Page 1

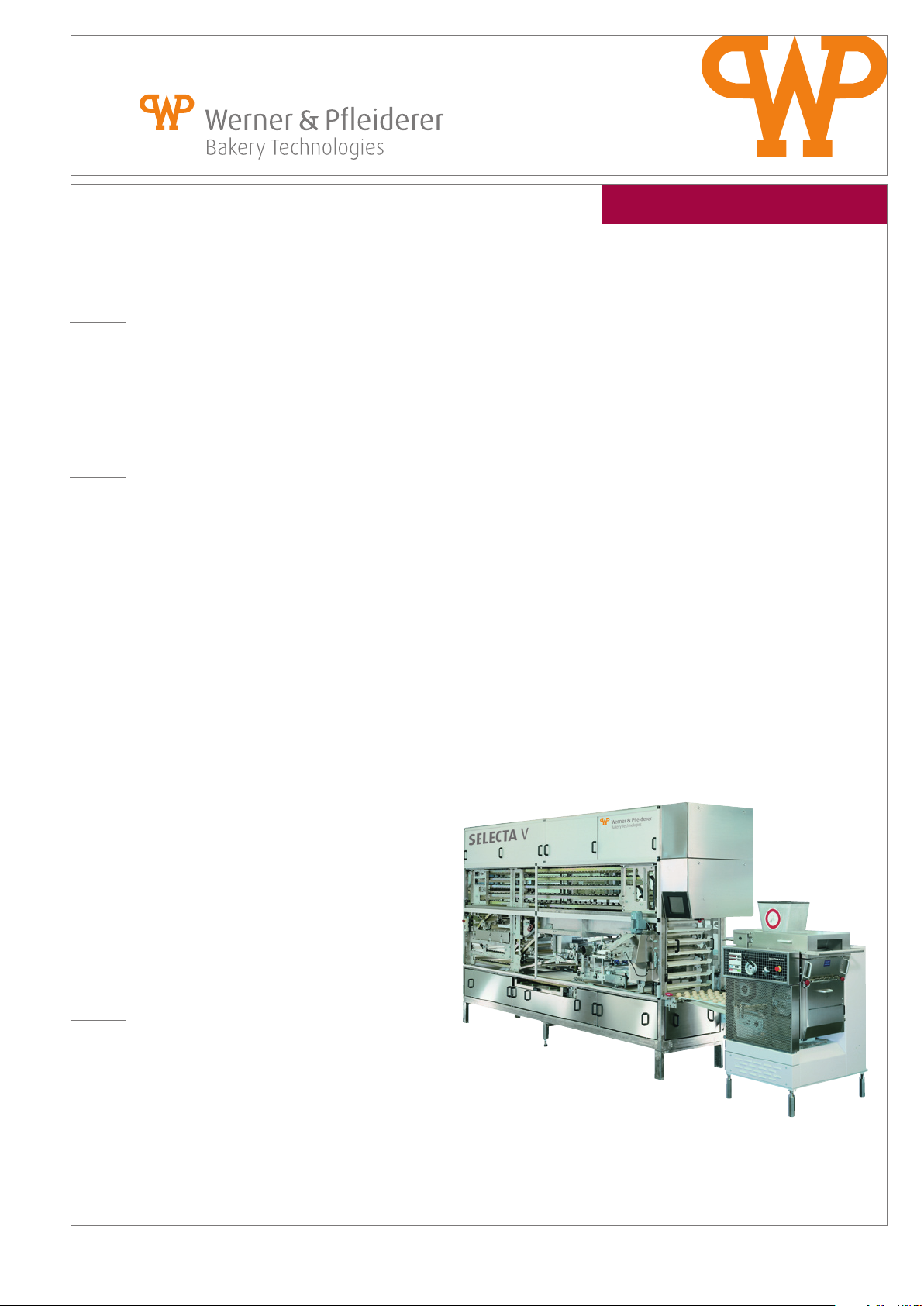

SELECTA MEGA

Moulded and cut rolls and even more –

everything perfect from one system.

