Page 1

BM 54 BT 1/2

Long Moulder 08.02.2009

Long Moulder

BM 54 BT

Universal Long Moulder

Specification

Universal long moulder suitable for wheat, wheat/rye

(up to 30% rye) dough’s.

Advantages

- Perfect long moulding results

- Separate curling belt

BAKERYWP

GROUP

- Separate drive moulding station for dough friendly long moulding

- Easy opening and cleaning of spring loaded pressure boards

- 2 sets (alt. 4 sets BM4-54) of sheeter rollers

with Ø 125 mm for perfect sheeting

- Perfect reading of settings for good repeating of processes

- Modern design in stainless steel

- Easy to operate and maintain

- Low noise level by geared belt drive

Basic execution BM 54 BT :

- Infeed conveyor

- Coverplates stainless steel

- Moulding bridge, stainless steel, glass bead blasted

- Adjustable synthetic pressure roller

- 2 adjustable synthetic sheeter rollers with scrapers

- Adjustable stainless steel curling net

- Rolling belt with adjustable speed

- Hingeable pressure board, adjustable in height with adjustable side guides

- Pressure board hingeable 2xV

- Maximum moulding length 420 mm.

* BM 54 BT in lengthened version with twisting device (Optional)

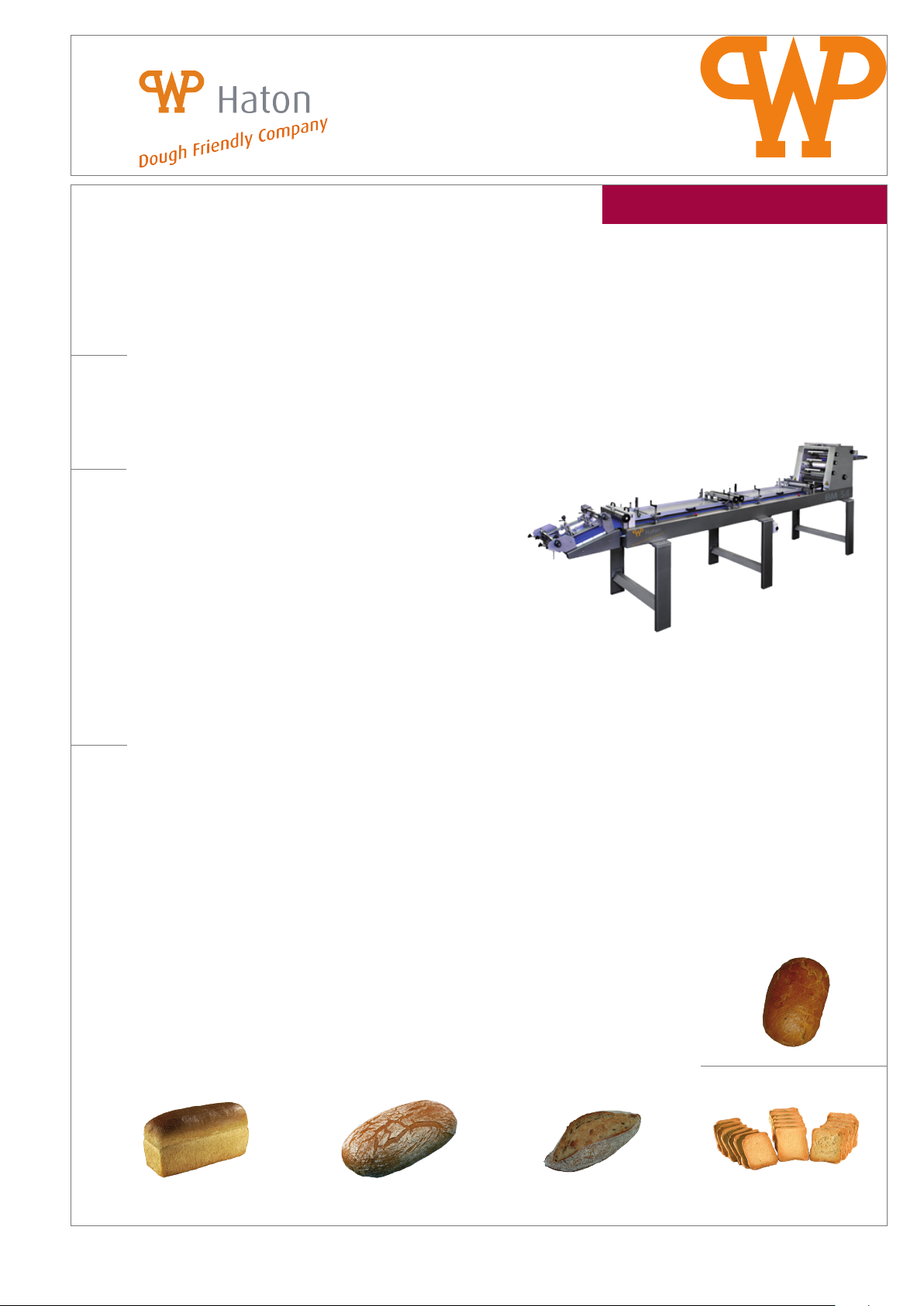

Illustration: BM 54 BT* (extended version)

Page 2

WP BAKERYGROUP

BM 54 BT 2/2

BM 54 BT

Technical details

Type Weight range

- BT 200 - 1100 gr.

- Capacity max. 3000 pcs/h., (by 1000 gramme dough weight).

Dimensions BM 54 BT Weight Connecting load

BM 54 BT standard with long nose BM 54 BT-L with long nose

- Length 4642 mm. - Length 6442 mm. - Net 980 Kg. - 230/400 V, 50 Hz + earth

- Width 972 mm. - Width 972 mm. - Gross Kg. - 0,55 KVA

- Height 1775 mm. - Height 1775 mm.

Options BM 54 BT

- BM 54 BT-L = lengthened version with 2 pressure boards

- Pre-set counter

- Adjustable centering rollers on infeed conveyor

- Drying device on 1st and 2nd sheeting roller pair (for mixed dough’s)

- Flourduster with on drive

- Separate belt drive

- Cutting device 2-pieces with nal moulding plate and spread-V

- Cutting- and twisting device 4-pieces with nal moulding plate

- Panner device, tracking, 5000 mm.

- overhead stopper - bottom stopper - peelboard stopper - tin signalisation

- Top belt running in opposite direction

- Flange rollers

- BM 454 with 4 sheeter rollers

Long Moulder 08.02.2009

® = registered trademarkAll details non-binding. Subject to change in the course of technical progress. All rights reserved.

Werner & Pfleiderer Haton B.V. Industrieterrei n 13, 5981 NK Panningen, The Netherlands.

Phone +31(0)77 -307-1860 . Fax +31(0)77-307-5148. info@ wp-haton.com . www.wp-haton.com

All details non-binding. Subject to change in the course of technical progress. All rights reserved.

Loading...

Loading...