Page 1

Technology you can count on

Operator’s manual

Version B 0702

English

No. : 97441

ROTARY HARVESTING

UNITS

330

Maschinenfabrik KEMPER GmbH & Co. KG • D- 48694 Stadtlohn

P.O. Box 1352 • Tel.: +49 (0) 25 63 / 88-0

E-mail: Info@Kemper-Stadtlohn.de

Internet: www.kemper-stadtlohn.de

Page 2

Design and model

claims

The construction and function of our products are subject to technical continuous and

further development, which means information and data pertaining to a delivery are

not binding.

Maschinenfabrik KEMPER GmbH & Co. KG

Postfach 1352 – D-48694 Stadtlohn

Tel. +49(0) 2563 / 88-0

E-mail: Info@Kemper-Stadtlohn.de

web: www. Kemper-Stadtlohn.de

Page 3

0611

Introduction

Foreword

Carefully read this operating manual to

familiarise yourself with the correct operation

and maintenance of the machine and to

prevent injury and damage to the equipment.

This operating manual and the safety labels

attached to the machine are available in

various languages (contact your KEMPER

dealer for details).

This operating manual is an integral part of

the delivery. When the machine is sold, the

manual must be handed over with the

equipment to the new owner.

All dimensions in this operating manual are in

metric units. Use only fitting parts and screws.

The directions of "RIGHT" and "LEFT" are

indicated relative to the direction of forward

travel of the machine.

Enter the product identification codes in the

respective section. Please copy all digits and

check them to be sure that they are correct. In

the event of theft of the machine, these codes

might assist the police in their enquiries.

These codes are also required by the KEMPER

dealer for spare part orders. We recommend

noting the codes also in another document.

The machine has been thoroughly tested and

inspected by your dealer prior to delivery.

The attachment may only be used for its intended

purpose and in line with standard agricultural

work practices (see section "Proper use"). Any

other use is deemed improper. The manufacturer

shall not be liable for damage caused by improper

use. Proper use includes compliance with the

operating, maintenance and repair instructions

and schedules laid down by the manufacturer.

The attachment may only be operated, serviced

and repaired by persons who are fully familiar

with the device and have been instructed

regarding possible risks. Always adhere to all

relevant accident prevention regulations and other

safety practices. Also observe the relevant

occupational health and road traffic regulations.

Modifications to the attachment are forbidden.

The manufacturer shall not be liable for any

damage resulting directly or indirectly from

modifications made to the equipment.

0611

Page 4

0611

Introduction

Inspection completed prior to delivery

The following tests, inspections, settings and maintenance tasks have been

completed prior to the delivery of the machine:

0611

1. Attachment properly mounted

Visual inspection for damage

2.

caused during transportation.

3. Lubricant applied to all lubrication

.

points

4. Friction clutches released.

5. Transmission checked for leakage.

6. All moving parts tested for smooth

movement

7. All hydraulic lines and connections

tested for leakage - all lines and

connections are tight.

.

8. All adhesive labels are OK.

9. Customer instructed in the operation of

the device, with special reference to risks

and safety measures.

Operating manual handed over to

10.

customer

.

Date:

Signature of dealer/Kemper

specialist:

