air.

There must be at least 20 cm of free space in

front of and behind the machine for cooling air

circulation.

• Protect the machine against heavy rain and

direct sunshine.

The machine is not allowed to be operated in the rain

as the protection class of the machine, IP23S, allows

preserving and storing outside only.

Never aim the spray of sparks from a grinding ma-

chine toward the equipment.

Page 6

6

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

3.3 Distribution network

All regular electrical devices without special circuits generate harmonic currents into distribution network. High

rates of harmonic current may cause losses and disturbance to some equipment.

X3 Power Source 400 / 400 AU

This equipment complies with IEC 61000-3-12 provided

that the short-circuit power Ssc is greater than or equal to

4.7 MVA at the interface point between the user’s supply

and the public supply network. It is the responsibility

of the installer or user of the equipment to ensure, by

consultation with the distribution network operator

if necessary, that the equipment is connected only to

a supply with a short-circuit power Ssc greater than or

equal to 4.7 MVA.

X3 Power Source 500

This equipment complies with IEC 61000-3-12 provided

that the short-circuit power Ssc is greater than or equal to

5.2 MVA at the interface point between the user’s supply

and the public supply network. It is the responsibility

of the installer or user of the equipment to ensure, by

consultation with the distribution network operator

if necessary, that the equipment is connected only to

a supply with a short-circuit power Ssc greater than or

equal to 5.2 MVA.

3.4 Connecting cables

3.4.1 Mains connection

The X3 Power Source is connected to a 380 – 440 V threephase network. On the back side of the machine, there

is a mains cable that does not hava a plug. Before use,

check the mains cable and install a suitable mains plug.

If the cable does not comply with the local electrical

regulations, replace it with a compliant cable.

L1 L2 L3

Replacement of the mains cable:

1. Unscrew the mounting screws on the cover plate

of the machine, and remove the case by lifting it.

2. Disconnect the phase leads from connectors L1,

L2, and L3, and disconnect the protective earth

lead.

3. Pass the cable to the machine through the mains

cable inlet ring at the rear of the machine, and

secure the cable with a cable clamp.

4. Connect the cable’s phase leads to connectors L1,

L2, and L3.

5. Connect the yellow-green protective earth lead to

its connector

6. Screw the cover plate back in place.

The mains cable or wall plug may be installed or replaced only by an electrical contractor or installer authorised to perform such operations.

Page 7

7

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

3.4.2 Wire feeder connection

On the front side of the power source, there are connectors for the interconnection cable

and the control cable for connecting the power source to the wire feeder.

To connect the wire feeder to the power source, complete the following steps:

1 2

3

1. Attach the wire feeder’s welding current cable to the plus (+) connector of the

power source. Hand tighten the connector with a clockwise push and twist action to

lock.

2. Attach the wire feeder control cable plug to the control socket of the power source.

3. Connect the shielding gas hose to the gas bottle or to the shielding gas distribution

system.

Normally the wire feeder should be connected to the plus (+) pole. However, with

some ller wires and shielding gases, you should connect it to the minus (-) pole, and the

earth return cable to the plus pole.

3.4.3 Earth return cable connection

Attach the earth return cable to the minus (–) connector. Hand tighten the connector

with a clockwise push and twist action to lock.

Attach the other end of the earth return cable to the workpiece before welding.

When attaching the earth return clamp to the work piece, remember to clean the

work piece surface so as to achieve safe and undisturbed operation.

Page 8

8

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

3.5 Optional accessories

3.5.1 Wheel sets

The X3 Power Source can be tted with wheels for easy

movement of the unit.

There are two dierent wheel sets available, one with

big rear wheels only and another with big rear wheels

and turning front wheels. Installation instructions are

delivered with the wheel set package.

x 4

x 4

3.5.2 Undercarriage

To enable easy movement of the unit, the power source

can be mounted on the P20 undercarriage. Installation

instructions are delivered with the undercarriage

package.

3.5.3 Wire feeder mounting plate

If you are using wheels or undercarriage, you can attach

the wire feeder on top of the power source using the X3

Wire Feeder Mounting Plate to create a compact welding

unit that is easy to move around.

To mount the wire feeder on top of the power source,

follow the instructions delivered with the mounting plate.

1 2

x 5

x 4

3.5.4 Gas heater

When using CO₂ shielding gas, a 110 V gas heater can be

connected to the power supply located at the back of the

X3 MIG Welder power source.

