Page 1

BM 2-40 + BM 2-40 Basic 1/2

Long Moulder 28.02.2012

Long Moulder - BM 2-40

Universal Industrial Moulder

Specification

Universal industrial moulder for tin and hearth bread, suitable for wheat dough’s

and mixed rye/wheat (up to max. 30% rye) dough’s.

Advantages

- Excellent moulding results

- Infeed conveyor with adjustable diabolo centering rollers and adjustable

- BM 2-40 Basic

pressure roller

- Two separate individually driven sheeting rollers with adjustable speed

- Progressive sheeting of the dough pieces with relaxation phase

- Separation of curling- and sheeting belt for an optimal synchronous

of curling belt and roller speed and an longer sheeting time

- Second sheeting station with upper belt or pressure board (option)

- Easy to clean scrapers on each roller

- Drying device on each roller

- Good accessibility of rollers and scrapers for easy cleaning

- Thickness and width dough piece adjustable through speed control

through recipe control via PLC

- Curling- and sheeting belt are adjustable in speed

- Pressure board hingeable for fast cleaning and accessibility

- Very modern and functional design in stainless steel

BAKERYWP

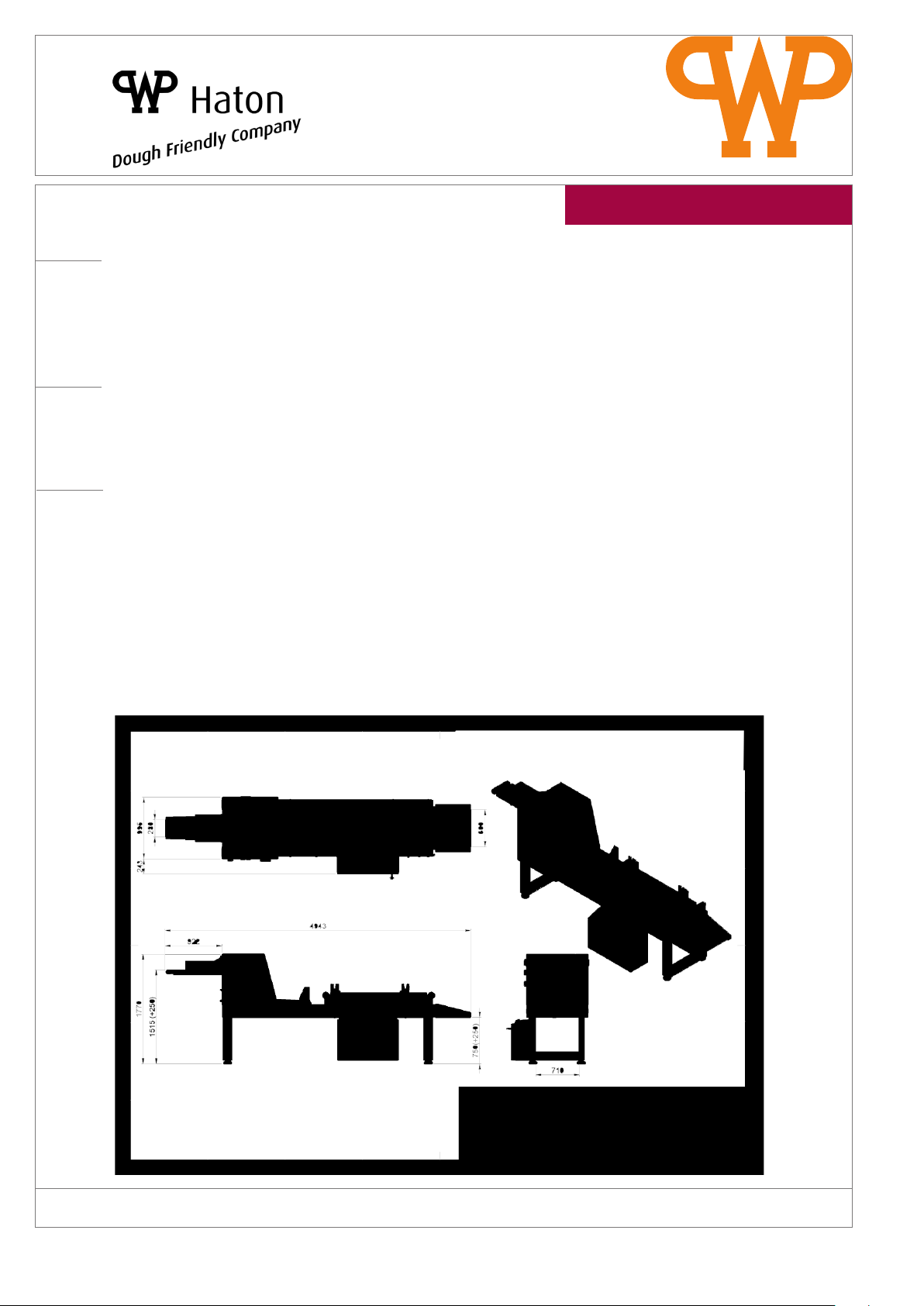

Illustration: BM 2-40

GROUP

Basic execution BM 2-40 :

- Infeed conveyor with pressure board

- Two sets of sheeting rollers, opening adjustable between 1 and 23 mm.

- Rollers made of arnite, width 400 mm, diameter 125 mm, equipped with

teon coated scrapers

- Two separate (option) individually driven sheeting rollers and scrapers on

each roller, turnable for easy cleaning

- Visual control of sheeting process

- Frame sheeting head made of aluminium

- Brushed stainless steel cover plates

- Moulding bridge in sand blasted stainless steel

- Pressure board adjustable in height between 10 and 70 mm, both on infeed

