Kemper KHS Mini Control System MASTER 2.0, KHS Mini Control System SLAVE Installation And Operating Instructions Manual

Page 1

Installation and Operating instructions

KEMPER KHS Mini Control System

KHS Mini Control System MASTER 2.0 Figure 686 02 008

KHS Mini Control System SLAVE Figure 686 02 006

Page 2

K410068602008-00 / 09.2018 2

TABLE OF CONTENTS

INFORMATION ....................................................................................... 3

1.1 Precautions ................................................................................................. 3

1.2 Important advice to the operator ................................................................... 3

1.3 Technical Data............................................................................................. 4

1.4 Scope of delivery | Accessories ...................................................................... 5

INSTALLATION ....................................................................................... 6

2.1 Wall mounting ............................................................................................. 6

2.2 Electrical installation .................................................................................... 7

2.3 Bus system overview .................................................................................. 11

COMMISSIONING ................................................................................. 14

3.1 Menu navigation ......................................................................................... 14

3.1.2.1 System settings ........................................................................................ 16

3.1.2.2 CAN bus setup .......................................................................................... 18

3.1.2.3 Device settings .......................................................................................... 19

3.1.2.4 Operating modes ....................................................................................... 23

3.1.2.5 Logbook ................................................................................................... 27

3.1.2.6 Change Program........................................................................................ 27

3.1.2.7 Valve manual mode ................................................................................... 28

ACKNOWLEDGE ERROR ......................................................................... 30

USB INTERFACE .................................................................................... 30

WEB BROWSER ..................................................................................... 31

6.1 Basic menu operation and functions .............................................................. 31

6.2 System settings .......................................................................................... 33

6.3 Device settings ........................................................................................... 35

6.4 Operating modes ........................................................................................ 50

6.5 Overview ................................................................................................... 60

6.6 Current values ............................................................................................ 61

6.7 Data transfer.............................................................................................. 62

6.8 E-Mail administration .................................................................................. 67

ERROR DESCRIPTION AND ERROR HANDLING ..................................... 69

ACCESSORIES | SPARE PARTS .............................................................. 71

KHS CABLE LIST ................................................................................... 73

APPENDIX ............................................................................................ 74

10.1 Valve technologies ...................................................................................... 74

10.2 Overview for system commissioning .............................................................. 76

Page 3

K410068602008-00 / 09.2018 3

INFORMATION

For installation, maintenance and operation

Installation and operation

Read the manual and follow the instructions

before installation!

Installation and maintenance must be carried

out by qualified plumbers.

Provide the manual to the plant operator and

keep on hand for further reference!

Make sure that the installation location is

frost-proof and not prone to flooding.

Priority must be given to the national

standards and provisions on sanitary

installations and accident prevention.

Warranty

No warranty in case of:

- Non-compliance with the manual.

- Damage due to incorrect installation.

- Unauthorised modification of the product.

Use

Thanks to the MASTER/SLAVE technology,

KHS Mini Control System can be used to

implement specific water exchanging

measures to maintain drinking water

hygiene. For each individual water

exchange group, time or temperaturecontrolled water exchange can be

configured individually or according to a

specified water volume.

Only skilled professional personnel are

permitted to operate electrical systems in

accordance with DIN EN 50110-1.

Do not use the device for other purposes

than described above in non-freezing

interiors. Any other uses constitute misuse.

Warnings used in the manual:

Warning!

Highlights risks that may result

in injury, material damage or

contamination of drinking

water.

Note!

Highlights risks that may result

in damage to the plant or

dysfunction.

▪ The reliability of the supplied unit is

only ensured when used as intended.

Never exceed the limits stated in this

documentation under any circumstances

▪ During assembly and maintenance,

make sure that the control is not

switched on.

▪ Use only original/approved spare parts

otherwise no warranty claims will be

recognized.

▪ Be sure to comply to local regulations

on waste recycling and disposal.

Page 4

K410068602008-00 / 09.2018 4

Technical Data

Operating voltage

230V, AC, 50 / 60Hz

Power input for the unit

10 W

Relay flushing valve output

230 V, 2 A

Relay alarm output

max. 230 V, 2 A

CAN bus subscribers

max. 62

Logbook entries

max. 50,000

Datalogging entries

max. 12 million

Ambient temperature range

0 °C to + 50 °C

Degree of protection

IP 54

Dimensions

200 x 130 x 60 [mm]

Integrated user interface (display + 4 keys)

▪ Settings

▪ Configuration

▪ System overview

▪ Data transfer

Network interface for web-based user

interface

▪ Settings

▪ Configuration

▪ System overview

▪ Data transfer

▪ E-mail management (fault message)

USB interface for USB mass storage

▪ Firmware update

▪ Web server update

▪ Reading out the flushing log

▪ Reading out the logbook

▪ Reading the configuration in and out

Language menu

▪ German

▪ English

▪ Dutch

Operating modes

Time controlled water exchange

Temperature controlled water exchange

Volume controlled water exchange

Routine

Datalogging

Backup

External switch function

▪ Change program

▪ System lock / Maintenance operation

Page 5

K410068602008-00 / 09.2018 5

Art.-No.

H1

[mm]

L1

[mm]

T1

[mm]

6860200800

120

200

58

Fig.

686 04

686 05

688 00

628 0G

138 4G

685 15

689 06 001

689 06 002

Page 6

K410068602008-00 / 09.2018 6

Installation

Allow only certified electricians to assemble and install electrical equipment.

Danger of fatal electric shock.

Rigid leads must form a loop for wiring so that there is no pressure on the

terminals and the housing closes without resistance.

Ill. 1 Illustration of the mounting holes for wall installation

Disturbance

space

Please pay attention to the disturbance space when installing the Control

System.

Left-hand side: Serial number of the KHS Mini Control System

Right-hand side: USB slot

Page 7

K410068602008-00 / 09.2018 7

Page 8

K410068602008-00 / 09.2018 8

2.2.1 Connection of the components

Terminal

characters

Meaning

1

Flushing valve – Switching output 230V

2

L (+)

Flushing valve – Voltage output 230V

3

N (-)

Flushing valve – N

4

L (+)

Power supply – L1 230V

5

N (-)

Power supply – N

6

SW IN

External input - 230V (MASTER only)

7

PE

Protective earth conductor – PE

8

H

A CAN bus – High

9

L

A CAN bus – Low

10

GND

A CAN bus – Ground

11

H

B CAN bus – High

12

L

B CAN bus – Low

13

GND

B CAN bus – Ground

14

+ 5V

Flow measurement valve – Voltage output 5V

15

FLOW

Flow measurement valve – Flow input

17

GND

Flow measurement valve – Ground

18

Input 1 Pt1000

19

Input 1 Pt1000

20

Input 2 Pt1000

21

Input 2 Pt1000

22

IN

Free drain / water sensor (conductors interchangeable)

23

IN

Free drain / water sensor (conductors interchangeable)

24

Alarm relay – External voltage input

25

Monitoring of ext. voltage = Fault

26

Monitoring of ext. voltage = Operation

24

25

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

Page 9

K410068602008-00 / 09.2018 9

KHS isolating valve + spring reset (Fig. 686 05)

KHS isolating valve (Fig. 686 04)

KHS CONTROL-PLUS (Fig. 138 4G)

[4] → bn (BN) = L

[5] → bu (BU) = N

[7] → ye/gn (YE/GN) = PE

L N PE

230V 230V +/- 10% AC 50/60Hz

Back-up fuse max. 16A

[6] → bn (BN) = L

Switch

230V 230V +/- 10% AC 50/60Hz

Back-up fuse max. 16A

[1] → bn (BN)

[2]

[3] → bu (BU)

bn bu

[1] → bn (BN)

[2] → bl (BK)

[3] → bu (BU)

bn bl bu

[14] → bn (BN)

Pt 1000 (optional) [15] → bu (BU)

[17] → bl (BK)

[18]

bn bu bl gy wh [19] → gy (GY) = Pt 1000 (optional)

[20] → wh (WH) = Pt 1000 (optional)

[21]

If the temperature is measured

using the CONTROL-PLUS, the

jumper on the board must be

changed from 4-wire to 2-wire.

