Page 1

02 286/1-d 0504

Subject to alterations.

Frankfurter Straße 17, D-71732 Tamm

Postfach 136, D-71730 Tamm

T: +49 (0) 71 41 / 202-0

F: +49 (0) 71 41 / 202-111

E: info@wpib.de

I: http://www.wpib.de

TTaakkee aa ddeecciissiivvee sstteepp -ttaallkk ttoo WWeerrnneerr && PPfflleeiiddeerreerr..

This publication and all its contents are copyright

protected. No reproduction by any part of this

publication is permitted without the prior written consent

of the copyright owners. This is also applicable for

duplicating, translating, microfilming and the saving in

electronic data systems.

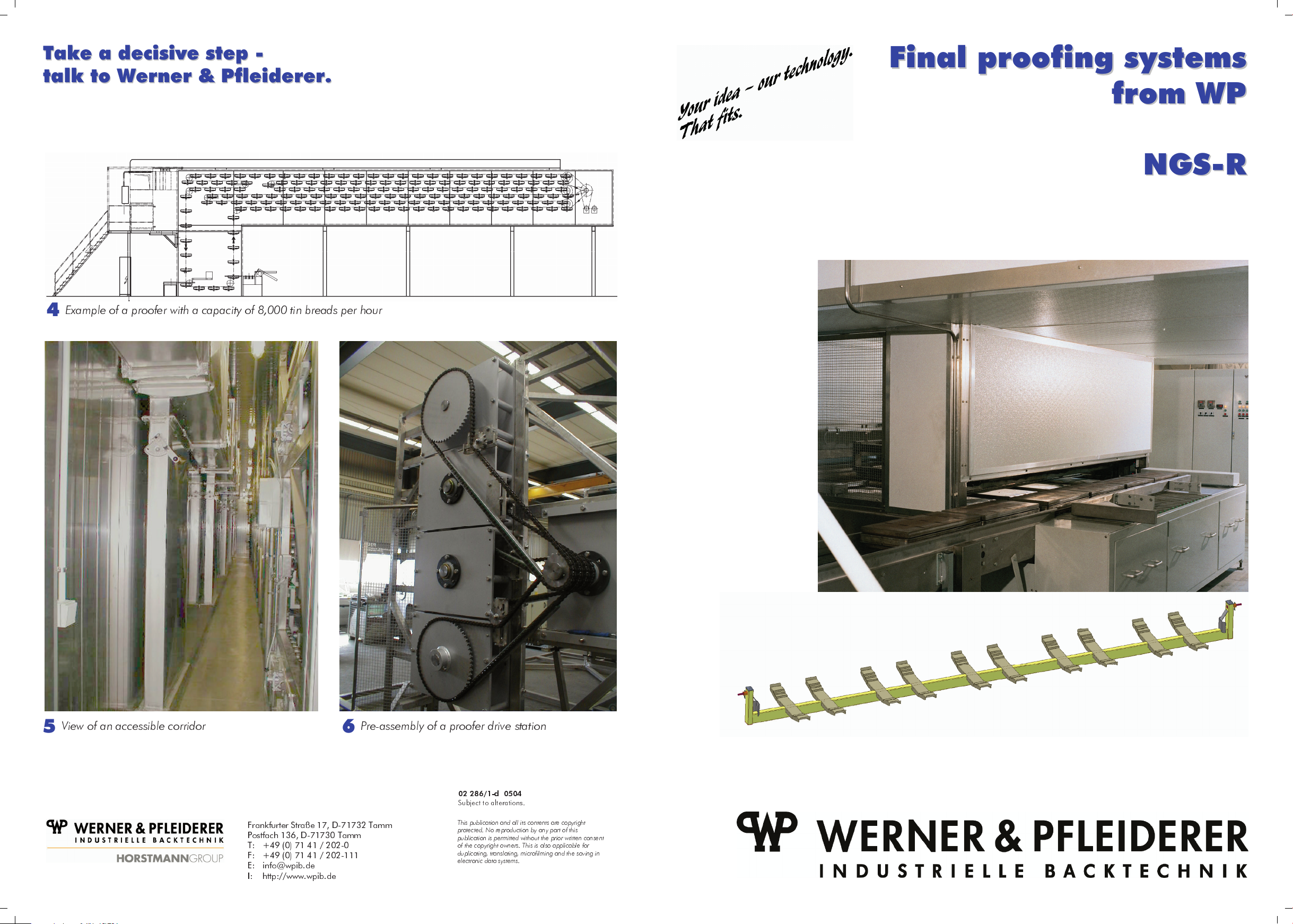

Example of a proofer with a capacity of 8,000 tin breads per hou

r

4

View of an accessible corrido

r

5

Pre-assembly of a proofer drive station

6

FFiinnaall pprrooooffiinngg ssyysstteem

mss

ffrroom

m

W

WPP

N

N

G

GSS--

R

R

Page 2

Application areas

The NGS-R is especially suited for the following products:

•

Tin products

•

Toast and sandwich bread

•

Sliced whole grain bread

•

Rusk and croûtons

•

Tray products

•

Rolls/Buns

•

Brioche

•

Baguette

•

Skorpor

•

Pizza

•

Oven bottom goods on trays or boards

Executions

•

Box type

•

L-shape as overhead type

•

T-shape as overhead type

Features

•

Frame construction in stainless steel

•

Closed sections

•

Hollow-pin chain acc. to DIN with ball bearings at the

pick up points of the carriers

•

Insulation panelling, aluminium on both sides

•

Circulation climate control incl. compact air condition

•

Accessible on both sides, with intermediate platform,

illuminated

•

Pneumatic chain/track tensioning

•

Levelled inside floor (for cleaning purposes)

•

Integrated unloading system with frequency controlled,

powered discharge pusher

•

Loader, separate unit, frequency controlled,

powered infeed pusher, safety fence

•

Automatic chain/track lubrication

•

Frequency controlled drive

•

Standardized components

•

PLC control

Options

