Page 1

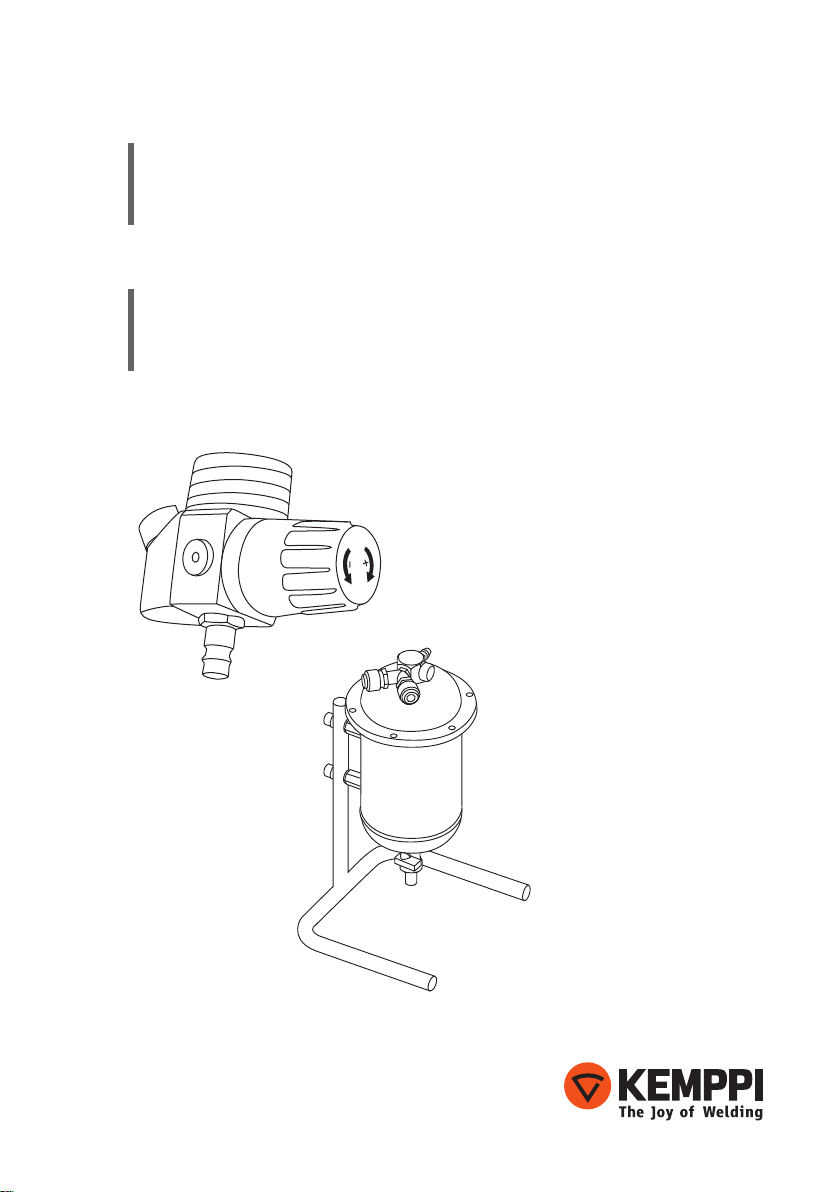

FreshAir

Pressure Flow Control

FreshAir

Pressure Conditioner

Operating manual

Brugsanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Bruksanvisning

Instrukcja obsługi

Manual de utilização

Инструкции по эксплуатации

Bruksanvisning

操作手册

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

RU

SV

ZH

Page 2

Page 3

OPERATING MANUAL

English

3© Kemppi Oy / 1309

Page 4

CONTENTS

1. Introduction ......................................................................... 5

1.1 General ...................................................................................... 5

1.2 About the product ................................................................... 5

1.3 Requirements for compressed air supplied from

the compressor ......................................................................... 6

