Page 1

WP BAKERYGROUP

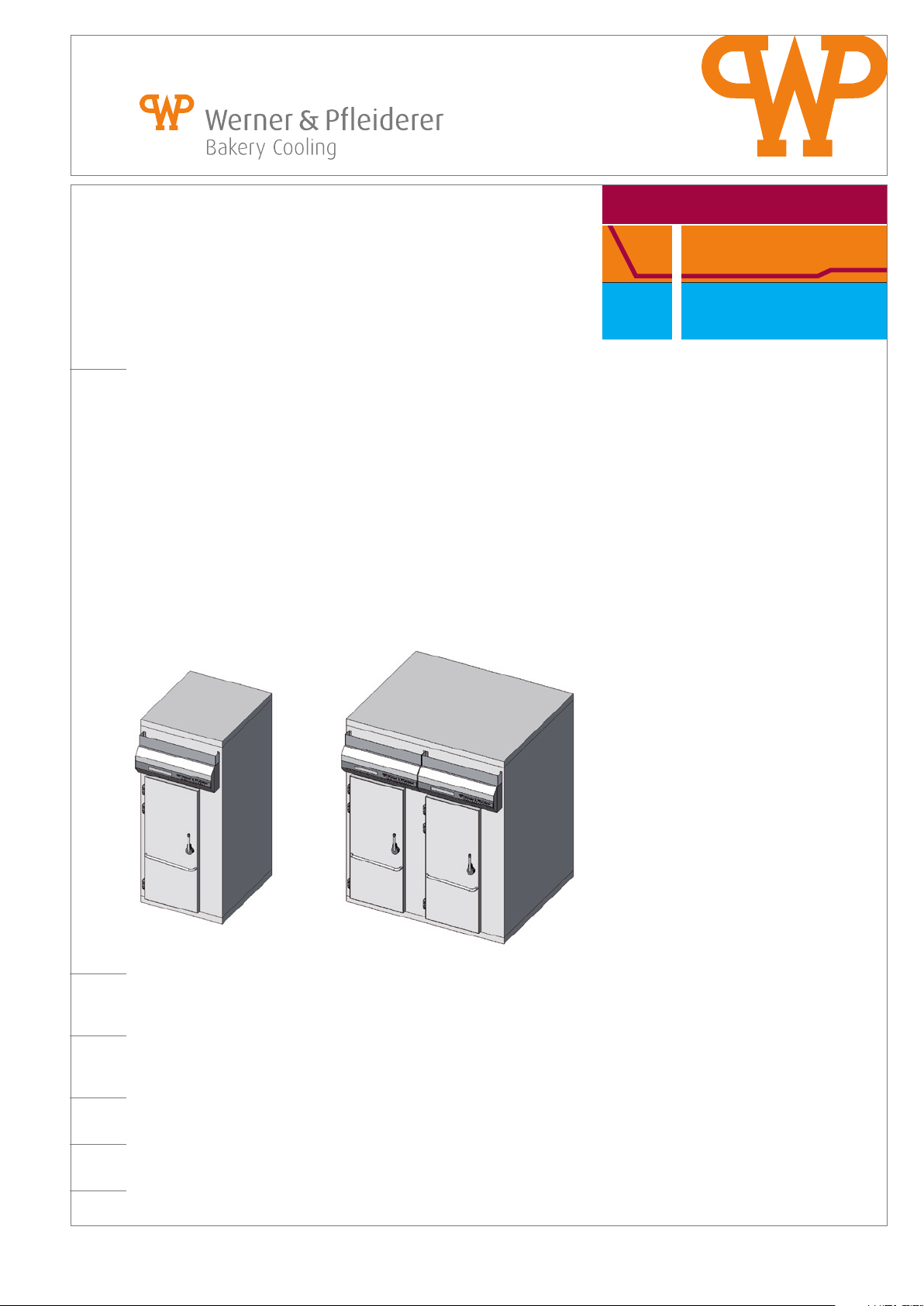

AROMA+COOLER

®

40.30 to 40.120

Temperature range -20/-28 °C

Moisture range approx. 70–95 % rel. hum.

Output from 3,000 to 12,000 rolls per hour

Properties

Werner & Pfleiderer flash coolers from the AROMA+COOLER® System Dieckmann series are designed specially for cooling

proofed and non-proofed dough pieces. The achievement of short cooling times through exact restricted guidance

of the cold air through the suction chamber system guarantees a considerable improvement in quality .

The WP Aroma Process provides you with all the advantages

– Optimum aroma, flavour, gloss, crispness and freshness.

– Rationalisation, saving of energy costs

– Uncooled transport, space-saving

The basis for the WP aroma process lies in the AROMA+COOLER® ʼSystem Dieckmannʼ. Dough pieces are cooled down efficiently,

gently, carefully and with little moisture removal. Dough pieces cooled down in this way have the right consistency for the following

stages of the aroma process. Only in this way is it possible to achieve the optimum aroma storage temperature (approx . +5°C) for

full aromatization, irrespective of whether the dough pieces are stored in racks stacked directly above each other or on trays in trolleys.

