Page 1

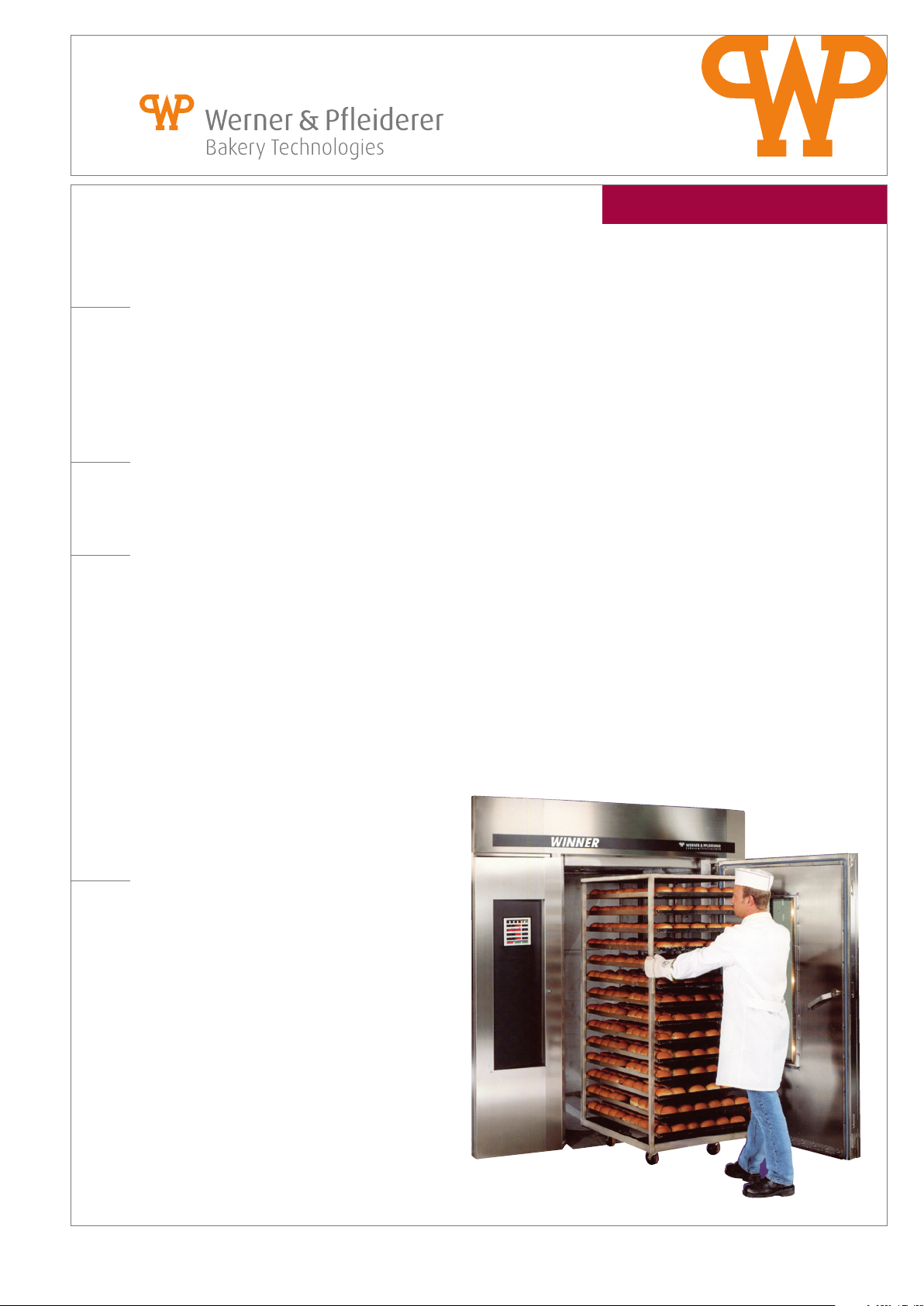

Baking Cabinet WINNER

High performance – low cost

Application

The WINNER baking cabinet with rotating trolley is suitable for baking

– Dark bread

– Traditional loaves

– All types of rolls

– Soft rolls

– Cakes

– Biscuits

– Croissants etc.

Specification

In standard design

– with ETS 10 control system

– with safety package (per CE standard)

– automatic rotary plate shut-off

Advantages

Large-scale, S-shaped heat exchanger

– No overheating

– Low number of welding points, long service life

No fixed lock

– Suitable for all trolley types – no special holders required on baking trolley

Exhaust duct installed in air circulation system

– Optimum energy efficiency

Large turning circle diameter of 1,250 mm

– All types of trolley up to 1,250 mm diagonal diameter can be used

Modular design

– Pre-fabricated assemblies for commissioning within 24 hours

Three-sided positioning possibilities

– Best possible use of space

Low constructional height

– Required minimum room height only 2.5 m

Large vapor extraction hood (option)

