Page 1

WP BAKERYGROUP

QUADRO ROUND – Industrial Line 1/2

Roll Line 08.12.2008

QUADRO ROUND – Industrial Line

Roll Line

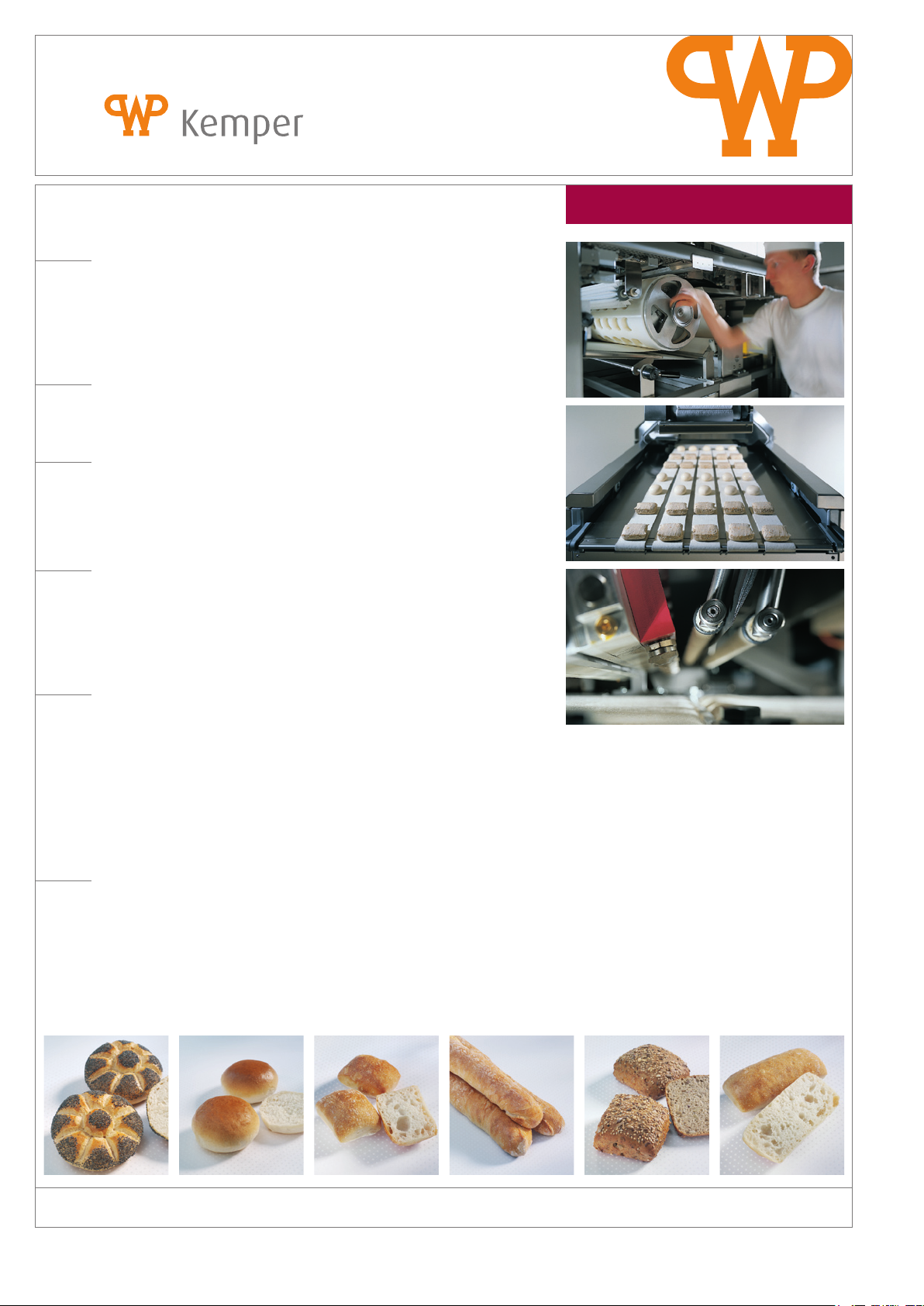

Industrial roll Line for the production of rustic rolls

35-1000 g/pce (larger weights on demand)

– Processing of quadratic, round and longmoulded rolls with just one system

– Due to the Quadro Round production process there ist no need for an intermediate proofer

– Fully automatic charging of the Kemper Quadro-Lines with the continuous dough strip machine RELAXER SK (optional)

– Dough strip production without stress, due to the Kemper Star Wheel System (optional)

– Electronic control with Touch Screen

Advantages

– Large production range

– Fast return of investment through a wide operating range

– Excellent price/performance ratio

– Enables 1-Man operation of the line

– Gentlest possible dough production process

– Reproducible process – Greater processing security – simple operation

– Space saving

– Larger product volume

– Implementing customer-specific requirement profiles by modular design of the machine

Page 2

QUADRO ROUND – Industrial Line

Weight range

Rustic rolls 35-150 g/pce (larger weights on demand)

Rustic breads up to 1000 g/pce

Round rolls 35-85 g/pce

80-140 g/pce* (larger weights

on demand)

*Change of roller knife and inner and outer moulding drum

Capacity 6-row (depends on weight)

Rustic rolls max. 12.000 pieces/h

Round rolls max. 12.000 pieces/h

Long moulded rolls max. 12.000 pieces/h

Dough

Wheat dough

Mixed wheat dough

Mixed rye dough

Ciabatta

Absorption rate: up to 75%

Products

Round Rolls

Rustic, quadratic rolls

Passau rolls

Schusterjungen

Minibaguette

Ciabatta

WP BAKERYGROUP

QUADRO ROUND – Industrial Line 2/2

Roll Line 08.12.2008

Characteristics

Program-controlled, user-friendly dough dividing and moulding machine for

gentle processing of any type of roll dough. High flexibility in the production

of baked goods in small and medium-scale operations with only one

machine. (e.g.: rustic rolls, square rolls, round rolls and optional Passau

rose rolls) Gentle processing of soft doughs with a dough absorption of up

to 75%. Integrated PLC, operation via a touch screen display. Implementing

customer-specific requirement profiles by modular design of the machine.

5 or 6-row design.

Options

– Oiling unit for Passau rolls

– Ram protection guard

– Additional moulding drum, outer

– Additional moulding drum, inner

– Additional roller knife

Kemper Bakery Systems - N.A. Subsidiary of the WPBAKERYGROUP . 3 Enterprise Drive . Suite 108 . Shelton. CT . 06484

Phone 203-929-6530 . Fax 203-929-7089 . sales@wpbakerygroupusa.com . www.wpbakerygroupusa.com

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...