Application

5-row combined small baking products system for the production of moulded rolls

and long-rolled products – cut and uncut for the production of

– Moulded goods

– Cut rolls

– Round dough pieces

– Long-rolled dough pieces

– Doughnuts

– Non-proofing operation (via bypass)

Advantages

MULTIMATIC® head machine

– With its known advantages

Touchscreen

– Reproducible quality

– Production safety

Pneumatic installation

– Dust and spray-water resistant

– Safe function and low-noise

Stainless steel design

– Hygiene

– Long service life

– High re-sale value

variable output

– Always optimum proofing and resting period

automated production process

– Reproducible quality

two in one: FORM- and ROLLMEISTER

– Large range of product with high output

Bypass belt (non-proofing operation)

– Depositing of all products from the MULTIMATIC® with variable

depositing layout on all types of proofing trays

double degermination station

– High hygienic safety

– Optimum degermination

robot-capable

– Extendable with tray loading device

WP BAKERYGROUP

SELECTA MEGA 1/2

Moulded and cut rolls system 08.12.2008

Specification

In standard design

MULTIMATIC® S – 5-row

– Dough funnel, alu-teflonized for approx. 40 kg dough volume

– Complete stainless steel paneling

– Main and moulding drives frequency controlled

– Moulding belt flour dusting

– Spreading belt 900 mm

– Portioning piston 50 mm, diameter for dough weights 35 – 85 g

– 1 chamber drum 58 – 64 g

Page 2

SELECTA MEGA

WP BAKERYGROUP

SELECTA MEGA 2/2

Moulded and cut rolls system 08.12.2008

SELECTA MEGA

– Stainless steel construction in compact design with basin trays

– Automatic chain tensioning

– Air conditioning

– Proofing time between input and long roller of 6 min. and a

further proofing time between long roller and cutting machine

of also 6 min. Proofing time of 12 min. up to stamping head

– Revolver stamping head with pneumatic connection and

connection possibility for max. 4 tool rows

– Kaiser roll stamper and pneumatic flour scatterer

– Pneumatic cutting machine for cutting dough pieces lengthways

– Manual cutting depth adjustment

– Pressure board I for production of cut rolls

– Seam position adjuster ahead of cutting machine

– Pneumatically adjustable hold-down rail

– Interchangeable, driven centering rollers

– Tray drying

– Depositing unit for proofing trays in 3 Euro-sizes

400 × 600, 580 × 780, 580 × 980 mm

racking length 1,000 mm

– Seam position adjuster at depositing unit, frequency controlled

– Bypass belt can be driven in-out pneumatically for non-proofing

operation

– Degermination station with intensive degermination program in

reinforced design

– Screen control via touchscreen

– Exhaust air fan for adjustment of proofing cabinet climate

– Proofing tray located as push-in shelf

– Ready equipped for connection of a tray loading device

– Operating side left in running direction

Technical Data

Options

– Side discharge belt

– Driven pressure roller on spreading belt

– Ram shield on operator side

– System height raise by 50 or 100 mm

– External moistening and scattering device

– Angle cutting device, 3-row – double cut

– Pneumatic piston lock from 5 to 4 rows or from 5 to 3

rows

– Data network for complete control of the MULTIMATIC® S

Accessories

– Chamber drum for extended weight range

– Spreading belt 500 mm, 900 mm or 1,250 mm

– Various stand tools for production of

· Star rolls

· Poppy seed rolls

· Curly rolls

· Rosette rolls

· Reschlingen rolls

· Pressed rolls

· Kärntner rolls

· Smooth round rolls

· Diamond-shaped rolls

– Moulding station for the production of Wachauer rolls

– Additional flour trough

– Various pressure boards for production of

· Cut rolls and hard rolls

· Stick products

· Baguette rolls

· Cylindrical products, hot dogs, etc.

