Page 1

WP BAKERYGROUP

AROMA+COOLER® 1/2

AROMA+COOLER®

Compact 40.15

Temperature range -15/-20 °C

Humidity range approx. approx. 70–95 % rel. hum.

Output 1,500 to rolls per hour

Werner & Pfleiderer rapid cooling units from the AROMA+COOLER® Dieckmann system series are specially designed for cooling

unproofed and proofed pieces of dough. Achieving short cooling times by precisely forcing the cold air to circulate via the

suction chamber system guarantees a considerable improvement in quality. AROMA+COOLER® Compact is ready to plug in and

its performance and build, with a capacity of up to 22 trays, are specially designed for use in small- to medium-sized bakeries.

Properties

– Dough pieces are cooled down efficiently, gently and with little moisture removal

– At an optimum aroma storage temperature of approx. +5°C, the flavour fully develops

– Subsequent storage in the GV AROMAT® WP cooling chamber keeps the dough perfectly moist

– The carefully controlled proofing curve provides a high proofing tolerance and proofing stability

– Storage in the plus range is possible for up to 36 hours

Air circulation

The cold air is sucked through the trays by the suction principle. This process is very effective because the stack of trays (socalled ‘aroma trays’) is connected to the docking station (with suction chamber) and hermetically sealed. This means that the

cold air is sucked through the trays over the dough pieces, ensuring that they are evenly cooled. Compared with flash-freezing,

because of the lower air volume and higher air temperature (–15°C/–20°C instead of –35°C), the suction principle is far kinder

to the dough pieces in terms of drying them out, and furthermore, it saves more energy.

