Page 1

think process!

SOFT STAR CT & SOFT STAR CTi

TECHNICAL SPECIFICATION

Products Capacity Weight range

think process!

Round dough pieces Soft Star CT

6 - 10 rows

per row max. 3,000 pcs./h

Dough absorption rate up to 65 %*

Timly cycle (max.) 50 Strokes / min

Soft S tar CTi

6 - 10 rows

per row max. 3,600 pcs./h

Dough absorption rate up to 65 %*

Timly cycle (max.) 60 Strokes / min

* depending on recipe & dough

OPTIONS

Blocking device

Additional outer moulding drum

Soft Star CT & Soft Star CTi

25 - 80 g (0.06 - 0.18 lb) (Standard)

15 - 180 g (0.03 - 0.4 lb)

(Multi-Measuring Drum)

Correction device on the spreading belt

Multi-Measuring Drum for another

weight range

WP KEMPER GMBH

Lange Straße 8-10 // 33397 Rietberg // Germany // Fon +49 5244 402-0 // Fax +49 5244 402-4220 //

info@wp-kemper.de // www.wp-kemper.de

© 2015 by WP Kemper GmbH, as at 11/2015 printed in Germany ® = registered Trademark

All information is non-binding. We reserve the right to make changes to reflect technical advancements.

SOFT STAR CT

& SOFT STAR CTi

the high-performance dough dividing &

moulding machines

Page 2

think process!think process!

SOFT STAR CT & SOFT STAR CTI

HYGIENIC AND WEIGHT ACCURATE AT VERY SOFT DOUGHS

The dough dividing- and moulding machines Soft Star CT and Soft Star CTi produces particularly efficient

dough balls with extremely high quality & weight accuracy. They are optimally adapted for processing

doughs with extremely high dough absorption and dough rest.

The maintenance of the machines are facilitated due to the separation of the dough processing area and

the drive area, as well as through the modular design of the machines.

Simple handling through good ergonomics, optimal accessibility, easy-to-exchange interchange parts and

a graphical user interface complete the profile of Soft Star CT and SoftStar CTi.

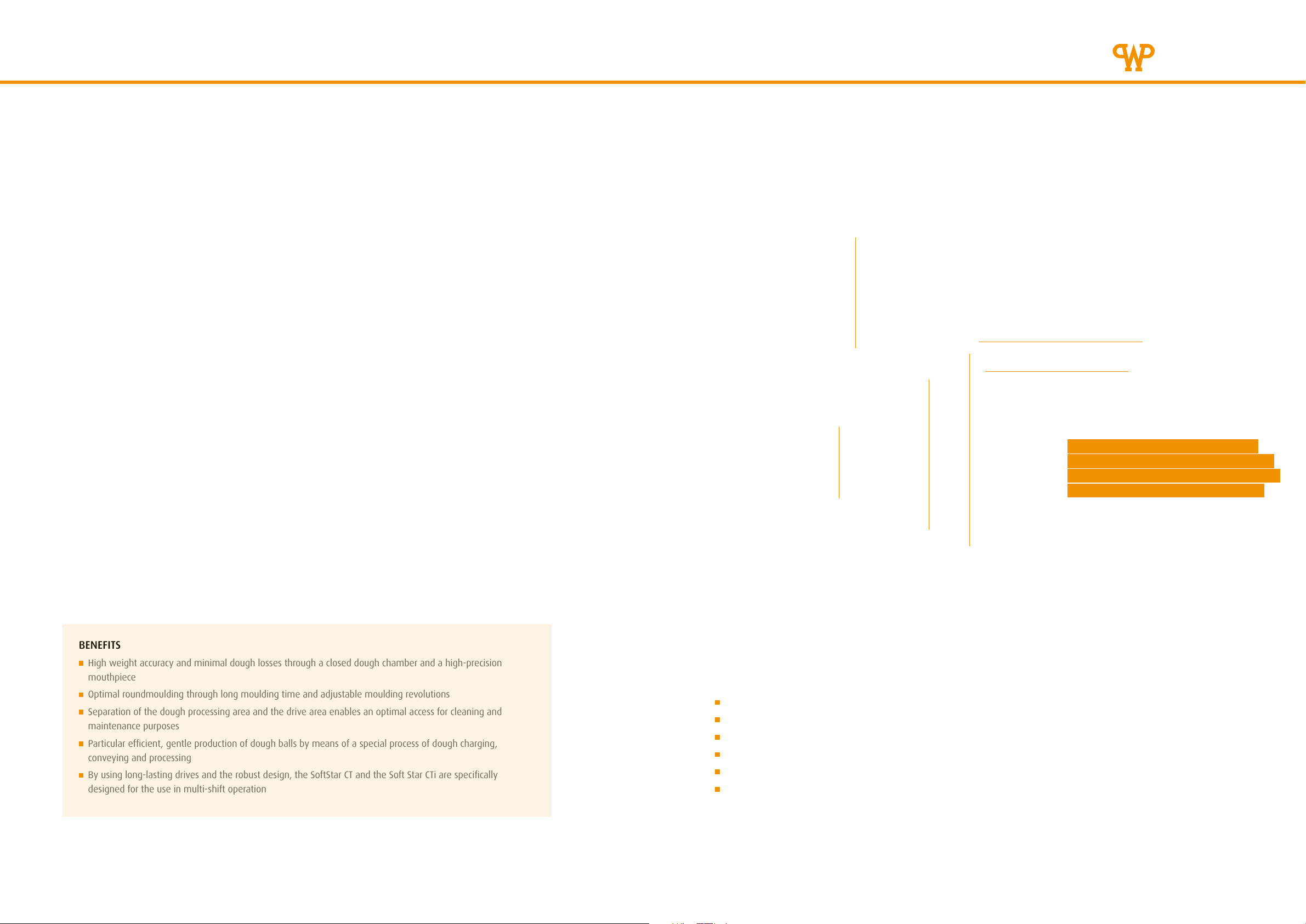

SOFT STAR CT & CTi IN DETAIL

Large hinged door at the

dough processing area

High ground clearance

Intermediate hopper

removable

Charging piston

removable

THE HYGIENIC DESIGN PROVIDES GOOD

ACCESSIBILITY TO ALL DOUGH CONTACTING

COMPONENTS. THUS, DOUGH RESIDUES CAN

BE REMOVED QUICKLY AND COMPLETELY.

BENEFITS

High weight accuracy and minimal dough losses through a closed dough chamber and a high-precision

mouthpiece

Optimal roundmoulding through long moulding time and adjustable moulding revolutions

Separation of the dough processing area and the drive area enables an optimal access for cleaning and

maintenance purposes

Particular efficient, gentle production of dough balls by means of a special process of dough charging,

conveying and processing

By using long-lasting drives and the robust design, the SoftStar CT and the Soft Star CTi are specifically

designed for the use in multi-shift operation

Measuring drum

easy accessible

The Soft Star CT fulfills high demands on performance and hygiene.

For claims on additional enhanced hygiene, as well as increased flexibility and automation provides

the SoftStar CTi opposite the SoftStar CT following value:

20% higher performance (up to 36,000 pcs. / h.) through high-performance drives

Block-off of the moulding drum at any position allows a flexible formation of rows

Infinitely variable moulding revolutions for an individual adaption to product requirements

Swiveling stainless steel dough chamber and tiltable mouthpiece for cleaning purposes

Frame made from stainless steel

Closed, patented flour duster with screw drive; decentralized filling

Dough chamber

removable

Loading...

Loading...