Page 1

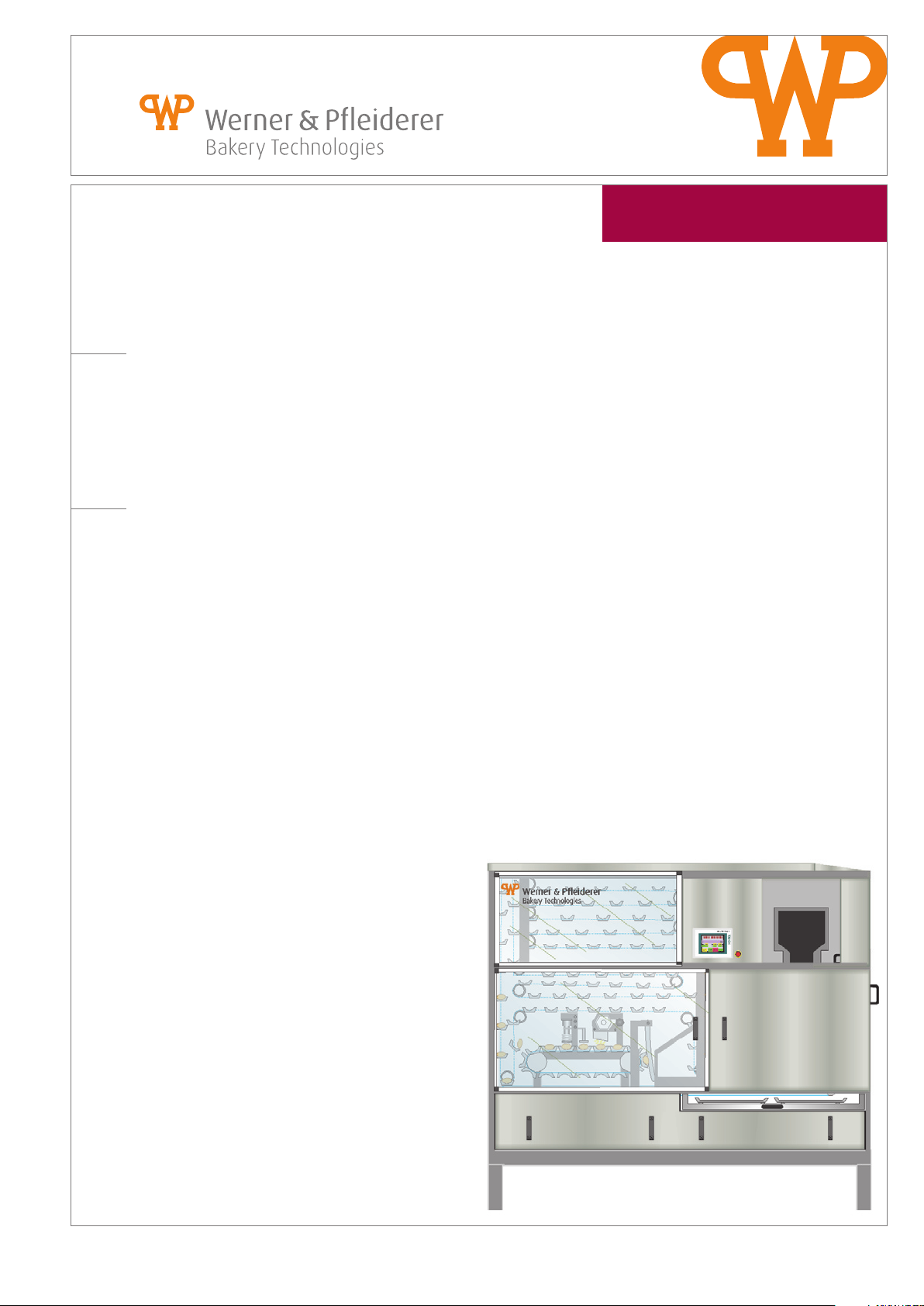

Compact stamped roll

plant with integrated

FORMPROFI ECO head machine

Features

Stamped roll plant with integrated dough portioner for producing

– Kaiser rolls

– Smooth round rolls

– Other stamped rolls

Stamped: weight range 40-65 g

Not stamped: weight range 30-90 g

Advantages

Integrated portioning machine

– Small size

– No dust emissions

– Even internal temperature and humidity

Revolving stamping head

– Up to 4 different stamping tools available

– Short setting-up time

– Variety of products

Depositing device with screen control

– Tray depositing can be individually adjusted

Separate stamping cup

– No sticking of dough pieces

Intensive sterilisation station

– Hygiene (E-conformity, LMHV (Lebensmittelverordnung, German Food Ordinance)

Variable depositing device

– Almost all trade standard carriers can be used

Siemens S7 control

– Programmed production processes

– Reproducable quality (processes) even if operator changes

– Monitoring of running time

Stainless steel version

– Hygiene

– Durability

– High resale value

WP BAKERYGROUP

FORMPROFI ECO 1/2

Compact stamped roll plant

with integrated head machine 29.04.2009

Page 2

FORMPROFI ECO

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Werner & Pfl eiderer Lebensmitteltechnik GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany

