Page 1

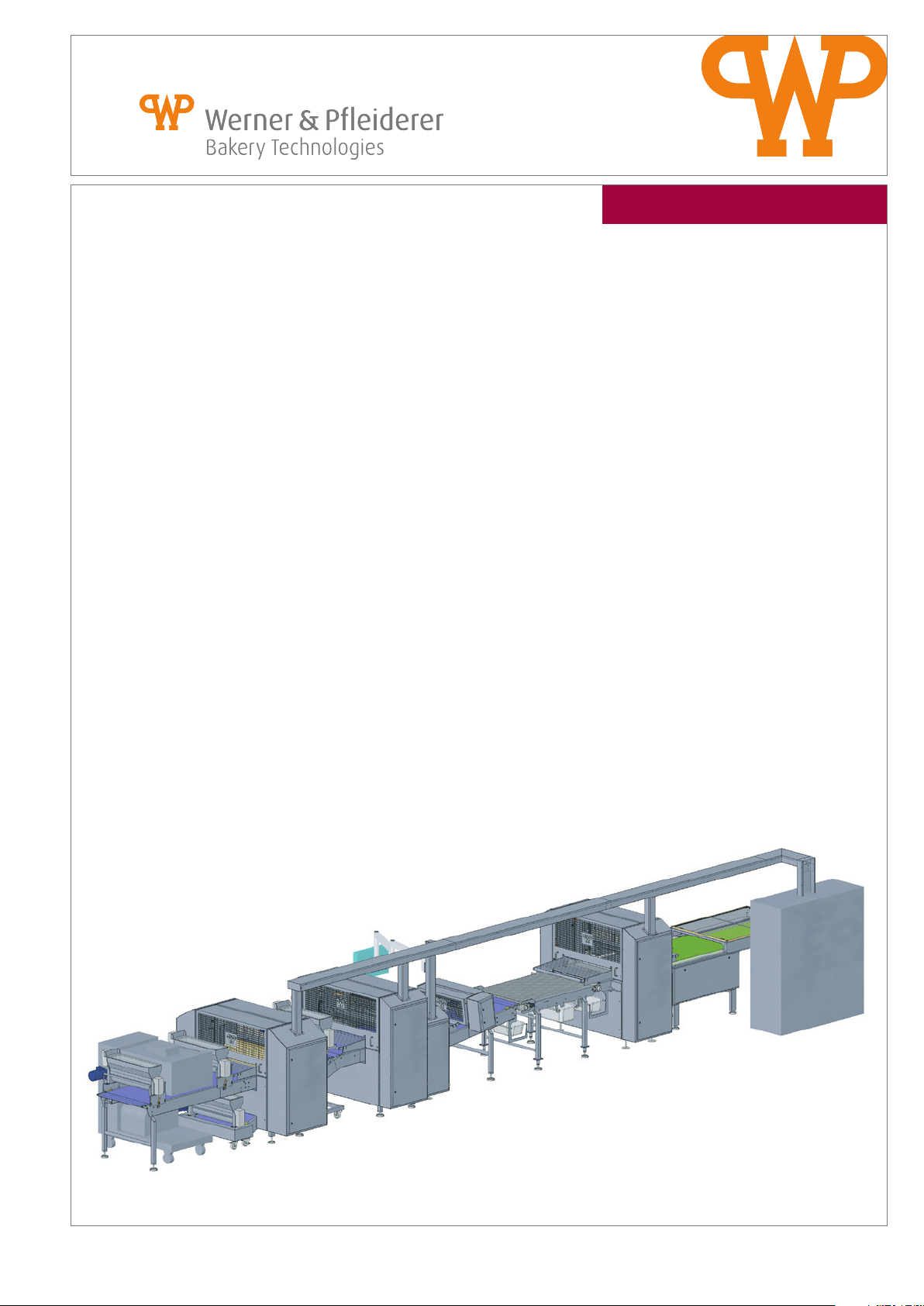

MAGICLINE

Laminating plant with modular design

MAGICLINE is a new laminating plant concept

from Werner & Pfleiderer with which it is possible

to assemble the ideal line for a multitude of

dough types and recipes. New is the modular

structure is, the possibility to put together the

desired individual configuration from a range

of functional modules: The user defines his

requirements, we create the optimal configuration

for him.