Page 9

9

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

4. OPERATION

4.1 Loading the ller wire

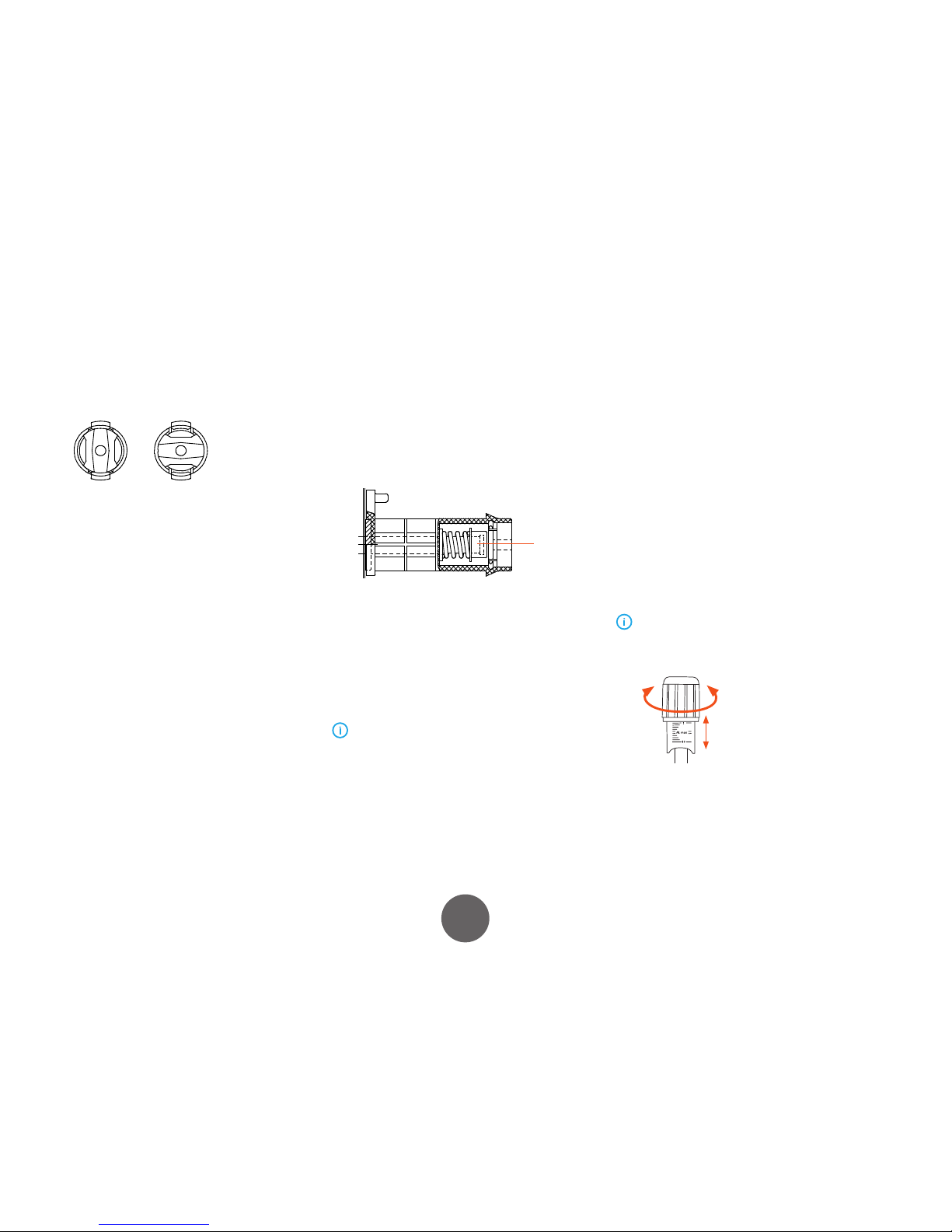

4.1.1 Mounting and locking the wire spool

LOCKED OPEN

• Release locking nails of wire spool hub by

turning locking knob a quarter round.

• Mount the spool at its place. Note rotating

direction of spool!

• Lock the spool with locking knob, locking nails

of hub remain to outside position and will lock

the spool.

4.1.2 Adjusting the spool brake

Brake force is adjusted through the hole behind the

locking clip. Remove the locking clip by hand, and adjust

the tension and pressure to the friction pads mounted

inside with a screw driver. See diagram and location A.

A

The load applied varies depending on the size and weight

of the ller wire and spool, but also on the wire feed

speed. The heavier the wire spool and the faster the feed

speed, the greater the need to increase the braking load.

Adjust the pressure, secure the locking clip, set the wire

feed speed and check that the braking force is enough

to ensure the ller wire does not spill from the spool on

overrun.

Too much or unnecessary loads can impact welding

quality, load and wear to the wire feed system.

4.1.3 Adjusting the pressure arms

Adjust the drive pressure to the ller wire with the thumb

screws mounted over the pressure arms. Notice the graduated scales indicating load. The load applied should be

sucient to overcome a light braking force applied by

hand to the ller wire, as it exits the welding gun contact

tip.

For smaller diameter and soft ller wires, less feed pressure is required. It should be possible to apply a light

breaking force to the ller wire by hand, as it exits the gun

contact tip. But slightly more wire ow restriction should

render the drives rolls to slip slightly over the ller wire

without deforming the wire.

