Page 1

WP BAKERYGROUP

MATADOR 1/2

Deck Baking Oven 26.02.2008

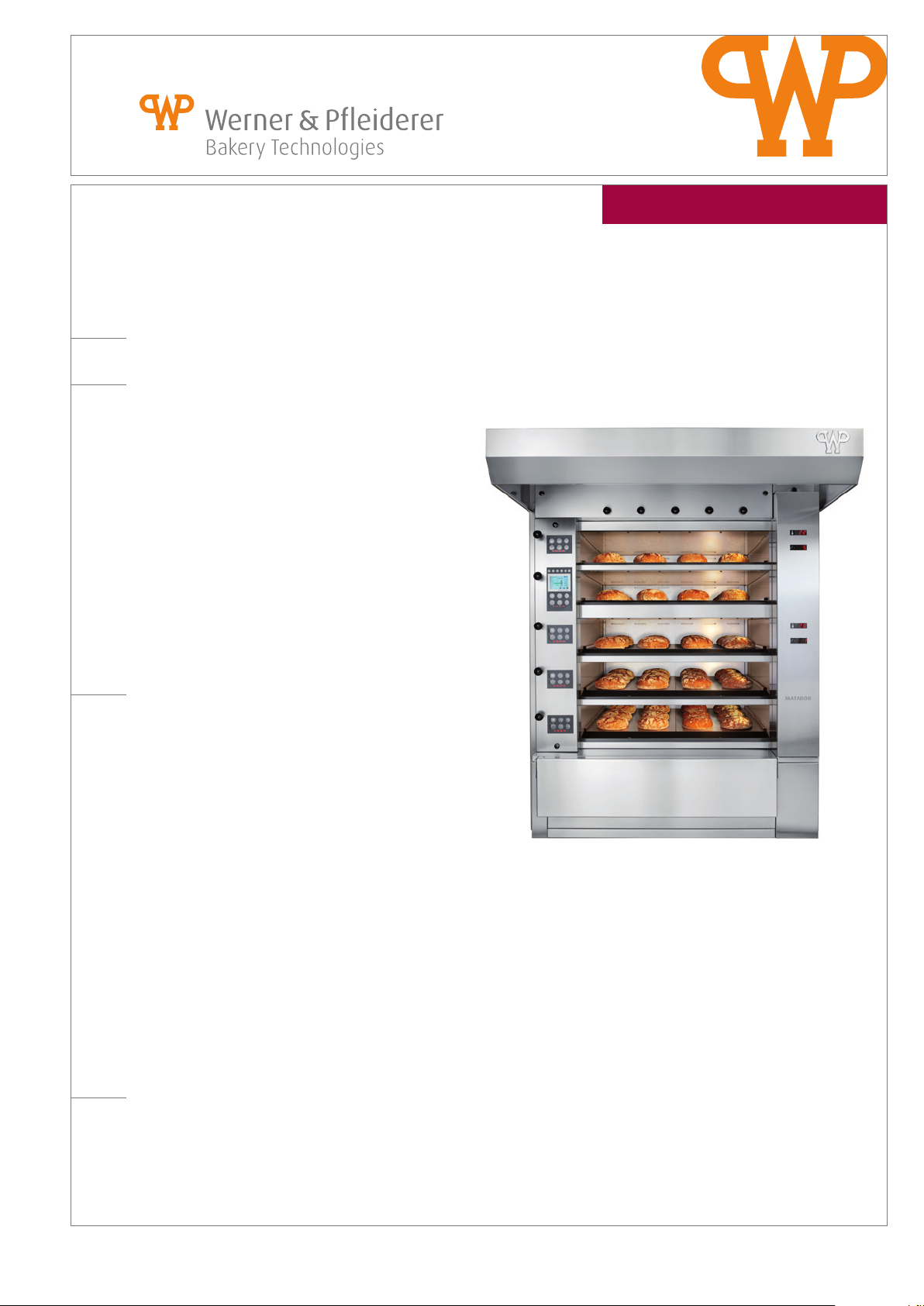

MATADOR Deck Baking Oven

Baking area from 86 to 205 sq.ft.

Application

The MATADOR Deck Baking Oven is suitable for baking bread, tin loaves (toast bread), rolls and fine pastry.