Page 5

0611

Introduction

0611

Page 6

0611

Table of contents

Page

Safety instructions............................................ 1

Permitted use................................................... 1.1

Identification of safety instructions.................... 1.2

Hazard symbols................................................ 1.3

Accident prevention regulations ....................... 1.4

Mechanical safety............................................. 1.5

Safety instructions for assembling and

removing the harvesting implement.................. 1.6

Safety instructions for working on equipment

containing fluids under high pressure...............1.8

Safety instructions for welding and for the

heating of components..................................... 1.9

EC declaration of conformity ........................ 2.0

Transfer of ownership of the equipment........... 2.1

Product liability – Obligation to provide

information........................................................ 2.2

General............................................................... 4

Description of the equipment............................ 4.1

Design of the harvesting implements with

description of the most important components. 4.2

Dimensions and weights of the implements ..... 4.3

Maintenance and testing .................................. 4.4

Tightening torques for metric bolts and screws 4.5

Transporting the equipment.............................. 4.6

Travelling on public highways........................... 4.7

Requirements made of forage harvesters ........ 4.8

Assisted steering.............................................. 4.9

Individual type approval.................................. 4.10

Hydraulic system............................................... 7

Valves............................................................... 7.1

Throttles ........................................................... 7.2

PTO..................................................................... 9

Description of interaction of the various

elements........................................................... 9.1

Description of the drives/transmissions with

inlet, drain and breather bores.......................... 9.2

Oil grades and capacities of the various

drives/transmissions......................................... 9.3

Lubricating schedule for the basic machine...... 9.4

Page

Clutches...........................................................10

Starting-off clutch (700 Nm) ...........................10.1

Starting-off clutch (800 Nm) ...........................10.2

Starting-off clutch (900 Nm), liquid-cooled .....10.3

Dismantling the clutches ................................10.4

Maintenance and service work ...................... 11

Star ratchet.....................................................11.1

Blades............................................................11.2

Maintenance of the crop intake and cutting

area................................................................11.3

Inspecting the crop guide track ......................11.4

Scrapers.........................................................11.5

Attachment frame........................................... 11.6

Faults and their causes..................................11.7

Operations Instructions..................................12

Starting, Turning, Reversing...........................12.1

Downed Maize, WPS .....................................12.2

Attaching and Detaching................................15

Attachment to John Deere forage

harvesters........................................................16

Make a note of serial number.........................30

All information, illustrations and specifications in this manual are based on the

latest information available at the time of publication. The right is reserved to

make changes at any time without notice.

0611

Page 7

Chapter 1 Chapter 1

Point 1.1/1.2 Point 1.1/1.2

0401

1

Safety instructions

Safety instructions

0401

1.1 Working with the

implement:

The Kemper harvesting implement with interface for selfpropelled forage harvesters is suitable for row-independent

harvesting of silage maize, whole crop silage, lucerne, oil seed

rape, field beans, sorghum, sunflowers and other stalk-type

crops.

This machine may only be used for the purpose for which it is

intended, in keeping with equipment safety regulations. Failure to

do so will nullify all liability in the event of any resulting injury or

damage. Use for the purpose for which it is intended also

includes the observation of our operating and maintenance

instructions and sole use of genuine Kemper replacement parts.

The harvesting unit may only be used, serviced and repaired by

persons who are familiar with the operation of this equipment or

who have been instructed regarding the hazards involved. (see

UVV 1.1 §1)

Important:

It is forbidden to work on the header (removal of blockages,

service and repair work) while the harvester engine is still

running.

The header has undergone CE testing and is marked

accordingly.

1.2 Recognising

warnings

This sign draws your attention to the safety

instructions mounted on the machine and

contained in the safety instructions.

You must observe all safety and general

accident prevention instructions.