•

Integrated, continuous working steam boiler

•

Execution of panelling in stainless steel on both sides

•

Hinged panelling at overhead section for cleaning

Trays

•

Stainless steel (standard)

•

Section tube with welded pick up rakes

•

one-level trays continuous run

•

multi-level trays intermittent run

•

several form dimensions possible through multiple multi-

cranked trays

Loading

•

Loading of trays through integrated holding table

•

Separate unit

•

Safety fence

•

Conveyor with magnetic rail or magnetic stopper,

frequency controlled

•

Infeed transport via plate chain, frequency controlled

•

Infeed pusher via linear gear motor unit,

frequency controlled

Unloading

•

Integrated discharge pusher via gear rack,

frequency controlled

•

Tray discharge/evacuation through/via integrated

discharge table

Circulation climate control

•

Heating via

•

Warm water

•

Low pressure saturated steam;

0,2 – 0,5 bar pressure above atmospheric

(105 – 113°C)

•

Electrical heater coils

•

Gas burner

•

Cooling via

•

Cold water

•

Direct heat exchanger

IInntteelllliiggeenntt ssyysstteemm ccoonncceeppttss..

•

Humidity via low pressure saturated steam

•

De-humidity via fresh air supply by means of conditioned

air and a condenser with backup heating to process

temperature

Advantages

•

Easy control (little sensors and actuators)

•

High operational reliability through minimum

control/monitoring mechanis ms

•

Low maintenance (e.g. maintenance-free ball bearings)

•

High standard of hygiene through closed sections, no

undercuts, even floor

•

Space-saving, little floor space (overhead-execution)

•

Controlled, smooth climate guidance

•

Gentle product handling due to frequency controlled

drives

•

Recumbent bakery product

•

Little noise development through plastic guide rails

•

Suitable for three shift operation

•

Quiet tray guidance at loading and unloading

IInnddiivviidduuaall ssyysstteemm ssoolluuttiioonnss..

