Page 1

Combi IV N 1/2

Long Moulder 08.02.2009

Long Moulder Combi IV N

Industrial Dough Long Moulder

Specification

The Combi IV N is a unique dough long moulder suitable for the industrial - and middle size bakeries for the production of wheat

and wheat/rye dough’s. Through its unique sheeting and turning station long sheeted dough pieces can be created with a lot

Advantages

- Unique sheeting system

- Sheeting rollers with anges in small execution

BAKERYWP

GROUP

of windings. Through this the water in the dough is perfectly spread in the dough piece, so that a homogeneous dough piece

arise with a ne structure and a short cylindrical shape which can be long moulded to the desired length.

- 3 pair of rollers

- 1 dough turning station

- Driven curling net

- Well known and proven long moulding system

- Heavy spring loaded pressure board

- Recipe control (option)

- Hingeable pressure board for easy cleaning

- Easy to operate and maintenance

Basic execution Combi IV N :

- Infeed conveyor with driven centering rollers

- 3 pairs of sheeting rollers

- Fan and scraper on third xed rollers

- Tipping device

- Driven curling net

- Moulding bridge with adjustable belt speed

- Panner device with own drive and top stopper

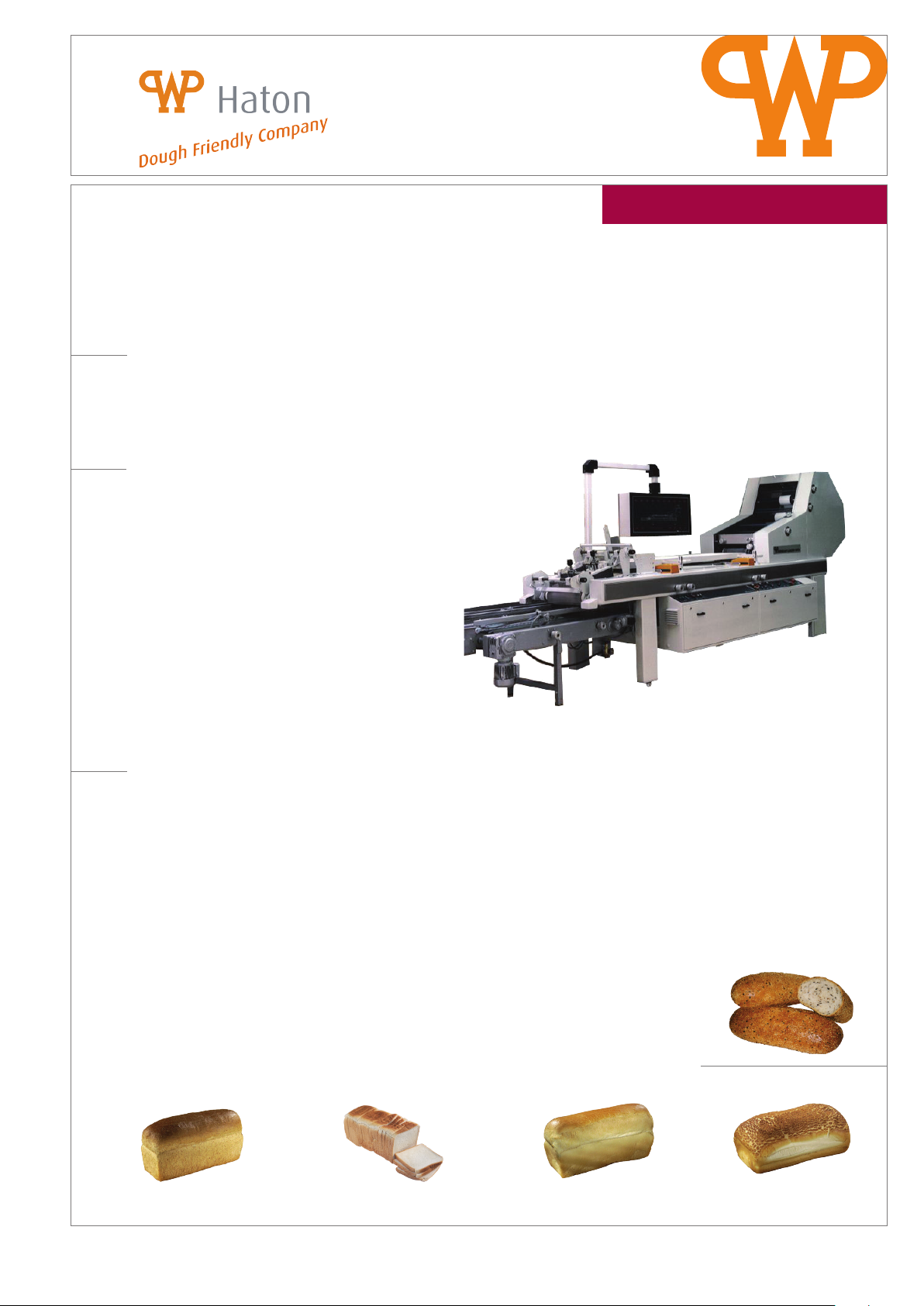

Illustration: Combi IV N

Page 2

WP BAKERYGROUP

Combi IV N 2/2

Long Moulder 08.02.2009

Combi IV N

Technical details

Type Weight range

- IV N 400 - 1100 gr.

- Capacity max. 3600 pcs/h.