Page 10

K410068602008-00 / 09.2018 10

KHS temperature measurement valve

(Fig. 628)

KHS Free Drain (Fig. 688 00)

Water sensor for leaks (Fig. 620 00)

Potential-free alarm relay

[22] → ws (WH)

[23] → br (BN)

ws br

In the as-delivered state, a

cable bridge is plugged

between Terminals 22 and

23. This must be removed

before connecting the KHS

Free Drain.

[22] → wh (WH)

[23] → bn (BN)

wh bn

In the as-delivered state, a cable

bridge is plugged between

Terminals 22 and 23. This must

be removed before connecting the

KHS water sensor.

[24] → 230V (2A) / 24V

[25] → OUT (fault)

[26] → OUT (operation)

230V (2A)

24V

Monitoring example: Faults and

mains voltage failures are reported

with external voltage to the

network warning lamp, the

warning horn or to the BMS.

ws

rt

BMS

Warning lamp

Signal horn

Page 11

K410068602008-00 / 09.2018 11

2.3.1 CAN bus cable

Bus cables for the wiring of CAN bus systems (controller area network) in accordance with

ISO 11898 must be used for bus systems with 120 Ω nominal impedance. Only when such

cables are used can a high level of data transfer security be guaranteed.

Recommended properties for the CAN bus cable

Cable type

CAN bus cable

Conductor material

Kupfer

Conductor cross-section and number of

wires

Cross-section Length

1 x 2 x 0,34 mm²

1 x 2 x 0,50 mm²

1 x 2 x 0,75 mm²

300 m

500 m

1000 m

Shielding

Braiding of tinned copper wires

Impedance at f ≥ 1Hz

120 Ω ± 15 %

2.3.2 CAN-Bus-Anschluss

Components

Designation

Number

of subscribers

per component

Max. number of

components per

-MASTER-

Control System SLAVE

1

62

KHS HS2 Hygiene

flushing box with one

connection

+

Can bus connection set

1

60

KHS HS2 Hygiene

flushing box with two

connections

+

Can bus connection set

2

30

The KHS Mini Control System has two

integrated CAN bus connections with

which up to 62 CAN bus participants can

be addressed. A maximum of 31 bus

subscribers can be connected to each

CAN bus connection.

max. 31 CAN

bus subscribers

max. 1000 m

(in total)

max. 31 CAN bus

subscribers

max. 1000m (in

CAN bus

Connection B

CAN bus

Connection A

2

1

Page 12

K410068602008-00 / 09.2018 12

KHS HS2

KHS HS2

KHS HS2

2.3.3 CAN bus subscriber arrangement

2.3.4 CAN bus cable connection

Wrong topology! Only line

topology allowed!

RIGHT

RIGHT

WRONG

Device 1

Device 2

CAN bus cable 1

CAN bus cable 2

Page 13

K410068602008-00 / 09.2018 13

2.3.5 Terminal resistor

The 120 Ω terminal resistor may only be installed in the last control component of a CAN bus

cable. The MASTER does not require a terminal resistor.

2.3.6 Connection of terminal resistor

All KHS Mini Controls

-SLAVE- are supplied with a

120 Ω terminal resistor.

For non-terminal SLAVE

controls, the resistor must

be removed!

Page 14

K410068602008-00 / 09.2018 14

Commissioning

Before commissioning, make sure the

connections have been made properly and

professionally and that the system is

properly protected. The pertinent

regulations (EN, VDE, etc.) and the

regulations of the local energy utility must

be complied with. After finishing the wall

installation and the electrical installation,

apply the mains voltage of 230V.

Allow only certified electricians to assemble and install electrical equipment.

Danger of fatal electric shock.

To simplify configuration and to guarantee correct installation, fill in the

system commissioning overview of the KHS Mini Control System (see supply

pressure, Chapter 10.2) before making the settings.

It is mandatory to fill in the form to be able to take advantage of the

optional factory support.

All menus have a "rolling" structure, i.e.,

pressing the "↓ key" on the last menu item

jumps back to the first menu item.

Keys

Description

Esc

Exit the menu / switch between overview and main menu

Roll backwards

OK

Confirm key

Roll forwards

The menu navigation of the KHS Mini Control System –MASTER 2.0– is divided in two types of

windows.

Window types

Description

General plan

The "General plan" window is used only for visualising the current

states. Viewing possible without password.

Main menu

Preset parameters can be viewed, changed and saved. Viewing not

possible without password.

14

Page 15

K410068602008-00 / 09.2018 15

3.1.1 General plan

The following illustrations explain the symbols of the "General

plan" menu interface of the KHS Mini Control System -MASTER

2.0-.

Symbol

Meaning

MAS

Overview -Master-

SLXX

Overview -SLAVE- with the number XX

HSXX

Overview KHS HS2 with the number XX

KHS VAV maximum flow isolating ball valve with servo drive created

KHS VAV maximum flow isolating ball valve opened

CAN bus of the Control System active

Fault detected

Leakage monitoring of Control System active

Flow sensor created (symbol flashes: flow control is active)

Symbol flashes: Time control activated

Temperature sensor created (symbol flashes: temperature control is

active)

P1 / P2

Activated program for the program switchover

1/8

Sheet 1 of 8

Detailed overview

*: A frame appears around the entry of the first

controller on the selected sheet (see 1). Pressing the

OK key once more opens the "Detailed overview" (see

2) of the selected control. Alternatively, press the ↑ or

↓ key to select another controller. The following table

describes the possible content of the detailed views.

Symbol

Meaning

Safety device

Safety valve closed or open

Temperature

Current value of the connected temperature sensor

Flow

Current value of the connected volume flow sensor

Volume

Volume of the last or current water exchange

Flushing duration

Volume of the forthcoming or current water exchange

SNo:

Serial number of the selected Control System

1x „OK“ Selects control (frame*)

2x "OK" Changes into detailed overview

2

1

Page 16

K410068602008-00 / 09.2018 16

3.1.2 Main menu

Main menu item

Function

System settings

Basic system settings (language; time; etc.)

CAN bus setup

Assignment of the Control System to the CAN bus

network

Device settings

Assignment of the actuators and sensors

Operating modes

Setting the operating modes for each water exchange

group

Logbook

Access to the event log

Program switchover

Settings for the program switchover

Manual valve operation

Specific manual operation of certain valves

Network setup

Settings for integration into an existing network

3.1.2.1 System settings

Language

Time

Date

S/W automatic

Alarm buzzer

Page 17

K410068602008-00 / 09.2018 17

Key press signal

Display contrast

Display illumination

Password

To protect the controller from unauthorised

external influences, a password can be

configured. If a password has been stored,

the password will be queried before every

setting.

Factory settings

Reboot the MASTER

All previous configurations will be lost!

The password "0000"

is the factory default

setting.

Page 18

K410068602008-00 / 09.2018 18

3.1.2.2 CAN bus setup

Before device settings can be made, the

Control System or KHS HS2 hygiene

flushing boxes, which are connected to

the -MASTER 2.0- by the CAN bus

cable, must be added to the CAN bus

network using the menu item "CAN Bus

Setup". The serial numbers of

connected devices are automatically

listed, and are assigned to a SLAVE in

the system.

Adding devices

Term

Meaning

SL XXXXXX

KHS Mini Control System -SLAVE- including serial number

HS XXXXXX V1 / V2

KHS HS2 hygiene flushing box including serial number

HS XXXXXX V1 / V2

Valve of the KHS HS2 hygiene flushing box (V2 = left; V1 =

right)

Deactivated

No device is added to the selected SLAVE

Serial number

Serial number KHS Mini Control System -SLAVE-

Serial number KHS HS2 Hygiene flushing box

Even if the KHS HS2

has two valves, it

only has one serial

number.

Ser.Nr.: XXXXXX

S/N: XXXXXX

Page 19

K410068602008-00 / 09.2018 19

Main view

When all the devices have been added,

they are displayed in the main view, as

shown below. The individual devices can

then be configured in Device settings.

3.1.2.3 Device settings

In the "Device settings" submenu, the

individual Control System are logically

assigned to the integrated actuators

and sensors. The valve control type is

also determined.

Control type

Description

B valve

Terminal flushing valve, with several A valves hydraulically

preconnected.

A valve

Flushing valve which switches the water exchange for one line.

C valve

Terminal flushing valve for one line.

Safety device

Valve which protects a distribution line.

Only

measurement

Slave for the acquisition and long-term monitoring of sensor

values.

