Page 1

V 700 1/2

Dough Divider 26.08.2010

Dough Divider V 700

Dough Divider

Specification

Universal dough divider, suitable for all common dough types such as wheat, wheat/rye, multi grain, whole wheat dough’s, as well for

sti pizza dough’s as for soft (French) dough’s.

Advantages

- High weight accuracy

- Dough friendly dividing with hydraulic adjustable pressure compensator

Basic execution V 700 :

- V 700 : 2, 3, 4, 4split, 5, 6, 6split, 8, 2/4, 3/6 pocket machine

WP BAKERYGROUP

- Accurate dividing of soft dough’s with long bulk fermentation

- Robust design

- Large weight range

- Frame out of rectangular, nickel coated tubular proles for easy access

- Open front design for visual control on discharge conveyor side

- Synthetic conveyor belt with quick-lock system

- Easily removable stainless steel dough hopper

- Self cleaning knife

- Trolley for easy cleaning

- Removable inner conveyor

- Control by full colour touch screen

- Wear resistant dividing system with dividing unit in ni-resist

- Solid construction of drive system and dividing mechanism

- High pressure oiling system, for minimum use of oil

- Automatic version with possibility for weight correction by means

of a check weigher

- Dividing unit ni-resist with reduced automatic oiling with 10 metering valves

- Oiling on conveyor

- Voluminator Compact U

- Discharge conveyor 500 mm., with quick-lock system, scraper and catch tray

- Separate drive on in- and outside conveyor with drum motors

- Pneumatic discharge ap with plastic scraper

- Hopper stainless steel, teonized 70 liters, H=1754 mm.

- Hopper base teonized

- Frequency inverter for variable speed

- Operation by means of touch screen (colour):

