Page 1

WP BAKERYGROUP

MINI QUADRO ROUND 1/2

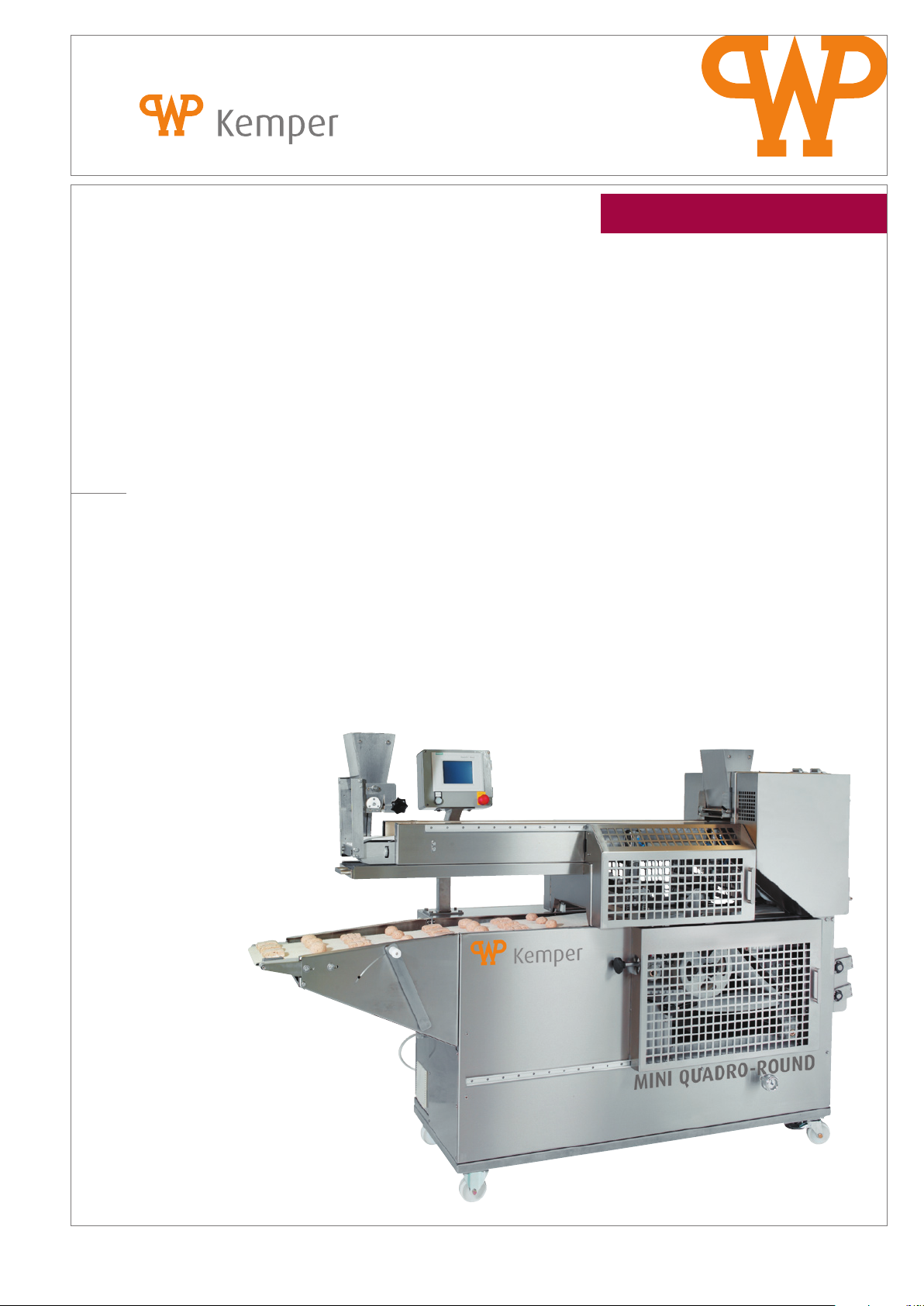

MINI QUADRO ROUND

Dough dividing and moulding machine

Quadratic roll: 30–1000 g/pce

Quadratic bread: up to 1000 g/pce

Round rolls: 30 –130 g/pce 3-rows and 80–130 g/pce 2-rows*

*Change of roller knife and inner and outer moulding drum

– Processing of quadratic and round rolls with just one system

– Optionally available with stamping and longmoulding station

– Dough dividing and moulding according to the patented “KEMPER QUADRO ROUND” principle

