Page 1

VACUSPEED

®

High performance vacuum cooling

Vacuum cell for very fast cooling of baked goods

Features

VACUSPEED® functions according to the principles of vacuum enthalpy cooling

Part-baked, hot goods are cooled by vacuum from the inside outwards to about

+4 °C. No freezing takes place.

VACUSPEED® means shock freezing is unnecessary for short and medium term storage.

The VACUSPEED® cell is suitable for cooling baked goods

– Rolls

– Bread, including rye bread

– Small pastries/fine pastries

– Cakes

Equipment

In standard production model

– Touchscreen control

(with remote diagnosis via Internet and USB connection)

– Solid stainless steel casing with ramp

– Differential pressure manometer

– Adjustable pump performance

– Rehydration

WP BAKERYGROUP

VACUSPEED 1/ 2

High quality vacuum cooling 29.04.2009

Advantages

Huge energy savings in various areas

– No more deep freezing logistics costs (freezer rooms,

cold stores, cold chain)

– Less energy is needed for final baking of goods at + 4 C than

for frozen goods

– Comparable performance shock frosters use up to 6 x more

energy than VACUSPEED

Large advantage in price

– With the same performance, VACUSPEED is about 80% more

cost-effective than a shock freezer

Time saved thanks to special technology

– Only takes about 30% of the time needed for cooling with a

shock freezer

Requires less space