and outfeed side

- Drying device on all sheeter rollers

- Side guide adjustable to <600 mm

- BM 2-40 Basic: xed drive of infeed conveyor, rollers, curling- and sheeting belt

Page 2

WP BAKERYGROUP

BM 2-40 + BM 2-40 Basic 2/2

Long Moulder 28.02.2012

BM 2-40

Technical details

Type Weight range

- 2-40 200 - 1100 gr.

- 2-40 Basic 200 - 1100 gr.

- Capacity max. 3000 pcs/h., at 1000 gr.

Dimensions BM 2-40 Weight Connecting load

- Length 4943 mm. max. - Net 980 Kg. - 230/400 V, 50 Hz + earth

- Width 995 mm. max. - Gross Kg. - 2,2 KVA

- Height 1770 mm. max.

Options BM 2-40

- Pre-set counter - In same direction running panning conveyor, length 5300 mm:

- Drying device on curling belt - stainless steel frame,

- Drying device on driven top moulding belt - two at chains in guides,

- Flange roller last roller pair - side guides, adjustable in height 215-475 mm,

- Driven moulding belt running ccw instead of pressure board - connection load 4,75 KVA,

- Flour duster with own drive - dimensions 6300x1030x2125 mm (lxwxh),

- Cutting device 2-pieces with nal moulding plate and spread V - net weight 300 kg,

- Twisting (cutting into 4-pieces + 90º turning) - Overhead stopper, pneumatically operated, compressed air 600 l/6 bar

- Extended version with 2 pressure stations (board or belt) - Bottom stopper, pneumatically operated, compressed air 600 l/6 bar

Decoration station - Peelboard stopper

-

- Extended version: belt width 600 mm, sheeting length 150-600 mm - Tin signalisation, shortage and back-up

® = registered trademark

Werner & Pfleiderer Haton B.V. Industrieterrei n 13, 5981 NK Panningen, The Netherlands.

Phone +31(0)77 -307-1860 . Fax +31(0)77-307-5148. info@ wp-haton.com . www.wp-haton.com

All details non-binding. Subject to change in the course of technical progress. All rights reserved.

Loading...

Loading...