Page 1

Installation and operating instructions

KEMPER Backflow Preventer BA Figure 361

1. Prerequisites for installation

Install the backflow preventer in

frost-free areas only! DIN EN 1717, DIN 1988

Comply with standards: DIN EN 12056, DIN 1986-100

Provide a drain line! Comply with the direction of flow!

Application area

According to DIN EN 1717, in order to maintain flawless functioning of the BA backflow preventer, a flanged dirt trap

must be installed in the direction of flow before the BA backflow preventer. Type BA backflow preventers that accord

with DIN EN 12729 are used to secure drinking water plants against back pressures and siphon back flow. Fluids up to

and including Fluid Category 4 as per DIN EN 1717/1988-100 are secured. They can be used for residential buildings,

industrial and commercial purposes with consideration of their specifications. Normally (normal functioning with pressure

fluctuations), the vent hole of the middle pressure chamber only allows a few drops through. During malfunctions,

the vent hole can allow the full volume flow of the service pipe through. For that reason, dimension the wastewater

connection to be sufficiently large according to DIN EN 12056 and DIN 1986-100. Assume the volume flow that could arise

through the service pipe on the backflow preventer BA (pay attention to the nominal flow rate!).

BA can secure the following hazard potential in accordance with the Fluid Category:

Category 4 (applies to backflow preventer BA)

Fluids that present a health hazard to humans due to the presence of one or more toxic or highly toxic substances or

one or more radioactive, mutagenic or carcinogenic substances.

The higher the classification, the greater the risk potential. For each category, DIN EN 1717 stipulates specific protection

valves. The Backflow Preventer BA, Figure 361 is approved without restriction for use up to and including Category 4. A

continual bacterial risk (Fluid Category 5) in extant piping systems must not exist.

2. Operating principle

The KEMPER BA Backflow Preventer is subdivided into 3 zones. In Zone 1, the pressure is higher than in Zone 2 and there

again higher than in Zone 3. A drain valve is connected to Zone 2, which opens latest when the pressure difference between

Zones 1 and 2 has decreased to less than 0.14 bar. The water from Zone 2 flows outdoors. That precludes the risk of backpressure or siphon back flow in the supply network. The pipeline is interrupted and the drinking water network is protected.

Intermittent dripping from the BA Backflow Preventer at the drain valve is not necessarily a malfunction.

Under such circumstances, the BA Backflow Preventer separates as intended!

The backflow preventer

- 1 -

Page 2

p

p

Note:

Do not connect any fast-closing valves or stopping equipment before or after the valve.

Fast closing, e.g. of solenoid valves or ball valves on devices and machines can lead to serious malfunctions in the

backflow preventer BA. For that reason, always use slowly closing valves or drives that close slowly.

If the inlet-side static system pressure is high, it is recommended to install a pressure reducing valve in the

supply line.