– A comparable performance shock freezer requires 3 x as much

space as VACUSPEED

Bacteria-free cooling

– The cooled baked goods have a low bacterial count due to

re-aeration with sterile air or protective gas

Differential pressure measurement for reproducable,

product-protecting cooling

Improved shelf life of baked goods

– No microbial contamination of baked goods due to rapid cooling

Problem-free storage at refrigerator temperatures for up to 2 weeks

High quality of baked goods after final baking

Minimum loss of moisture

Proven, durable technology

High performance vacuum cooling

– Will hold up to 2 trolleys with a load of up to 700 dough pieces per trolley

VACUSPEED® can be integrated in fully automatic production lines

– Industrial use of the versatile and flexible vacuum enthalpy technology

– Products can be cooled quickly and hygienically

®

®

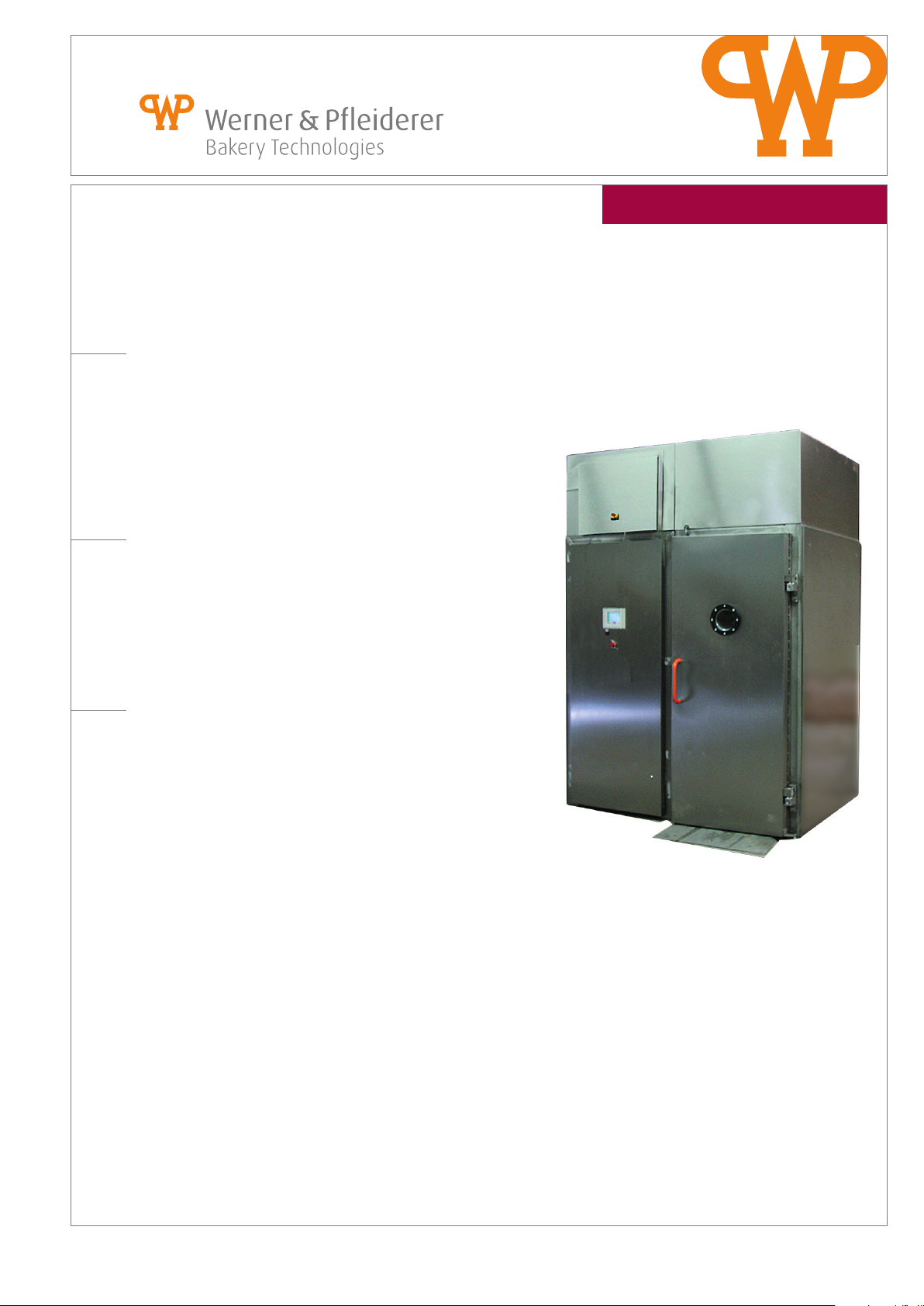

Picture: VACUSPEED

Page 2

WP BAKERYGROUP

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Werner & Pfl eiderer Lebensmitteltechnik GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany

Fon +49 (0) 98 51-905-0 . Fax +49 (0) 98 51-905-342 . info@wp-l.de . www.wp-l.de

VACUSPEED 2/ 2

VACUSPEED

®

Sliced bread can be cooled to slicing firmness without the danger of recontamination

Tested quality

The Bremerhavener Institut für Lebensmitteltechnologie und Bioverfahrenstechnik (BILB)

