Page 1

WP BAKERYGROUP

B / V 300 D 1/2

Dough Divider 26.08.2010

Dough Divider

B / V 300 D

Universal Dough Divider

Specification

This dough divider is suitable for most common types of dough as well as sensitive dough’s.

The divider handles a big variety of dough types such as wheat, wheat/rye, sti (pizza)

dough’s, as well soft (French) dough’s.

Advantages

- Robust design

- Long lifespan by using wear-resistant materials

- Minimum oil consumption

- High weight precision

- Dough friendly dividing at a high capacity

- Self-cleaning knife

- Hingeable dough hopper for easy cleaning

- Voluminator with low and high pressure setting

- Good handling of practical all common dough types

- Easy access for cleaning and maintenance

- Extreme weight ranges possible

Basic execution B 300 D :

- B 300 D : 1, 1/2, 2/4 pocket machine

- Dividing unit with automatic oiling, 6 xed dosing valves

- Conveyor : cross 720 mm.

- Mechanical discharge ap with plastic scraper

- Hopper, stainless steel, 60 liters, H=1629 mm., with safety ring

- Operation : on / o / emergency stop

- Main piston, dividing chamber and hopper: wear-resistant chrome nickel alloy

- Measuring pistons bronze

- Knife hardened steel

- Cover plates, stainless steel, brushed, with Schmersal safety switches

- Frame : steel, nickel coated

- Crankshaft and drive rods cast iron, nickel coated

Basic execution V 300 D :

- V 300 D : 1, 1/2, 2/4 pocket machine

- Voluminator Compact U

- Dividing unit with automatic oiling, 6 xed dosing valves

- Conveyor : cross 720 mm.