WP BAKERYGROUPWP BAKERYGROUP

MAGICLINE 1/2

modular laminating plant 01.02.2008

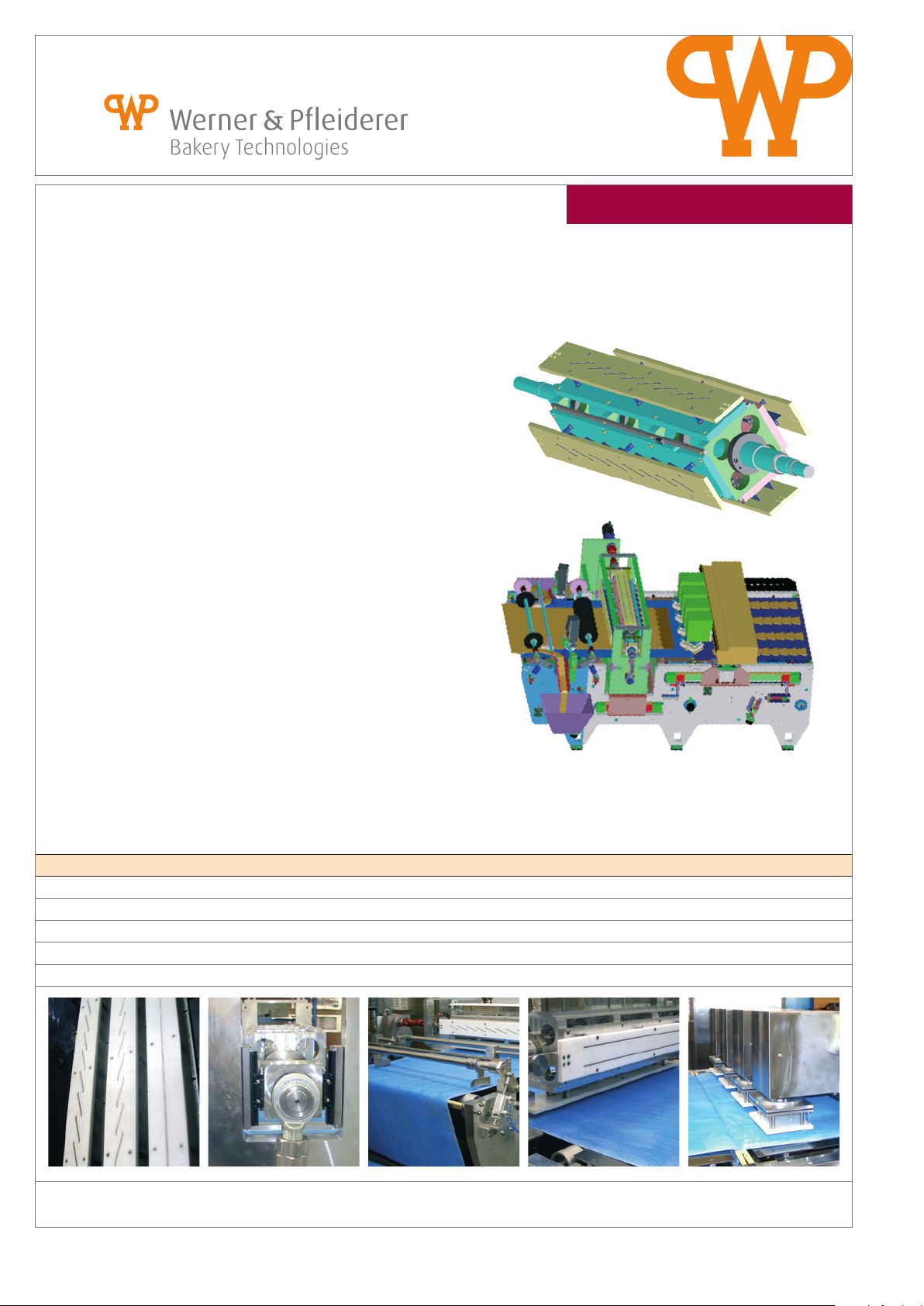

NEW The dough sheet former is equipped with adjustable scrapers, which make it

possible to exactly loosen the dough sheet from the form roller in exactly the right

position according to the required dough path.