Page 8

Chapter 1 Chapter 1

Point 1.3 Point 1.3

0401

Safety instructions

0401

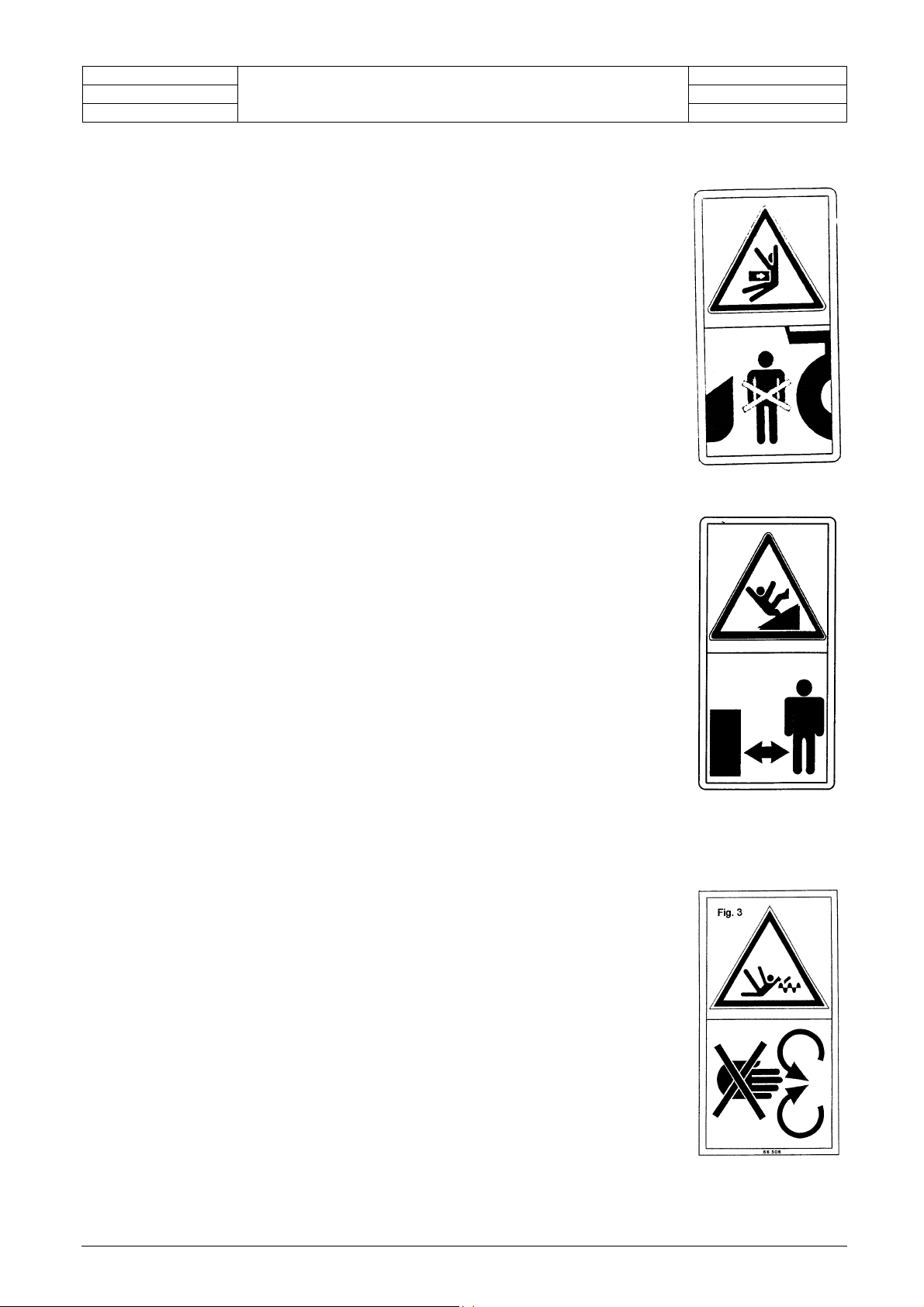

1.3 Safety

instructions:

Read the safety instructions and warning

signs mounted on the machine and contained

in the operating instructions carefully.

Make sure that all signs can be easily read.

Replace any signs which cannot be clearly

read.

Before you start working with the machine,

make sure you are familiar with the overall

machine operation.

Always ensure the machine is in good

condition.

Unauthorised modifications will impair the

proper functioning of the machine.

Switch off the engine and remove the

ignition key before commencing all

service and repair work.

Do not climb on to the machine before

the power system has cut out,

the engine has stopped and the

ignition key has been removed.

Page 9

Chapter 1 Chapter 1

Point 1.3 Point 1.3

0401

Do not enter the hazard area between

the header and the machine.

Safety instructions

0401

Never put your hands in the

auger while it is still turning.

Do not access the intake parts of the

implement before the power system has cut

out, the engine has stopped and the ignition

key has been removed.