Zone 2

Zone 1

Supply-side anti-

ollution check-valve

Figure 1: Sectional view

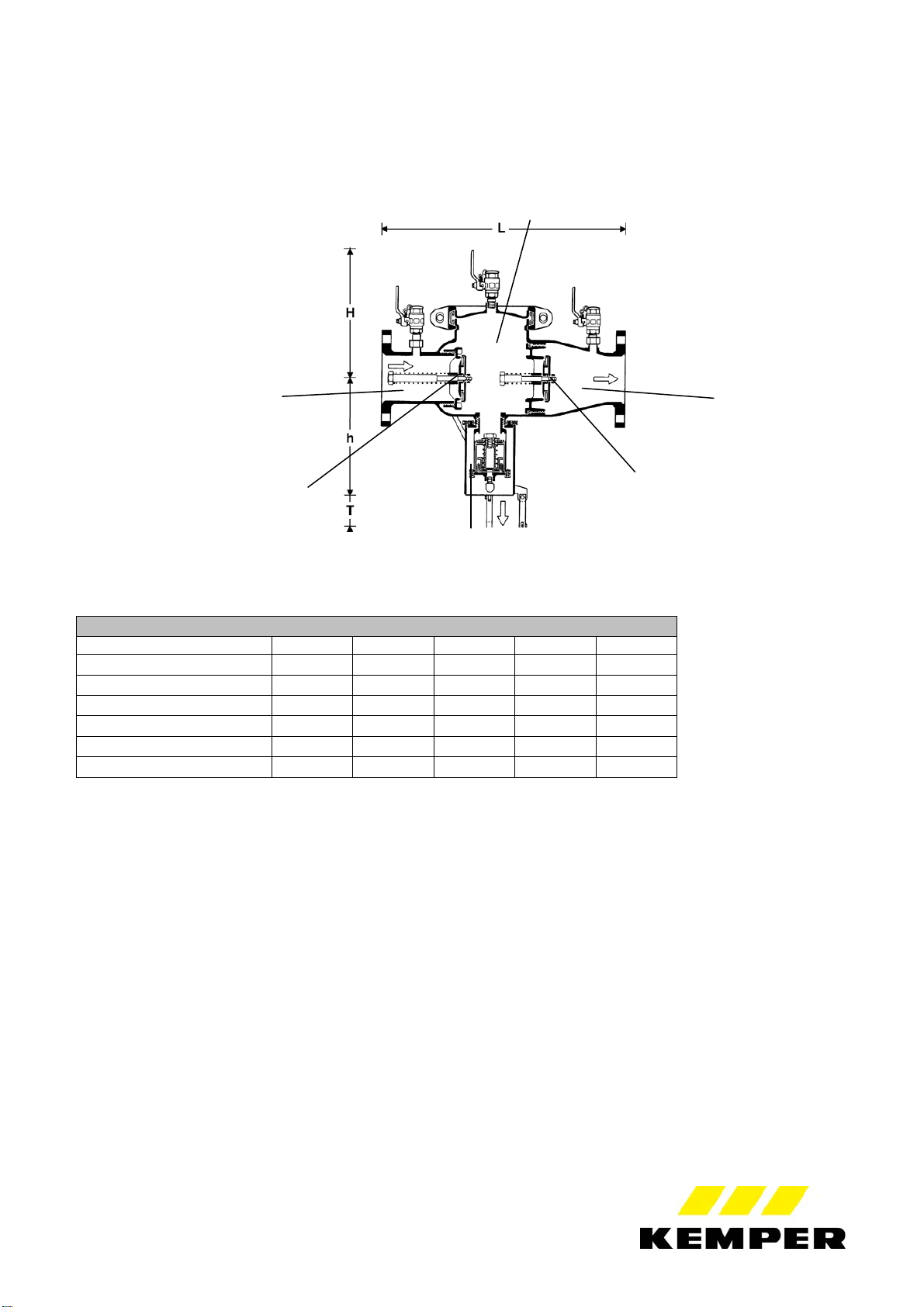

Dimension

Nominal width DN 65 80 100 150

Installation height (H) mm 245 245 245 285

Installation height (h) mm 270 270 300 300

Installation depth (D) mm 60 60 60 60

Length (L) mm 559 559 559 695

Nominal flow at delta p=1 bar m³/h 45 54 85 191

Weight kg 31.3 32.6 34 52.6

Table 1: Dimensions: Backflow Preventer BA Figure 361

Drain valve

Discharge-side anti-

ollution check-valve

Zone 3

3. Installation

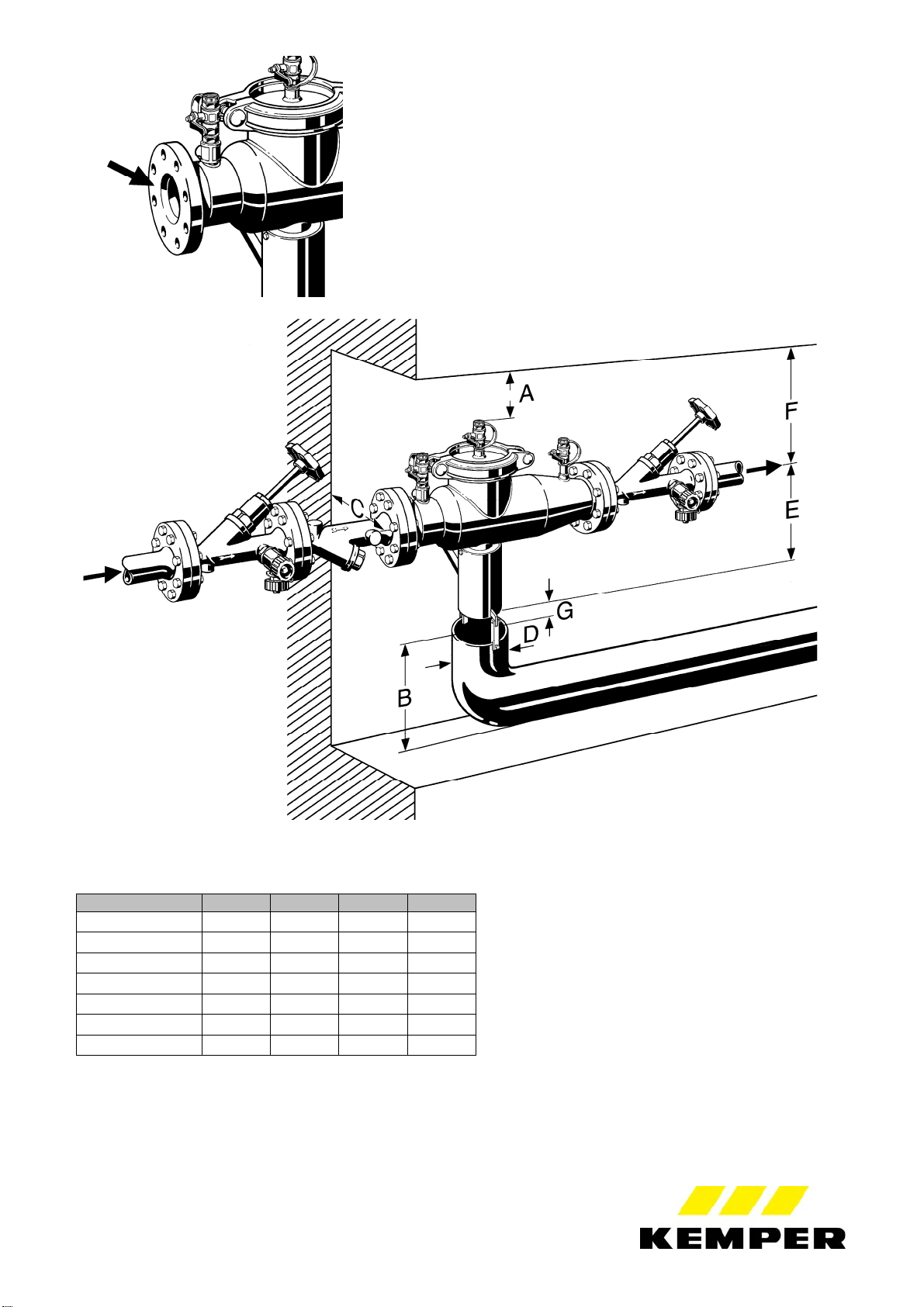

The BA Backflow Preventer must be installed level. Provide cut-off valves in front of and behind the backflow preventer.

In addition, a dirt trap must be connected upstream which prevents the backflow preventer from damage and functional

impairments due to coarse dirt.

Install the backflow preventer free of tension and without flexural moment as follows:

1. Thoroughly rinse connecting pipe

2. Check connections on backflow preventer for cleanliness (Figure 2)

3. Install backflow preventer as in Figure 3. While doing so, comply with the following points and those in Chapter 3.1:

Flow in direction of arrow

Maintain installation clearances

Make sure there is good accessibility

Make drain lines without any tight bends and keep them short. Connection dimension acc Table 2

Install the drain line so that the drain connection and the drain valve can be removed for inspection.

A material-steadying zone of 5 x DN after the BA is recommended

- 2 -

Page 3

Figure 2:

Connection area

Figure 3: BA Backflow Preventer protection device with installation prerequisites and dimensions.

Connection sizes 65 80 100 150

A 650 650 650 650

B 600 600 600 600

C 160 160 160 200

D 150 150 150 150

E 345 345 345 375

F 895 895 895 935

G 75 75 75 75

(Dimensions in mm)

Table 2: Dimensions for installation prerequisites

- 3 -

Page 4

3.1 Notes for secure installation

If there are supply pressure fluctuations, without water removal a short triggering of the drain valve can occur. For that

reason, we recommend installing a pressure reducing valve before the backflow preventer.