Compact 40.15 24.09.2009

+

rapid

cooling

storage

0

AROMA+COOLER

-

®

proofing

GV AROMAT

-5 / +15 °C-15 / -20 °C

Benefits

– Optimum aroma, taste, gloss, crispness and freshness

– Optimum soft/moist dough pieces due to much lower

moisture removal

– Streamlining due to easy handling

– Ready to plug in as a compact unit and, therefore,

immediately ready to use

– Uncooled transport, space-saving

– Energy cost saving due to much lower consumption

– Efficient airflow over the dough pieces

– Faster cooling in 10 to 15 minutes

– Plastic aroma trays as well as conventional trays

(aluminium, wood) can be used

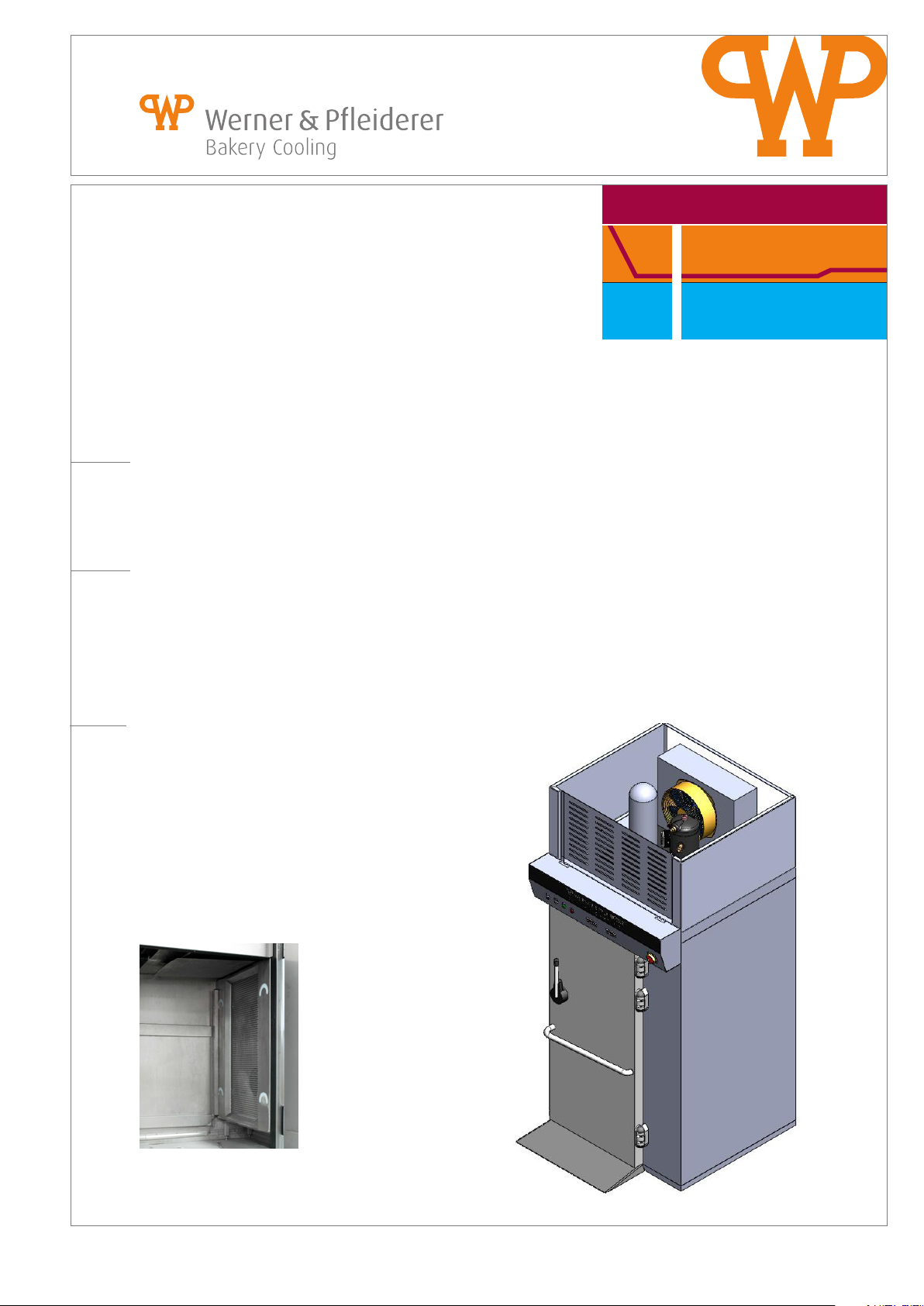

Docking chamber

Page 2

All details non-binding. Subject to change in the course of technical progress. All rights reserved. ® = registered trademark

WP BAKERYGROUP

WERNER & PFLEIDERER Koeling Benelux B.V. Industrieterrein 9 D . 5981 NK Panningen . Netherlands

Fon +31 (0) 77-850 70 60 . Fax +31 (0) 77-850 70 61 . info@wp-baker ycooling.com . www.wp-bakerycooling.com

WERNER & PFLEIDERER Lebensmitteltechnik Kälte GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany .

Fon +49 (0) 98 51-905-510 . Fax +31 (0) 77-850 70 61 . info@wpbakerygroup.com . www.wpbakerygroup.com

AROMA+COOLER® 2/2

Compact 40.15 24.09.2009

AROMA+COOLER®

Compact 40.15

Technical details

Output

1,500 rolls per hour

Cooling time

10 to 17 minutes

Cell housing

– Panels in 80-mm PU insulation, foamed, free of CFCs, HCFCs and HHCs

– Comes as a compact unit ready to plug in without assembly on-site

k value

0.24 W/sq m

Surfaces

Standard finish

– Inner walls: stainless steel

– Outer walls: stainless steel

– Unit front: stainless steel, sanded

Base

– TECFLOOR system, PU-insulated, 40 mm, with directly foamed stainless-steel base panel 0.8 mm

– 3-mm-thick stainless-steel panel laid on top in the form of a trough with raised sides

Ram protection

Inside with stainless-steel square profiles

Doors

Rotating door with clearance of 70 × 165 cm and

– 3 door hinges

– Solid press lever fastener for commercial use

– Ram protection inside and outside

– Door seal

– Door frame heating

– Multiple abrasive rubber for sealing down to the base

Control system

via EMS controller complete with electrical control cabinet, pre-wired according

to VDE regulations and easy to operate

Output of the individual units is related to the tray dimensions

– 40 × 60 cm for 16 pieces of dough each of 60 g

– 60 × 80 cm for 32 pieces of dough each of 60 g

22 trays 40 × 60 cm per trolley

11 trays 60 × 80 cm per trolley

Equipment

– Design ready to plug in

– Soft start

– Oil sump heating

– Pressure-controlled, speed-regulated condenser for energy-saving operation

– All necessary safety precautions

Dieckmann system rapid suction cooler

Compact type. For trays 40 × 60/60 × 80

Output dough pieces qty 1.500 AROMA+COOLER 40.30

Tray trolleys qty 1

Cooling time 40 x 60 trays min. 10 – 13

Cooling time 60 x 80 trays min. 13 – 17

Outer dimensions (W × D × H) cm 116 x 101 x 251

AROMA+COOLER

Compact 40.15

Other AROMA+COOLER units

available in larger versions

AROMA+COOLER 40.45

AROMA+COOLER 40.60

AROMA+COOLER 40.90

AROMA+COOLER 40.120

Loading...

Loading...