– Collection of hot baking chamber air

All maintenance and service parts are standard products

– Available everywhere worldwide

WP BAKERYGROUP

WINNER 1/2

Baking Cabinet 25.03.2008

Options

– Large vapor extraction hood

– Push-through version with a 2nd door on the rear side

Page 2

WP BAKERYGROUP

WINNER 2/2

Baking Cabinet 25.03.2008

Baking Cabinet WINNER

Technical Details

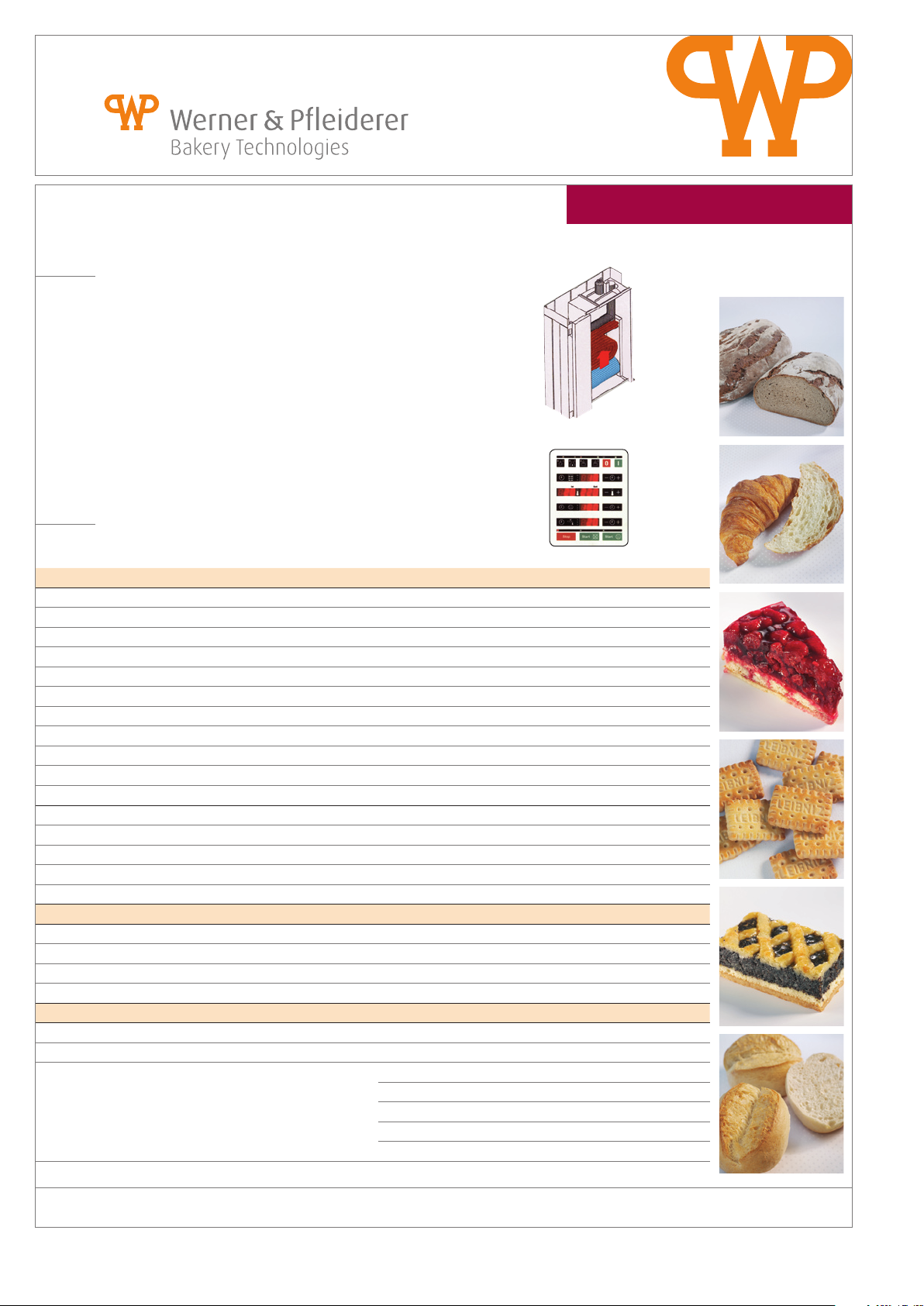

The WINNER heat exchanger sets new standards

The new, patented heat exchanger operates by superior heating concept , i.e.

with a top-mounted circulating fan. The design has a lot fewer welding points

and its S-shape provides the pipes with more room for expansion without placing

too much strain on the material. This means that there is virtually no danger of

welding seams rupturing. The exhaust duct is also installed in the air circulation

system. This enables the oven to achieve optimum energy efficiency with

calculable savings.

ETS 10 control system

The straightforward, logically designed control panel is easy to understand even

for newly trained personnel. The hard-wearing foil keyboard is easy to clean.

Technical Data

Dimensions

Width in mm 2,100

Depth with 1 door in mm 1,700

Depth with additional doors at rear in mm 1,852

Height without extractor in mm 2,456

Height with extractor hood in mm 2,770

Required room height without hood in mm 2,600

Required room height with hood in mm 2,850

Clear baking chamber door height in mm 1,850

Clear baking chamber door width in mm 1,090

Oven weight in kg 1,600 incl. hood

Baking trolley for WINNER with 1 door

Max. baking trolley height in mm 1,810

Baking trolley size Nearly all standard baking trolley sizes possible

Rotating circle in mm 1,250

Max. rotary plate load in kg 350

Baking trolley for WINNER with additional doors at rear Only baking trolley with Rototherm centering

Baking trays

For WINNER with 1 door

Max. baking tray size in mm 800 × 1,000 (31 × 39”)

For WINNER with additional doors at rear

Max. baking tray size in mm 600 × 1,000 or 2 × 530 x 650

Connected loads

Current supply for electrical heating in kw 60

Current supply for fans and control system in kVA 2.5

Possible operating voltages 200 V – 50 / 60 Hz

230 V – 50 / 60 Hz

400 V – 50 Hz

440 V – 50 / 60 Hz

(Other voltage ratings available on request) 415 V – 50 Hz

Heating output (oil/gas)in kw 95

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Werner & Pfleiderer Lebensmitteltechnik GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany

Fon +49 (0) 98 51-905-0 . Fax +49 (0) 98 51-905-342 . info@wp-l.de . www.wp-l.de

Loading...

Loading...