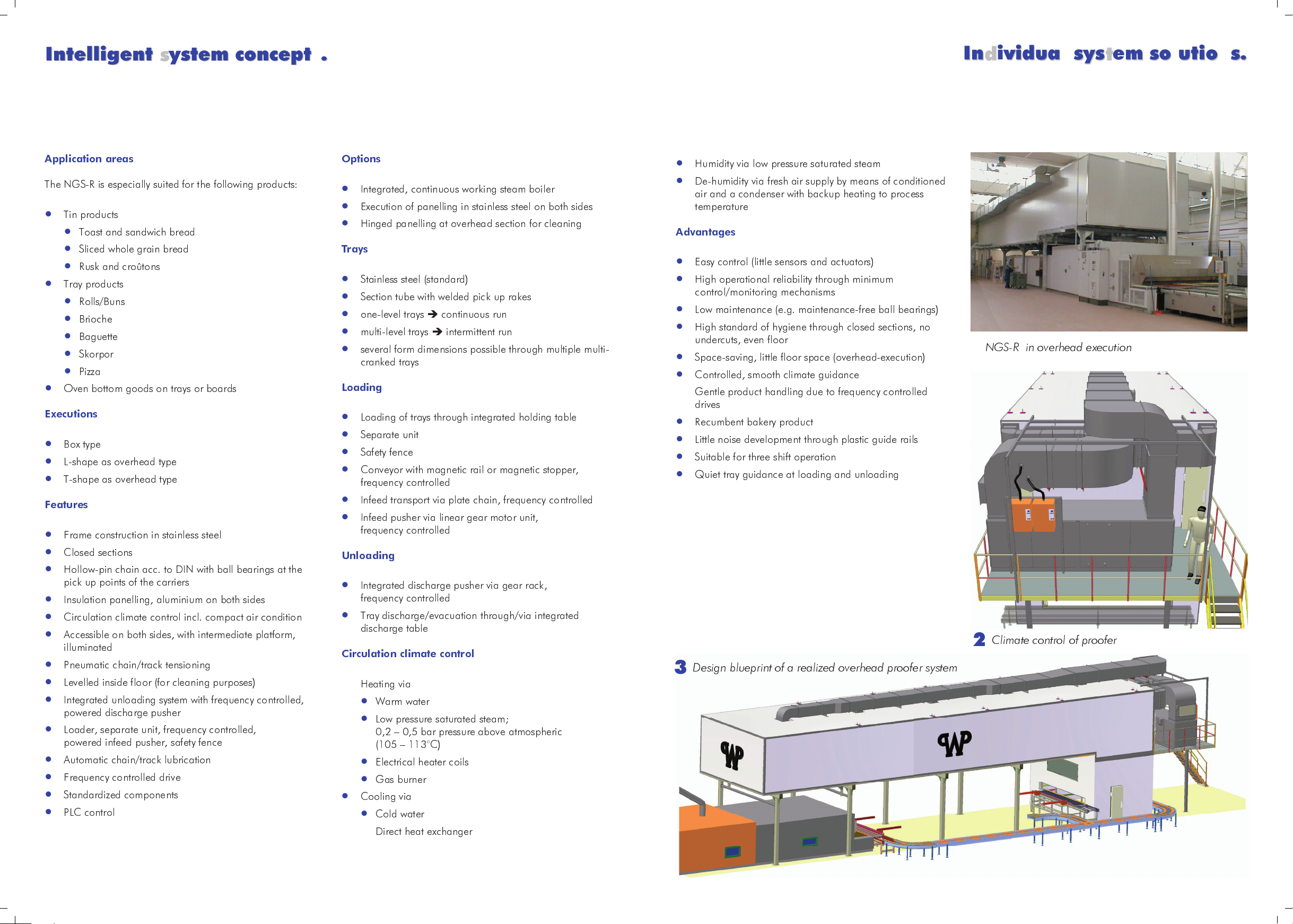

NGS-

R in overhead execution

1

2

3

Climate control of proofer

Design blueprint of a realized overhead proofer system

Loading...

Loading...