Configuration of the B Valve

Device selection Control type

Valve

See Miscellaneous settings

Check to see if the antenna icon can always be

seen and if the LEDs light up green on all KHS

Mini Control System. Only then has a proper

connection been established.

When using A/B valve technology, always make sure that the B valve is

configured first. A valves can then be assigned to the B valve. The assignment

of the A valves is shown in the following. For information on valve technology,

please see Chapter 10.1.

Page 20

K410068602008-00 / 09.2018 20

See Miscellaneous settings

Configuration of the A Valve

Device selection Control type

B valve

See Miscellaneous settings

Configuration of the C Valve

Device selection Control type

Valve

See Miscellaneous settings

Configuration of the safety device

Device selction Control type

Valve

You are recommended not to link more than 5 A valves to one B valve.

Page 21

K410068602008-00 / 09.2018 21

Configuration of flow measurement

Device selection Control type

Select sensor

Select sensor

See Miscellaneous settings

Configuration of volume flow sensor

Select sensor

Configuration of temperature sensor

Select sensor

Medium Frsot protection limit Target temperature

see Configuration

of volume flow

sensor

See Configuration

of temperature

sensor

The measuring range of the sensor can be determined by means of a sticker

on the installed flow measurement valve.

Page 22

K410068602008-00 / 09.2018 22

Miscellaneous settings

Alarm relay setting

Operating cylce reset

Software version

HS2 Simultaneous opening of V1/V2

Alarm in the event of the Control System own

faults, or in the event of system faults.

After 20,000 operating cycles of a flushing valve,

a maintenance request is generated. After

maintenance, the operating cycles of the actuator

should be reset.

Overview of the software version of the selected

Control System.

Setting for the simultaneous opening of two

valves in a KHS HS2.

Depending on the flow rate, the following

instructions apply with regard to sound protection

and free discharge.

V1 V2 V1 V2

OK OK OK

OK OK OK OK

OK OK OK OK

4 l/min

> 15 l/min

15 l/min

10 l/min

Page 23

K410068602008-00 / 09.2018 23

3.1.2.4 Operating modes

In the "Operating modes" submenu, programs and times are added to the actuators and

sensors.

Mode

Description

Time Control

Triggers a water exchange of defined duration at a certain

point in time.

Temperature control

Triggers a water exchange when a predefined start

temperature is reached, until a predefined stop temperature

is reached.

Volume control

Triggers a water exchange with a defined flush volume at a

certain point in time.

Backup

Backs up a distribution line by means of a water sensor in a

predefined time window.

Datalogging

Acquires sensor values in a predefined time window with a

predefined sampling rate.

Routine

Triggers a water exchange for a predefined duration or

quantity if a temperature control has not actuated for a

certain time.

If two or more valves are simultaneously opened in a drinking water

system, under certain circumstances pressure fluctuations or a large

pressure drop can occur in the system. For that reason, make sure

beforehand that the required flow pressure is continuously guaranteed at

all tapping points. You are recommended not to perform simultaneous

water exchanging measures.

If the program switch is "Activated" (see Chapter

3.1.2.6), a query is presented during the operating

modes configuration to determine the program this

applies to (see right). The two mentioned flushing

programs can be switched using an external

manual switch. The electrical connection is shown

in Chapter 2.2.

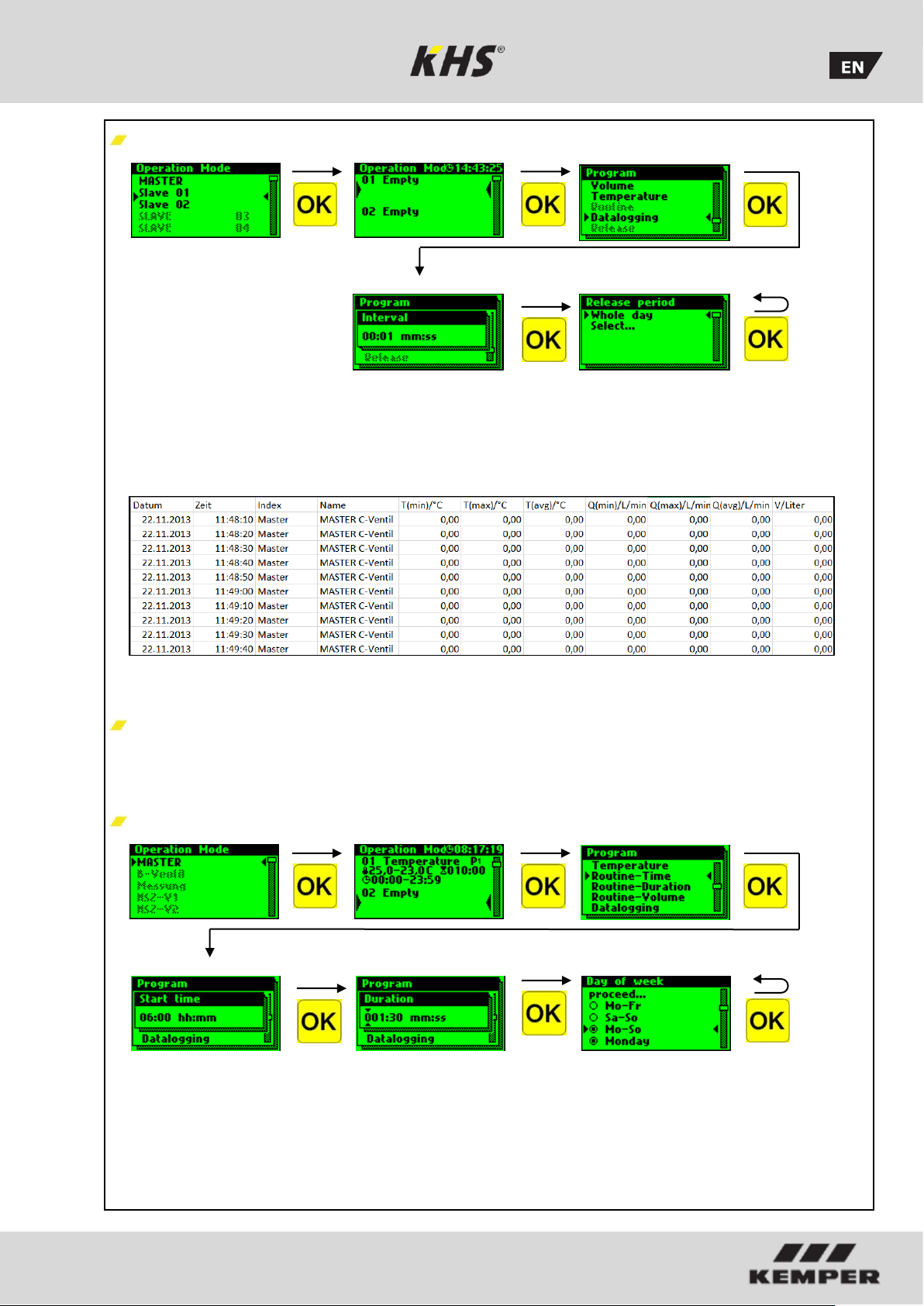

Configuration of time control

Page 24

K410068602008-00 / 09.2018 24

Configuration of volume control

Configuration of temperature control

Configuration of the safety device

Page 25

K410068602008-00 / 09.2018 25

Configuration of datalogging

The following shows an exemplary

extract from a CSV log file. In the written

log file you can find a detailed listing of

the entire measured data. They are

sorted by date, time, index, name and

the measured data of the connected

measurement valve. Up to 12 million

lines can be saved.

Routines

If temperature flushing is configured, a

routine duration is automatically

activated. Generally speaking, it is

possible to choose between the following

routines:

Routine time

Page 26

K410068602008-00 / 09.2018 26

Routine Duration

Routine Volume

After your Control System have been successfully configured, you are

recommended to save the configuration as a backup file. If the KHS Mini Control

System -MASTER 2.0- is defective it can be quickly replaced and the

configuration can be read in. This saves having to configure everything again.

Page 27

K410068602008-00 / 09.2018 27

The two mentioned flushing programs can be switched using an external

manual switch. The electrical connection is shown in Chapter 2.2.

3.1.2.5 Logbook

The "Logbook" submenu provides a

facility for opening event logging. Press

the "↑" and "↓" keys to change between

the individual logbook entries. The

event log documents the water

exchange operations, error messages

and configuration changes made by the

Kemper KHS Mini Control System (see

the following illustration).