· Crusty rolls

– Double, intensive degermination station

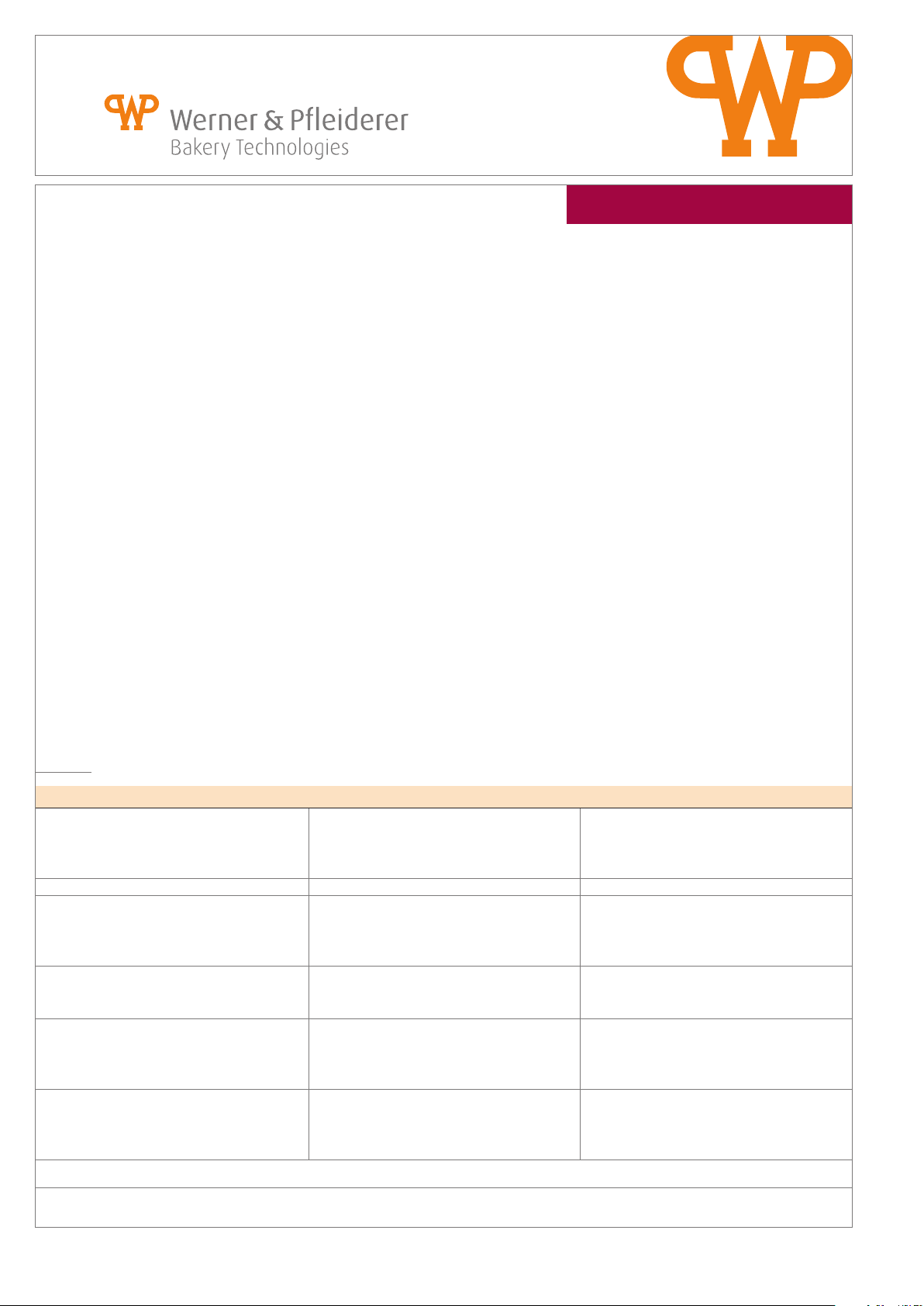

SELECTA SELECTA MEGA 6000 SELECTA MEGA 9000

Hourly output *

Moulded goods – 5-row pcs./h

Cut rolls – 4-row pcs./h

Baguette rolls /Crusty rolls – 3-row pcs./h

Pre-proofing time min. 12 10 10 12 12 12

Weight range

4-row g

3-row g

Via bypass belt g

Proofing tray size mm 400 x 600

Connected loads

Electric kW

Cold water connection “

Compressed air – 1/2“ plug connection

Dimensions

B x D x H mm

Inlet opening mm

Inlet opening with split design mm

* Hourly output variable according to product

Werner & Pfleiderer Lebensmitteltechnik GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany

Fon +49 (0) 98 51-905-0 . Fax +49 (0) 98 51-905-342 . info@wp-l.de . www.wp-l.de

6,000

–

–

7 Normal m³/h or 117 Nl/min. up to 6 – 8 bar

4,400 x 1,000 x 2,250

–

5,700

–

40 – 65

35 – 85

up to 85

580 x 780

580 x 980

12

1/4

1,000 x 2,000

1,000 x 2,000

–

–

4,300

9,000

–

–

7 Normal m³/h or 117 Nl/min. up to 6 – 8 bar

4,400 x 1,000 x 2,800

–

7,200

–

40 – 65

35 – 85

up to 85

400 x 600

580 x 780

580 x 980

13

1/4

1,000 x 2,500

1,000 x 2,000

5,400

–

–

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...