- Mechanical discharge ap with plastic scraper

- Hopper, stainless steel, 60 liters, H=1629 mm., with safety ring

- Operation : on / o / emergency stop

- Main piston, dividing chamber and hopper: wear-resistant chrome nickel alloy

- Measuring pistons bronze

- Knife hardened steel

- Cover plates, stainless steel, brushed, with Schmersal safety switches

- Frame : steel, nickel coated

- Crankshaft and drive rods cast iron, nickel coated

- Stop position

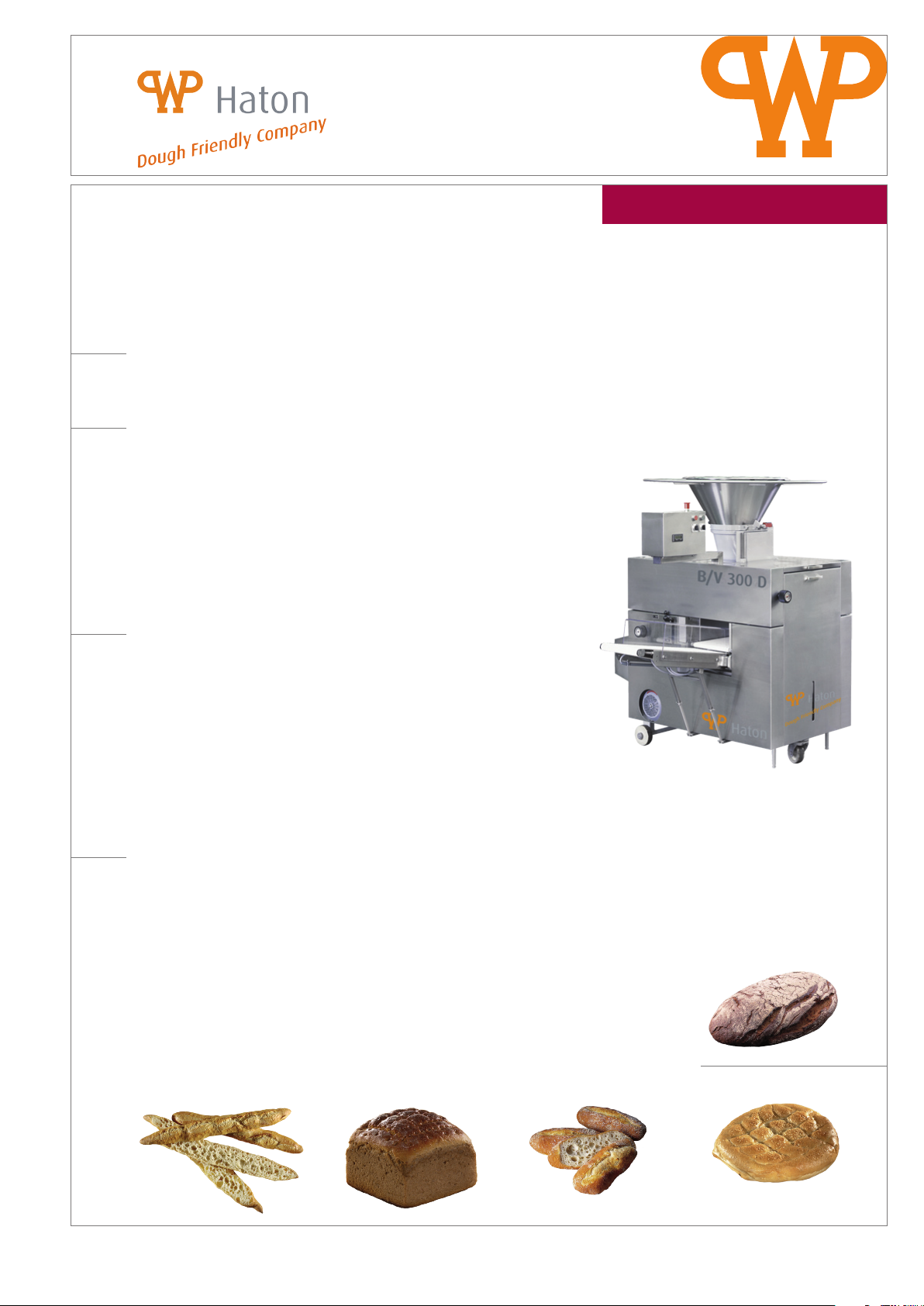

Illust ration: B / V 300 D

Page 2

B / V 300 D

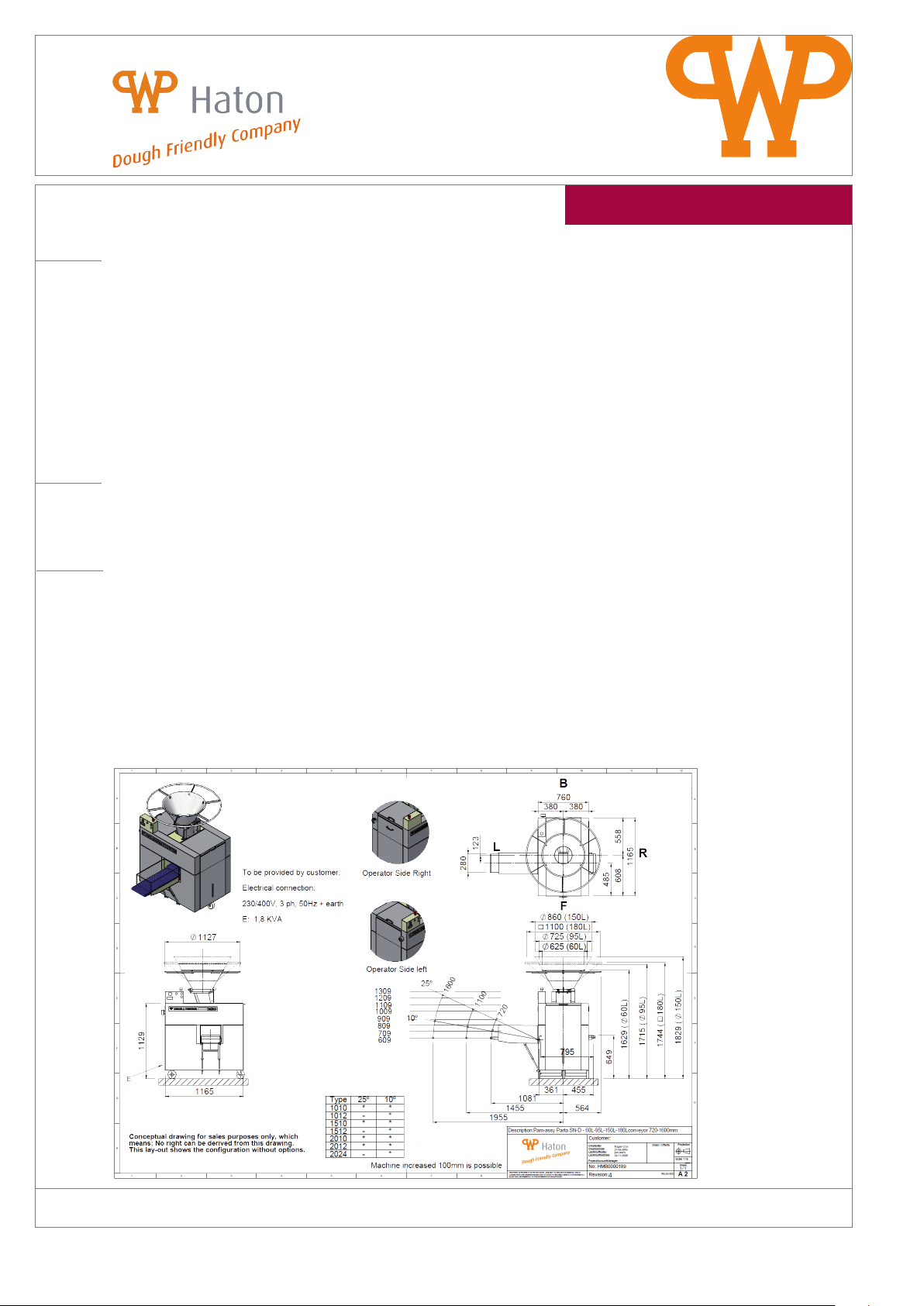

Technical details Pockets / Variable (option)

Type Weight range Capacity (xed) by means or frequency inverter with digital display

- Type 1010 1 / 100 - 1200 gr. - 925 or 1030 pcs/h. - 507-1160 or 637-1456 or 700-1600 pcs/h.

- Type 1510 1 / 200 - 1800 gr. - 925 or 1030 pcs/h. - 507-1160 or 637-1456 or 700-1600 pcs/h.

- Type 2010 1 / 400 - 2400 gr. - 925 or 1030 pcs/h. - 507-1160 or 637-1456 or 700-1600 pcs/h.

- Type 1012 1 / 100 - 1200 gr. - 925 or 1030 pcs/h. - 507-1160 or 637-1456 or 700-1600 pcs/h.

2 / 50 - 300 gr. - 1850 or 2060 pcs/h. - 1014-2320 or 1274-2912 or 1400-3200 pcs/h.

- Type 1512 1 / 200 - 1800 gr. - 925 or 1030 pcs/h. - 507-1160 or 637-1456 or 700-1600 pcs/h.

2 / 50 - 500 gr. - 1850 or 2060 pcs/h. - 1014-2320 or 1274-2912 or 1400-3200 pcs/h.

- Type 2012 1 / 400 - 2400 gr. - 925 or 1030 pcs/h. - 507-1160 or 637-1456 or 700-1600 pcs/h.