Excessive pressure causes attening of the ller wire

and damage to coated or cored ller wires. It also causes

undue wear of the feed rolls and increases gearbox load, so

reducing service life.

Page 10

10

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

4.1.4 Feeding the filler wire

Ensure that the groove of the feed roll matches the diameter of ller wire used. Release

the wire end from the spool and cut o any deformed section. Be careful the wire does

not spill from the spool sides

1. Connect the welding gun and tighten the collar.

2. Straighten about 20 cm of ller wire and ensure the tip has no sharp edges. File if

necessary, as a sharp wire edge may damage the wire gun liner – particularly softer

plastic liners.

3. Present the ller wire tip to the back of the wire feed rolls and press the wire inch

switch on the wire feed panel. Feed the wire to the gun contact tip and prepare to

weld.

4. Press the Wire Inch button and allow the ller wire to feed through the gun cable to

the contact tip.

4.1.5 Wire feed mechanism DuraTorque 400

Wire guide tubes

ø mm colour outlet tube middle tube inlet tube

Ss, Al,

(Fe, Mc, Fc)

plastic

0.6 SP007437 SP007429 SP007293

0.8 – 0.9 SP007438 SP007430 SP007294

1.0 SP007439 SP007431 SP007295

1.2 SP007440 SP007432 SP007296

1.4 SP007441 SP007433 SP007297

1.6 SP007442 SP007434 SP007298

2.0 SP007443 SP007435 SP007299

2.4 SP007444 SP007436 SP007300

Fe, Mc, Fc

metal

0.8 – 0.9 SP007454 SP007465 SP007536

1.0 SP007455 SP007466 SP007537

1.2 SP007456 SP007467 SP007538

1.4 – 1.6 SP007458 SP007469 SP007539

2.0 SP007459 SP007470 SP007540

2.4 SP007460 SP007471 SP007541

Page 11

11

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

Wire feed rolls, plastic

ø mm colour lower upper

Fe, Ss,

(Al, Mc, Fc)

V-groove

0.6 W001045 W001046

0.8 – 0.9 W001047 W001048

1.0 W000675 W000676

1.2 W000960 W000961

1.4 W001049 W001050

1.6 W001051 W001052

2.0 W001053 W001054

2.4 W001055 W001056

Fc, Mc, (Fe)

V-groove, knurled

1.0 W001057 W001058

1.2 W001059 W001060

1.4 – 1.6 W001061 W001062

2.0 W001063 W001064

2.4 black W001065 W001066

Al, (Fc, Mc, Ss, Fe)

U-groove

1.0 W001067 W001068

1.2 W001069 W001070

1.6 W001071 W001072

Wire feed rolls, metal

ø mm lower upper

Fe, Ss,

(Al, Mc, Fc)

V-groove

0.8 – 0.9 W006074 W006075

1.0 W006076 W006077

1.2 W004754 W004753

1.4 W006078 W006079

Fc, Mc, (Fe)

V-groove, knurled

1.0 W006080 W006081

1.2 W006082 W006083

1.4 – 1.6 W006084 W006085

2.0 W006086 W006087

Al, (Fc, Mc, Ss, Fe)

U-groove

1.0 W006088 W006089

1.2 W006090 W006091

1.6 W006092 W006093

Mount the lower feed roll, ensuring that the pin on the shaft ts in the cut on the

feed roll.

Page 12

12

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

4.2 Controlling the welding system

4.2.1 Setup panel

Use the Setup panel on the X3 Power Source to change

the settings of your welding system.

1

Gas test button

Press to test the shielding gas ow.

X3

MIG

Welder

1

4

5

2

3

6

2

Gas select button

Press to select either CO₂ or mixed

shielding gas (MAG).

3

Press to select between 2T and 4T gun

trigger modes.

4

Crater ll button

Press to select the Crater ll mode ON

or OFF.

5

Wire feed speed adjustment knob

Turn to set the wire feed speed value for

the Crater ll mode.

6

Voltage adjustment knob

Turn to set the welding voltage value for

the Crater ll mode.

4.2.2 Starting the power source

To start the power source, turn the main switch to position ‘I’. Initially, the rmware version number is displayed

in the LCD display. After that, the rmware number is replaced with the parameter display, and the machine is

ready for setup.

4.2.3 LCD display

The X3 MIG Power Source is equipped with an LCD display. Welding parameter settings

are made through the X3 Wire Feeder control panel for wire feed speed (A) and voltage

(V). During welding the display always shows the welding current (A) used.

The average welding values remain on display for 10 seconds after you stop welding.

The upper part of the display shows wire feed speed, the selected welding voltage and

gas type selection. The lower part of display shows the Crater ll values.

4.2.4 LED indicators

There are two LED indicator lights on the top of the control panel.

1 2

1. The ON light indicates that the power source is turned on.

2. The second light indicates that the machine is over heated.

The machine stops automatically when it reaches its maximum operating temperature. If the heat indicator led is on, the machine has exceeded its normal maximum operating temperature. Stop welding and wait until the led turns o. The machine is then ready

for welding to continue.