NEW With the integrated duo satellite head (with exchangeable rollers) the dough

sheet is extremely gently, evenly but very effectively worked from both sides at

the same time. This processing step is largely responsible for the later volume of

the product and its even form. The dough sheet is reduced to the required thickness

without changing its structure.

During the development of the line, the gentle

processing of the dough was always given

priority – it is pressed and not stretched in

particular, the use of a second satellite head

on the under side helps to ensure the gentle

processing. The dough stays free of tension and

keeps its texture, it does not stick.Dry and even,

it is the ideal basis for further processing steps.

The key part of the plant is the dough sheet

former which forms the base product, a

continuous dough sheet with all parameters

finely maintained. Various functional modules

are used for processing, cutting, folding, filling

and strewing. The exact thickness of the dough

sheet is computer-controlled according to the

recipe. Variable widths means a wide product

range; the fine adjustment minimises the waste.

A cross roller, whose speed and working width are variable, increases the width

of the dough sheet to the desired size. The following calibrating head with Teflon

coated rollers smoothes the surface and reduces the dough sheet to its final

thickness. With the following modules the cutting width and length and/or the final

form and surface finish are realized.

A special characteristic with large products is the possibility for the Guillotine

to move along the belt with the product and thus make a clean cut.

Through the employment of a Check weigher small deviations in the volume

weight can be corrected automatically by changing the cutting length.

For processing very soft doughs and doughs with long proofing times the Relaxer

from WP Kemper is used as a pre-portioner; Driven, floured belts running between

the side guides form the necessary dough sheet. Also in this application the

thickness of the dough sheet is reduced using the duo satellite head, without

damaging its structure.

Page 2

MAGICLINE

Cross-cutting with the revolver cutter – the advantages

NEW Revolver cutting head for trimming, long cutting and

cross cutting the dough sheet, for positioning and placing the

dough pieces

– computer controlled tool changing

– One tool bar with four knife combinations

– Cutting in single lines and not in closed shape

– Separation of the dough pieces in the running direction

by moving the cutting unit

– Cutting tool with scraper plate

– Separation of cutting and spreading = a clean cut

– Gentle dough processing in the Steps „cutting and turning”,

the dough pieces are not damaged

– Product changes are simple, no tools are necessary

– Production is reliable because there are few components

and dough rest is avoided

– Easy cleaning helps compliance with hygiene regulations

– Product weight can be precisely set by finely adjusting

the length of the dough pieces

WP BAKERYGROUP

MAGICLINE 2/2

modular laminating plant 01.02.2008

Technical data Revolver cutter, spreader and coiler

Process step Dough sheet forming Turning Coiling

Working width 500 – 900 mm 500 – 1,100 mm 500 – 1,100 mm

No of rows – 1 – 9 1 – 4

Stroke rate – 50/Min = 3,000/h 30 – 50/Min = 1,800 – 3,000/h

Production (Stroke rate x no of rows) – 3,000 – 27,000/h 1,800 – 12,000/h

Stroke rate, row number and production rate/h are all dependent on the product parameters Dough piece geometry, size and dough charateristics

Werner & Pfleiderer Lebensmitteltechnik GmbH. von-Raumer-Straße 8-18. 91550 Dinkelsbühl. Germany

Fon +49 (0) 98 51-905-0. Fax +49 (0) 98 51-905-342. info@wp-l.de. www.wp-l.de

All details non-binding. Subject to change in the course of technical progress. All rights reserved.

Loading...

Loading...