2 / 100 - 1050 gr. - 1850 or 2060 pcs/h. - 1014-2320 or 1274-2912 or 1400-3200 pcs/h.

- Type 2024 2 / 100 - 1050 gr. - 1850 or 2060 pcs/h. - 1014-2320 or 1274-2912 or 1800-3200 pcs/h.

4 / 50 - 400 gr. - 3700 or 4120 pcs/h. - 2028-4640 or 2548-5824 or 2800-6400 pcs/h.

Dimensions (depending on execution) Weight Connecting load

- Length 2520 mm. max. - Net 720 kg. - 230/400 V, 3 Ph, 50 Hz + earth

- Width 1225 mm. max. - Gross 880 kg. - 1,8 KVA

- Height 1829 mm. max.

Options B / V 300 D Extra option, only for the V 300 D

- Hopper 95 l, 150 l, 250 l - Hybride main piston, reduced oil

- Hopper teonized for round hoppers 95 and 150 liters

- Oiling on hopper

- Pre-set counter

- Stop position on dividing unit for easy cleaning

- Servo weight adjustment with digital read out

- Frequency inverter for variable speed

- Discharge conveyor (standard 1100 mm.), 1600 mm.

- Mechanical our duster

- Curling net on discharge conveyor

- Separate drive on in- and outside conveyors with motorreductors or drum motors

- Increasing the machine with 100 mm.

WP BAKERYGROUP

B / V 300 D 2/2

Dough Divider 26.08.2010

Werner & Pfleiderer Haton B.V. Industrieterrei n 13, 5981 NK Panningen, The Netherlands.

Phone +31(0)77 -307-1860 . Fax +31(0)77-307-5148. info@ wp-haton.com . www.wp-haton.com

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

Loading...

Loading...