Page 1

Up to +35 °C

Proofi ng

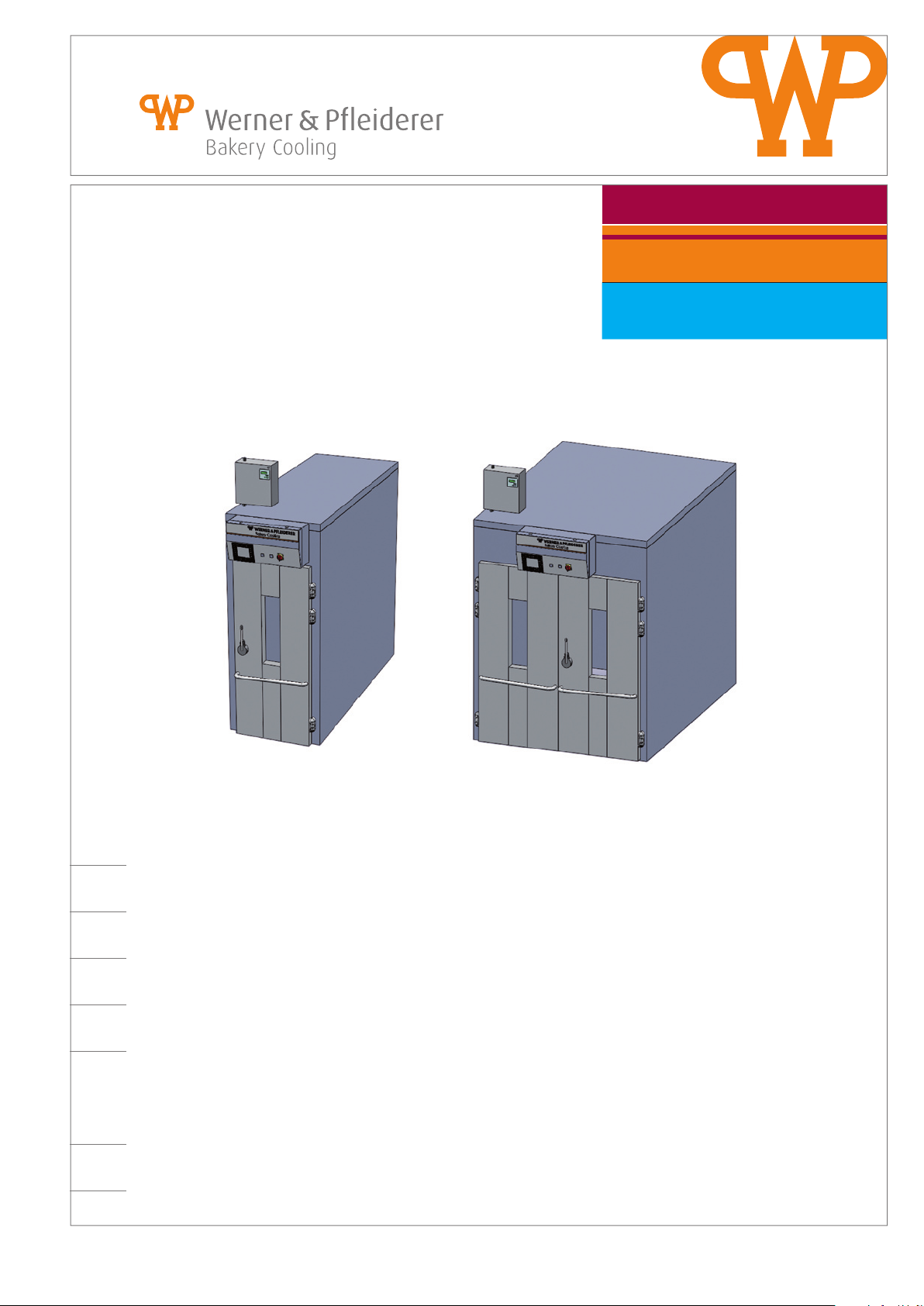

GRF 1/2

Proofi ng Chamber 01.08.2008

Proofi ng chamber GRF

Temperature range up to +35 °C

Moisture range approx. 75 – 95 % rel. hum.

Proofi ng chambers of the series GRF assist the development of aroma in dough pieces and improve the quality

of your products by optimum air guidance control. The Werner & Pfl eiderer air guidance system, together with

the high relative humidity, ensures optimum proofi ng of products.