The room in which the backflow preventer is installed must be freely accessible at all times and always be frost free. Ensure

good ventilation.

If the drain line is also being used by other equipment/plants, it must be correspondingly dimensioned (pump

stations/sewage system)

No additional, unprotected drinking water connections are permitted after the backflow preventer.

Within the downstream system, the individual connections are not secured from each other against backflow. If required,

provide individual protection.

The backflow preventer must be easily accessible at all times. Manometer connections and controls must not be obstructed.

While installing backflow preventers, make sure the water that leaks during the separation process is safely drained off.

Installation in shafts and rooms endangered by flooding is prohibited. For inspection and maintenance reasons, provide

cut-off valves in the direction of flow before and after the backflow preventer.

The backflow preventer must be installed flood proof.

Provide the drain valve control with an effective safeguard, i.e., in case of failure, the vent hole opens completely. In this

case, for 1 bar pressure in the middle chamber, calculate with the following dimensions. Dimension the dewatering line

correspondingly.

Hydraulic values

DN 65 80 100 150

m³/h 35 35 35 35

Table 3: Drain lines (sewage system connection dimensioning)

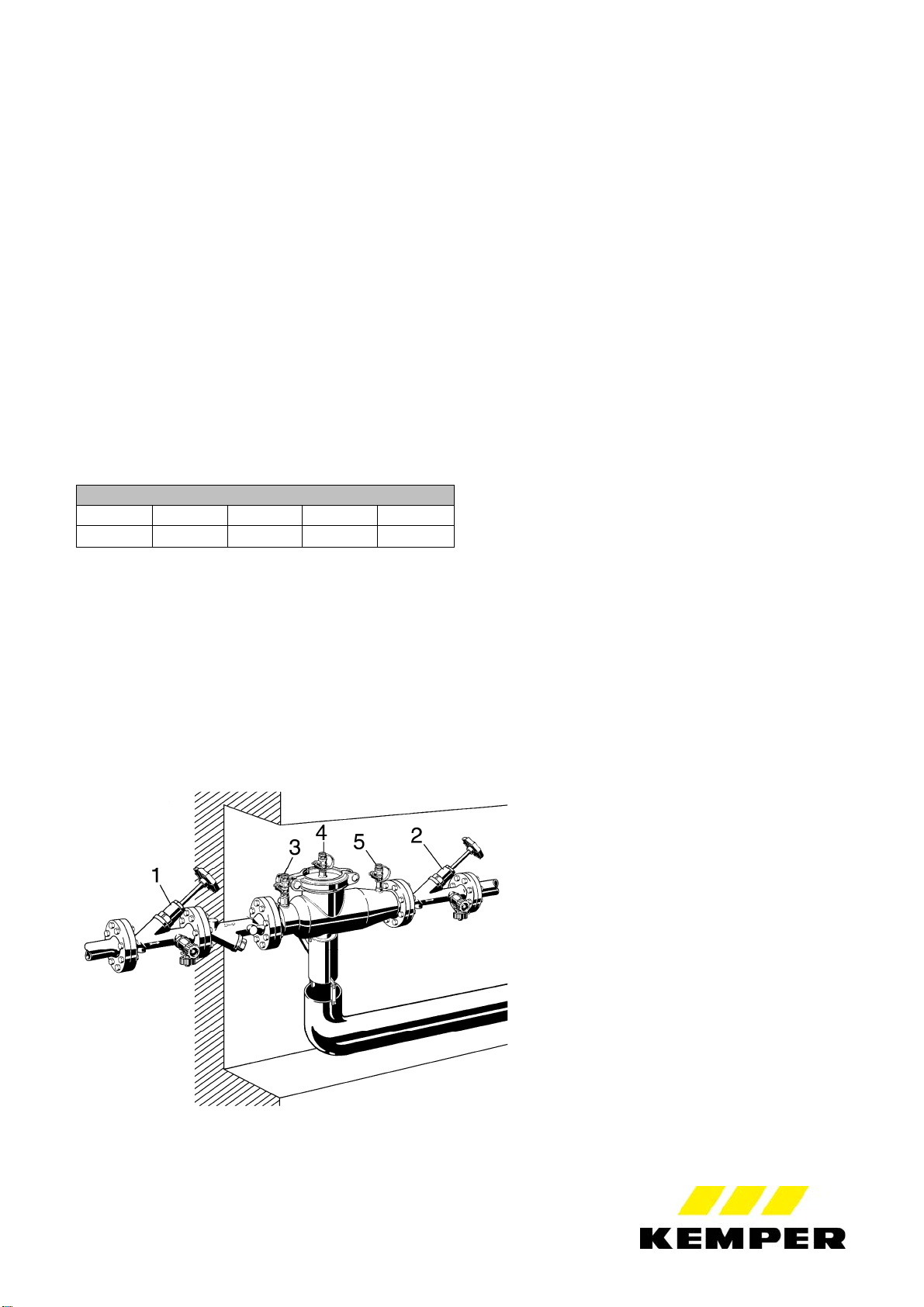

4. Commissioning

Commission the backflow preventer in this sequence:

1. Slowly open cut-off valves 1 and 2.

During this process, it is possible the drain valve opens intermittently.

2. Vent the system through ball valves 3, 4, and 5.

Open each ball valve until water comes out. It is important to open every ball valve to make sure that all chambers are

vented.

3. The backflow preventer is ready for operation.

Figure 4:

Commissioning the BA Backflow Preventer

safeguards

- 4 -

Page 5

5. Inspection

In compliance with standards on drinking water protection and hygiene regulations, the user/operating organisation is

given the following specifications:

As per DIN EN 1717, Point 4.6, perform regularly scheduled maintenance on the safeguards. As per DIN EN 806-5

1 x annual maintenance is applicable Europe-wide. Check their proper functioning in regularly scheduled intervals in

compliance with the national or

regional stipulations.

For DE, in accordance with DVGW W 570-1 (April 2007) under 4.7 it is stipulated that the maintenance must be

performed 1 x annually.

For CH, perform the maintenance/inspection as per SVGW W3 Supplement 1 (2000), W/TPW 126 (April 1994) and