Up to 50,000 logbook entries can be

saved.

... ....

Ill: Illustration of a logbook entry index 9-10, configuration change

3.1.2.6 Change Program

With the KHS Mini Control System MASTER 2.0- it is possible to switch

between two flushing programs or to

block them using an external switch. The

programs can also be activated or

deactivated in the "Switch program"

submenu. The "External input" or

"External switch" can be assigned to a

program switch in this submenu.

Progr. Switchover Progr. Deactivate switchover

Block system/select program

Select external input action

The stored logbook entries can be saved through the USB interface on a USB

memory stick. This function is explained in detail in Chapter 5.

Page 28

K410068602008-00 / 09.2018 28

3.1.2.7 Valve manual mode

With the KHS Mini Control System MASTER 2.0-, it is possible to run a

function test of the valves using the

"Valve manual mode" submenu.

Furthermore, the valves can be

individually addressed during

maintenance. The functions are shown in

the following illustration.

Maintenance:

A function test is recommended after configuring the "Device settings"

submenu to rule out possible errors immediately.

Valve manual mode Select system crtl. Automatic mode

Open

Closed

3.1.2.8 Network setup

To establish a connection between the PC

and the KHS Mini Control System MASTER 2.0-, the required network

configurations can be set up in the

"Network setup" submenu.

Connection

Description

PC ↔ MASTER

The IP addresses of the two devices should not differ greatly

from each other.

PC ↔ LAN ↔ MASTER

You can obtain the appropriate parameters for integration

into your network from your system administrator

The following parameters are configured as factory defaults:

IP-Adresse: 10.1.23.150

Subnet: 255.255.255.0

Gateway: 10.1.23.1

Page 29

K410068602008-00 / 09.2018 29

Nework setup Setting the IP address

Setting the gateway

Setting the network mask

Prim. DNS Server einstellen

Setting the sec. DNS server

Setting the http user name

Tiggering a test email

Page 30

K410068602008-00 / 09.2018 30

Acknowledge error

All the errors that occur in the system are

sent to the KHS Mini Control System MASTER 2.0- and are signalled

acoustically by means of a buzzer. It is

possible to integrate an alarm relay (see

Chapter 2.2). In normal operation, the

alarm relay is energized ("pulled") with

voltage. If there is an error, the voltage

drops and an acoustic signal reports the

error. Here it does not matter what

different effect the error has on the

system. The control goes into alarm

latching and has to be acknowledged by

the user after the malfunction has been

repaired.

USB interface

Data can be transmitted comfortably with

the USB interface of the KHS Mini Control

System MASTER 2.0-. Data can be

imported by the device and also exported

from the device. It is also possible to use

the USB stick to install updates not only

for the Control System but also for the web

browser.

The USB menu is not visible in normal

mode. The menu is automatically

activated when a USB memory stick is

connected to the KHS Mini Control System

-MASTER 2.0-.

Max. storage capacity of the USB stick

16 GB

File system FAT32

1

2

3

A detailed list of

possible errors and

their corrections is

given in chapter 7.

Page 31

K410068602008-00 / 09.2018 31

USB menu

Meaning

Copy logbook to USB stick

All saved events are stored on the USB stick in

the form of a CSV file.

Copy flushing log to USB stick

All saved flushing processes are stored on the

USB stick in the form of a CSV file.

Copy configuration to USB stick

All settings are stored on the USB stick in the

form of a CFG file.

Read configuration from USB

stick

A saved configuration can be written from the

USB stick into the controls.

Copy data log to USB stick

When the "Datalogging" mode is activated, the

measured values recorded can be copied onto

the USB stick.

Software update from USB stick

Control System software update by means of a

UPE file, using the USB stick.

Copy web server from USB stick

Web browser update using the USB stick.

Web browser

The KHS Mini Control System -MASTER

2.0- is a web-based Control System. Using

a web browser, basic settings,

configurations and changes can be carried

out easily.

Chapter 6 concerns only the web browser interface. You can find the

complete operating instructions on the web browser with the button and

Downloads, or through the Service/ Download section of our website,

www.kemper-olpe.de.

To use the web browser, the following minimum system requirements must

be met:

Java script must be activated

Mozilla Firefox Version 22.0.1 or higher

Google Chrome Version 31.0 or higher

Windows Explorer Version 10.0 or higher

or an alternative browser Safari, etc.

Please note Chapter 3.1.2.8 and make sure you know which network

settings of the Control System are stored.

Page 32

K410068602008-00 / 09.2018 32

The WEB browser is subdivided into seven

menu interfaces. They can be selected

through the web browser tabs shown in

Fig. 6.1.1. In the individual menu

interfaces, you can make the basic

settings, the configurations and changes.

Use the WRITE TO CONTROL button to

save your parameters. If you do not want

to store the changes in the system, use

the

DISCARD CHANGES

button.

Ill. 6.1.1 Menu tab of the web browser

The web browser interface can also be used with a tablet PC or a

mobile phone. Here, the input interfaces are changed slightly. When

using with a mobile phone, the menu tabs can be seen over the

button (see below). The modes of functioning of the individual menu

interfaces remain unchanged; merely the graphics of the components

are not displayed.

The username “KHS”

and password "0000"

is the factory default.

Page 33

K410068602008-00 / 09.2018 33

In the "SYSTEM SETTINGS" menu

interface you can make settings for user

data, date / time, network, external switch

function and other settings.

User data

To

create a user for the web browser of your KHS Mini Control

System, choose a user name and a suitable password. To save the

settings, click the WRITE TO CONTROL button. After the settings

have been saved, you must identify yourself every time the web

browser is started. To do this, enter the user name you have just

chosen and the relevant password in the input dialogue that then

opens, as shown in Fig. 6.2.1. Use by several users is not possible.

Ill. 6.2.1 Input dialogue Identification

The username “KHS”

and password "0000"

is the factory default.

Page 34

K410068602008-00 / 09.2018 34

Date / Time

The

current time and current date of the KHS Mini Control System

-MASTER 2.0- are displayed in the grey boxes. To set the Control

System time, click the APPLY DATE/TIME button. This causes the

Control System to apply the date and time settings of your PC, for

example. The KHS Mini Control System -MASTER 2.0- can switch

automatically between daylight saving and standard time. If you do

not want this setting, click the button. If the button is showing

, the switchover between daylight savings and standard time is

not automatic

Netzwork

To

establish a connection between the PC and the KHS Mini Control

System -MASTER 2.0- using a web browser, the required network

configurations can be entered in the boxes IP address, Subnet,

Gateway, prim. DNS and sec. DNS.

You can obtain the appropriate parameters for

integration into your network from your system

administrator.

The following parameters are configured as factory

defaults:

IP address: 10.1.23.150

Subnet: 255.255.255.0

Gateway: 10.1.23.254

The network settings can only be loaded when the configuration

is loaded using a USB stick. They are not imported when the

configuration is loaded using the web server.

Program switch

With the KHS Mini Control System -MASTER 2.0- it is possible to

switch between two flushing programs. The programs can be

configured in the Operating modes menu interface and the individual

Control System can be added (see Chapter 6.2).

If the button for the program switchover is set to , the external

program switching is deactivated. If the button for the program

switchover is set to , the external program switching is active.

The names of the flushing programs can be changed with an entry

in the related box. Use the "Current operating mode" drop-down list

to manually switch the flushing programs in the web server and to

block them for maintenance purposes. Use the "External input"

drop-down list to set the operating mode of the external input.

Maintenance:

The two flushing programs mentioned above can

be switched using the web browser and can be

blocked for maintenance purposes.

Page 35

K410068602008-00 / 09.2018 35

Other settings

The

KHS Mini Control System -MASTER 2.0- can activate an internal

buzzer in case of faults. If the related button displays , the alarm

buzzer is activated.

If the related button displays , the alarm buzzer is not activated.

Using the drop-down menu you can also customise the language

setting of the control.

In the "DEVICE SETTINGS" menu

interface, the individual KHS Mini Control

System with integrated actuators and

sensors are logically linked to each other.

Selection interface

The "DEVICE SETTINGS" menu interface is a dynamic interface.

