Page 1

WP BAKERYGROUP

Matador V 1/2

Deck Baking Oven 01.02.2008

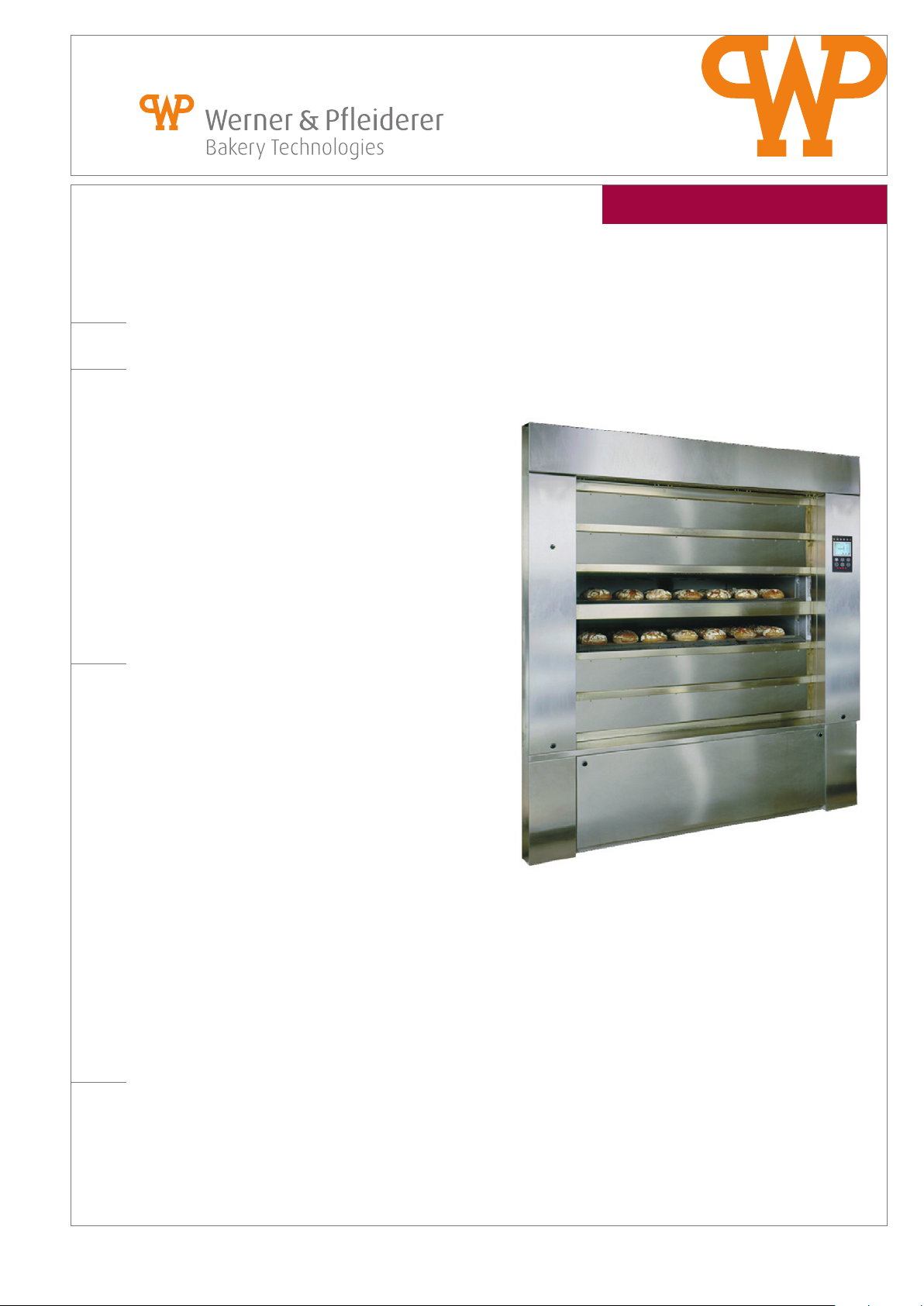

MATADOR V Deck Baking Oven

Ideal production oven for use with semi- and fully automatic

loading machines. Baking area from 8 to 43 m²

Application

The MATADOR Deck Baking Oven is suitable for baking bread, tin loaves (toast bread), rolls and fine pastry.

