Page 1

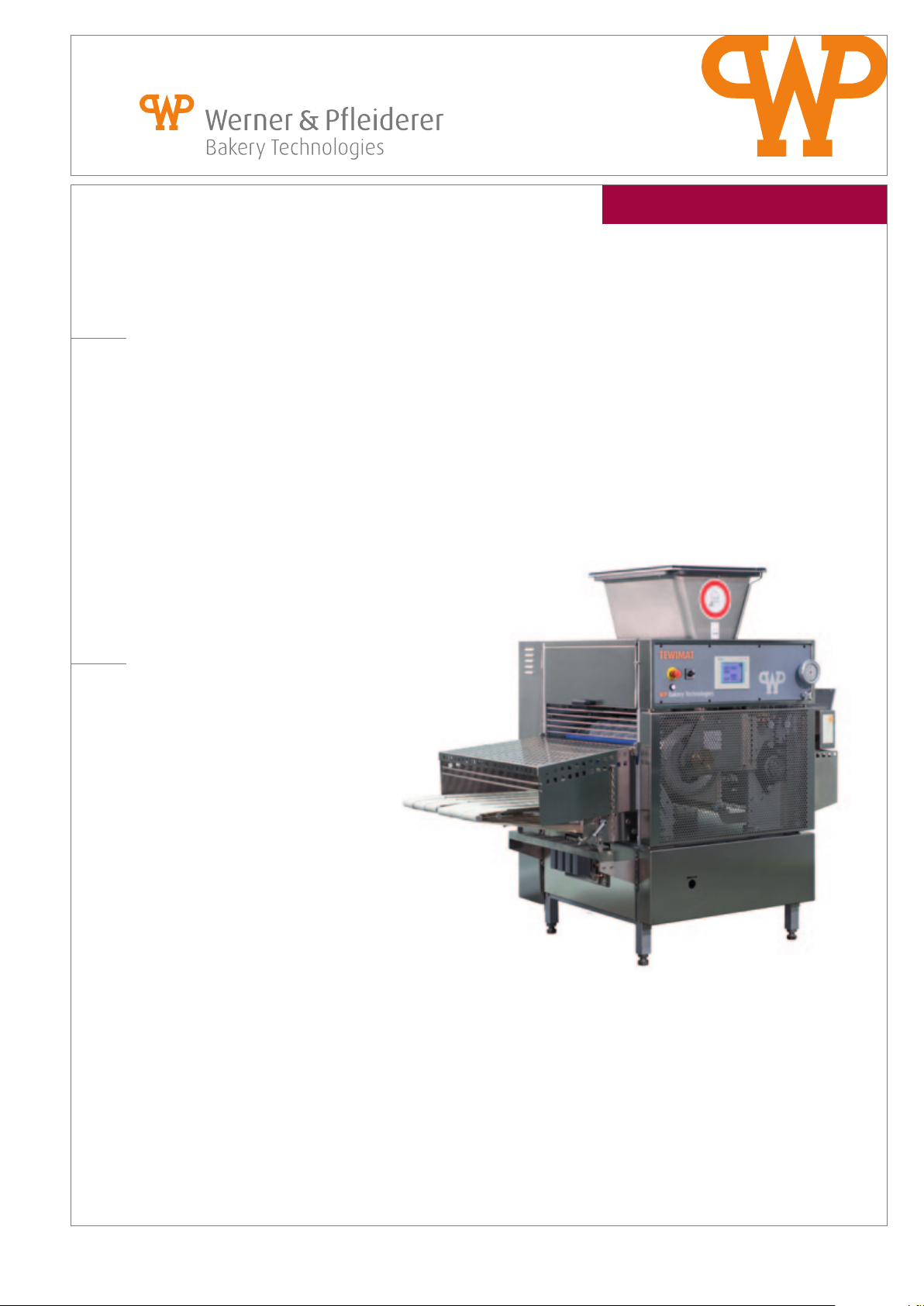

Dough Dividing and

Roundmoulding Machine

TEWIMAT

High capacity Dough Dividing and Roundmoulding Machine

for the production of round dough pieces using

– Wheat dough

– Mixed rye dough

– Doughnut dough

– Fruited dough

– Graham dough

Absorption rate 48 - 60% (using middle European flour)

Weight range 28 – 300 g/Pce (Weight depending on rows)

Rows 3 – 6 (TEWIMAT L) 3 – 10 (TEWIMAT S)

WP BAKERYGROUP

TEWIMAT Dough Dividing and 1/2

Roundmoulding Machine 11.09.2012

Advantages

Cleantec spreader belts (Option)

– Hygiene safety

Divided cleaning brush

– For easy cleaning

Removable belt driving roller (Option)

– For easy cleaning

Suction dividing technology

– No charging roller and dividing knife

– Sensitive dough structure remains intact

innovative double piston system (Option)

Large production range

– also processing special doughs

oil free dividing process

high dividing accuracy

– up to 100 g +/- 1,5 – 2 g deviation*

– from 100 g +/- 1,5 – 2 % deviation*

* depending on dough consistency

– large dividing range from 28 to 300 g/Pce

high flexibility

– flexible No. of rows, as the measuring pistons are easily

interchangeable and lockable

– flexible weight setting by limiting the measuring piston stroke

– flexible weight range with double measuring pistons

– flexible capacity setting, adjustable through controls

Programming capacity, moulding intensity and weight

Drum moulding principle

– different chamber drums for an optimum moulding result

hydraulically adjustable dividing system

De-gassing device

– allows proofing gases to escape during the filling stroke

– high dividing accuracy, even at low filling pressure

all dough guiding parts can be removed extensively without tools

Stainless steel panels

Machine is easy to clean

Comparative to illustration

Page 2

TEWIMAT

Equipment

– Dough hopper capacity 80 kg (TEWIMAT L), 120 kg (TEWIMAT S)

– Touch Control S 7

– Measuring unit

– Chamber and Moulding Drum

– Spreading belt 900 mm

– Flour duster

– Guided moulding belt

– Automatic pneumatic moulding belt tensioner

– Simple mechanical construction

Options

– Measuring unit with different piston diameters

– Chamber and Moulding Drums in different sizes and row numbers

– Spreading belts in different lengths

– Dough hopper with 240 kg (TEWIMAT L), 300 kg (TEWIMAT S)

– Electrically switchable clutch between TEWIMAT and following devices

– Blower with especially cold and soft doughs

– Additional greasing for soft and sticky doughs.

WP BAKERYGROUP

TEWIMAT Dough Dividing and 2/2

Roundmoulding Machine 11.09.2012

Technical Data

TEWIMAT L + S*

Max. hourly capacity in pce

per row

at max. weight in g

per dough piece

* Power rating for continuous operation, not Start-Stop-operation

L x W X H in mm

Electrical supply value in kVA 4,5 5,5

Main drive in KW 3,0 3,0

Moulding drive in KW 1,5 1,5

Rows 3-6 3-10

Weight range* 28 to 250 28 – 300

Weight range

with adjustable double pistons**

* Weights dependent on piston diameter and number of rows

3000 2850 2500 2000 approx.

1800

100 125 160 200 250 300 (only

TEWIMAT L TEWIMAT S

28 to 250 28 – 300

approx.

1800

model S)

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Werner & Pfl eiderer Lebensmitteltechnik GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany

Fon +49 (0) 98 51-905-0 . Fax +49 (0) 98 51-905-342 . info@wp-l.de . www.wp-l.de

Loading...

Loading...