Storage in the WP GV AROMAT cooling chamber keeps the dough pieces nice and succulent and ideally moist – another ideal

precondition for aromatization. The specially controlled proofing curve provides very high proofing tolerance and stability. Storage is

possible in the plus range for up to 36 hours.

AROMA+COOLER® 1/2

40.30 to 40.120 01.08.2008

+

Rapid

cooling

Storing

0

AROMA+COOLER

-

®

-5 / +15 °C-20 / -28 °C

GV AROMAT

Proofing

Advantages

Easy handling, efficient air stream over the dough pieces, faster cooling (10 to 15 min.), greatly reduced moisture extraction,

much lower energy consumption, optimum moist dough pieces, increase in quality of the baking products

Dimensions

We offer standard AROMA+COOLER® for all bakery operations The design of the systems is based

on a dough piece output rate of 3,000 – 12,000 rolls per hour.

Cell housing

Panels in 100 mm PU insulation, foamed, free of CFCs, HCFCs and HHCs.

k value

0.20 W/m²K

System

Tongue and groove system with foamed-in eccentric turnbuckle joints for easy, fast assembly on site.

Page 2

WP BAKERYGROUP

®

40.30 to 40.120 01.08.2008

AROMA+COOLER

Surfaces Standard Finish

Inner walls stainless steel

Outer walls sheet steel, galv., white, RAL 9002

System front stainless steel, grain ground

Optional stainless steel panelling for all surfaces

Floor

The floor of the TECFLOOR system is also fitted with 100 mm thick PU insulation with direct foamed-on 0.8 mm

stainless steel panels. Mounted on this, there is a 3 mm thick steel plate in the form of a trough with raised sides.

Ram protection

Inside allround stainless steel square profile

Doors

Rotating door with clear dimensions of 80 × 200 cm:

– 3 door hinges, rising

– Solid press lever fastener for commercial use

– Ram protection inside and out

– Door seal

– Door frame heating

– Multiple rubber abrasive for floor seal

Technology

The output of the AROMA+COOLER® is based upon a feed quantity of 3,000 to

12,000 rolls per hour and rapid cooling time of 10 to 15 minutes.

AROMA+COOLER® 2/2

Air guidance

The cold air is sucked through the trays by suction principle. |This process is very effective because the stack

of trays is hermetically enclosed and sealed at the docking station by suction chambers so that the cold air can

now only be sucked through the trays over the dough pieces. It is many more times effective than flash-freezing

because of the much lower air volume and its higher temperature (-15/-20 °C instead of -35 °C).

Control system

via EMS controller

– Complete with electrical switch cabinet, pre-wired to VDE regulations.

– Very easy to operate

Each WP cooling machine is fitted with machine control switch, soft-start, oil sump heating, pressure/speed

controlled liquefier fans for energy-saving operation and all necessary safety precautions. Separate liquefiers

with < 56 db(A) or with < 38 dB(A) as ultra-quiet unit can be used wherever low-noise installation is required.

Flash Suction Cooler System Dieckmann

Type 40. For trays sized 40 x 60/60 x 80

Output: No. of dough pieces 3,000 4,500 6,000 9,000 12,000

Trays Trolleys Number 1 2 2 4 4

Cooling time for 40 x 60 trays in minutes 13 17 13 17 13

Cooling time for 60 x 80 trays in minutes 17 25 17 25 20

Outer dimensions in mm B X D X H 130 x 150 x 300 130 x 210 x 300 130 x 210 x 300 250 x 210 x 300 250 x 210 x 300

Outputs for individual machines relate to

– 40 trays per trolley

– 16 dough pieces per tray à 40 x 60 cm, 32 dough pieces per tray à 60 x 80 cm

– weight per piece 60g

WERNER & PFLEIDERER Koeling Benelux B.V. Industrieterrein 9 D . 5981 NK Panningen . Netherlands

Fon +31 (0) 77-850 70 60 . Fax +31 (0) 77-850 70 61 . info@wp-bakerycooling.com . www.wp-bakerycooling.com

WERNER & PFLEIDERER Lebensmitteltechnik Kälte GmbH . von-Raumer-Straße 8-18 . 91550 Dinkelsbühl . Germany .

Fon +49 (0) 98 51-905-510 . Fax +31 (0) 77-850 70 61 . info@wp-l.de . www.wp-l.de

AROMA+COOLER

40.30

AROMA+COOLER

40.45

AROMA+COOLER

40.60

AROMA+COOLER

40.90

AROMA+COOLER

40.120

All details non-binding. Subject to change in the course of technical progress. All rights reserved.

Loading...

Loading...