Page 13

13

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

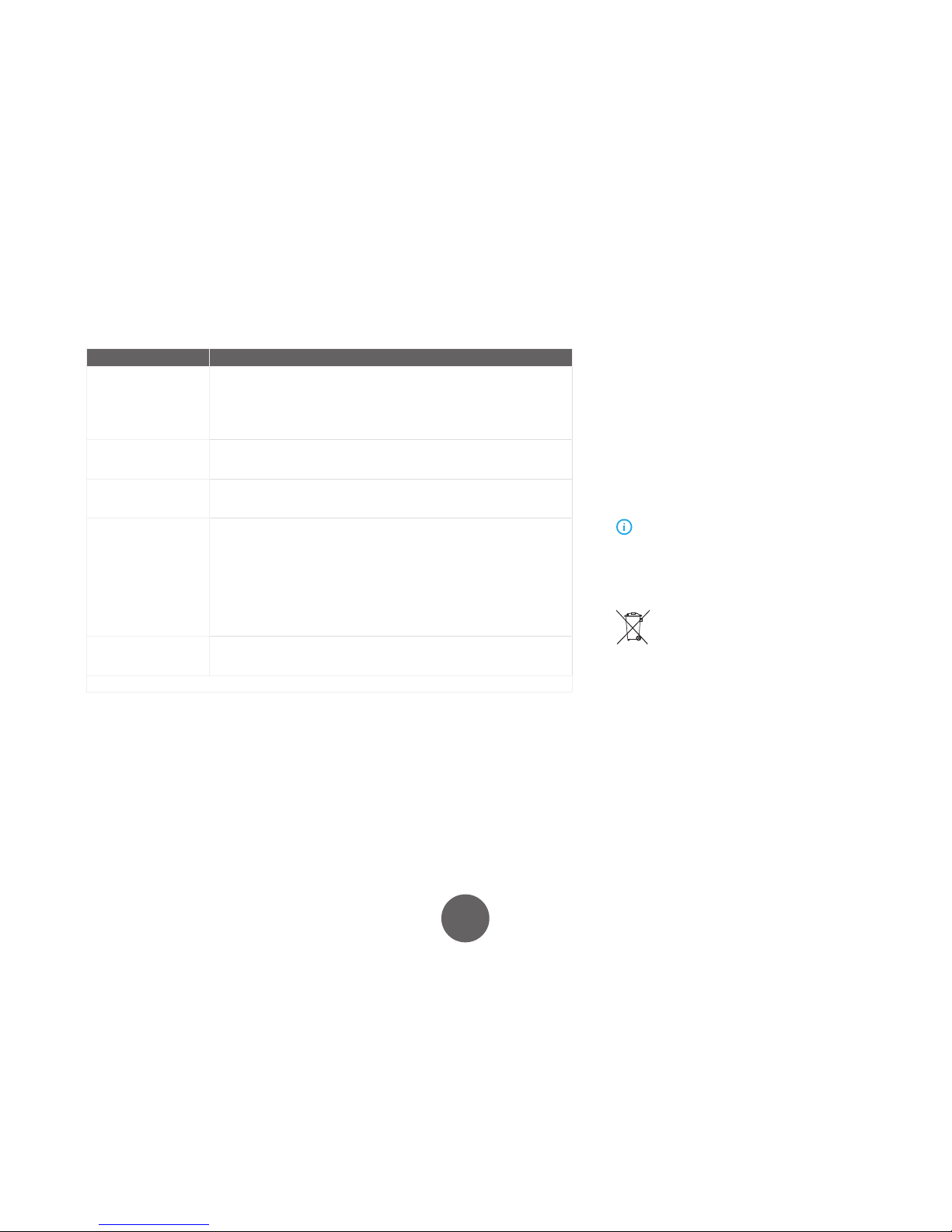

4.2.5 Settings menu parameters

In Settings menu you can enable or disable welding parameters and adjust their

values.

Parameter Values

CrE Creep start 1 = On / 0 = O

PrE Pre gas 1 = On / 0 = O

Pre gas Pre gas 1 = On / 0 = O

Pos Post gas 1 = On / 0 = O

Ign Hard ignition

Makes the arc ignition stronger by increasing welding

voltage at the start of the weld.

1 = On / 0 = O

HSt Hot stop

Enhances the end of the weld in certain applications

by delaying the arc extinction and raising the welding

voltage at the end of welding. Especially useful in tack

welding.

1 = On / 0 = O

BUr Burn back time

Time that torch will be live after welding has stopped

to prevent ller wire from sticking to the work piece.

(-01 = Use defaults from welding program.

Integer (ms):

-01…999

LOC Panel Lock

Locks the setup panel and prevents welding

parameters from being changed.