- stop position - servo weight adjustment - pre-set counter

- Discharge ap and positioning roller controlled from touch screen

- Main piston plastic/aluminium

- Automatic switch of in case of no oil

- Measuring pistons bronze

- Knife hardened steel

- Cover plates stainless steel, brushed, with Schmersal safety switches

- Frame steel, nickel coated

- Crankshaft and drive rods cast iron, nickel coated

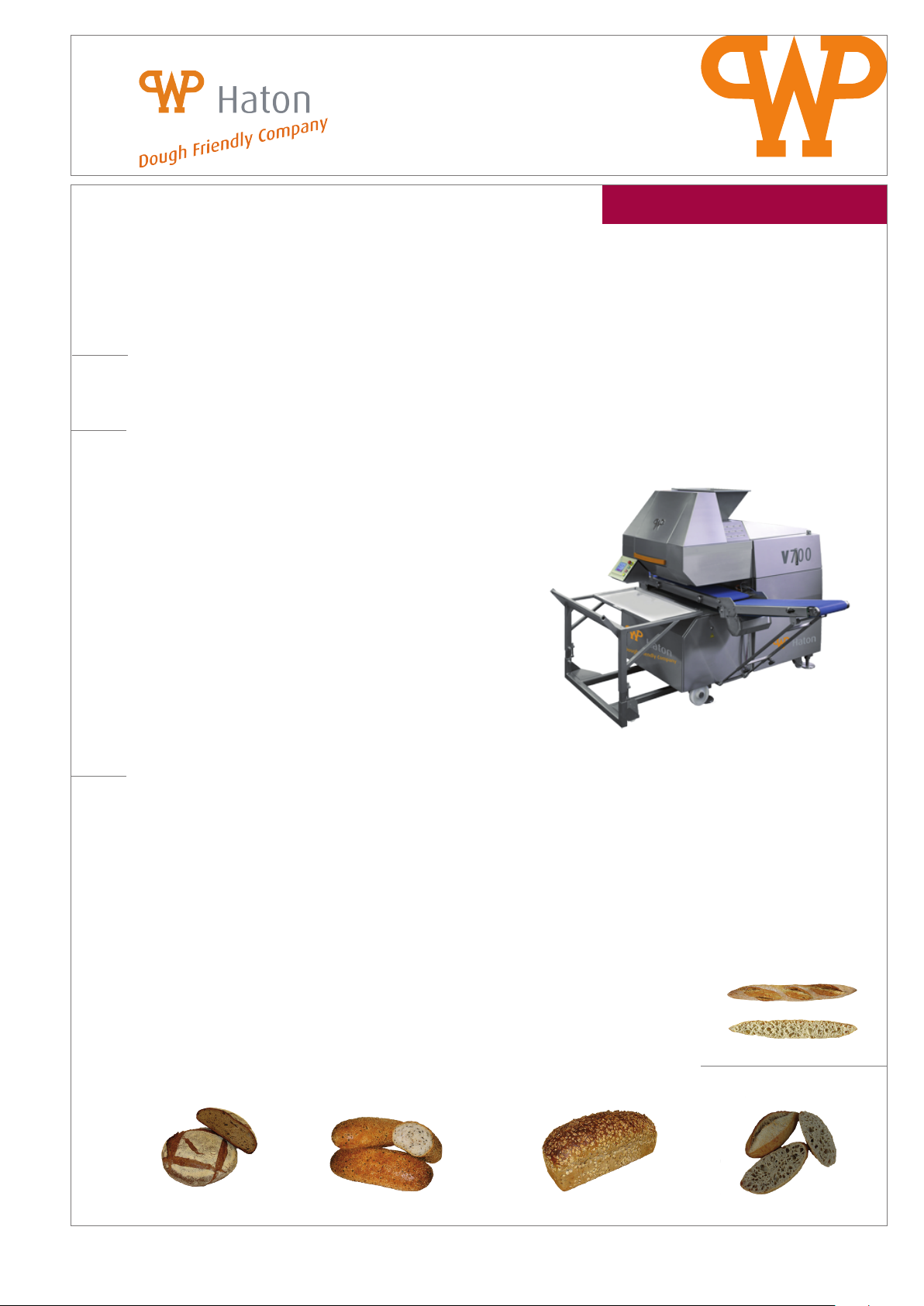

Illust ration: V 7 00

Page 2

WP BAKERYGROUP

V 700 2/2

Dough Divider 26.08.2010

V 700

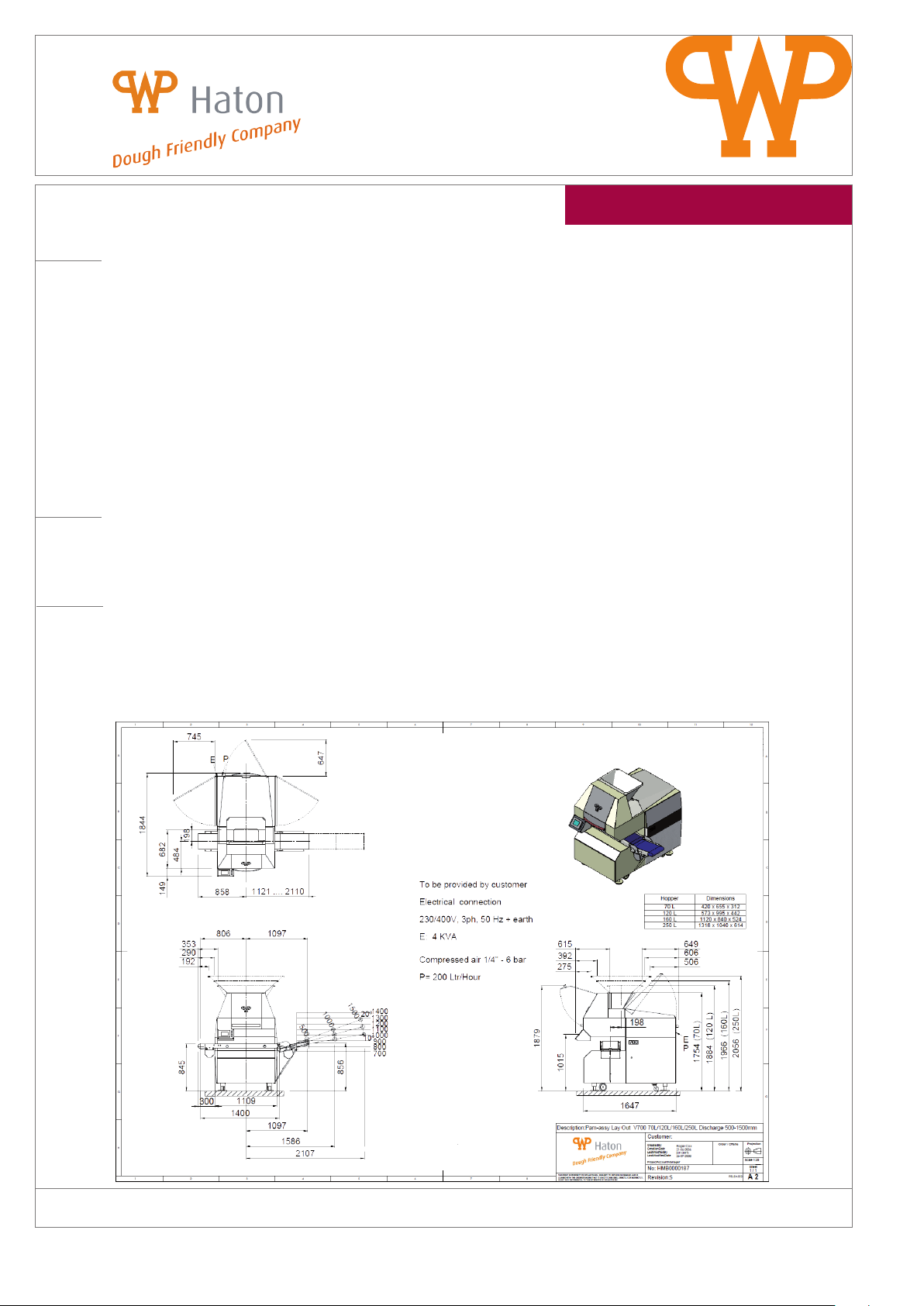

Technical details

Type Partitions Weight range Capacity

- Type V 700-2 10 /25 mm. 400 - 2550* / 400 - 2400 gr. 1000 - 3000 pcs/h.

- Type V 700-3 10 / 25 mm. 300 - 1650* / 300 - 1400 gr. 1500 - 4500 pcs/h.

- Type V 700-4 10 / 25 mm. 200 - 1200* / 200 - 1000 gr. 2000 - 6000 pcs/h.

- Type V 700-4split 2x L / 2x R 150 - 925 gr. 2500 - 6000 pcs/h.

- Type V 700-5 10 / 25 mm. 150 - 950* / 150 - 800 gr. 2500 - 7500 pcs/h.

- Type V 700-6 10 / 25 mm. 150 - 750* / 150 - 600 gr. 3000 - 9000 pcs/h.

- Type V 700-6split 3x L / 3x R 150 - 600 gr. 3000 - 9000 pcs/h.

- Type V 700-8 10 mm. 25 - 275* gr. 4000 - 9600 pcs/h.

