Page 1

ECO

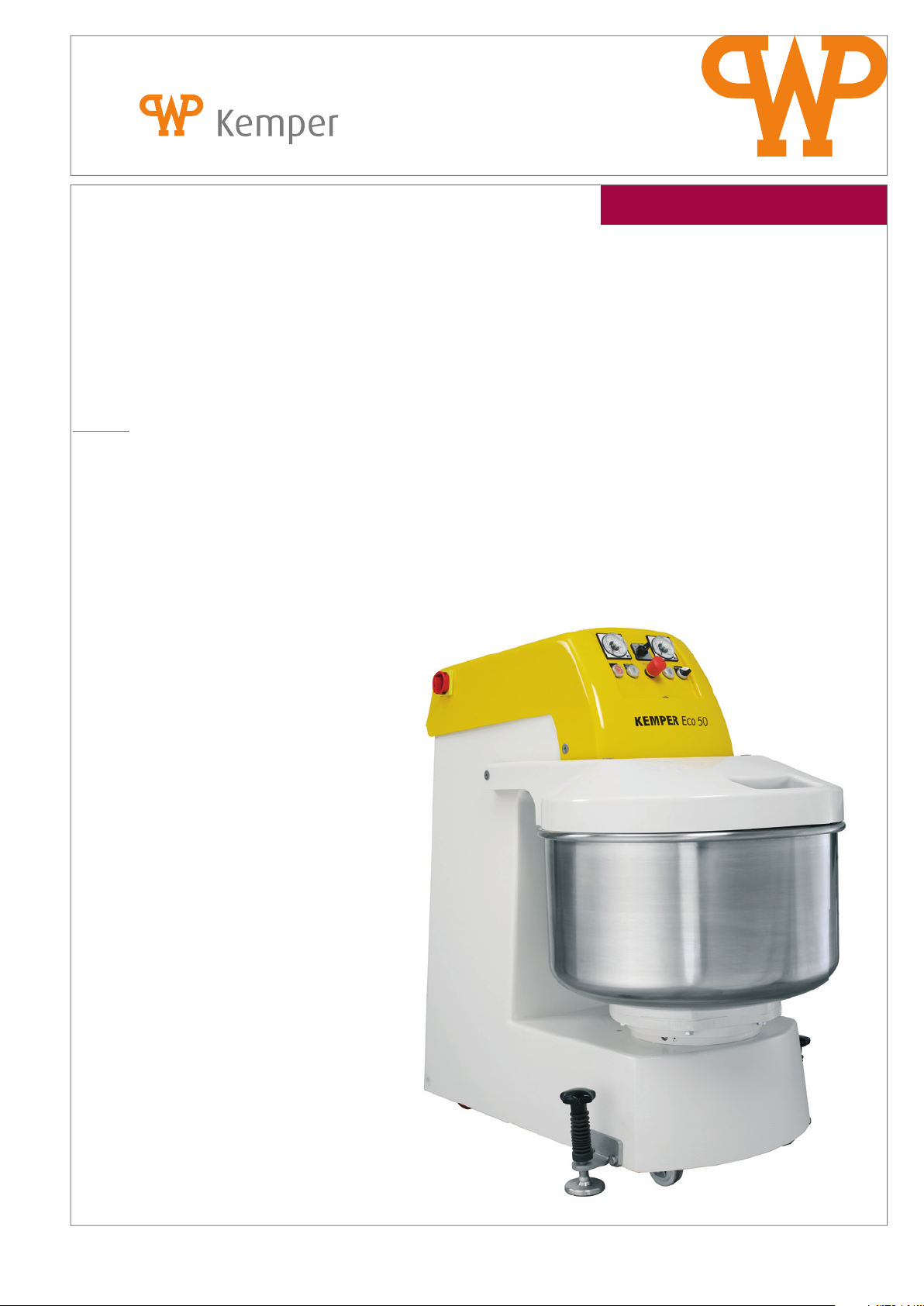

Spiral Mixer mobile

30 – 125 kg of fl our

– direct bowl drive via gear motor and generously dimensioned crossed roller bearing

– robust, smoothly rounded, ergonomic machine design - bowl and mixing tools made from stainless steel, high polished

– KEMPER-3-Zone-Mixing principle (spiral; guide bar)

– Reversing switch – clockwise/anticlockwise bowl rotation

Benefi ts

– direct bowl drive via gear motor, therefore no wearing parts

and no maintenance at those hard to reach points

– quiet, well-balanced movement

– fast cleaning due to smooth dust repellent surfaces

– production of light, easy to process dough

– simple, faster mixer

ECO 1/2

Spiral mixer mobile 08.12.2008

WP BAKERYGROUP

Page 2

ECO

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

EMIL KEMPER GMBH . Lange Straße 8 – 10 . 33397 Rietberg . Germany .

Fon + 49 (0) 5 244 -402-0 . Fax + 49 (0) 5 244 -402-220 . info@emil-kemper.de . www.emil-kemper.de

WP BAKERYGROUP

ECO 2/2

Spiral mixer mobile 08.12.2008

Size Capacity Capacity Connector plug Connector plug Dimensions

ECO 30 30 45 1,0/4,0 0,75 1.085 x 782 x 1.265

ECO 50 50 80 1,0/4,0 0,75 1.195 x 782 x 1.265

ECO 75 75 120 2,7/7,8 1,10 1.280 x 885 x 1.300

ECO 100 100 160 2,7/7,8 1,10 1.420 x 940 x 1.300

ECO 125 125 200 2,7/7,8 1,10 1.420 x 940 x 1.300

flour (kg) dough (kg) Spiral (kW) Bowl (kW) (L x B x H) in mm

Characteristics

– Steel stand

– Bowl and mixing tool made from stainless steel, high polished

Plastic flour dust protection cover

– Control in machine head; contactor control

– build-inmo tor proteczion, automatic operating cycle

– two eletro-mechanical timers

– manual/automatic selector switch

– push-button control

– illuminated buttons

– clockwise/anti-clockwise bowl rotation

Options

– Temperature sensor PT 100 (internal dough

temerature)

– Stainless steel stand

– Program control

Siemens S7 PLC

– Bowll with drain screw

– Special tool

– Bowl scraper for mixers “mobil”

– Special paint finish

Loading...

Loading...