‘LOC’ ashes on the screen on attempt to change

parameters. Setting is remembered on the next

startup.

1 = enabled with

code 769

0 =disabled with

code 769

FAC Fact ory re set

Resets the user interface and special settings to

factory defaults on menu exit.

1 = On / 0 = O

To enable or disable welding parameters

1. Open Settings menu by pressing Crater ll and Gas test buttons

simultaneously.

2. Use Gas select and 2T/4T buttons to navigate to the desired parameter.

3. Press Crater ll button to toggle the the state of the parameter (On or O ).

4. Exit the menu and save the changes by pressing Crater ll and Gas test buttons

simultaneously.

To set values for Burn back time or Panel lock code

1. Open Settings menu by pressing Crater ll and Gas test buttons

simultaneously.

2. Use Gas select and 2T/4T buttons to navigate to BUr or LOC menu item.

3. Press Crater ll button to activate a single digit so that it starts to blink.

4. Use Gas select and 2T/4T buttons to increase and decrease the value of the

digit.

5. Press Crater ll to activate another digit.

6. Press Crater ll and Gas test simultaneously to exit the menu and save the

changes.

To use carbon arc gouging

+

Press Crater ll and 2T/4T to enter the gouging

mode.

+

Adjust the voltage with Gas select and 2T/4T

buttons.

Activate another digit by pressing Crater ll

button.

+

Exit gouging mode by pressing Crater ll and

2T/4T simultaneously.

Output terminals are live in carbon arc gouging mode.

Page 14

14

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

4.2.6 Wire feeder control panel

Use the Control panel on the X3 Wire Feeder to adjust the

welding parameters.

1

2

3

1. Wire feed speed

Turn to adjust the wire feed speed. The amperage

level is automatically changed to match the wire

feed speed setting. See the value tables at the end of

this manual.

2. Welding voltage

Turn to adjust the welding voltage level. The voltage

level determines the arc length.

3. Wire inch

Press to feed the ller wire into the welding gun.

4.3 Selecting shielding gas

Press the shielding gas selection button to set the shielding gas type to either CO₂ or mixed gas according to the

gas you are using.

Select CO₂ if you are using carbon dioxide. Select Ar + CO₂

(MAG) if you are using mixed gas.

X3 MIG Welder has a factory set Pre gas time of 0.2 s

and a Post gas time of between 2 – 4 s, depending on the

welding power settings.

4.4 Gas test

To test the shielding gas ow, press the gas test button

once. The shielding gas starts to ow and stops automatically after 20 seconds.

To interrupt the gas test, press the button again.

4.5 Trigger logic and Crater ll function

The purpose of Crater ll is to facilitate controlled nishing

of welding and to reduce the welding faults caused by

the nal crater. The Crater ll parameters can be specied

in the Setup panel.

2T mode

MIG welding with 2T mode of the gun trigger.

• Push the trigger – welding starts after preset Pre

gas time.

• Release the trigger – welding ends. Post gas

ows for preset time.

1. 2.

1. Pre gas time

2. Post gas time

Page 15

15

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

2T mode and Crater ll function

• Push the trigger – welding starts after preset Pre

gas time.

• Release the trigger – values drop to preset Crater

ll level and welding ends after preset time. Post

gas ows for preset time.

1. 2. 3.

1. Pre gas time

2. Crater ll time

3. Post gas time

4T mode

MIG welding with 4T mode of the gun trigger.

• Trigger pushed down – ow of shielding gas

starts.

• Trigger released – welding starts.

• Trigger pushed down – welding ends and shielding gas ow continues.

• Trigger released – ow of shielding gas ends.

Post gas time at least preset minimum.

1. 2.

1. Pre gas time

2. Post gas time

4T mode and Crater ll function

• Trigger pushed down – ow of shielding gas

starts.

• Trigger released – welding starts.

• Trigger pushed down – welding values change

to Crater ll level.

• Trigger released – welding ends. Post gas time

ows for preset time.

1. 2. 3.

