Page 1

WP BAKERYGROUP

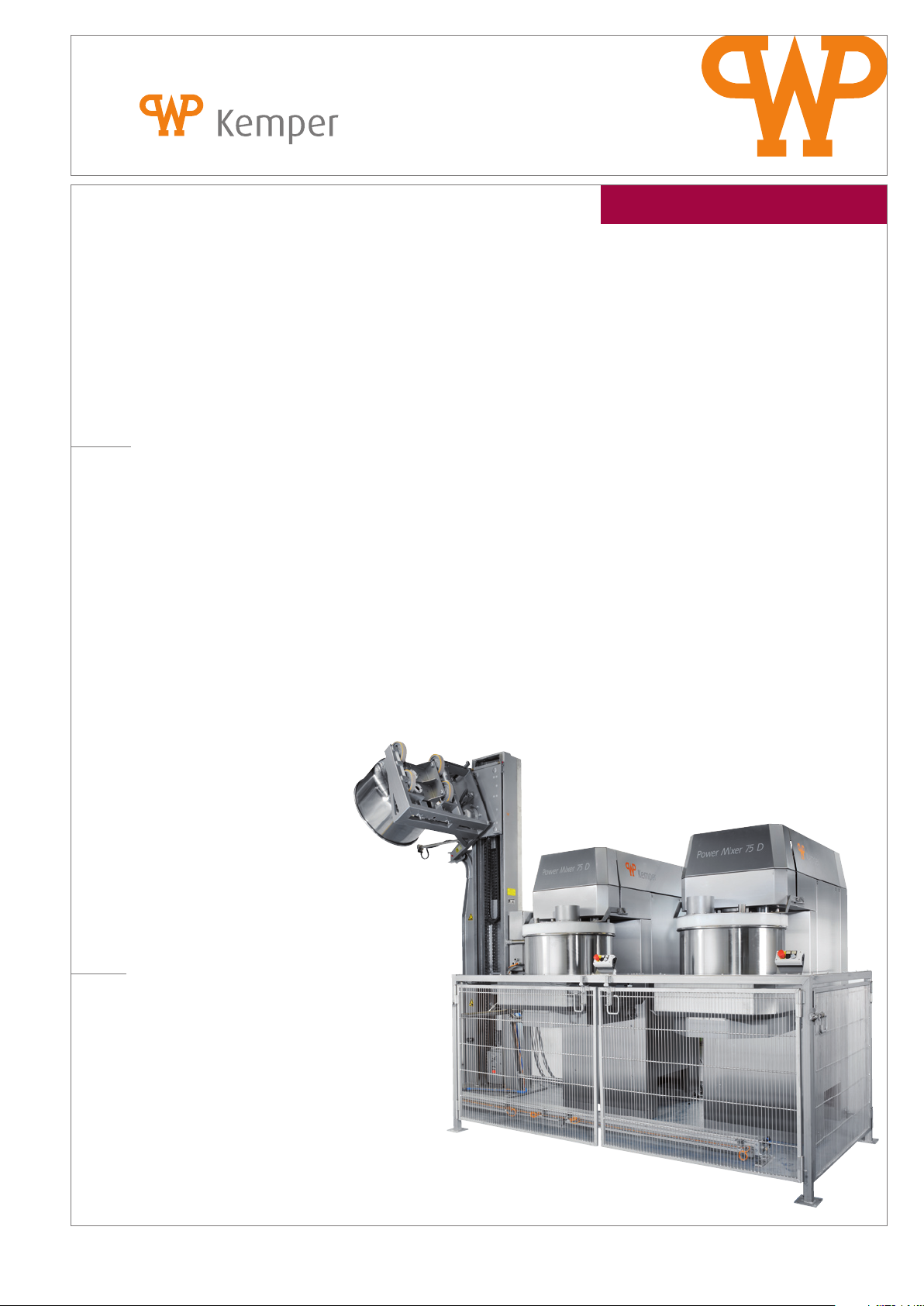

POWER ROLL SYSTEM 1/2

Fully automatic mixing system 05.12.2008

POWER ROLL SYSTEM

Fully automatic mixing system

Flexible and fast dough processing

– Double spiral mixing tools

– Robust, smoothly rounded and ergonomic machine design

– Large diameter base opening in the bowl

– Generously dimensioned free space under the mixing bowl

– Connection possibilities for mixer raw material charging

– Double frictional wheel drive for model 150; Toothed belt drive for sizes 75 and 320

– Touch Screen (on request with connection to central switch box)

Benefits

– Short mixing times, high hourly capacity, with the 3 Zone Mixing Principle

– User friendly and easy to clean mixer

– Quick, dough friendly and fully automatic mixer discharge into downstream dough conveying equipment

– Individual process oriented adjustment of the dough flow.

– A fully automatic dough production is possible in combination with a dough conveying equipment

– Fully automatic raw material charging is possible

– Quiet and safe mixing process

– Simple programming of individual program sequences

– Multi-Phase control as an option

Options

– Multi-phase control for spiral and bowl drive

– Revolution counter

– CO2 cooling

– connection to central switch box

– energy measuring system

– batch protocol management

Page 2

POWER ROLL SYSTEM

Mixing system consisting of (example):

– 2x double spiral mixer “PM 75 / 150 D” with bottom discharge

– 1x transport unit (bowl conveyor) incl. bowl

– 1x switch box for dough mixing system

Optional

– 1x Bowl tippers “HK 200” with scraping device

– 1x platform with dosing hopper

WP BAKERYGROUP

POWER ROLL SYSTEM 2/2

Fully automatic mixing system 05.12.2008

Bowl transport belt, consisting of

– 2x Mounting position for double spiral mixer “PM 75 / 150 D”

– 1x Mounting position for lifting tipper “HK 200” -TS

– 1x bowl “PM 75” -TS / “PM 150” -TS / “PM 320” -TS

The bowl is transported to the required positions

via a rail-mounted trolley. The trolley is driven

via a frequency inverter-controlled motor.

Max. dough quantity / hour ca. 1.920 kg ca. 3.840 kg

2 x „PM 75 D“ 2 x „PM 150 D“

Cycle time: 7.5 min 7.5 min

Raw material charging 1.0 min 1.0 min

Mixing time 5.5 min 5.5 min

Discharge 1.0 min 1.0 min

Cycle time 4.0 min 4.0 min

Batches / hour 15 15

Batch size 120 240

EMIL KEMPER GMBH . Lange Straße 8 – 10 . 33397 Rietberg . Germany .

Fon + 49 (0) 5 244 -402-0 . Fax + 49 (0) 5 244 -402-220 . info@emil-kemper.de . www.emil-kemper.de

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...