The selection interface of the installed KHS Mini Control System

are shown on the left-hand side. Click on the desired KHS Mini

Control System to open the relevant input box.

The changes must be written into the control after

every change in the input box. If another KHS Mini

Control System is selected immediately after a

change in the selection interface, the changes are

automatically discarded.

Page 36

K410068602008-00 / 09.2018 36

Input box

If a KHS Mini Control System is selected in the selection

interface, the input box appears on the right-hand side.

Use this box to allocate the related actuators and sensors

to the KHS Mini-Control System.

If an error occurs in the Control System, it can be

reported across the entire system. To do this, set the

button to . The remaining input options of the input

box are explained in the following.

Adding devices

Configuration (B valve)

Select control type

Choose the available control

types that can be used by the

selected KHS Mini Control

System from a drop-down list.

The KHS Mini Control System MASTER 2.0 - should control a B

valve in this sample project.

Select valve

The possible valves are selected from

a drop-down list. In this sample

project, the KHS Mini Control System

-MASTER 2.0- should actuate a KHS

VAV maximum flow isolating ball valve

with spring reset and servo drive.

Alarm relay reports system-wide error

Page 37

K410068602008-00 / 09.2018 37

Select sensor

The possible sensors are selected from

a drop-down list. In this sample

project, the KHS Mini Control System MASTER 2.0- should actuate a KHS

CONTROL PLUS

Save settings

To

allow the new parameters of the

input box to become effective, the

settings must by saved by clicking the

WRITE TO CONTROL button.

Page 38

K410068602008-00 / 09.2018 38

Configuration of the A valve

Select control type

Choose the available control types that

can be used by the selected KHS Mini

Control System from a drop-down list.

The KHS Mini Control System should

actuate an A valve in this sample

project.

Select the relevant B valve

Each A valve must be assigned to

a B valve. The available KHS Mini

Control System that are linked to

a B valve can be selected from a

drop-down list. The KHS Mini

Control System in this sample

project should be assigned to the

B valve of the KHS Mini Control

System -MASTER 2.0-.

Page 39

K410068602008-00 / 09.2018 39

Select valve

The possible valves are selected

from a drop-down list. In this

sample project, the KHS Mini

Control System should actuate a

KHS VAV maximum flow isolating

ball valve with servo drive.

Select sensor

The possible sensors are selected

from a drop-down list. The KHS

Mini Control System in this

sample project should actuate a

KHS temperature sensor Pt

1000.

Page 40

K410068602008-00 / 09.2018 40

Select the medium to be

monitores

Select the medium to be monitored

from a drop-down list. In this sample

project, it is cold water.

The temperature ranges are then

configured.

Save settings

For

the new parameters of the input

box to become effective, the settings

must be saved by clicking WRITE TO

CONTROL.

Page 41

K410068602008-00 / 09.2018 41

Configuration oft he C valve

Select control type

Choose the available control

types that can be used by the

selected KHS Mini Control

System from a drop-down list.

The KHS Mini Control System

should actuate a C valve in this

sample project.

Select valve

Die möglichen Ventile werden

mittels einer Dropdownliste

gewählt. Die KHS Mini Systemsteuerung soll im gegebenen

Musterprojekt ein KHS VAVVollstromabsperrventil mit Federrückzug und Stellantrieb ansteuern.

Page 42

K410068602008-00 / 09.2018 42

Select sensor

The possible sensors are selected from

a drop-down list. The KHS Mini Control

System in this sample project should

actuate a KHS temperature sensor Pt

1000.

Page 43

K410068602008-00 / 09.2018 43

Select the medium to be

monitored

Select the medium to be monitored

from a drop-down list. In this sample

project, it is cold water.

The temperature ranges must then be

configured.

Select sensor

The possible sensors are selected from

a drop-down list. In this sample

project, the KHS Mini Control System

should actuate a KHS CONTROL PLUS

Page 44

K410068602008-00 / 09.2018 44

Save settings

For

the new parameters of the input

box to become effective, the settings

must be saved by clicking WRITE TO

CONTROL

Configuration of the safety device

Select control type

Choose the available control types

that can be used by the selected KHS

Mini Control System from a drop-down

list. In this sample project, the KHS

Mini Control System should function

as a safety valve

Page 45

K410068602008-00 / 09.2018 45

Select valve

The possible valves are selected from a

drop-down list. In this sample project,

the KHS Mini Control System should

actuate a KHS VAV maximum flow

isolating ball valve with servo drive.

Save settings

For

the new parameters of the input

box to become effective, the settings

must be saved by clicking WRITE TO

CONTROL.

Page 46

K410068602008-00 / 09.2018 46

Configuration of measurement

Select control type

Choose

the available control types that

can be used by the selected KHS Mini

Control System from a drop-down list.

The KHS Mini Control System -SLAVEin this example should act as a

measurement SLAVE.

Select sensor

The

possible sensors are selected

from a drop-down list. The KHS Mini

Control System - SLAVE - should be

assigned to a KHS CONTROL PLUS.

Page 47

K410068602008-00 / 09.2018 47

Save settings

For

the new parameters of the input

box to become effective, the settings

must by saved by clicking the WRITE

TO CONTROL button.

Configuration of the KHS HS2 Hygiene flushing box V1

Change Name

…V1 Connection right

…V2 Connection left

Use the APPLY NAME button to transmit

the selected system name

.

The KHS HS2 hygiene flushing box is displayed visually

.

Page 48

K410068602008-00 / 09.2018 48

Select control type

A control type (C valve) is assigned to

the KHS HS2 hygiene flushing box by

means of a drop-down list.

Select sensor

The

possible sensors are selected from

a drop-down list. A KHS temperature

sensor Pt 1000 can be assigned to the

KHS HS2 hygiene flushing box.

Select the medium to be

monitores

Select

the medium to be monitored

from a drop-down list. In this sample

project, it is cold water. The

temperature ranges are then

configured.

Page 49

K410068602008-00 / 09.2018 49

Select valve

An internal volume flow sensor can be

added to the KHS HS2 hygiene flushing

box by means of a drop-down list.

Save settings

For

the new parameters of the input

box to become effective, the settings

must by saved by clicking the WRITE

TO CONTROL button.

Page 50

K410068602008-00 / 09.2018 50

In the "OPERATING MODES" menu

interface, the control-specific TIMERS are

configured for the KHS Mini Control System.

Depending on the control type, a TIMER

defines flushing times, measurement

intervals, backup times, routine intervals,

temperature flushing etc.

Selection interface

In the "OPERATING MODES" menu interface, you will

find the selection interface of the added KHS Mini

Control System on the left-hand side. Click the desired

KHS Mini Control System to open the input box.

1

2

The changes must be written into the

control after every change in the

input box. If another KHS Mini

Control System is selected

immediately after a change in the

selection interface, the changes are

discarded.

1

Page 51

K410068602008-00 / 09.2018 51

Input box

If a KHS Mini Control System is selected in

the selection interface, the relevant input

box appears on the right-hand side.

Click the ADD LINE button to add up to 16

lines to the TIMER. Press the button to

delete the line in question from the TIMER.

Click the RESORT TIMER button to delete

all deactivated lines and to push empty

lines to the back. The remaining input

options in the lines are explained below.

Ill. 6.3.1 Overview of system commissioning for the sample project

The

selected times and temperatures serve as examples. The values must

always be set for each building and for each type of use and medium so that

representative measurement values are generated and intended use is

maintained for the system.

2

2

Page 52

K410068602008-00 / 09.2018 52

Configuration of time control (A valve)

Select type

After

a line has been added using ADD

LINE, the line type is selected. The KHS

Mini Control System in this sample

project is connected to an A valve. To

time control the water exchange, the

"Time flushing" line type must be

selected from a drop-down list.

Define times

Af

ter a line type has been selected,

define the times. In the "Time control"

line type, a starting time and the

duration of the water exchange must be

stated. Furthermore, the desired

weekday can be selected from a dropdown list. Click the box of the weekday

in question to activate it with a check

mark.

Page 53

K410068602008-00 / 09.2018 53

Save settings

the new parameters of the input box to

become effective, the settings must by

saved by clicking the WRITE TO

CONTROL button.

Configuration of volume flushing (A valve)

Select type

After

a line has been added using ADD

LINE, the line type is selected. To volume

control the water exchange, the "Volume

flushing" line type has to be selected

from a drop-down list.

