Page 1

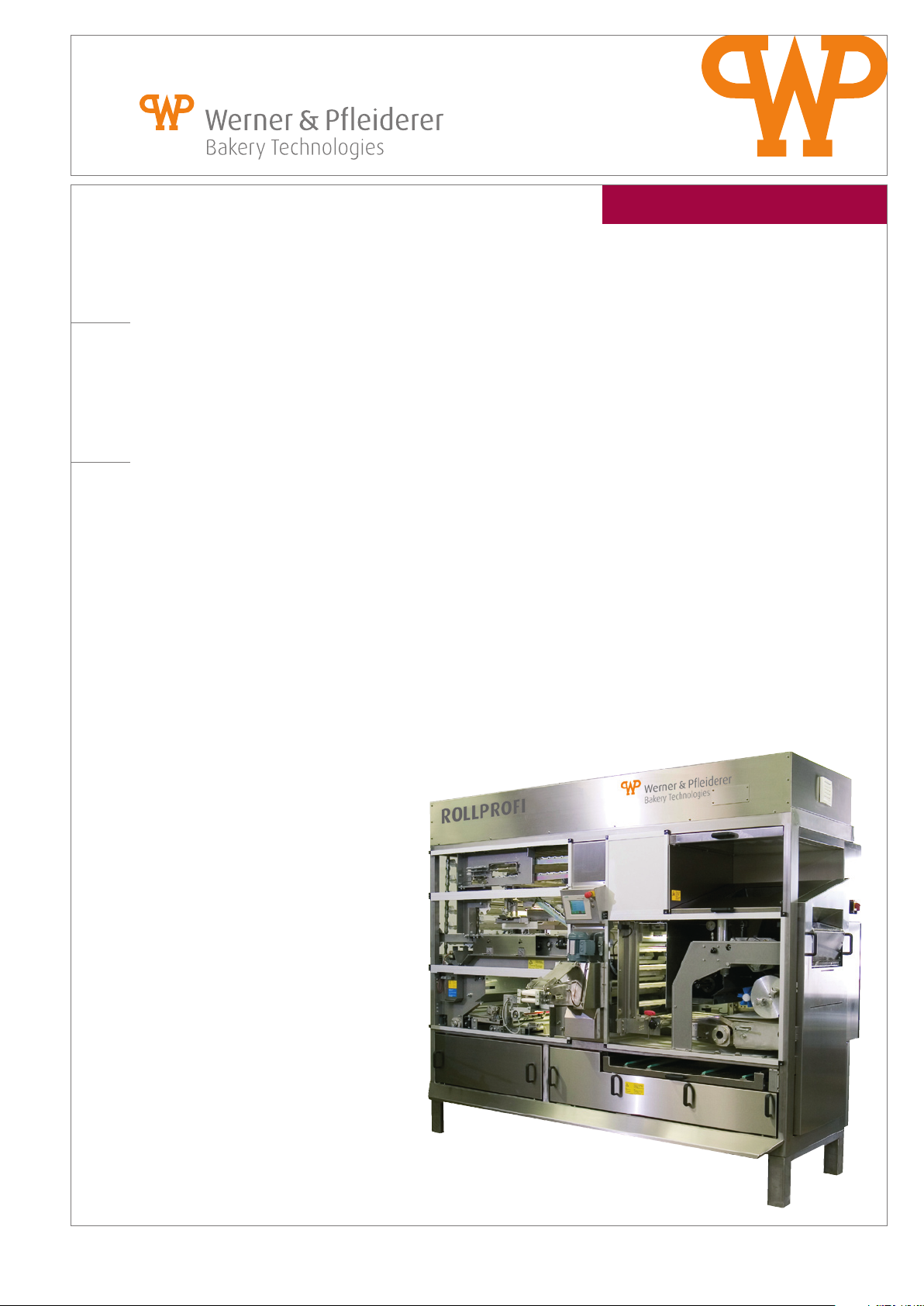

ROLLPROFI

Compact hard roll machine

with integrated head machine

Properties

Hard roll machine with integrated dough divider for the production of

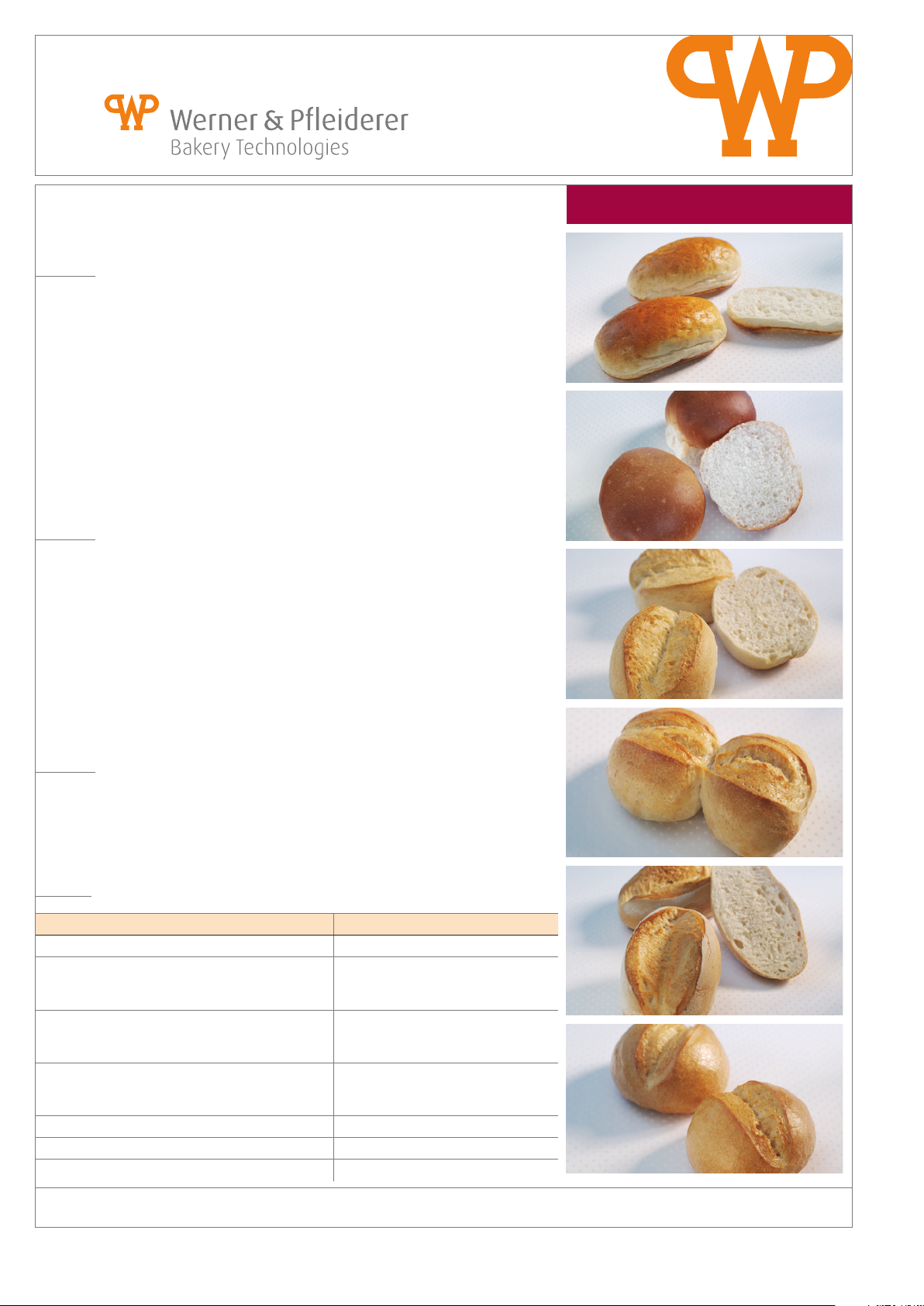

– Hard rolls

– Smooth round rolls

– Long-rolled rolls

– Twin products

in a weight range from 30–85 g, depending on the number of rows and

the design of the products

Advantages

Extended pre- and intermediate proofing

– High volume yield

– Low structure influence

– Craftsman’s quality

Adjustable cutting station

– Optimum baking appearance

– Product variety

Variable depositing device

– Use of nearly all standard commercial proofing trolleys (per Euro-scale)

Exchangeable pressure boards

– Product variety

– Extended range of use

Variable output

– Always the optimum proofing and resting time for all

types of dough process

Intensive degermination station

– Hygiene

– CE conformity

– LMHV

Automated production process

– Consistent reproducible quality even with

changing personnel

Siemens S7 control system

– Programmed production processes

– Running time control

Stainless steel design

– Hygiene

– Long service life

– High re-sale value

WP BAKERYGROUP

ROLLPROFI 1/2

Hard-roll machine 01.08.2008

Page 2

ROLLPROFI

Specification

In standard design:

– Integrated suction divider with rotary peeler

– Drum moulder

– Stainless steel construction in compact design

– Pre-proofing time of 6 min. in front of long-rolling station

and 6 min. between long-roller and cutting machine.

– Automatic chain tensioning

– Rack drying

– Parking device for proofing trolleys of the 3 Euro-sizes