W/TPW 135 (April 1994). In W/TPW 135, in Point 3 Maintenance, the maintenance/inspection is stipulated

as periodical, but at least every 2 years. W/TPW 126 requires the backflow preventer BA to be checked for the first time

after the first year of operation. In addition, Offprint no. 1377 of SVGW 8/96 is pointed out.

For NL, in VEWIN Waterwerkblad WB 1.4 G (November 2005 under Point 4 it is stipulated that backflow preventers BA

need to be checked for proper operation and maintained 1x annually.

The following applies:

The functional and maintenance measures cover the function test, visual inspection of the interior parts and

the cleaning or replacement of the functioning parts as stated under Points 3 and 4 in the operating instructions.

This inspection should also include the related valves. Only authorised specialists are allowed to perform

maintenance. Document the inspection on the attached control plate with date and signature. In addition, Appendix

1 on inspection and maintenance is recommended. Put the Backflow preventer BA cartridge through a visual inspection

in the installed state during every maintenance to the extent this is possible through the housing opening.

The manufacturer recommends replacing the cartridge every 10 years.

Measuring instrument for differential pressure measurement: Suitable

differential pressure manometer;

measurement case, Figure 360 99, is recommended.

The KEMPER differential pressure

5.1 Connect test adapter

- Screw on adapter G1/2-G1/4

- Screw on adapter G1/4 with plug-on coupling

Comply with local regulations.

A

B

C

- 5 -

Page 6

5.2 Preparing the differential pressure manometer

- Connect the test hose with the adapter *+*

and *-* of the differential pressure manometer to each side.

5.3 Connect differential pressure manometer

for function test inlet anti-pollution check-valve and drain valve

- For each test hose, plug on and latch a quick coupler to the

adapter (bleeder valves must be closed on the hoses.)

- Connect the test hose of Test valve A to

the connection marked ``+``` on the differential pressure

manometer.

- Connect the test hose of Test valve B to

the connection marked ``-``` on the differential pressure

manometer.

- A = Supply pressure zone, B = Middle pressure zone,

C = Back pressure zone

5.4 Function test, inlet anti-pollution

check-valve

- Connect measuring instrument as per 4.3

- Open Test valves A and B and vent the measurement lines

through the bleeder valves on the test hoses. Then close

the bleeder valves and leave Test valve A and B open.