Page 54

K410068602008-00 / 09.2018 54

Define times

Ist

er a line type has been selected,

define the times. In the "Volume control"

line type, a starting time, the duration

and the volume of the water exchange

must be specified. Furthermore, the

desired weekday can be selected from a

drop-down list. Click in the box of the

weekday in question to activate it with a

check mark.

Save setting

For

the new parameters of the input

box to become effective, the settings

must by saved by clicking the WRITE TO

CONTROL button.

Page 55

K410068602008-00 / 09.2018 55

Configuration of temperature flushing (A valve)

Select type

(Temperature flushing)

After

a line has been added using ADD

LINE, the line type is selected. The KHS

Mini Control System in the sample

project is linked to a temperature

measurement valve. To temperature

control the water exchange, the

"Temperature control" line type has to be

selected from a drop-down list.

Define times

I

a line type has been selected, define

the times. A starting and stopping time

has to be specified for the "Temperature

flushing" line type. Furthermore, the

desired weekday can be selected from a

drop-down list. Click in the box of the

weekday in question to activate it with a

check mark.

Page 56

K410068602008-00 / 09.2018 56

Routine time

In

this sample project, it is cold water.

The cold water temperature in winter

could always be below the starting

temperature. Nevertheless, to prevent

stagnation, routine water exchanges can

simulate operation for the intended

purpose. The "Routine" line type can be

selected from the drop-down list.

The desired weekday can also be

selected from a drop-down list. Click in

the box of the weekday in question to

activate it with a check mark.

Routine time

If there is no temperature flushing within 7

days, water exchange is guaranteed

through the "Routine time" operating mode.

In the "Routine time" operating mode, the

starting time, the duration and the

weekdays of the water exchange can be

defined.

Routine duration

If there is no temperature flushing within

the configured interval, the water exchange

is guaranteed through the "Routine

duration" operating mode. To accomplish

that, the decisive interval (max. 168 h) and

the duration of the water exchange can be

stored in the "Routine duration" operating

mode.

Routine volume

If there is no temperature flushing within

the configured interval, the water exchange

is guaranteed through the "Routine volume"

operating mode. To accomplish this, the

decisive interval (max. 168 h), the volume

and the maximum flushing time of the water

exchange can be assigned to the "Routine

volume" operating mode.

Save settings

For the new parameters of the input

box to become effective, the settings

must by saved by clicking the WRITE

TO CONTROL button.

Page 57

K410068602008-00 / 09.2018 57

Configuration of a KHS HS2 Hygiene flushing box V1 (interval flushing)

Select interval

After

a line has been added using ADD

LINE, the line type is selected. The

"Routine duration" line type is selected

from the drop-down list.

Here, the "Routine duration" line type

corresponds to one interval flushing

operation.

Define times

After

a line type has been selected,

define the times. In the "Routine

duration" line type, the duration and

the interval of the water exchange must

be specified.

Save settings

Fo

r the new parameters of the input

box to become effective, the settings

must by saved by clicking the WRITE

TO CONTROL button.

Page 58

K410068602008-00 / 09.2018 58

Configuration of the safety device

Select type

After a line has been added using ADD

LINE, the line type is selected. The

"Release" line type is selected from the

drop-down list.

Define time

Af

ter a line type has been selected,

define the times. A starting and stopping

time has to be specified for the "Release"

line type. Furthermore, the desired

weekdays can be selected from a dropdown list. Click in the box of the weekday

in question to activate it with a check

mark.

Configuration of measurement (datalogging)

Select type

Na

er a line has been added using ADD

LINE, the line type is selected. The KHS

Mini Control System in this sample

project is connected to a KHS Control

Plus flow measurement valve. To record

the flow measurement valve

measurement data at the same time, the

"Datalogging" line type must be selected

from a drop-down list.

Page 59

K410068602008-00 / 09.2018 59

Define times

After a line type has been selected,

define the times. A starting and stopping

time has to be stated for the

"Datalogging" line type. Furthermore,

the desired weekdays can be selected

from a drop-down list. Click in the box of

the respective weekday to activate it with

a check mark. The interval time states

the storage rate of the measurement

values

.

Save settings

For the new parameters of the input

box to become effective, the settings

must by saved by clicking the WRITE

TO CONTROL button.

Page 60

K410068602008-00 / 09.2018 60

In the „OVERVIEW“ menu interface, the

configured valves and the linked sensors

are shown in an overview. Pure

measurement valves are not listed in the

“OVERVIEW”.

Overview

The overview merely shows the

current states. No configurations can

be carried out on this interface.

Click a valve to open the input box of

the "SYSTEM SETTINGS" menu

interface of the selected component.

If a valve is highlighted in black, this

means it is closed. If the valve is

highlighted in grey, it is open. If the

valve is highlighted in red, there is a

fault.

Manual mode / Automatic

The actuators can be triggered

manually. Click the button to open a

selection window. Use the selection

window to choose between three

settings (C valve) or five settings (A/B

valve) from a drop-down list. The

button indicates a fault in the system.

Automatic = Standard setting

Manual OPEN = Opens valve

Manual CLOSE = Closes valve

Group OPEN = With the A valve, the B

valve also opens

Group CLOSE = both close again

After

a setting has been selected, the

duration of the setting can be defined.

Use the APPLY button to apply the

setting. Press the CANCEL button to

cancel the action.

60

Page 61

K410068602008-00 / 09.2018 61

The „CURRENT VALUES“ menu interface

shows the current values oft he connected

KHS Mini Control System and their sensors.

Click

the button to open the

input box of the "DEVICE SETTINGS"

menu interface of the selected KHS

Mini Control System.

Page 62

K410068602008-00 / 09.2018 62

You can use the "DATA TRANSFER"

menu interface to load

configurations, software updates,

logbook entries and the created

datalogging files.

Page 63

K410068602008-00 / 09.2018 63

Software update

The "Software update" function can be

used to install a software update on the

connected KHS Mini Control System. To

do this, click the Search button. The

UPE files open in the window that then

opens, see Fig. 6.7.1. After the LOAD

UPDATE button has been pressed, a

confirmation appears as shown in Fig.

6.6.2. Click the OK button to load the

selected setup into the Control System.

Ill. 6.7.1 Selection dialogue „Upload setup file“

Ill. 6.7.2 „Delete software update“ confirmation

As a precautionary measure, please backup your configuration before

making an update.

Page 64

K410068602008-00 / 09.2018 64

Configuration

Loading a configuration from a file

The "Configuration" function can be

used to install an existing configuration

in the connected KHS Mini Control

System. To do this, click the Search

button. The CFG file opens in the

window that then opens, see Fig. 6.7.3.

After the LOAD CONFIGURATION FROM

FILE button has been clicked, the

selected configuration is then loaded

into the Control System.

The network and e-mail settings can

only be loaded when the configuration

is loaded using a USB stick. They are

not imported when the configuration

is loaded using the web server.

Backing up the configuration

You can use the "Configuration"

function to backup parameterised

configurations of the connected KHS

Mini Control System to your PC. To do

this, click the WRITE CONFIGURATION

TO FILE button. In this window, see Fig.

6.7.4, you can back up the CFG file to

the desired folder on your PC.

Ill. 6.7.4 Selection dialogue „Back up configuration file“

After successfully configuring your Control System, you are

recommended to save the configuration as a backup file. If the

KHS Mini Control System -MASTER 2.0- is defective, it can be

quickly replaced and the configuration can be read in. This

saves having to configure everything again.

Ill. 6.7.3 Selection dialogue „Upload configuration file“

Page 65

K410068602008-00 / 09.2018 65

Logbook

You can use the "Logbook" function to

open and save the event log as a CSV

file. The event log documents the water

exchange operations, error messages

and configuration changes made by the

Kemper KHS Mini Control System.

Based on the documentation about the

location, duration of the water

exchange and the temperatures,

recordings can be made across a

defined time period to verify the state

of hygiene of the drinking water

system. To open the CSV file, click

OPEN LOGBOOK AS CSV. A dialogue

window then opens, where you can

select whether the flushing log should

be saved or if it should be immediately

opened (see Fig. 6.7.5).

