Page 1

BIP 72-M 1/2

Intermediate Proofer 08.02.2009

Intermediate Proofer BIP 72-M

Intermediate Proofer

Specification

Intermediate proofer which is suitable for many common dough types,

such as wheat and wheat/rye dough’s with a low percentage of rye,

Advantages

- Frame made of modular closed tubular proles out of stainless steel

- Processing without our dusting

Basic execution BIP M :

- Infeed photo-cell, capacity 1200 pcs/h.

without the use of any dusting our.

The intermediate proofers from the type BIP 72 are developed for fully

automatic proong/resting of the dough pieces between rounder and

long moulder.

- All frame parts in stainless steel or nickel coated, no painted parts in dough area

- Teonized transfer box for dough transfer between pockets without sticking

problems

- Stainless steel trays

- Removable and washable plastic dough cups

- Round dough cups for dough balls results in a optimum proong

- Ultraviolet light for protection against mould

- Reliable infeed systems

- Plexiglass windows for visual inspection

- Performance reliable thanks to many years of experience

- Variable proong times

BAKERYWP

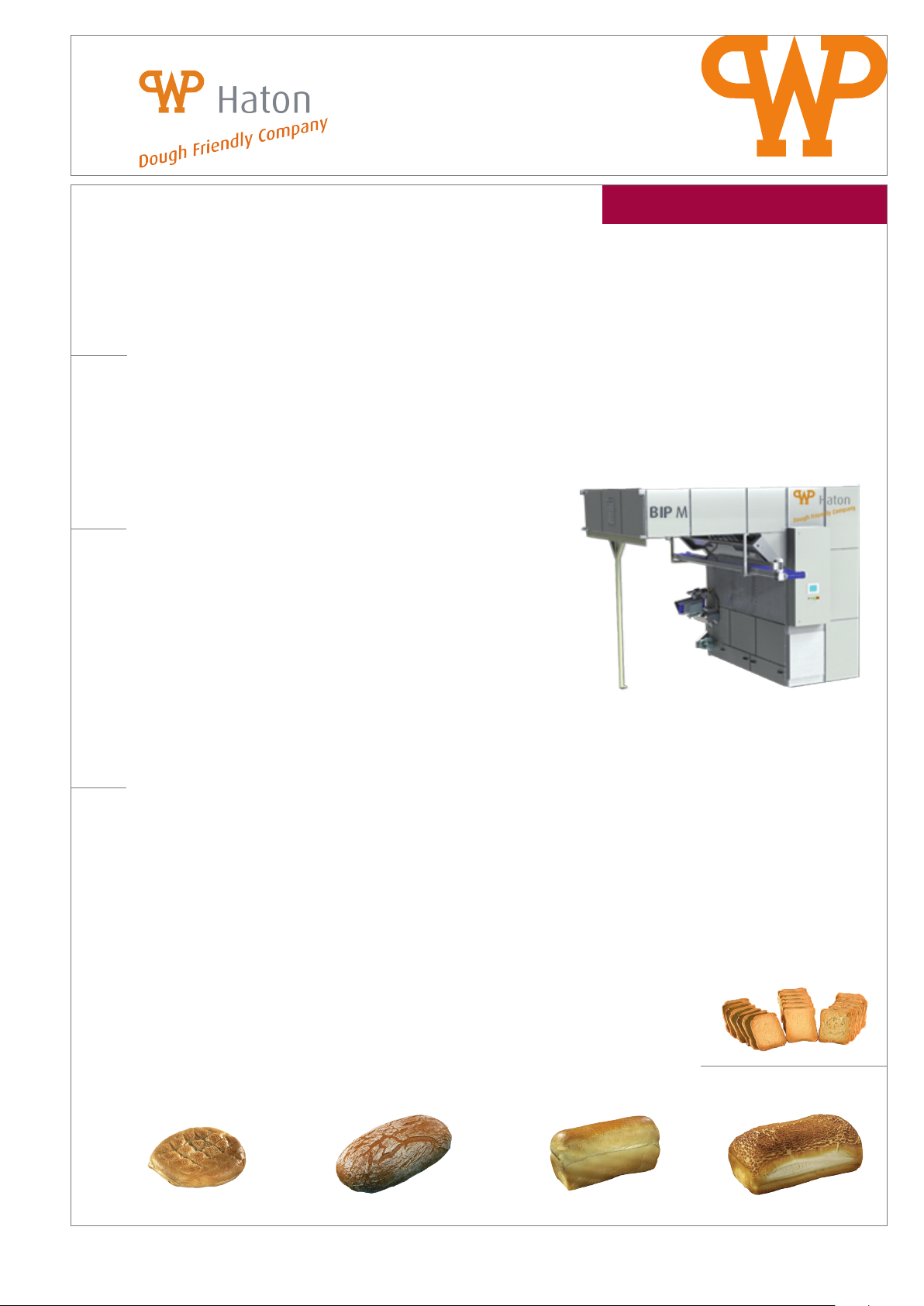

Illustration: BIP M

GROUP

- Infeed V-stepbelt, capacity 1800 pcs/h, single infeed

- Infeed V-stepbelt, capacity 3600 pcs/h, dual infeed

by means of 2-way ippergate

- Proofer runs intermittently / continiously

- Pockets round, polyaethylene, diameter 190 mm.

- Plexiglass windows

- Frame, turning device and panels stainless steel

- Chain with chain guides

- Shafts and chain wheels nickel plated

- Integrated switchboard panel

- CPU control for proofer with dual infeed, capacity 3600 pcs/h.

- Stop switch for correct tray position

- Discharge chute with outfeed on last row

- Attaching head to existing ceiling

Page 2

WP BAKERYGROUP

BIP 72-M 2/2

Intermediate Proofer 08.02.2009

BIP 72-M

Technical details

Type: Infeed photo-cell Type: V-stepbelt, single infeed Type: V-stepbelt, dual infeed

(Capacity < 1200 pcs/h.) (Capacity < 1800 pcs/h.) (Capacity < 3600 pcs/h.)

Net contents Net contents Net contents