Specification

In standard design:

– with special stone baking plates

– with smooth front

– with integrated extractor

– with stainless steel doors

– with Navigo control

Advantages

Special hot gas flow control – Zyklotherm

– Absolute consistency of heat distribution even in the

sensitive front area of the oven

Dimensionally stable heating register

– Baking at highest temperatures e.g. for rye-content,

very crusty loaves

– Optimum base formation for all types of bakery products

– Unsurpassed consistency of baking results

High temperature variability

– Baking with flexible temperature curves possible

High performance piped steam system in the burner chamber

– Sufficient saturated steam for baking “batch for batch”

Steam distribution system

– Fast, even steam distribution in the baking chamber

Steam overpressure system

– Rapid exchange of dry hot air for steam

Steam extraction

– Rapid, force-fed de-steaming for steam-sensitive products and for baking crispness

High ovens

– Even heat radiation with still baking atmosphere are a guarantee for best baking and flavour development

Future-oriented design

– Upgradable with semi- or fully automatic loading systems

Burner installed on rear side of oven

– Loading unit can continue production at front side on other ovens during maintenance work.

Options

Navigo Plus control system

Draw-plate ovens

Combitherm

– with Navigo Plus control system – random temperature selection in the oven groups

– with Navigo control system – upper oven group colder

Similar to illustration

Page 2

Double width Triple width

MDV 80 MDV 100 MDV 144 MDV 150 MDV 180 MDV 220 MDV 230 MDV 260 MDV 430

Baking area m² 8 10 14 14.4 17.3 21.6 21.6 25.92 43.2

Ovens Length in mm 1,600 2,000 2,000 2,000 2,400 2,000 2,400 2,400 2,400

Width in mm 1,200 1,200 1,200 1,800 1,800 1,800 1,800 1,800 1,800

Number of ovens 4 4 6 4 4 6 5 6 10

Oven Length in mm ca. 2,659 3,059 3,059 3,059 3,459 3,059 3,459 3,640 3,900

Width in mm ca. 1,830 1,830 1,830 2,435 2,435 2,475 2,475 2,475 2,880

Height 2,310 2,310 2,800 2,310 2,310 2,800 2,521 2,800 4,300

Minimum required

room height

in mm 2,900 2,900 3,400 2,900 2,900 3,500 3,120 3,500 5,500

Number of

draw-plate ovens max.

Standard 2 2 – – – – – – –

Combitherm 2 2 – – – – – – –

Load per oven 1 kg traditional loaf 24 32 32 – 60 – 60 – –

Total load 1 kg traditional loaf 96 128 192 – 240 – 300 – –

Electrical connection for

fan and control system

in kVA 3.5 3.5 4.2 4.2 3.5 4 4.2 10 35

Heating output in kW 64 79 110 110 110 145 130 180 240

Operating possibilities Manual-loading possible X X X X X – X* – –

Only operable with loading system – – – – – X – X X

* Important! Top oven at a height of 1.9 m

Matador V 2/2

Deck Baking Oven 01.02.2008

MATADOR V

Technical details:

Controls

Navigo plus

– Fully automatic baking program with random-choice, freely

programmable baking stages

– Temperature curve progress

– Freely programmable per oven group

– Program-controlled automatic steam extraction

– Automatic steam regulator

– Freely programmable steam volume

– Recipe management + recipe storage card

(storing data)

– Pictogram control possible

– Possible oven control (networking of individual ovens)

– Recording of actual data for program optimization

– Manual operation possible

– Service menu with fault signal history

– With remote display per oven group

Oven-Control (in Navigo control system)