1. Pre gas time

2. Crater ll time

3. Post gas time

Page 16

16

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

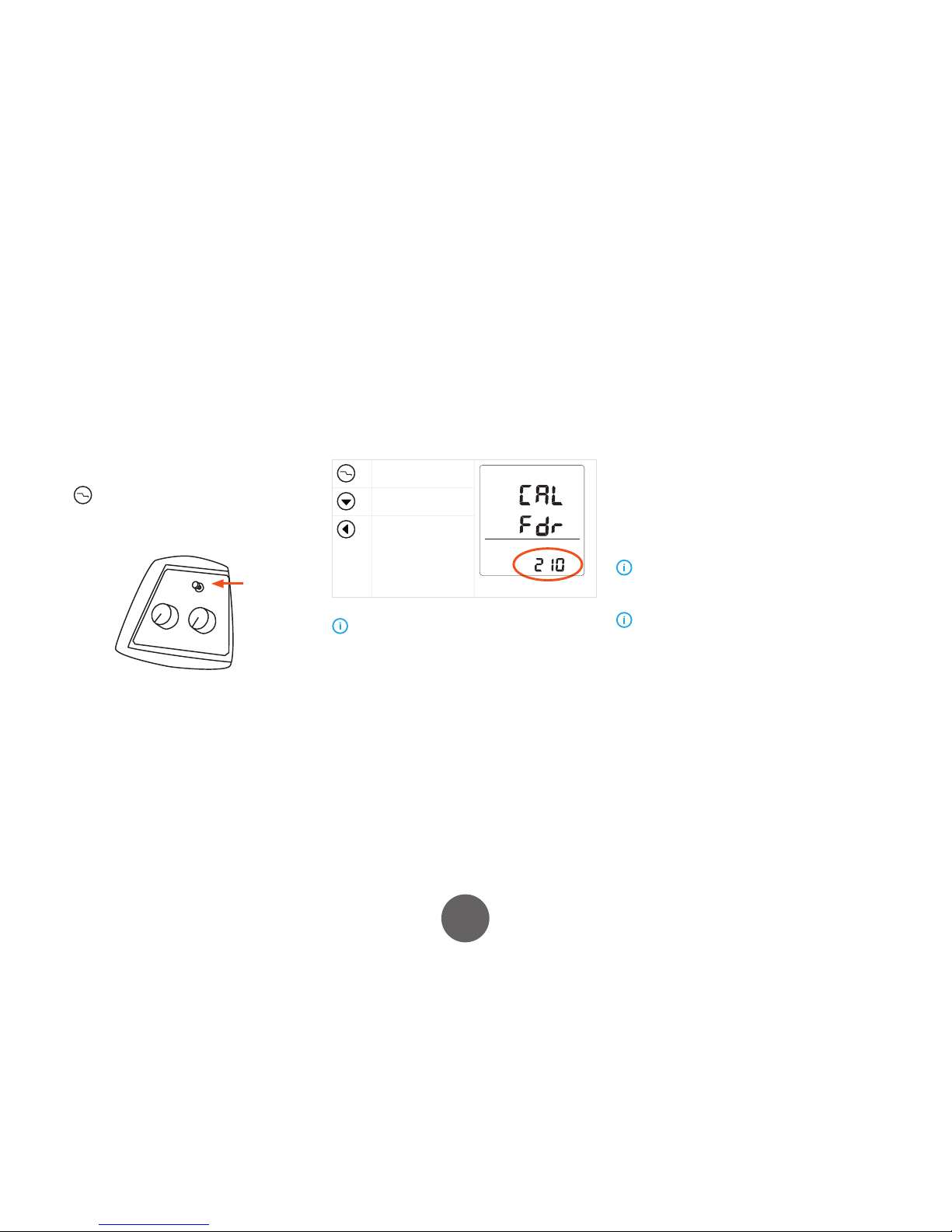

4.6 Calibrating wire feed speed

To ensure that the pre-sets and meter displays work as

planned, you must calibrate the wire feed speed on your

X3 MIG Welder.

To calibrate the wire feed speed

1. At the power source control panel, press the Crater

ll button for 3 seconds.

2. Cut the ller wire at the contact tip.

3. Press Wire Inch button at the wire feeder. Wire feed

starts and continues for 12 seconds.

4. When wire feed stops, cut the wire at the contact tip

and measure the length of the fed wire in mm.

5. At the power source control panel, enter the length

of the wire using the following buttons.

Toggle between the

digits of the number

Increase the digit by

one

Decrease the digit

by one

If you enter a value that does not t in, the machine

forces the value within the acceptable limits. .

6. Press Wire Inch button again. Wire feed starts and

continues for 2 seconds.

7. When wire feed stops, cut the wire and measure its

length.

8. At the power source control panel, enter the length

of the wire.

9. Press Wire Inch button.

To skip the calibration, do one of the following:

• Exit the calibration mode by pressing Crater ll

button for 3 seconds.

• Exit the calibration mode by leaving the machine

idle for 5 minutes.

• Turn o the machine before the step 9 to exit the

calibration mode and keep the old calibration

values.

The X3 Wire Feeder 300 must always be calibrated

before the rst use and if combined with a dierent X3

Power Source.

Check the wire feeder’s calibration regularly. Correctly

calibrated wire feeder ensures quality welds.

Page 17

17

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

5. TROUBLESHOOTING

Problem Cause

The machine stops

working. Overheating

indicator is lit, and Err 4 is

displayed.

The machine has overheated.

• Ensure that cooling air has unrestricted ow.

• The machine’s duty cycle has been exceeded.

If no other damage is caused, the fan starts working and the machine recovers

within a couple of minutes.

If the problem persists, please contact Kemppi service representative.

Machine stops working.

Err 2 or Err 3 is displayed.