1.4 Manufactured by ...................................................................... 6

2. Preconditions for Use ........................................................ 6

3. Unpacking and Assembly ............................................... 7

3.1 Unpacking FA Pressure Flow Control ...................................... 7

3.2 Assembly ................................................................................... 8

4. Usage ...................................................................................... 9

4.1 Inspection before every use .................................................... 9

4.2 Air ow test ............................................................................... 9

5. Maintenance and Cleaning...........................................11

6. Spare Parts ..........................................................................11

6.1 Assembling FA Pressure Conditioner ....................................11

6.2 Filter for FA Pressure Conditioner ..........................................12

7. Troubleshooting ...............................................................13

8. Storage .................................................................................13

9. Warranty ...............................................................................14

10. Technical Data ...................................................................14

11. Ordering codes ..................................................................15

4 FreshAir Pressure Flow Control / Conditioner

Page 5

1. INTRODUCTION

1.1 General

Congratulations on choosing the FreshAir (FA) respiratory protective system.

Used correctly, Kemppi products can signicantly increase the productivity

of your welding, and provide years of economical service.

This operating manual contains important information on the use,

maintenance and safety of your Kemppi product. The technical

specications of the equipment can be found at the end of the manual.

Please read the operating manual and other instructions carefully before

using the equipment for the rst time.

For more information on Kemppi products, contact Kemppi Oy, consult an

authorised Kemppi dealer, or visit the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to change without

prior notice.

Important notes

Items in the manual that require particular attention in order to minimise

damage and personal harm are indicated with the ’NOTE!’ notation. Read

these sections carefully and follow their instructions.

1.2 About the product

FreshAir (FA) is a respiratory protective system which is based on the

principle of circulated pressurized air in the hood. A supply of clean, ltered

breathing air creates positive pressure inside the headpiece, which prevents

the external contaminated air from entering the user’s breathing zone.

A suitable compressed air source complying to EN 12 021 standard and

supplying hygienically clean breathing air, can be connected to the FA

Pressure Flow control valve. If the air does not comply with this standard,

install the FA Pressure Conditioner ltration unit before the FreshAir Pressure

Flow Control valve unit.

FA Pressure Flow Control is equipped with a pressure gauge for checking

the input pressure. The air at the outlet of a FA Pressure Conditioner lter

unit complies with EN 12 021 standard, if it is used within the temperature

range 10 – 60 °C and the air from the compressor complies with the

requirements explained later in this manual. Up to two users can be

connected to the FA Pressure Conditioner ltration unit.

NOTE: FreshAir Pressure Conditioner does not remove carbon monoxide (CO)

and carbon dioxide (CO₂).

EN

Disclaimer

While every eort has been made to ensure that the information contained

in this guide is accurate and complete, no liability can be accepted for any

5© Kemppi Oy / 1309

Page 6

EN

errors or omissions. Kemppi reserves the right to change the specication of

the product described at any time without prior notice. Do not copy, record,

reproduce or transmit the contents of this guide without prior written

permission from Kemppi.

1.3 Requirements for compressed air supplied from

the compressor

• FA Pressure Conditioner can only be connected to a compressor which

supplies air at an oxygen concentration of 20 – 22 % vol.

• The carbon dioxide concentration must not exceed 500 ppm and the

carbon monoxide concentration must not exceed 15 ppm.

• The maximum concentration of water in the air may be 50 mg/m at

the rated pressure of 1 – 20 MPa. The humidity of the supplied air must

be controlled to prevent the unit from freezing.

1.4 Manufactured by

Manufactured for and on behalf of Kemppi Oy by:

CleanAir Ltd.

2. PRECONDITIONS FOR USE

Before you can use the system correctly and safely, you must fully

understand all of the following precautions.

• It is forbidden to use the unit in explosive environments.

• The system may only be used in environments where the probability

of damaging the supply hose is small and the user’s movement is not

limited.

• If the unit is used in environments with high temperatures, the supply

hose must be resistant to such eects.

• During an extreme work load, the pressure in the hood may reach

negative values and the user may feel air deciency. In such case the

protection of air passages is reduced.

• In the FreshAir system it is forbidden to use oxygen-enriched air or

oxygen. There is a risk of explosion.