– Remote diagnosis via Internet

– Screen operation via Internet

– Networking of individual ovens

– Master Slave

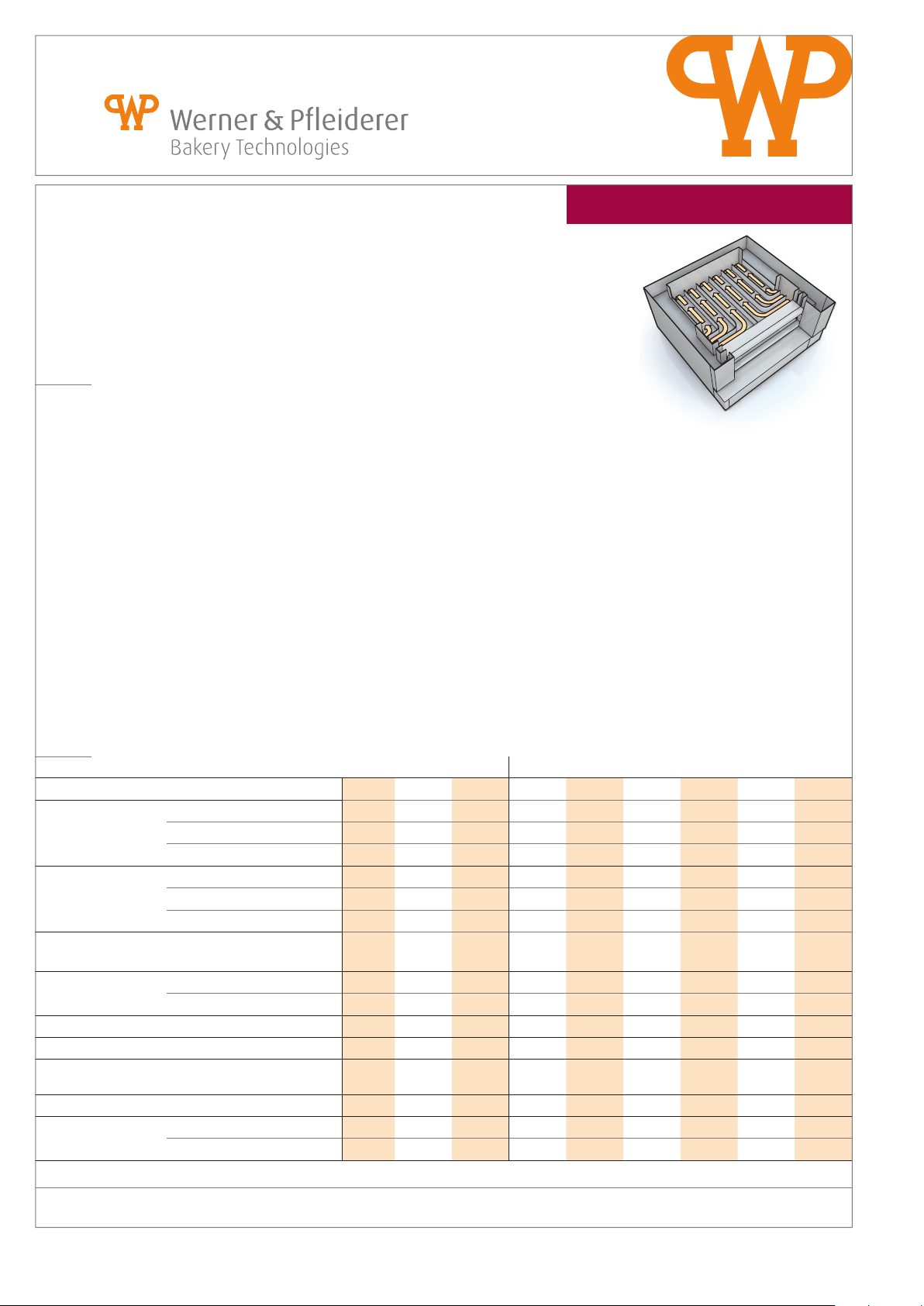

ZYKLOTHERM® heating system “special hot gas fl ow control”

Navigo

– Only one control panel

– Each oven is fi tted with a steam button for manual control of the steam

– Automated baking program with random-choice, freely programmable

baking stages

– Temperature curve progress

– Freely programmable per oven group

– Freely programmable steam volume

– Recipe management + recipe storage card

(storing data)

– Pictogram control possible

– Possible oven control (networking of individual ovens)

– Recording of actual data for program optimization

– Manual operation possible

– Service menu with fault signal history

The cross-section through the oven shows how the hot gas is fed through the channels by the shortest possible

route. It enters at the front in the most sensitive oven area. Real consistency is guaranteed by the unique

ZYKLOTHERM

®

heating system. Crispness, crustiness, even browning and full aroma development are guaranteed

as a standard with the MATADOR.

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

WP BAKERYGROUP

Werner & Pfl eiderer Lebensmitteltechnik GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany

Fon +49 (0) 98 51-905-0 . Fax +49 (0) 98 51-905-342 . info@wp-l.de . www.wp-l.de

Loading...

Loading...