The mains voltage is either too low (Err 2) or too high (Err 3). *

The machine recovers automatically, when the mains voltage is in the

recommended range (342 – 484 V).

Machine stops working.

Err 43 is displayed.

The wire feeder motor is overloaded.

Check that you are using the right wire type and that the wire feed route is

unobstructed.

Poor welding result Several factors aect the welding quality.

• Check wire feed calibration.

• Check that the ear th return clamp is properly attached, the point of contact is

clean and that the cable and its connectors are intact.

• Check the voltage and wire speed settings on the control panel are correct for the

given wire size and type.

• Check that the shielding gas ow rate at the gun nozzle is correct.

• Check that the shielding gas is suitable for the ller wire used.

• Check that the wire feed is constant, and adjust if necessary.

• Check that the mains voltage is not too irregular.

Main switch indicator does

not switch on

The machine has no mains voltage

• Check the mains fuses

• Check the mains cable and the wall plug

* Contact Kemppi service in case of Err 2 and Err 3 without mains voltage cause.

6. MAINTENANCE

6.1 Regular maintenance

Check regularly the electrical connections of the machine. Clean any oxidised connections, and tighten the

loosened cable connections.

Let authorised Kemppi service workshop make periodic

service to your machine. Appropriate use and regular

service guarantee trouble-free use of the machine. This

allows you to avoid interruptions and increase the productivity of the machine.

NOTE! Remember that the machine may be repaired

only by an electrical contractor or installer authorised to

perform such operations.

6.2 Disposal of the machine

Do not dispose of electrical equipment with normal

waste!

In observance of European Directive 2002/96/EC on

waste electrical and electronic equipment, and its implementation in accordance with national law, electrical

equipment that has reached the end of its life must be

collected separately and taken to an appropriate environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional collection centre, per

the instructions of local authorities or a Kemppi representative. By applying this European Directive you will

improve the environment and human health.

Page 18

18

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

7. TECHNICAL DATA

X3 Power Source 400 / 400 AU 500

Mains connection voltage 3~, 50/60 Hz 380 – 440 V (–10 %…+10 %) 380 – 440 V (–10 %…+10 %)

Mains connection cable H07RN-F 4 G4 4 G4

Rated power at max. current 60 % ED 17.6 kVA 24.5 kVA

100 % ED 12.5 kVA 17 kVA

Supply current (maximum) I

1max

27 A 37 A

Supply current (eective) I

1e

19 A 29 A

Idle power Pi < 20 W < 20 W

Open circuit voltage U

av

52 – 57 V 57 – 62 V

No-load voltage, U

0

U

0

47 – 57 V 51 – 62 V

Fuse 25 A 35 A

Output 60 % ED 400 A / 34 V 500 A / 39.0 V

100 % ED 310 A / 29 V 390 A / 33.5 V

Welding current and voltage range 25 A/15 V – 400 A/38V 25 A/15 V – 500 A/43 V

Power factor at max current λ 0.88 0.90

Eciency at max current η 89 % 90 %

Operating temperature range –20...+40 °C –20...+40 °C

Storage temperature range –40...+60 °C –40...+60 °C

EMC class A A

Minimum short-circuit power SSC of supply network 4.7 MVA 5.2 MVA

Degree of protection IP23S IP23S

External dimensions L x W x H 629 x 230 x 414 mm 629 x 230 x 414 mm

Weight 32 kg 36 kg

Power supply for auxiliary devices U

aux

110 V/150 W 110 V/150 W

Standards IEC 60974-1

IEC 60974-10

IEC 60974-1

IEC 60974-10

The equipment complies with the requirements for the CE mark.

Page 19

19

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

X3 Wire Feeder 300

Operating voltage U

1

24 V

Gun connection Euro

Wire feed mechanism 4-roll

Filler wires Fe 0.6 – 1.6 mm

MC/FC 0.8 – 2.0 mm

Wire feed speed 0 – 25 m/min

Wire spool weight (max) 20 kg

Wire spool diameter (max) 300 mm

Operating temperature range –20...+40 °C

Storage temperature range –40...+60 °C

Degree of protection IP23S

External dimensions LxWxH 590 x 240 x 445 mm

Weight

Standards IEC 60974-5

IEC 60974-10

The equipment complies with the requirements for the CE mark.