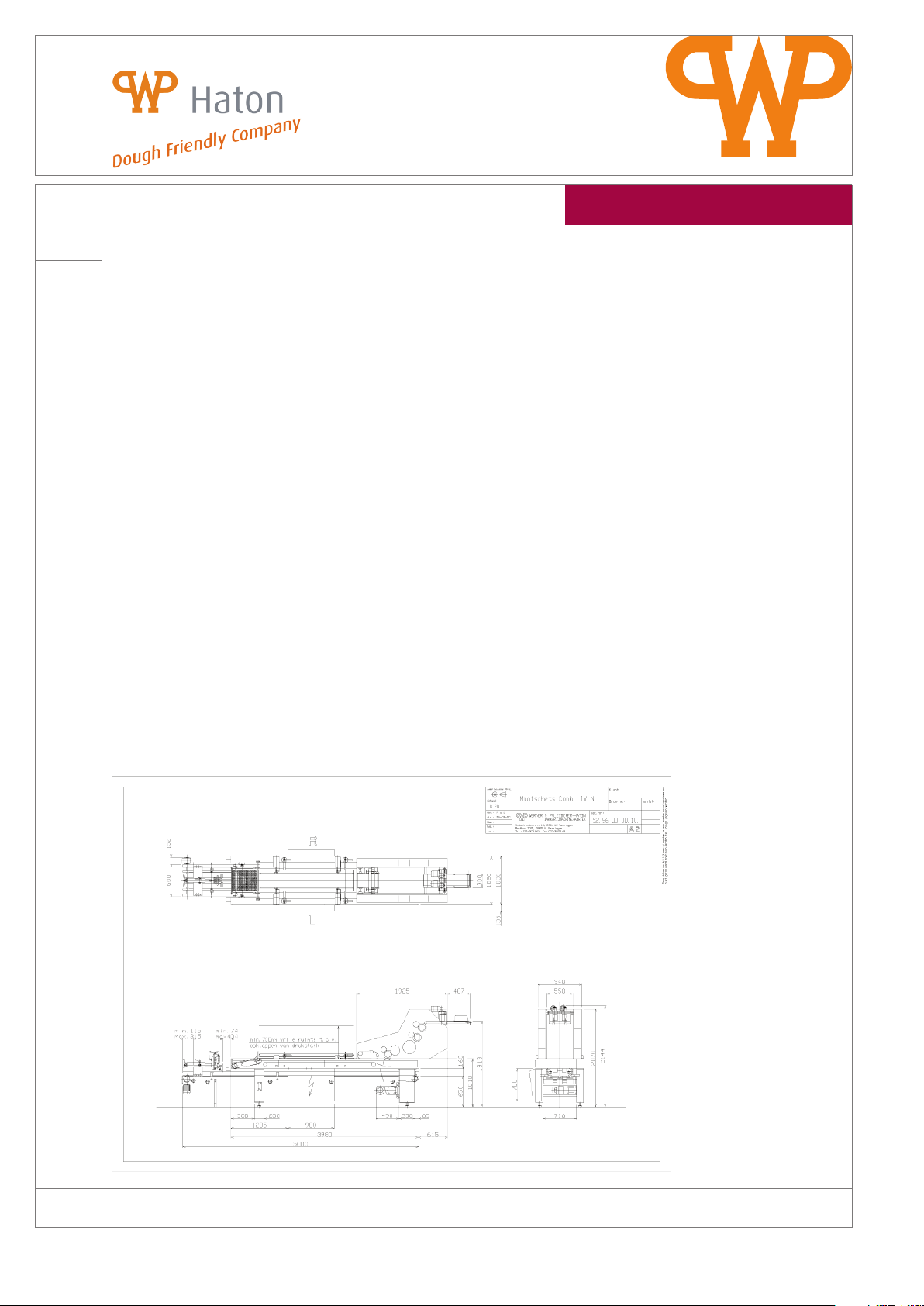

Dimensions Combi IV N Weight Connecting load

Without panner device With panner device

- Length 5200 mm. - Length 6300 mm. - Net 1500 Kg. - 230/400 V, 50 Hz + earth

- Width 1030 mm. - Width 1030 mm. - Gross Kg. - 4 resp. 4,75 KVA

- Height 2125 mm. - Height 2125 mm.

Options Combi IV N

For moulding bridge and sheeting head

- Driven curling net

- Divided pressure board

- Wafer device (singular)

- Cutting device, 2-pieces

- Cutting device, 2-pieces with spread-V

- Twisting device 4-pieces (running in same direction with topstopper)

- Electronic pieces counter (with pre-set counter)

For Panner device

- Panner device 2,5 of 5 meter with top- or bottom stopper

- Dierent panner conveyor length per 1000 mm.

- Extra bottom stopper

- Separate top stopper

- Extra peelboard stopper (tracking)

- Tin signalization: shortage and back-up

- Depositing/centering device (triangles)

- Depositing/centering device (triangles), positioning left and/or right-middle (capacity max. 2800 pcs/h)

® = registered trademark

Werner & Pfleiderer Haton B.V. Industrieterrei n 13, 5981 NK Panningen, The Netherlands.

Phone +31(0)77 -307-1860 . Fax +31(0)77-307-5148. info@ wp-haton.com . www.wp-haton.com

All details non-binding. Subject to change in the course of technical progress. All rights reserved.

Loading...

Loading...