confirms the following advantages for the VACUSPEED® cell

– No phase separation within the rolls due to ice formation

– Good crust structure with long-lasting crispness

– No breaking off for crusty goods

– Smooth product surface, uniform colour appropriate

to type of bake goods

– Attractive exterior after final baking

– Marked storage stability over a long period

– Product expansion depending on product/recipe

Options

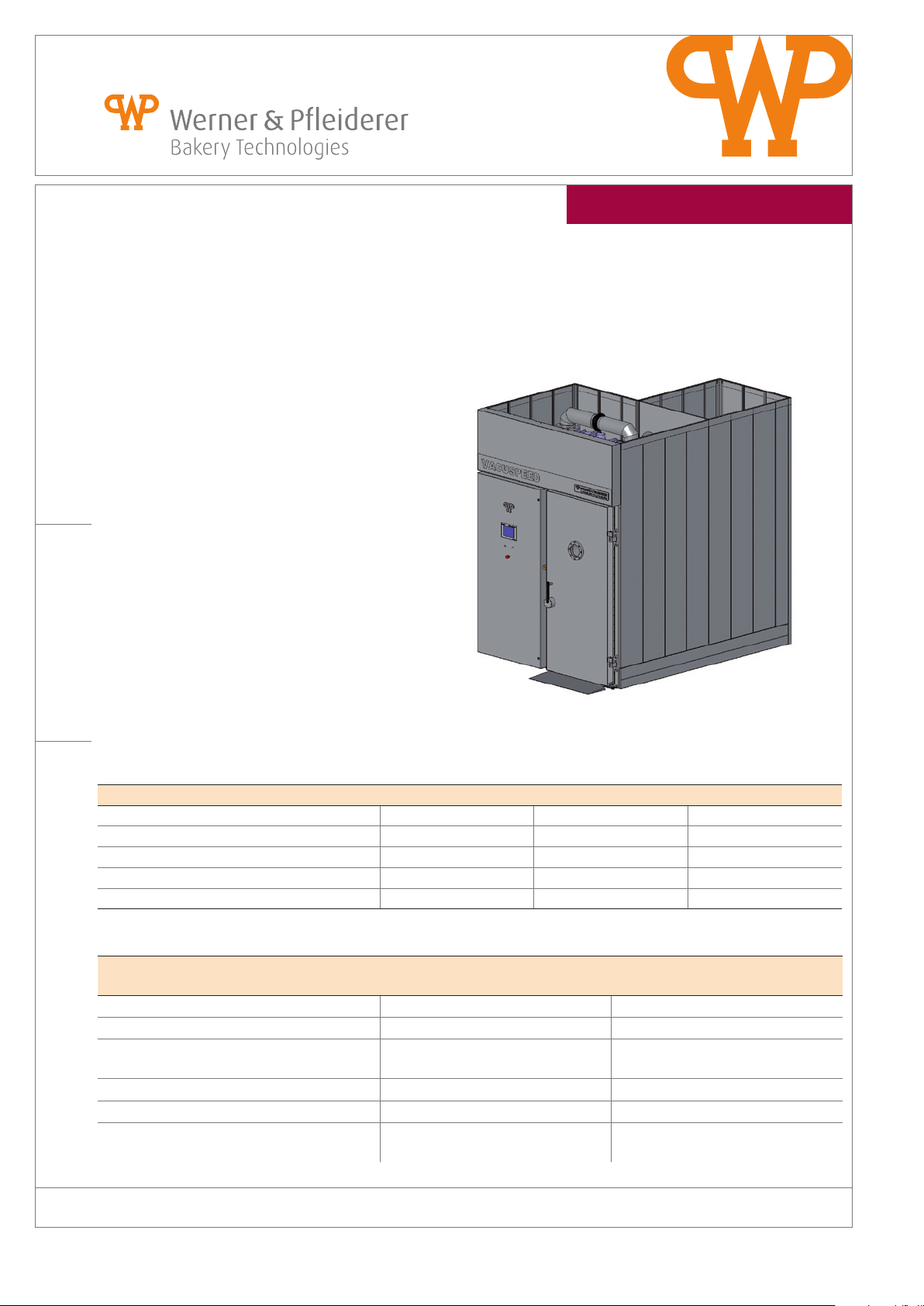

– Two chamber lengths for 1 - 2 trolleys

– Water cooling equipment for steam condensation

High quality vacuum cooling 29.04.2009

Picture: VACUSPEED with long chamber

Technical specifications

Non-dimensional comparison of vacuum cooling (VACUSPEED) with conventional cooling (storage and shock freezers)

with the same production capacity

Storage freezer Shock freezer VACUSPEED (TYPE 1140)

Trolleys 1 1 1

Energy requirements 6.4 7.3 1

Space required 6.5 8.8 1

System costs 2 1.6 1.0

Productive capacity 1 1.0 1.0

VACUSPEED TYPE 1140* TYPE 2500*

1 trolley (Euroblech 980 x 580 mm or 780 x

580 mm)

Exterior dimensions W x D x H approx. 2,130 x 1, 610 x 2,975 approx. 2,130 x 2, 960 x 2,975

Door opening (clearance) mm 800 x 1,950 800 x 1,950

Size of opening for entry into

building (entry dismantled, in parts) W x H mm 1,210 x 1,800 1,210 x 2,400

Total weight kg approx. 3,500 approx. 5,000

Connected load kW 19 19

Water cooling equipment (optional)

Connected load

W x D x H mm

kW

900 x 1,900 x 2,000

16

2 trolleys (Euroblech 980 x 580 mm) or

3 trolleys (Euroblech 780 x 580 mm)

900 x 1,900 x 2,000

16

*Name of type refers to usable chamber depth in mm

Loading...

Loading...