• If another accessory apart from FreshAir (e.g. a spray gun) is connected

to the compressed air supply, the user must make sure that a sucient

air ow to the hood is secured even at the maximum air consumption

by this accessory.

• Before every use of the unit, check that the air ow is higher than the

minimum value specied in the technical parameters.

• If the unit stops supplying air for any reason, the user must leave the

contaminated area immediately.

• The unit, in a combination with a welding helmet or a hard hat, is

6 FreshAir Pressure Flow Control / Conditioner

Page 7

not recommended for users with beard or long hair extending to the

respiratory zone.

• Beware of a higher CO concentration in the air supply, which may

occur if the compressor does not work properly when lubricating oil

burns due to high temperatures.

• The supply air pressure must be within the range 300 – 1000 kPa.

• The supply pressure hoses may only be located in such places of the

workplace where they cannot be damaged.

• The maximum working pressure of the hose supplied to the

conditioner is 1000 kPa.

• Before connecting the unit to the air distribution, it is necessary to

check what medium is in the line and what is its quality. For the FA

Pressure units, it is necessary to provide breathable air according to

EN 12 021 standard.

• The FA Pressure unit can be combined with Beta 90 FreshAir or Delta

90 FreshAir head tops.

• Information on head parts are provided in the instructions for use of

the FreshAir head parts.

FA Pressure Conditioner

• Pressure hose for FA Pressure Conditioner is not antistatic and the

maximum temperature to which they are resistant without damage is

70 °C.

• The maximum length of the hose from the compressed air distribution

or FA Pressure Conditioner to the head unit must not exceed 10 m.

• The recommended temperature range of use ideally is 10 – 40 °C. At

lower temperatures, the use of the protective hood with air supply

may be unpleasant. The lowest allowable temperature for use of FA

Pressure is 10 °C.

NOTE! If the recommendations stated in this manual are ignored, the warranty

is automatically invalidated and the level of personal protection may not meet

the designated standards.

EN

3. UNPACKING AND ASSEMBLY

3.1 Unpacking FA Pressure Flow Control

Check that the delivery is complete and no damage occurred during

transport.

7© Kemppi Oy / 1309

Page 8

EN

Content of the FA Pressure Flow Control assembly

FreshAir Pressure unit 1 pc

Belt for the unit 1 pc

Air hose 1 pc

Air ow indicator 1 pc

Operating manual 1 pc

We recommend using the FA Pressure Conditioner together with the FA

Pressure Flow Control in order to guarantee the supplied breathing air

quality. The supplied compressed air in the breathing air distribution system

must meet EN 12 021 standard.

Content of the FA Pressure Conditioner assembly

FA Pressure Conditioner unit 1 pc

Unit stand 1 pc

Screws for connecting the unit to the stand 2 pcs

Washer 4 pcs

Operating manual 1 pc

3.2 Assembly

FA Pressure Flow Control + FA Pressure Conditioner

1. Check that all components are in good condition with no visible

damage.

2. Connect FA Pressure Conditioner to a suitable breathing air

distribution system. The air source must be equipped with safety

valve. If the FA Pressure Conditioner is not used, the air supply must

comply with EN 12 021 standard.

3. Attach the enclosed hose connector and screw it in.

4. It is recommended to use only original hoses supplied by the

manufacturer and certied according to the applicable standard.

5. Check that the air pressure in the distribution system corresponds to

the range 300 – 1000 kPa.

6. Attach the unit onto your belt and t the connecting hose to it.

7. Using the quick coupling, connect the pressure hose from the

compressed air source to the FA Pressure unit. The hose from FA

Pressure Conditioner to FA Pressure Flow Control must not be longer

than 10 metres.

8. Check the air ow as explained in section 4.2: "Air ow test". The lowest

allowable ow rate is 170 l/min.

8 FreshAir Pressure Flow Control / Conditioner

Page 9

4. USAGE

4.1 Inspection before every use

Do the following checks always before you start using the equipment:

• Visually check individual parts, particularly the air hose and sealing

elements for damages.

• Check that the hose is tted correctly to the air unit and to the head

part connector.

• The air pressure in the distribution system must be in the range

300 – 1000 kPa.