Page 20

20

X3 MIG Welder© Kemppi Oy 2018 1814

OPERATING MANUAL

8. ORDERING CODES

X3 Power Source 400 X31004000

X3 Power Source 400 (AU) X31004000AU

X3 Power Source 500 X31005000

X3 Wire Feeder 300 X31003000

Welding guns

MMT 42 3.0 m 6254213MMT

MMT 42 4.5 m 6254214MMT

Interconnection cables

Interconnection cable 50-1.8-G 50 mm², 1.8 m, max. 300 A 6260508

Interconnection cable 70-1.8-GH 70 mm², 1.8 m 6260518

Interconnection cable 50-5-GH 50 mm², 5 m, max. 300 A 6260500

Interconnection cable 70-5-GH 70 mm², 5 m 6260501

Interconnection cable 50-10-GH 50 mm², 10 m, max. 300 A 6260513

Interconnection cable 70-10-GH 70 mm², 10 m 6260514

Interconnection cable 50-15-GH 50 mm², 15 m, max. 300 A 6260515

Interconnection cable 70-15-GH 70 mm², 15 m 6260516

Interconnection cable 70-20-GH 70 mm², 20 m 6260523

Interconnection cable 70-30-GH 70 mm², 30 m 6260633

Optional extensions

Extension cable 50-10-G 50 mm², 10 m, max. 300 A 6310510

Extension cable 50-15-G 50 mm², 15 m, max. 300 A 6310515

Extension cable 70-10-G 70 mm², 10 m 6310710

Extension cable 70-15-G 70 mm², 15 m 6310715

Earth return cables

Earth return cable, X3 MIG Welder 50 mm², 5 m, max. 300 A 6184511

Earth return cable, X3 MIG Welder 70 mm², 5 m 6184711

Accessories

X3 Wheel Set X37000001

X3 Four Wheel Set X37000002

X3 Wire Feeder mounting kit X37000003

P20 undercarriage 6185261

Fe 0.8 mm,

CO₂

N

mm

1 1.5 2 3 4 6 8 10

:

m/min

2.8 4.0 5.0 8.0 11.5 14.0 16.0 18.0

<

V

14.5 17 18 21 24 26.5 29 31.5

;

A

45 60 80 110 140 160 170 190

Fe 0.8 mm,

Ar + 15 –

25% CO₂

N

mm

1 1.5 2 3 4 6 8 10

:

m/min

2.8 4.0 5.0 8.0 11.5 14.0 16.0 18.0

<

V

14.5 16.5 17.5 20 22.5 25.3 28 30

;

A

50 70 90 120 150 160 180 200

Fe 1.0 mm,

CO₂

N

mm

1.2 1.5 2 3 4 6 8 10 12

:

m/min

2.2 3.0 4.3 6.0 7.3 9.7 12.0 15.0 18.0

<

V

16.5 18.0 19.5 22.2 24.0 27.3 31.0 35.0 38.0

;

A

60 85 120 150 170 200 230 260 285

Fe 1.0 mm,

Ar + 15 –

25% CO₂

N

mm

1.2 1.5 2 3 4 6 8 10 12

:

m/min

2.2 3.0 4.3 6.0 7.3 9.7 12.0 14.5 18.0

<

V

15.6 17.2 18.8 19.8 21.4 25.9 31.5 33.8 35.0

;

A

60 90 125 155 170 205 240 280 300

Fe 1.2 mm,

CO₂

N

mm

1 1.5 2 3 4 6 8 10 12 16 20

:

m/min

1 2 3 3 4.5 6 8.5 10 11 12.5 14

<

V

14.2 17 19 19.8 22 24 29.5 32 34 37 39

;

A

40 90 120 140 155 185 230 265 280 300 330

Fe 1.2 mm,

Ar + 15 –

25% CO₂

N

mm

1 1.5 2 3 4 6 8 10 12 16 20

:

m/min

1 2 3 3.6 4.5 6 8.5 10 11 12.5 14

<

V

13 15.7 17.5 18.8 20 21.5 27.5 31.5 32.8 35.5 37

;

A

50 95 125 145 165 200 245 285 300 330 345

Fe 1.6 mm,

CO₂

N

mm

1.2 1.5 2 3 4 6 8 10 12 16 20

:

m/min

1.0 1.3 1.8 2.8 3.0 3.5 5.0 5.5 6.0 7.0 13.0

<

V

16.0 17.5 19.6 21.5 22.5 24.5 30.0 31.5 33.0 36.0 40.0

;

A

75 95 130 185 195 215 275 295 315 350 500

Fe 1.6 mm,

Ar + 15 –

25% CO₂

N

mm

1.2 1.5 2 3 4 6 8 10 12 16 20

:

m/min

1.0 1.3 1.8 2.8 3.5 4.3 5.0 5.8 6.5 7.5 13.0

<

V

13.2 14.6 16.8 20.0 22.0 24.6 27.0 30.4 33.5 36.0 40.0

;

A

85 105 135 195 225 250 280 330 370 400 500

Page 21

And you know.

userdoc.kemppi.com

Declarations of Conformity – Overensstemmelseserklæringer –

Konformitätserklärungen – Declaraciones de conformidad –

Vaatimustenmukaisuusvakuutuksia – Déclarations de conformité –

Dichiarazioni di conformità – Verklaringen van overeenstemming –

Samsvarserklæringer – Deklaracje zgodności –

Declarações de conformidade – Заявления о соответствии –

Försäkran om överensstämmelse – 符合性声明

Loading...

Loading...