- 6 -

A

A

+‐

B

+‐

B

C

C

Page 7

- Close the stop valve before and after the valve.

- Using the bleeder valve on the test hose (Test valve B),

slowly bleed the pressure of the middle pressure zone and

watch the differential pressure display at the same time.

The differential pressure rises until the anti-pollution

check-valve starts to open. The drain valve must not

trigger during this.

- Close the bleeder valve on the test hose (Test hose B).

The differential pressure must remain constant.

Note: During the measurement, it is mandatory that

there is no flow in the backflow preventer BA!

A

5.5 Function test, drain valve

- Connect measuring instrument as per 4.3

- Open Test valves A and B and vent the measurement

lines through the bleeder valves on the test hoses.

Then close the bleeder valves and leave Test valve A

and B open.

A

- Close stop valve before and after the valve

- Using the bleeder valve on the test hose (Test valve A),

slowly bleed the supply pressure of the supply pressure

zone and watch the differential pressure display and

drain valve at the same time. The drain valve must trigger

before the display reaches the value 140 mbar (when the

valve triggers, the differential pressure initially rises only

slightly and then falls again)!

- Close bleeder valve. The bleeder valve must be closed

tightly again.

A

- 7 -

+‐

+‐

B

C

B

C

+‐

B

C

Page 8

5.6 Connect differential pressure manometer

and absolute pressure manometer for function

test output anti-pollution check-valve

- Connect the test hose from Test valve B to the

connection marked ``-`` on the differential pressure

manometer.

- Connect absolute pressure manometer with adapter to

Test valve C.

5.7 Function test, outlet anti-pollution

check-valve

- Open the stop valve before and after the valve and

fill the valve.

- Read pressure on scale and write down the value.

- Close stop valves and use Test valve B and Bleeder valve

B to depressurise the middle pressure zone. During this,

it is possible that a slight pressure drop

scale due to "setting".

- Wait at least 2 minutes. The outlet-side anti-pollution

check-valve is leakproof when the pressure remains

constant during this time.

occurs on the

A

A

A

+‐

B

+‐

B

+‐

B

C

C

C

- 8 -

Page 9

6. Removal, installation and cleaning the drain valve

Both anti-pollution check-valves and the drain valve can be removed for maintenance purposes.

All work can be performed without removing the housing from the pipeline (inline service).

Only authorised specialists are allowed to perform maintenance.

1. Close cut-off valves 1 and 2.

2. Reduce the pressure by opening the ball valves.

3. Unscrew pressure control line 14 on the drain valve.

4. After loosening the screws, pull down drain connection 7 and unscrew with the help of an oil filter strap.

5. Take off the drain valve.

6. If necessary, clean or replace.

If no dirt particles are visible but a fault was observed while inspecting the drain valve (see Chapter 5.2), the drain

valve should be replaced (see accessories/spare parts).

Clean the area around the valve seat and the opening slot (e.g., by carefully blowing out)

7. Assemble in the reverse sequence.

Grease the O-rings well with Unisilikon 250 or a grease that does not contain mineral oil.

ATTENTION! Otherwise it is possible that the O-rings will be destroyed.

Replace damaged O-rings, see Chapter 13, Spare parts

8. Close the ball valves.

9. Slowly open the cut-off valves.

10. Vent the system through the ball valves.

11. Check the drain valve, see Chapter 5.2.

12. Connect the dust plugs to the ball valves.

Never dismantle the anti-pollution check valve and drain valve from each other. High danger of injury!

Figure 7: Removal, installation and cleaning the drain valve

- 9 -

Page 10

6.1 Removal, installation and inspecting the anti-pollution check valve (refer to Figure 4)

1. Close cut-off valves 1 and 2.

2. Reduce pressure by opening ball valves 3, 4, and 5.

3. Take off cover.

4. Remove the anti-pollution check-valve.

For DN 65-150, first unscrew the discharge anti-pollution check valve and then the supply anti-pollution check valve.

You can obtain an assembly tool as an accessory.

Danger of injury! The anti-pollution check-valve is spring preloaded.

5. Check for leakproofness by filling water from the rear.

Leaky anti-pollution check-valves must be replaced. Repair is not possible.

6. Assemble in the reverse sequence.

For DN 65-150: - grease O-ring and thread well on the anti-pollution check valve with Unisilikon 250.