Operation

In standard design:

– with special stone baking plates

– with stainless steel baking chamber doors

– with Navigo control system

Advantages

Special hot gas flow control – Zyklotherm

– Absolute even spread of heat distribution even in the

sensitive front oven area

Dimensionally stable heat register

– Baking at maximum temperatures, e.g. for rye-based,

strong-crust loaves

– Optimum base formation for all types of bakery products

– Unsurpassable consistency of baking results

High temperature variability

– Baking possible with flexible temperature curves

High performance piped steam system in the burner chamber

– Sufficient saturated steam for baking "batch for batch"

Steam distribution system

– Fast, even steam distribution in the baking chamber

Steam overpressure system

– Rapid exchange of dry hot air for steam

Steam extraction

– Rapid, force-fed de-steaming for steam-sensitive products and

for baking crispness

High ovens

– Even heat radiation with still baking atmosphere are a guarantee

for best baking and flavour development

Future-oriented design

– Upgradable with semi- or fully automatic loading systems

Options

Navigo Plus or Navigo control system

Draw-plate ovens

Combitherm

– with Navigo Plus control system – random temperature selection in the oven groups

– with Navigo control system – upper oven group colder

Folding table

Stainless steel paneling for side and rear walls

Illustration: MATADOR with optional extras

Page 2

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

WP BAKERYGROUP

MATADOR 2/2

Deck Baking Oven 18.05.2009

MATADOR

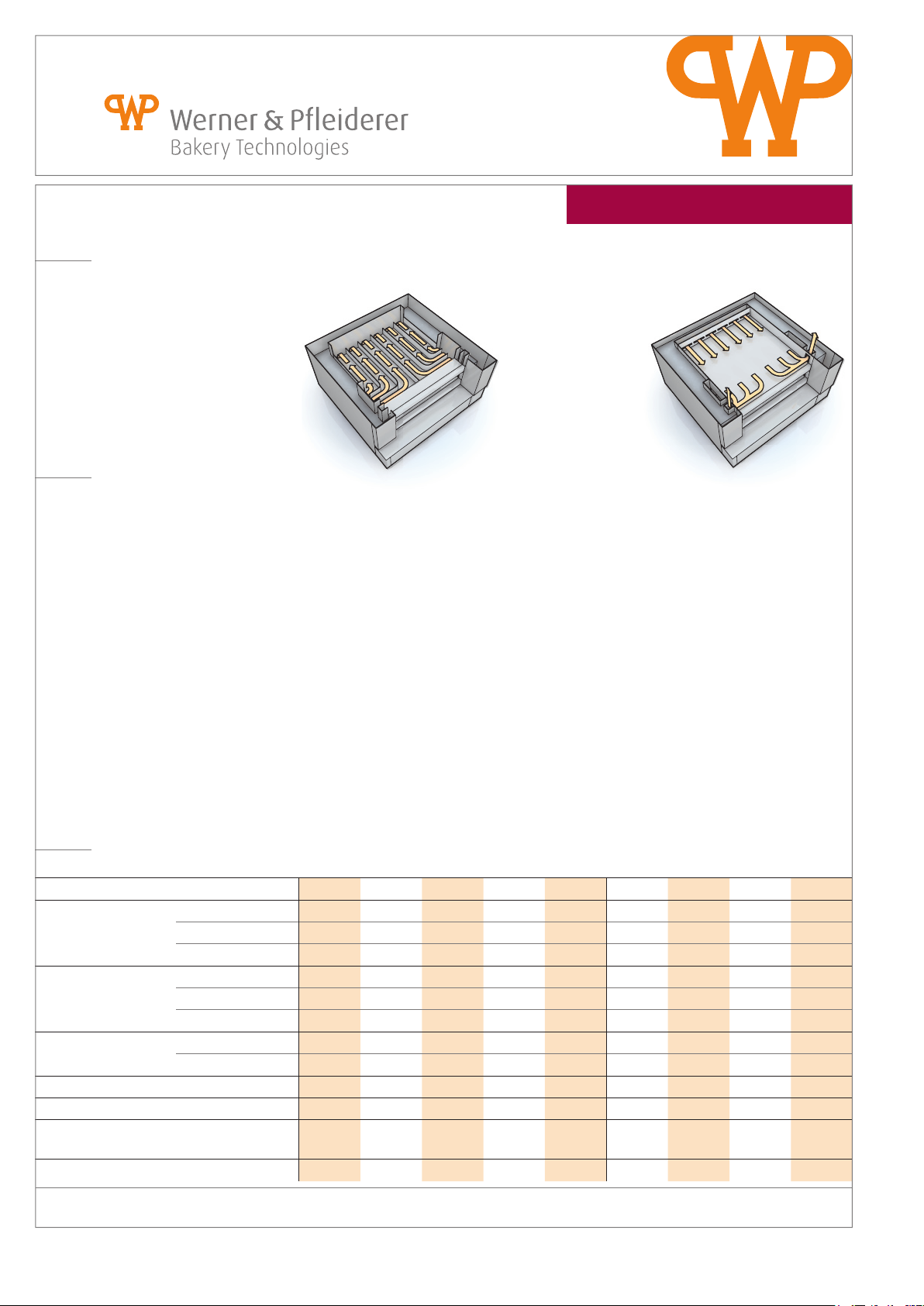

ZYKLOTHERM® heating system “special hot gas fl ow control” Saturated steam – steam distribution system

The cross-section through the oven shows how the hot gas

is fed through the channels by the shortest possible

route. It enters at the front in the most

sensitive oven area. Real evenness is

guaranteed by the unique

ZYKLOTHERM

Crispness, crustiness, even browning

and full fl avour development are

guaranteed with the MATADOR.

®

heating system.

Controls

Navigo plus

– Fully automatic baking program with random-choice, freely

programmable baking stages

– Temperature curve progress

– Freely programmable per oven group

– Program-controlled automatic steam extraction

– Automatic steam regulator

– Freely programmable steam volume

