Page 1

WP BAKERYGROUP

MULTIROLL BASIC LINE 1/2

Roll Machine 29.02.2008

Roll machine

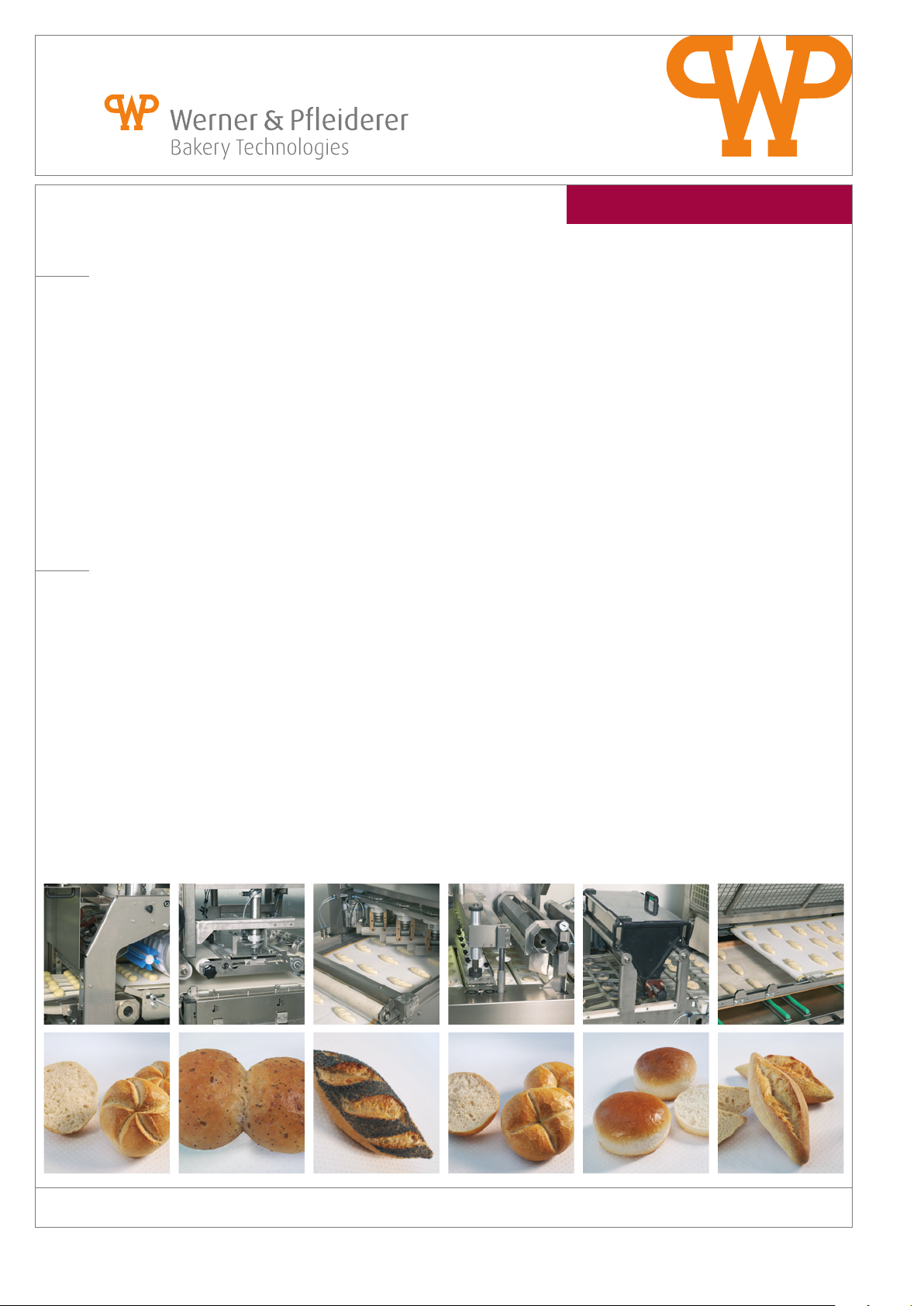

MULTIROLL BASIC LINE

Modular roll baking system with integrated MULTIMATIC C

head machine for a maximum of flexibility & versatility

Dough yield approx. 150 – 160 %

g/pc. approx. 35 – 85 (stamped products g/pc. approx. 35 – 65)

Rows 3 – 5

pcs. per hour max. 5000

Properties

Interchangeable function module, high product versatility, high flexibility, small space requirement

Advantages

Integrated Multimatic head machine with its known advantages

– Small space requirement, no climate change

Interchangeable pressure boards

– Large product versatility, flexible area of use

Programmable upper belt speed

– Adapted handling method for each dough recipe and process

Drive module with intermediate belt, mobile, (patented)

– Precondition for changing various exchange modules

Various exchange modules

– Large product range, high flexibility

Stainless steel design

– Long service life, hygiene, high resale value

Illustration shows possible system configuration

Page 2

WP BAKERYGROUP

MULTIROLL BASIC LINE 2/2

Roll Machine 29.02.2008

MULTIROLL BASIC LINE

Technical Data

Products

Formed goods

Round dough pieces

Flat-rolled dough pieces

(Hamburger)

Long-rolled dough pieces

Moistened products

Dusted products

Angle-cut products

Technical Details

DY approx. 150 – 160 %

approx. 35 – 85 g/pc.

3 – 5 row max. 5,000 pcs. per hour

Exchange modules & options

Exchange modules

Long roller, stamp, angle and long cutter, moistening, dusting, timing roller, depositing unit, processing table

Dough

Wheat dough

Wheat mix dough

Rye mix dough

Grain dough

Special dough

Dimensions

Height approx. 2,360 mm

Width approx. 1,180 mm

Length depending on design

Specification

Multimatic Type C – 5 row integrated into pre-proofing cabinet

Dough funnel, alu-teflonized, holding volume approx.

35 kg dough

Stainless steel panelling

Drive motor 1.5 kW

Portioning chamber in low-wear materials

Drive parts (not dough-handling parts) dust and spraywater protected

Hydraulic system for gentle dough handling and

exact portioning

Increment drive with synchronized switch

Spreading belt 900 mm

Portioning piston 50 mm Ø for dough weights approx.

35 – 85 g

1 chamber drum 58 – 64 g

Options

Upper belt long roller with driven, frequency controlled upper belt

End position change with the depositing unit frequency controlled

Intermediate belt I

Mobile change mobile change trolley

Angle cutting station

Stamping head / Dusting

Timing roller

Dusting container

More than 10 different pressure variations

Werner & Pfleiderer Lebensmitteltechnik GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany

Fon +49 (0) 98 51-905-0 . Fax +49 (0) 98 51-905-342 . info@wp-l.de . www.wp-l.de

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...