400 × 600 mm, 580 × 780 mm, 580 × 980 mm,

racking length 1,000 mm

– Push-in possibility for proofing trolleys (standard: left)

– De-germination station

– Siemens-S7 computer control

– Operating side left in running direction

Options

– Air conditioning

– Side discharge belt

– Exhaust fan for correction of the proofing cabinet atmosphere

during continuous operation

– Ram protection on the operating side

– Parking device with end position changer

– Proofing trolley locator as drawer

– Machine vertical lift by 50 or 100 mm

– Stacker for 2 pressure boards

– Double-intensive degermination

– Preparation for air conditioning

– End position changer

– Pressing station in place of cutting machine

WP BAKERYGROUP

ROLLPROFI 2/2

Hard Roll Machine 01.08.2008

Accessories

– Chamber drum for extended weight range

– Various pressure boards for the production of:

· Hard rolls

· Stick products and baguette rolls

· Cylindrical products, hot dogs etc.

· Crusty rolls

Technical Details

Hourly output pcs. per hour 3750

Pre-proofing time in min. 12

Weight range in g

long-rolled 40–75

round 30–85

Proofing trolley dimensions in mm 400 × 600

580 × 780

580 × 980

Connected loads

Current in kW 7.5

Water connection in “ ½

Compressed air 2 Nm³ / h at 6 bar

Dimensions (L x B x H) in mm 2,600 x 1,500 x 2,250

Required minimum room height in mm 2,600

Werner & Pfleiderer Lebensmitteltechnik GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany

Fon +49 (0) 98 51-905-0 . Fax +49 (0) 98 51-905-342 . info@wp-l.de . www.wp-l.de

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...