Dimensions

We offer a standard GRF series in single, double and triple width design for all bakery operations.

Air conditioning housing

Panels in 80 mm PU insulation, foamed, free of CFCs, HCFCs and HHCs.

k value

0.24 W/m²K

Connection system

Tongue and groove system with foamed-in eccentric turnbuckle joints for easy, fast assembly on site.

Surfaces Standard Finish

Inner walls stainless steel

Outer walls sheet steel, galv., white, RAL 9002

System front stainless steel, grain ground

Optional stainless steel panelling for all surfaces

Floor

Proofi ng chambers do not have a base fl oor. The wall panels are mounted on stainless steel U-profi le sections on the fl oor on site.

Ram protection

Inside allround stainless steel square profi le 40 × 120 mm

+

0

-

WP BAKERYGROUP

Page 2

WP BAKERYGROUP

GRF 2/2

Proofing Chamber 01.08.2008

Proofing Chamber GRF

Doors

Rotating door with clear dimensions of 80 × 200 cm or double wing rotating door with clear dimensions of 176 × 200 cm

Per rotating door

– 3 door hinges, rising

– Solid press lever fastener for commercial use

– Ram protection inside and out

– Door seal

– Rubber abrasive for floor seal

Technology

The Werner & Pfleiderer air conditioning system specially designed for proofing processes, together with the high relative

humidity, is a guarantee for optimum proofing.

Air guidance

The conditioned air is fed into the room via a lowered stainless steel ceiling. Stainless steel rails are mounted at a distance

to the wall in the air intake and blow-out areas. Cold air is blown out on one side of the cell and fed back slowly over the

dough pieces to the air conditioner on the other side.

Moistening

by external steam moisteners in stainless steel housing; the hygienically pure steam is fed very evenly into the

system through steam nozzles and spread throughout the chamber by the air conditioning unit.

Control system

Via WP-FRM-computer control

– Control cabinet per VDE, pre-wired

– Very easy operation

– Fully automatic proofing program

Technical details

TYPE Outer width

(mm)

Single-width

GRF 1-2050 1,000 2,050 2,480 800 1,870 2,000 800 × 2,000 C6-B 8

GRF 1-2650 1,000 2,650 2,480 800 2,470 2,000 800 × 2,000 C6-B 8

GRF 1-3050 1,000 3,050 2,480 800 2,870 2,000 800 × 2,000 C6-B 8

GRF 1-3400 1,000 3,400 2,480 800 3,220 2,000 800 × 2,000 C6-B 8

Double-width

GRF 2-2050 1,960 2,050 2,480 1760 1,870 2,000 1,760 × 2,000 C6-B 9

GRF 2-2650 1,960 2,650 2,480 1760 2,470 2,000 1,760 × 2,000 C6-B 9

GRF 2-3050 1,960 3,050 2,480 1760 2,870 2,000 1,760 × 2,000 C6-B 9

GRF 2-3400 1,960 3,400 2,480 1760 3,220 2,000 1,760 × 2,000 C6-B 9

Triple-width

GRF 3-2050 2,920 2,050 2,480 2720 1,870 2,000 800 + 1,760 × 2,000 C6-B 10

GRF 3-2650 2,920 2,650 2,480 2720 2,470 2,000 800 + 1,760 × 2,000 C6-B 10

GRF 3-3050 2,920 3,050 2,480 2720 2,870 2,000 800 + 1,760 × 2,000 C6-B 10

GRF 3-3400 2,920 3,400 2,480 2720 3,220 2,000 800 + 1,760 × 2,000 C6-B 10

WERNER & PFLEIDERER Koeling Benelux B.V. Industrieterrein 9 D . 5981 NK Panningen . Netherlands

Fon +31 (0) 77-850 70 60 . Fax +31 (0) 77-850 70 61 . info@wp-baker ycooling.com . www.wp-bakerycooling.com

WERNER & PFLEIDERER Lebensmitteltechnik Kälte GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany .

Fon +49 (0) 98 51-905-510 . Fax +31 (0) 77-850 70 61 . info@wp-l.de . www.wp-l.de

Outer length

(mm)

Outer height

(mm)

Operating width

(mm)

Operating depth

(mm)

Operating height

(mm)

Door

(mm)

Steam

generator

Conn. load

(kW)

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...