- Type V 700-2/4 10 mm. 400 - 2550* / 200 - 1200*gr. 1000 - 3000 / 2000 - 6000 pcs/h.

- Type V 700-2/4 25 mm. 400 - 2400 / 200 - 1000 gr. 1000 - 3000 / 2000 - 6000 pcs/h.

- Type V 700-3/6 10 mm. 300 - 1650* / 150 - 750* gr. 1500 - 4500 / 3000 - 9000 pcs/h.

- Type V 700-3/6 25 mm. 300 - 1400 / 150 - 600 gr. 1500 - 4500 / 3000 - 9000 pcs/h.

* Not possible in case of sti cky or soft dough’s

Dimensions (depending on execution) Weight Connecting load

- Length 2961 mm. max. - Net 1550 kg. - 230/400 V, 3 Ph, 50 Hz + earth

- Width 1647 mm. max. - Gross kg. - 3 KVA

- Height 2056 mm. max.

Options V 700

- Hopper, teonized, 120, 160, 250 liters - Belts, felt

- Hopper with HDPE covering - Plastic cover for touch screen

- Oiling on hopper - Oil catch pan under machine, movable

- Discharge conveyor 500 mm. per 100 mm., - Connection for checkweigher

up to 1500 mm. i.o.v. 1600 mm. - Curling net on discharge conveyor

- Flour duster with independent drive - Increasing the machine with 100 mm.

Werner & Pfleiderer Haton B.V. Industrieterrein 13, 5981 NK Panningen, The Netherlands.

Phone +31(0)77 -307-1860 . Fax +31(0)77-307-5148. info@ wp-haton.com . ww w.wp-haton.com

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...