– Recipe management + recipe storage card

(storing data)

– Pictogram control possible

– Possible oven control (networking of individual ovens)

– Recording of actual data for program optimization

– Manual operation possible

– Service menu with fault signal history

– With remote display per oven group

Steam in excess, baking batch for batch – not

a problem for the MATADOR. Saturated

steam fl ows rapidly into the

ovens. 75% relative

humidity is already

achieved before the end of

the fi rst minute. The hot

baking chamber air is fed out

through exhaust fl aps together

with excess steam.

Navigo

– Only one control panel

– Each oven is fi tted with a steam button for manual

control of the steam

– Automated baking program with random-choice,

freely programmable baking stages

– Temperature curve progress

– Freely programmable per oven group

– Freely programmable steam volume

– Recipe management + recipe storage card

(storing data)

– Pictogram control possible

– Possible oven control (networking of individual ovens)

– Recording of actual data for program optimization

– Manual operation possible

– Service menu with fault signal history

Oven control (in Navigo control system)

– Remote diagnosis via Internet

– Screen operation via Internet

– Networking of individual ovens

– Master Slave

Technical details:

MD 80 MD 100 MD 101 MD 122 MD 125 MD 121 MD 150 MD 151 MD 190

Baking area sq.ft 86 108 108 129 135 129 161 161 205

Ovens Length in inch 63 79 63 63 79 63 79 63 79

Width in inch 47 47 47 47 47 71 71 71 71

Number of ovens 4 4 5 6 5 4 4 5 5

Oven Length in inch approx 100 116 104 104 120 100 116 104 120

Width in inch approx 72 72 72 72 72 96 96 96 96

Height in inch approx 91 91 91 91 91 91 91 91 91

Number of

draw-plate ovens max.

Load per oven 1 kg traditional loaf 24 32 24 24 30 36 48 36 48

Total load 1 kg traditional loaf 96 128 120 144 160 144 192 180 240

Electrical connection for

fan and control system

Heating output in kW 64 79 79 90 90 88 110 110 122

Kemper Bakery Systems - N.A. Subsidiary of the WPBakeryGroup . 3 Enterprise Drive . Suite 108 . Shelton . CT . 06484

Phone 203-929-6530 . Fax 203-929-7089 . sales@wpbakerygroupusa.com . www.wpbakerygroupusa.com

Standard 2 2 3 - 3 2 2 3 3

Combitherm 2 2 3 - 3 2 2 3 3

in kVA 4.2 4.2 5.3 5.3 5.3 5.3 5.3 6.6 6.6

Double width Triple width

Loading...

Loading...