• Check that the air ow in the hose is sucient.

• Ensure that air is supplied into the head part breathing zone.

4.2 Air ow test

When measuring the air ow, follow the instructions delivered with the ow

indicator. If the ow rate is dierent, proceed as follows.

EN

1. Pull plastic screw cap out to the adjustment position and turn counterclockwise by hand until it stops.

2. Lever the cap o from the regulation valve with a at screwdriver.

9© Kemppi Oy / 1309

Page 10

EN

3. Let the noise silencer stay in place and connect the ow meter to the

regulation valve. Turn on the air supply and adjust the ow rate to

170 l/min using a at screwdriver.

4. Air ow is sucient, if the top of the cone is placed in the green area. Read

the ow meter manual.

5. Close the air supply. Remember that there is still some pressure in the

conditioner for a few seconds after the air supply is closed.

6. Firmly replace the plastic cap to the regulation valve body with a rm

pressing action.

WARNING: This test is an indication of mechanical lter state. However, the

absorption capacity of the activated carbon lter in the FA Pressure Conditioner

may already be exhausted, even at a sucient ow rate. The lter should be

replaced when you smell a noticeable odour, but at least every 3 months.

10 FreshAir Pressure Flow Control / Conditioner

Page 11

5. MAINTENANCE AND CLEANING

FA Pressure Flow Control unit

Every time you nish work, it is recommended to clean the FA Pressure Flow

Control unit, to check individual parts and to replace the damaged ones.

• Cleaning must be carried out in a well ventilated room. Avoid

inhaling the harmful dust settled on individual parts of the unit and

accessories.

• It is forbidden to use cleaning agents containing solvents or abrasives.

Mild soap detergent and warm water is recommended.

• The air hose can be rinsed with clean water.

• Use a damp cloth for cleaning. Each part must be wiped dry after

cleaning.

FA Pressure Conditioner

• Once a week, drain the condensate from the bottom of the unit, using

the drain cock located at the base of the unit. Before completing

this operation, it is recommended to disconnect the unit from the

compressed air supply.

• Replace the lter at least once every three months. After this period,

viruses and bacteria may proliferate in the units lter and if it is used

regularly, the absorption capacity of the activated carbon to eliminate

odour may be exhausted. If the air leaving FA Pressure Conditioner

smells in any way, replace the lter immediately. When replacing the

lter, clean the inner part of the container with a dry cloth.

EN

6. SPARE PARTS

6.1 Assembling FA Pressure Conditioner

Screw the pressure conditioner body onto the stand.

11© Kemppi Oy / 1309

Page 12

6.2 Filter for FA Pressure Conditioner

The FA Pressure Conditioner contains a combined lter which removes oil

mist, smells and avours from industrially produced compressed air.

NOTE: The lter does not remove CO and CO₂.

Read the instructions for use and replacement.

Replacing FA Pressure Conditioner lters:

EN

1.

2.

x 6

3.

1. Unscrew the top part of the lter pressure container (6 screws).

2. Remove the contaminated lter, wipe the inside of the container.

3. Check the condition of the rubber seal in the top cover. If the seal is

damaged, replace it.

4. Install a new lter on the container cover and screw it back.

5. Check the container for leakage. If the container is not absolutely tight,

tighten all screws that fasten the top cover.

4.

12 FreshAir Pressure Flow Control / Conditioner

Page 13

7. TROUBLESHOOTING

Fault Probable cause Recommendation

The unit does not work

at all.

The unit does not supply

the sucient amount of air.

During the use, if there is a sudden decrease or increase in air supply and the

user is located in a contaminated area, it is necessary to leave the workplace

immediately and check the following:

• The unit is assembled correctly.

• The lter condition in FA Pressure Conditioner is in good condition.

• The air hose is not damaged during the use.

• The noise damper in FA Pressure FC is not clogged.

• The seal on the safety hood is in good condition.

Compressed air supply failure. Check the compressed air source.