– Electronic control with Touch Screen

– Self-supporting stainless steel frame with panels

– Optionally available with automatic depositing unit

Advantages

– Fast return of investment through a wide operating range

– Excellent price/performance ratio

– Further increase in product range

– Very gentle dough division through patented “Quadro Round” principle

– Processing of dough with an absorption of up to 70%

– Reproducible process – Greater processing security – simple operation

– Quick and simple cleaning – short non-productive times

– Maximum productivity and rationalisation effect

Dough dividing and moulding machine 08.12.2008

Page 2

MINI QUADRO ROUND

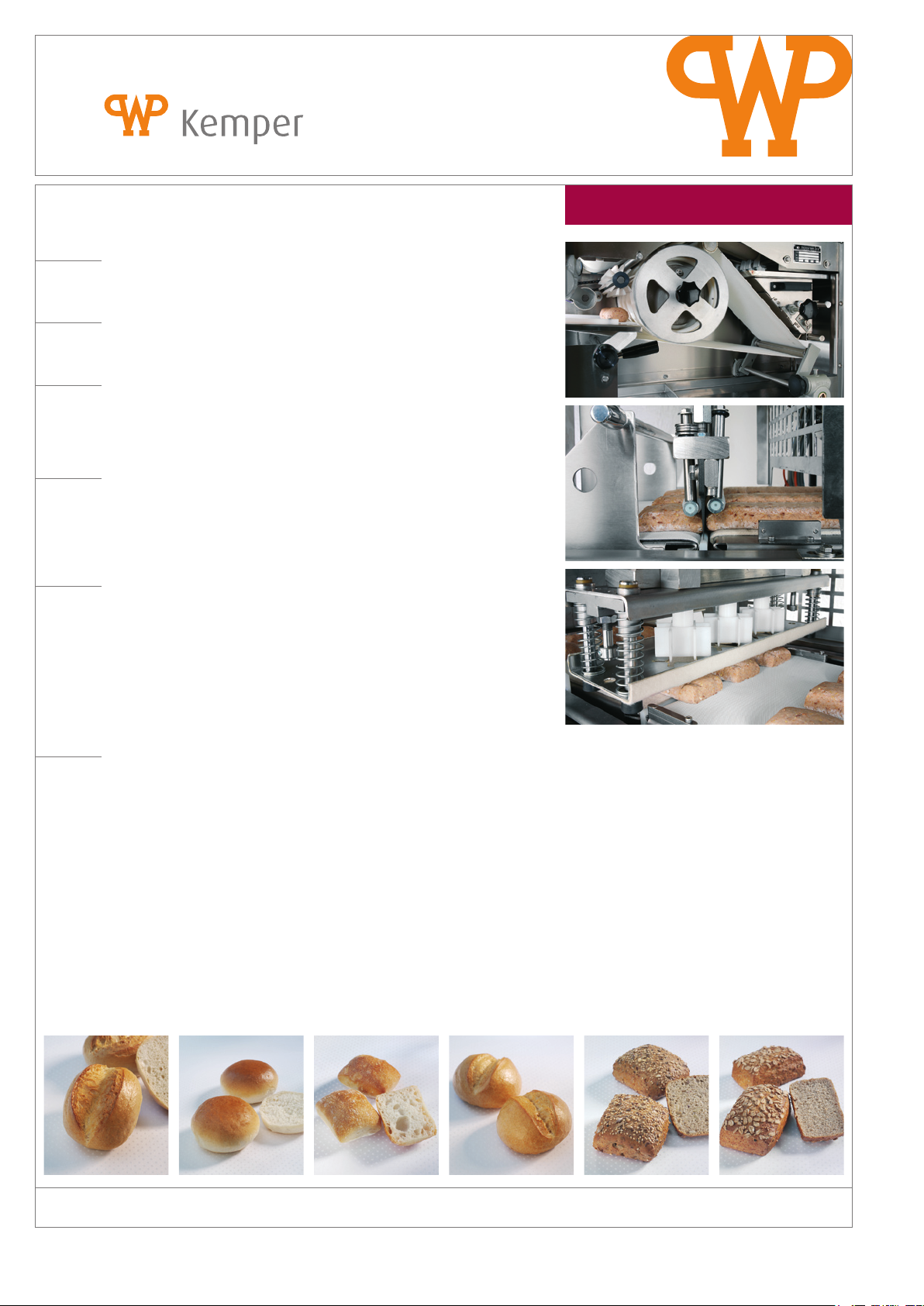

Weight range

Rustic rolls: 30–1000 g/pce

Round rolls: 30–130 g/pce

Capacity

3-row: rustic rolls up to 4.000 pieces/h à 70 g

3-row: round rolls up to 3.000 pieces/h à 70 g

Dough

Wheat dough

Mixed wheat dough

Mixed rye dough

Ciabatta

Products

Rustic, quadratic rolls

Round Rolls

Ciabatta

Schusterjungen

Minibaguette

Dimensions

Hight approx. 1.700 mm

Width approx. 760 mm

Length approx. 2.350 mm

Energy consumption 1,5 KW

WP BAKERYGROUP

MINI QUADRO ROUND 2/2

Dough dividing and moulding machine 08.12.2008

Characteristics

This program-controlled dough dividing and moulding machine is designed

for gentle processing of any type of roll dough with a dough absorption of

up to 70%. The speciality is the possibility to produce quadratic, rustic rolls

of handmade quality. The compact machine offers a high degree of

production flexibility for small and medium-size operations. Cost-effective

“QUADRO ROUND” with small footprint. Larger product volume (20-30%).

Shorter or no intermediate proofing required. Processing of doughs

with a long bowl resting period. Further modules such as resting zone,

longmoulding, stamping or cutting stations can be added; Self-supporting

sheet steel frame construction, stainless steel panelling; easy cleaning due

to simple design.

Kemper Bakery Systems - N.A. Subsidiary of the WPBAKERYGROUP . 3 Enterprise Drive . Suite 108 . Shelton . CT . 06484

Phone 203-929-6530 . Fax 203-929-7089 . sales@wpbakerygroupusa.com . www.wpbakerygroupusa.com

Options

– Stamping station

– Additional stamping tool

– Additional roller knife

– Additional moulding drum

– without roundmoulding station

– Depositing unit for “MINI QUADRO ROUND”

– Seeding unit in combination with set-down unit

– Seeding unit “KL” incl. dual moistening system

– Additional rotary plate

– Additional felt-lined rotary plate

– Longmoulder for “MINI QUADRO ROUND”

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...