- 376-416/8-2/3111/1467* 379 - 360-376-416/8-2/3111-1467* 361 - 360-376-416/8-2/3111-1467* 355

- 392-432/8-2/3111/1734 395 - 376-392-432/8-2/3111-1734 376 - 376-392-432/8-2/3111-1734 370

- 408-448/8-2/3111/2001 411 - 392-408-448/8-2/3111-2001 391 - 392-408-448/8-2/3111-2001 386

- 424-464/8-2/3111/2268 427 - 408-424-464/8-2/3111-2268 407 - 408-424-464/8-2/3111-2268 401

- 564-624/12-2/3111/1467 571 - 540-564-624/12-2/3111-1467 544 - 540-564-624/12-2/3111-1467 538

- 588-648/12-2/3111/1734 595 - 564-588-648/12-2/3111-1734 567 - 564-588-648/12-2/3111-1734 561

- 612-672/12-2/3111/2001 619 - 588-612-672/12-2/3111-2001 590 - 588-612-672/12-2/3111-2001 584

- 636-696/12-2/3111/2268 643 - 612-636-696/12-2/3111-2268 612 - 612-636-696/12-2/3111-2268 607

* (-net-gross/number of rows-number of legs/height/head length)

Weight range

Options BIP M

- Infeed at front, outfeed backside

- Hot air blower on infeed to avoid sticky dough’s

- Exhaust fan (manual operation)

- Exhaust fan with hygrostat

- Fully automatic climatisation

- Central switching

- CPU control for proofer with photo-cell infeed and V-stepbelt single infeed

- Master slave regulation

- Adjustable discharge conveyor on last 3 rows for 12-piece proofer

- Adjustable discharge conveyor on last 4 rows for 8-piece proofer

- Stainless steel net on discharge chute in case of dropping height 1000 mm.

- Discharge conveyor with own drive, reversible, outfeed on all rows. With discharge roller and discharge chute.

- Discharge conveyor with own drive, reversible, outfeed on all rows. With discharge roller and frequency inverter (for dual infeed).

- Dierent proofer height 2844 mm, whereby the head lenght will be adjusted to reduce the dierence

- Photo-cell controlled infeed

- 1600 gr., 1800 gr. for mixed dough’s

Connecting load

- 230/400 V, 50 Hz + earth

® = registered trademark

Werner & Pfleiderer Haton B.V. Industrieterrei n 13, 5981 NK Panningen, The Netherlands.

Phone +31(0)77 -307-1860 . Fax +31(0)77-307-5148. info@ wp-haton.com . www.wp-haton.com

All details non-binding. Subject to change in the course of technical progress. All rights reserved.

Loading...

Loading...