Do not damage the O-ring when installing.

The tightening torque for the anti-pollution check-valve is 100-120 Nm.

7. Close the ball valves.

8. Open the cut-off valves.

9. Vent the system through the ball valves.

10. Check the backflow preventer, see Chapters 5.1 to 5.3.

11. Connect the dust plugs to the ball valves.

7. Important information instructions for your safety

Use the device solely in a technically flawless condition and as intended for use, safety and hazard aware while complying

with the installation and operating instructions. Have all malfunctions that could impair safety repaired immediately.

The BA Backflow Preventer, Figure 361, is intended solely for the application areas named in these installation and

operating instructions. Any different use or use beyond and above that is considered non-intended usage.

8. Troubleshooting

Errors Possible causes Remedy

Other Strong pressure fluctuations in the

water network.

Fluctuating admission pressure Install a pressure reducer before the

Supply-side anti-pollution check valve

or drain valve

is soiled

Leaky supply anti-pollution check valve Remove the anti-pollution check valve

Drain valve does not close Deposits on the valve seat Remove the drain valve

Damaged O-rings Remove drain valve and replace O-ring

Leaky drain valve Remove the drain valve

Drain valve does not open Clogged pressure control line Remove and clean the pressure control

Table 4: Troubleshooting

Install a water surge (hammer) damper

behind the backflow preventer

backflow preventer

Remove and clean anti-pollution check

valve

line

9. Technical data

Total pressure drop: max. 1.0 bar at nominal flow

Flow media: Water at 60 °C

Operating pressure: max. 10 bar

Minimum supply pressure: 1.5 bar

Ball valve connection: G ½ with connection size DN 65-150

Connection sizes Weight ca. in kg Total length in mm Nominal flow rate in m³/h

DN 65 32 559 45

DN 80 32.5 559 54

DN 100 33 559 85

DN 150 57 695 191

Table 5: Technical data

- 10 -

Page 11

10. Flow diagram

Connection sizes DN 65 to 150

Pressure drop in valve Δp (bar)

Flowrate V (m3h)

11. Materials

Housing Stainless steel

Anti-pollution check-valve Stainless steel

Other interior parts Stainless steel

Compression spring Stainless steel

Sealing disc EPDM

Drain valve housing Stainless steel

Drain valve, other interior parts POM

Drain valve, compressed spring Stainless steel

Drain valve, membrane EPDM

Drain valve, sealing disc EPDM

Drain valve Stainless steel

Table 6: Materials

12. Accessories

KEMPER differential pressure measuring case

Differential pressure manometer in a representative aluminium case, ideal for inspecting and maintaining all

KEMPER BA Backflow Preventers, Figures 360 and 361

Content of the Differential Pressure Measurement Kit, Figure 360 99

2 G1/4 adapters with plug

coupling

Differential pressure manometer

with scale range to 1 bar

2 test hoses, preassembled with

plug-and-socket connections and bleed

valves

- 11 -

2 G1/2 and G1/4 adapters

1 absolute pressure manometer

with scale range to 10 bar

Page 12

Replacement tools for anti-pollution check-valve

For flange version DN 65-100

For flange version DN 150

Assembly wrench

DN 65-DN 100 Figure 361 99 009

DN 150 Figure 361 99 010

13. Spare parts

Anti-pollution check valve, supply side Anti-pollution check valve, discharge side

DN 65 – DN 100 Figure 361 98 002, DN 65 - DN 100 Figure 361 98 003,

DN 150 Figure 361 98 006 010 DN 150 Figure 361 98 007

Ball valve Gasket set Bleed valve

DN 65 - DN 150 Figure 361 99 004 DN 65 – DN 100 Figure 361 99 005 DN 65 – DN 150 Figure 361 98 001

DN 150 Figure 361 99 008

Gebr. Kemper GmbH + Co. KG

Metallwerke

Harkortstr. 5

D-57462 Olpe

Tel. 0 27 61 - 8 91 - 0

Fax 0 27 61 - 8 91 -1 75

Tinfo@kemper-olpe.deT

- 12 -

K410036100002-00 01/14

www.kemper-olpe.de

Technical subject to change.

Page 13

- 13 -

Loading...

Loading...