Page 1

Dough hopper 1/2

Dough hopper 08.02.2009

Dough Hopper

Dough hopper

Specification

Dough hoppers are particularly used in industrial dough handling systems for automatic feeding and portioning of a complete batch

Advantages

- Hopper and frame in stainless steel

- Suitable for many dierent types of dough

BAKERYWP

GROUP

(up to 900 litre) of dough to the divider. By this the pressure and the amount of dough in the dough hopper of the divider are constant,

which is important for an accurate weight consistency.

- Dierent dough hopper sizes possible

- Dierent types of material inside the hopper to avoid sticking possible

- Automatic control

- Hopper movable for easy cleaning (option)

- Extraction rollers (option)

Basic execution dough hopper :

- Robust construction in standard and/or customer specic execution

- Frame stainless steel

- Platform with safety rail

- Hopper, teonized or HDPE coated

- Ladder stainless steel, removable

- Pneumatic controlled dough slide

- Dough level detection with 2 photo-cells

- Oil spraying device, pneumatic (4 nozzles)

- For placing above Parta U, V 700, V 900, MUC, TWL or TWS with HKL

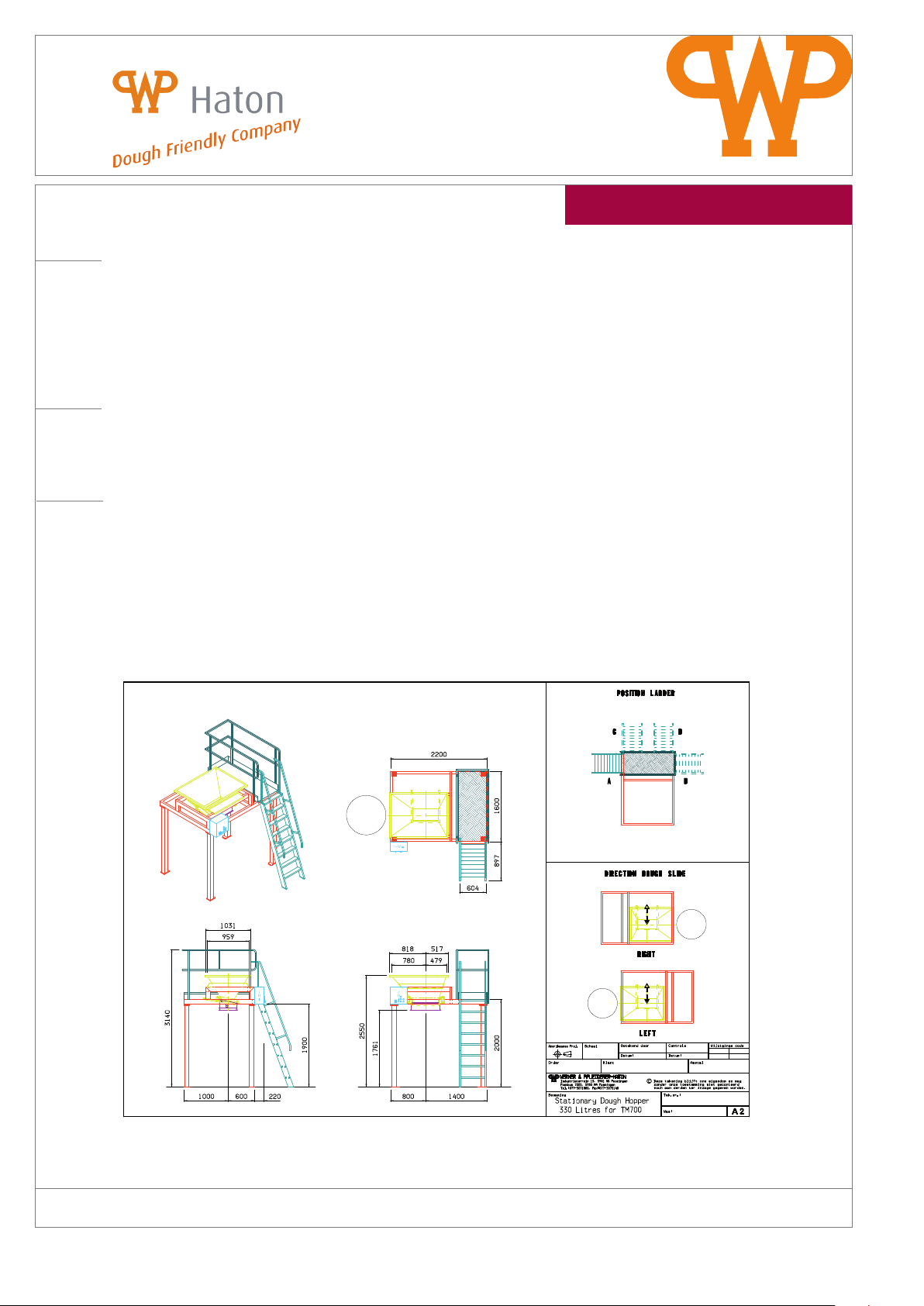

Illustration: Dough hopper

Page 2

WP BAKERYGROUP

Dough hopper 2/2

Dough hopper 08.02.2009

Dough Hopper

Technical details

Type

(Hopper contents depending on divider and dough bowl ca. 300 liters)

- Dough hopper contents for Parta SN 240 liters

- Dough hopper contents for Parta U 285 liters

- Dough hopper contents for V 500 330 liters

- Dough hopper contents for B/V700 330 liters

Weight Connecting load Compressed air

- Net 300 Kg. - 230/400 V, 50 Hz + earth - Consumption 100 l/h at 6 bar pressure

- Gross Kg. - 0,3 KVA

Options Dough hopper

- Dough level detection in the dough hopper, acoustic or visual signal

- Motor operated dough slide

- Capacity hopper up to 500 litres

- Capacity hopper up to 900 litres

- Hopper inside teon coated, outside stainless steel

- Extraction rollers

- Hopper movable for cleaning perposes

Werner & Pfleiderer Haton B.V. Industrieterrei n 13, 5981 NK Panningen, The Netherlands.

Phone +31(0)77 -307-1860 . Fax +31(0)77-307-5148. info@wp-haton.com . w ww.wp-haton.com

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...