Fon +49 (0) 98 51-905-0 . Fax +49 (0) 98 51-905-342 . info@wp-l.de . www.wp-l.de

Equipment

In standard version

– Integrated suction divider with rotary disc

– Drum moulder

– Compact stainless steel construction

– Pre-proofing time 11 minutes before the stamping head

– Ventilator to correct temperature and humidity within the proofing chamber

– Revolving stamping head with up to 4 rows of tools

– Kaiser stamp and adjustable flour duster

– Tray frame drying

– Depositing device for trays carriers in 3 eurosizes,

400 x 600, 580 x 780 and 580 x 980, retracting length 1,000 mm

– Push-in option for carriers (standard left)

– Sterilisation station

– Siemens S7 computer control

– Maintenance-free tray frame chains

WP BAKERYGROUP

FORMPROFI ECO 2/2

Compact stamped roll plant

with integrated head machine 29.04.2009

Accessories

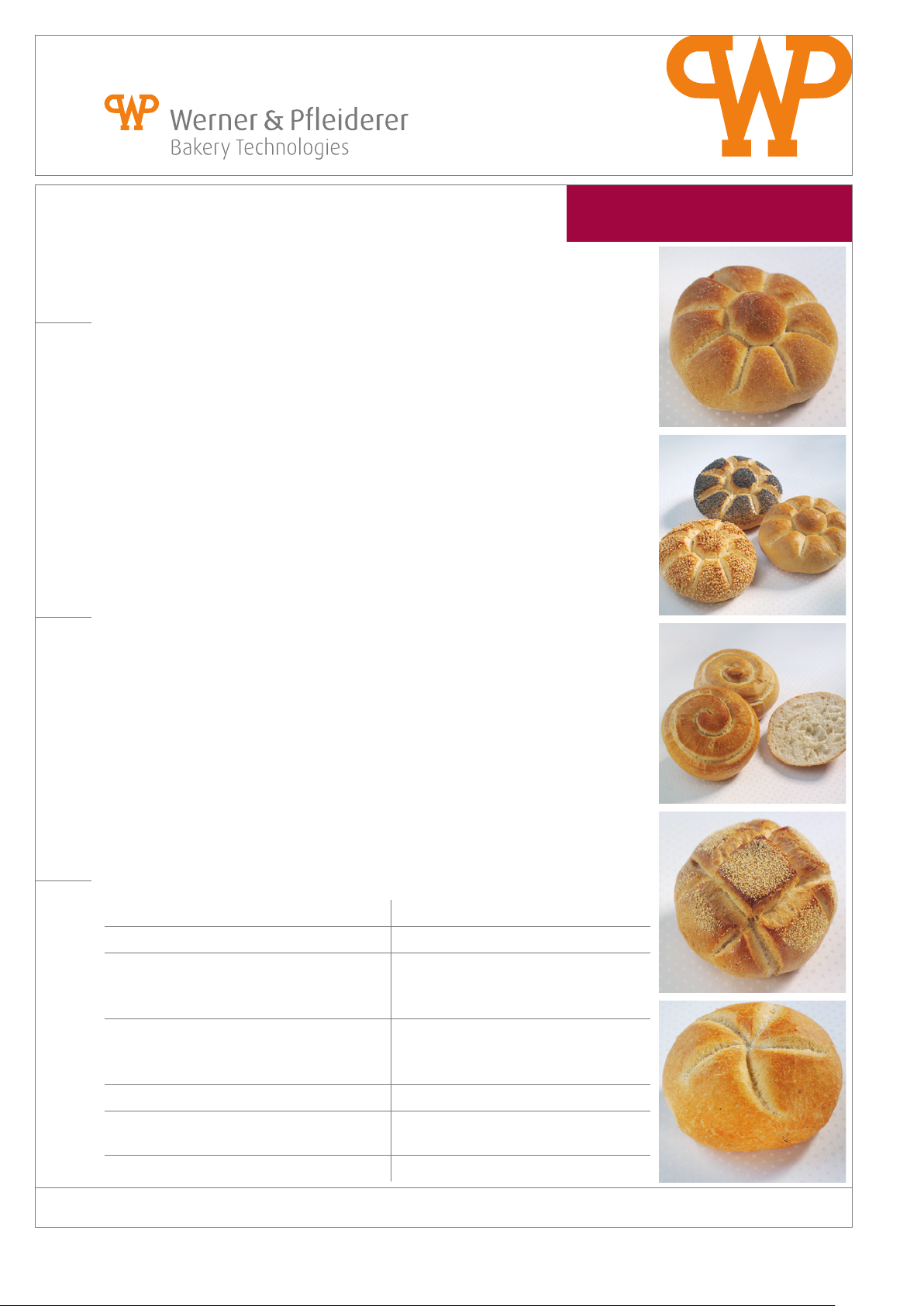

– Various stamping tools for the production of:

· Star rolls

· Button rolls

· Rosette rolls

· Pressed rolls

· Ring rolls

· Kärntner rolls

– Additional chamber drum

Technical specifications

Hourly capacity

Pre-proofing time

Weight range

Stamped

Not stamped

Tray carrier dimensions

Connected electrical load

Dimensions

L x W x H

Minimum height of room required

pieces/hour 3,000

minutes 11

g 40-65

g 30-90

mm 400 x 600

mm 580 x 780

mm 580 x 980

kW 4.5

mm 2,600 x 1,150 x 2,350

mm 2,400

Loading...

Loading...