The KHS Mini Control System have a facility

to be used as measuring instruments. To do

this, the Control System that are connected

to a sensor, as described in Chapter 6.3, are

configured. Use the "Datalogging" function

to generate, delete and save the recorded

measurement data records in the form of a

CSV file on the PC. Up to 12 million lines can

be backed up. Click the

CREATE LOGFILE button to generate the

current CSV file, which is not yet completely

full. Click the CSV file to open a dialogue as

shown in Fig. 6.7.6. Here you can select

whether the flushing log should be saved or

immediately opened. Use the button to

open a query as shown in Fig. 6.7.7. Click

OK to delete the selected file.

Ill. 6.7.5 Opening the CSV log file dialogue

Page 66

K410068602008-00 / 09.2018 66

Ill. 6.7.6 Openeing the CSV data log file dialogue

Ill. 6.7.7 „Delete file“ confirmation

Ill. 6.7.8 shows an extract of a CSV log file.

In the log file you will find a detailed list of

the entire measured data; sorted by date,

time, index, name and the measured data of

the connected measuring valve.

Ill. 6.7.8 Illustration of an extract of a CSV log file

As described in Chapter 6.3, the sampling interval of the measured

values can be set using the "OPERATING MODES" menu interface.

Page 67

K410068602008-00 / 09.2018 67

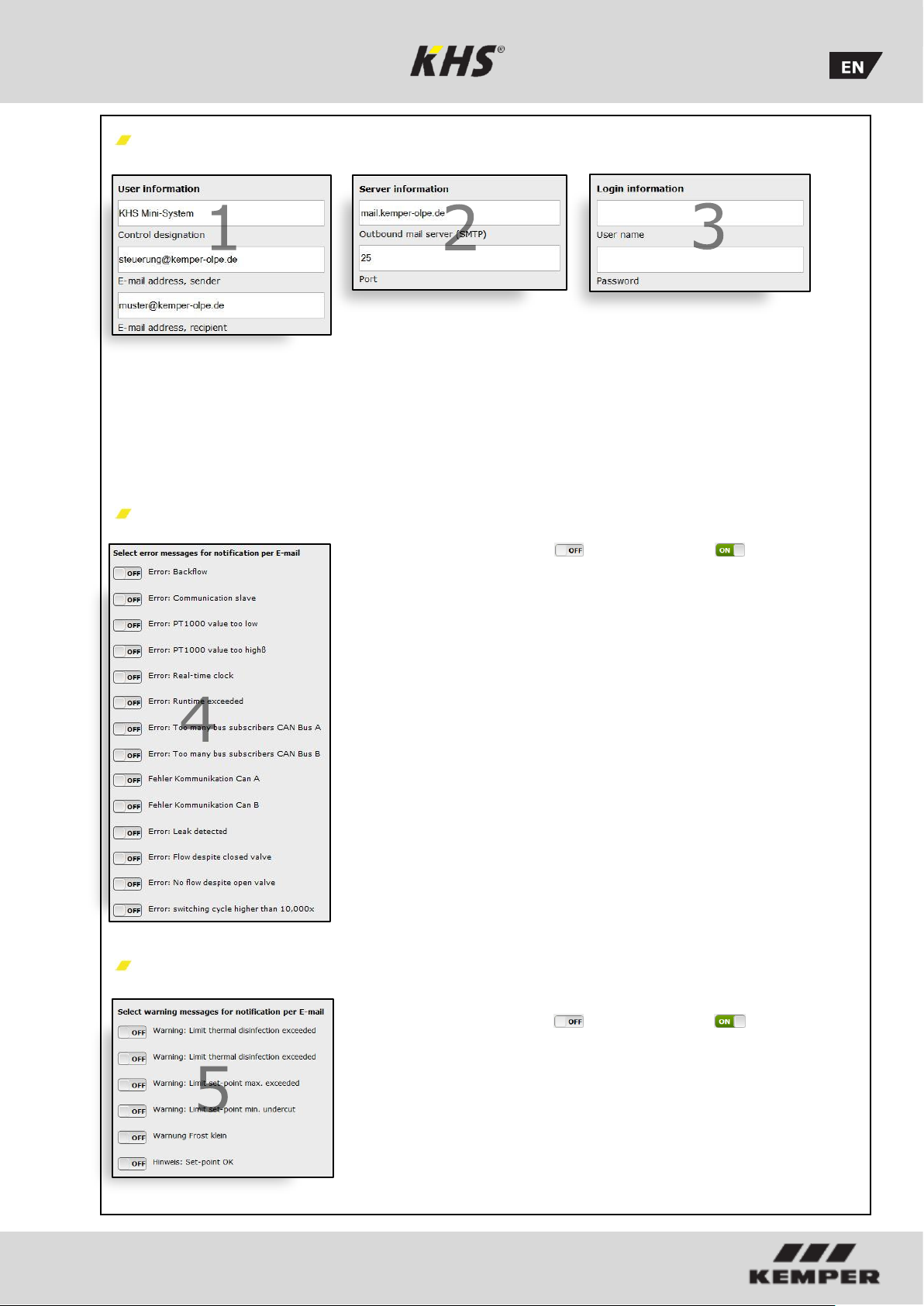

If errors or warning messages occur, the

KHS Mini Control System -MASTER 2.0- can

send them directly to the plant operating

organisation by e-mail.

In the "EMAIL ADMINISTRATION" menu

interface, a selection of error and warning

messages can be individually configured.

Furthermore, the e-mail configuration is set

with the user, server and login information

functions.

Page 68

K410068602008-00 / 09.2018 68

User information | Server information | Login information

To enable the KHS Mini Control System MASTER 2.0- to send error and warning

messages to the plant operating

organisation, the e-mail settings have to be

configured. Here, an internal company e-

mail account can be created, or an

independent provider can be used if he

works without encryption. The control name

can be used to allocate a location, e.g.

Cologne Gymnastics Hall.

Select error messages for notification per email

If the button is set to , the relevant

notification about a possible error is

activated. If an error occurs, an error

message is sent to the plant operator by email.

Select warning messages for notification per email

If the button is set to , the relevant

notification about a possible warning is

activated. If a warning occurs, an error

message is sent to the plant operating

organisation by e-mail.

Page 69

K410068602008-00 / 09.2018 69

Error description and error handling

Error description / Error handling

Status

LED

Status LED

Status LED

Status LED

Status LED

General error

Flashes red

Backwater in drain

Drain is clogged or cannot accept

the flushing volume.

Check the drain

channel, channel

acceptance capacity.

Error message!

Defective control will be

completely blocked

Backwater in drain

Float switch on the drain has a

cable break

Replace cable / switch

Error message!

Defective control will be

completely blocked

Temperature flushing

switched off during

runtime

Medium did not reach the switch-

off temperature in the set time

Check the installation

setup and the

maximum flushing

time.

Error message!

Temperature operating

mode is blocked in the

defective control.

Volume flushing

switched off during

runtime

Set volume not reached

Check the installation

setup and the

maximum flushing

time.

Error message!

Volume operating mode is

blocked in the defective

control.

PT1000 value too

high

Sensor defective / No sensor

available

Replace sensor / Check

inputs on the MASTER

Error message!

Temperature flushing

operating mode is blocked

in the defective control.

PT1000 value too low

Sensor defective / No sensor

available

Replace sensor / Check

inputs on the MASTER

Error message!

Temperature flushing

operating mode is blocked

in the defective control.

Leak on sensor

Pipe failure, moisture on the

sensor

Check the local area

and remove the

moisture

The safety valve is

blocking the system.

Real-time clock data

inconsistent

Data in the clock are not

consistent

Check the time & date

and adjust if necessary.

Check battery/replace

if applicable

All time-based services

are running on incorrect

time/date.

Flow detected with

valve closed"

Flow is detected by the flow

measurement valve when the

valve is closed

Check the function of

the flushing valve

Error message! The

involved valve will be

blocked.

"No flow detected

despite open valve"

No flow is detected during a

flushing process.

Check the flushing line

and the flushing valve

Error message! The

involved valve will be

blocked.

Page 70

K410068602008-00 / 09.2018 70

Error description / Error handling

Status

LED

Status LED

Status LED

Status LED

Auswirkung

Bus error

Flashes orange

No response from the

SLAVE

Cable break, incorrect installation,

interference fields

Check CAN bus cables

and installation

Faulty SLAVE does not

function

No response from the

SLAVE

SLAVE does not have voltage

Restore SLAVE power

supply

Faulty SLAVE does not

function

No response from the

SLAVE

SLAVE with its corresponding

serial number no longer part of

the plant (e.g., after a

replacement)

Assign the correct

serial number to the

SLAVE or delete the

device from the system

Faulty SLAVE does not

function

CAN bus line fault

Cable break, incorrect installation,

interference fields

Check CAN bus cables

and installation

CAN bus and all SLAVEs

do not function.