Hose damage. Check that connecting hoses are

Air hose or air channel blocked. Check and remove the possible

Air escapes through leakages. Check all sealing elements and

The bae is clogged. Replace the bae in FA Pressure

The lter in FA Pressure

Conditioner is clogged.

not damaged.

obstacle.

connections, check that the hose

is not damaged and without

leaks.

Flow Control.

Replace the lter.

EN

8. STORAGE

All parts of a FreshAir system must be stored in an environment with

temperature between 0 – 40 °C and humidity between 20 – 80 % Rh. The

storage life is 2 years for the product if stored in its original unopened

package. Temporary transportation to and from site is permitted, providing

the units are stored in a dry container.

NOTE! Batteries get discharged even if not in use. Therefore for long-term

storage it is highly recommended to charge the NiMH batteries every

12 months.

13© Kemppi Oy / 1309

Page 14

EN

9. WARRANTY

There is a 12 month warranty covering production defects and a 6 month

warranty for batteries.

The warranty begins from the date of purchase. The claim must be lodged

with the dealer. The paid invoice or receipt must be produced if claiming on

the warranty.

Warranty is void if there is evidence of mechanical intervention or abuse of

the unit(s). Warranty does not cover, in particular, defects caused by a late

replacement of the lter or by using a lter damaged by attempted cleaning

with compressed air.

10. TECHNICAL DATA

FreshAir Pressure Flow Control

Minimum air ow 170 l/min-1

Maximum air ow > 400 l/min-1

Weight of unit 250 g

Inlet connection

Outlet connection MINI DN 5

Noise level of unit 61 dB

Belt size 60 – 150 cm

Supply pressure range 300 – 1000 kPa

Recommended temperature range at work 10 – 60 °C

Recommended air humidity range at

workplace

Certication Class 2A

20 – 80 % Rh

FreshAir Pressure Conditioner

Maximum air ow 500 l/min

Weight without lter 6300 g

Weight including lter 6800 g

Inlet connection Compatible with RECTUS series 25,26 a CEYN320

Outlet connection Compatible with RECTUS series 25,26 a CEYN320

Recommended temperature range at work 10 – 60 °C

Recommended air humidity range at

workplace

14 FreshAir Pressure Flow Control / Conditioner

20 – 80 % Rh

Page 15

Certication If the requirements of TP-610050-1 are met, it

Notied body for CE testing:

Výzkumný ústav bezpečnosti práce, v.v.i. – ZL

Testing Laboratory No. 1024

Jeruzalémská 9, 116 52 Praha 1

Authorized Body 235

Notied Body 1024

11. ORDERING CODES

Packages

FA PRESSURE FLOW PACK

FA PRESSURE FLOW SPIRAL HOSE

FA PRESSURE CONDITIONER UNIT

complies with EN 12 021

includes:

FA Pressure ow control set (W007496)

and

FA Pressure ow hose (W007501)

10 m W007506

W007515

W007504

EN

FreshAir Pressure Flow Control set

valve and belt W007496

Spare parts and consumables

FreshAir Pressure Noise silencer W007498

FreshAir Pressure Control valve cap W007499

FreshAir Pressure Air tting W007500

FreshAir Pressure Flow hose exible connection W007501

FreshAir Pressure Flow Control belt W007502

FreshAir Pressure Flow indicator RD40x1/7“ W007503

FreshAir Pressure Conditioner unit W007504

FreshAir Pressure Conditioner lter W007505

FreshAir Pressure Flow Spiral hose 10 m W007506

15© Kemppi Oy / 1309

Page 16

KEMPPI OY

Kempinkatu 1

PL 13

FI-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

UNITED KINGDOM

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GmbH

Perchstetten 10

D-35428 Langgöns

DEUTSCHLAND

Tel +49 6 403 7792 0

Telefax +49 6 403 779 79 74

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD.

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY,

LIMITED

Room 420, 3 Zone, Building B,

No.12 Hongda North Street,

Beijing Economic Development Zone,

100176 Beijing

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区宏达

北路12号

创新大厦B座三区420室 (100176)

电话: +86-10-6787 6064

+86-10-6787 1282

传真: +86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

Kazura Garden,

Neelankarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

www.kemppi.com

1918830

1309

Loading...

Loading...