Too many bus

subscribers

CAN bus A

More than 31 SLAVEs are

connected to

CAN bus A

Rewire the BUS

subscribers or change

the position of the

MASTER in the bus

system.

CAN bus A faulty.

Communication and

functions can be impaired.

Too many bus

subscribers

CAN bus B

More than 31 SLAVEs are

connected to

CAN bus B

Rewire the BUS

subscribers or change

the position of the

MASTER in the bus

system.

CAN bus B faulty.

Communication and

functions can be impaired.

Communication error

CAN bus A

Cable break, incorrect installation,

interference fields

Check CAN Bus A

cables and installation

Affected SLAVEs do not

function

Communication error

CAN bus B

Cable break, incorrect installation,

interference fields

Check CAN Bus B

cables and installation

Affected SLAVEs do not

function

Page 71

K410068602008-00 / 09.2018 71

Description of warnings / notices

Status

LED

Status LED

Status LED

Status LED

Status LED

Warnings

flashes

red

Operating cycles

exceed 20,000

The VAV on the defective SLAVE

has performed more than 20,000

operating cycles

Replace VAV bonnet in

accordance with the

maintenance manual

and reset the operating

cycles.

The warning message

cannot be confirmed.

SLAVE continues to

operate normally.

No influence

Thermal disinfection

limit exceeded

The monitored temperature has

exceeded the set limit value.

Check to see if it needs

to be set otherwise.

Entry in logbook and

optional message via

email.

Set-point max. limit

exceeded

The monitored temperature has

exceeded the set limit value.

Check to see if it needs

to be set otherwise.

Entry in logbook and

optional message via

email.

Set-point min. limit

undercut

The monitored temperature has

undercut the set limit value.

Check to see if it needs

to be set otherwise.

Entry in logbook and

optional message via

email.

Frost protection limit

undercut

The monitored temperature has

undercut the set limit value.

Prevent danger of

valves freezing up.

Entry in logbook and

optional message via

email.

Notes

No

influen

ce

Set-point OK

Notice that the monitored

temperature is in the target

range.

No action needed!

Entry in logbook and

optional message via

email.

Lights

up

green

Control in standby

No flushing pending. Control in

standby

No action needed!

No influence

Flash

es

gree

n

Flushing is running

The valve on the involved control

is flushing / is open.

No action needed!

Entry in logbook.

Accessories | Spare parts

Optionally available accessories

FIGURE

KHS VAV with servo drive 230 V

686 04

KHS VAV plus with spring-reset servo drive (230 V)

686 05

KHS drain with overflow monitor

688 00

KHS temperature sensor fitting Pt 1000

628 0G / 629 0G

KHS flow measurement valve

638 4G / 138 4G

Leakage water sensor

620 00 001

Page 72

K410068602008-00 / 09.2018 72

Spare parts

Pos.

Art.-No.

Designation

Note

Installation advice

(1)

6260201900

Network cable for KHS

Mini Control System

MASTER 2.0;

hardware stand 2.0

For Master

hardware stand

2.0

(2)

6860202000

Network cable for KHS

Mini Control System

MASTER 2.0;

hardware stand 2.01

For Master

hardware stand

2.01

(3)

6860202100

Network cable for KHS

Mini Control System

MASTER 2.0;

For hardware

stand 2.0

additionally cable

6860202000 is

required.

Service department application technology

Tel. +49 2761 891-0

(4)

6860202200

Micro SD card for

network module in KHS

Mini Control System

MASTER 2.0

---

Service department application technology

Tel. +49 2761 891-0

1 2 3

4

Page 73

K410068602008-00 / 09.2018 73

KHS cable list

This list of cables only shows examples

of applications. The exact design of the

cables in questions must be carried out

on site by the planner on the basis of

Designation Art.-No.

[-] [-] [mm²] [mm] [m] [-]

KHS quarter turn stop

valve PLUS with spring

reset servo drive (24 V)

KHS quarter turn stop

valve with servo drive

(24 V)

KHS quarter turn stop

valve PLUS with spring

reset servo drive (230V)

KHS quarter turn stop

valve with servo drive

(230 V)

KHS free drain with

overflow sensor

686 01 015…032

686 00 015…032

686 05 015…032

685 15 032…050

686 04 015…032 5 x 1.50 mm² 1000 NYM-J

688 00 020...032 2 x 2 x 0.80 mm **

the ambient conditions (temperature,

frequency, routing type, mechanical

load).

Cable cross-section /

diameter

3 x X mm²

(power supply)

+

2 x 2 x 0.80 mm **

(position feedback)

5 x X mm²

(power supply)

+

2 x 2 x 0.80 mm **

(position feedback)

3 x 1.50 mm² 1000 NYM-J

Max. cable

length

700 (X=1,50)

10

00 (X=2,50)

250 (X=1,50)

450 (X=2,50)

1000

Cable type*

NYM-J

+

J-Y(ST)Y

NYM-J

+

J-Y(ST)Y

J-Y(ST)Y

Kemper CONTROL PLUS

flow measurement valve

Vortex principle

Kemper CONTROL PLUS

flow measurement valve

Vortex principle

KHS flow and

temperature sensor

Pt 1000

Leakage water sensor 620 00 00100 2 x 2 x 0.80 mm ** 500 J-Y(ST)Y

CAN bus cable

The application is based on

the ISO 11898 international

standard.

138 4G 015…050

138 6G 015…050 4 x 2 x 0.80 mm ** 300 J-Y(ST)Y

628 0G 015...050

629 0G 015...050

4 x 2 x 0.80 mm **

2 x 2 x 0.80 mm ** 1000 J-Y(ST)Y

1 x 2 x 0.34 mm² **

1 x 2 x 0.50 mm² **

1 x 2 x 0.75 mm² **

300 J-Y(ST)Y

300

500

1000

CAN bus cable

* Possible cable type for fixed routing, without mechanical load

** Shielded cable lead

According to VDE 0815: The specification of signal transmission cables with

respect to the diameter is specified in mm.

Page 74

K410068602008-00 / 09.2018 74

Appendix

The following chapter shows the various

valve technologies based on exemplary

illustrations.

10.1.1 A-/B Valve technology

In A/B valve technology,

several riser branches or

distribution lines are connected

to a common flushing line.

Here, one A valve and the B

valve are successively opened

and closed together. This

guarantees that there is no

idling in the flushing lines and

there is no water exchange

between the pipelines to be

flushed.

Example of a flushing process:

A1 and B1 open in accordance

with the specifications, A1 and

B1 close

A2 and B1 open in accordance

with the specifications, A2 and

B1 close

A3 and B1 open in accordance

with the specifications, A3 and

B1 close

A4 and B1 open in accordance

with the specifications, A4 and

B1 close

Please note:

If valve A1 is flushing, the

pending flushing processes of

other valves are blocked. With

temperature flushing, these

are then carried out

successively by the system.

A Valve

B Valve

KHS maximum flow isolation

ball valve with servo drive

Figure 686 04 230 V AC

KHS PLUS maximum flow isolation ball

valve with servo drive and spring reset

Figure 686 05 230 V AC

Page 75

K410068602008-00 / 09.2018 75

10.1.2 C valve technology

KHS PLUS maximum flow isolation ball

valve with servo drive and spring reset

Figure 686 05 230 V AC

C valve technology makes it

possible to exchange the water of

an individual riser branch or of

one individual distribution line

independent of the other water

exchanging valves.

Page 76

K410068602008-00 / 09.2018 76

You can find the write-in form at: www.kemper-olpe.de at "Building Technology" in the

service download area.

Page 77

K410068602008-00 / 09.2018 77

Page 78

K410068602008-00 / 09.2018 78

K410068602008-00 / 09.2018

Gebr. Kemper GmbH & Co. KG

Harkortstraße 5

D-57462 Olpe

Service-Hotline +49 2761 891-800

info@kemper-olpe.de

www.kemper-olpe.de

Loading...

Loading...