Page 10

Chapter 1

p

Point 1.3 Point 1.3

0401

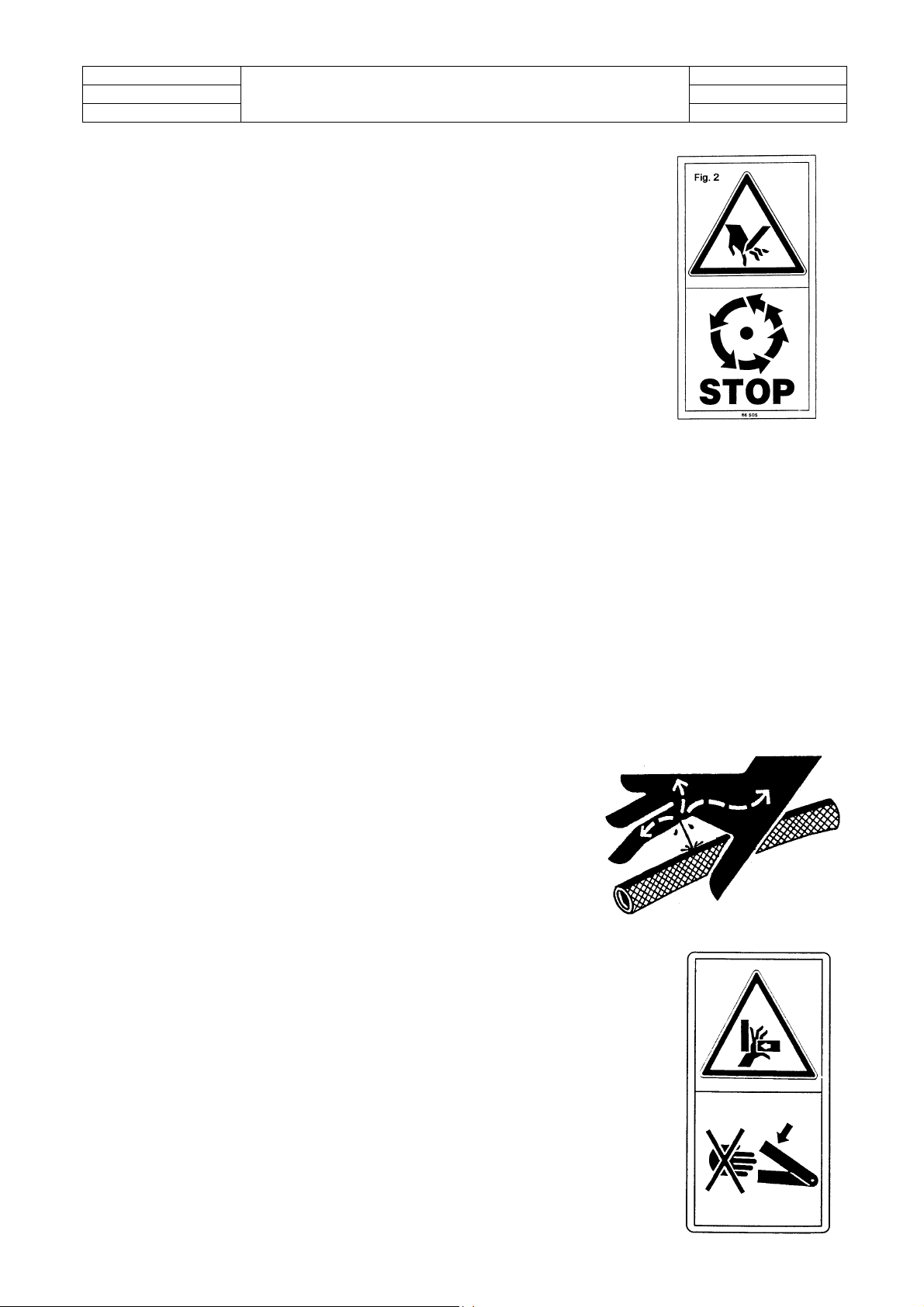

Do not touch any moving

Safety instructions

Chapter 1

0401

arts.

Beware of pressurised

fluids emitted from the

system!

Never place your hands in areas where

there is a crush hazard while it is still

possible for parts to move.

Page 11

Chapter 1 Chapter 1

Point 1.4 Point 1.4

0401

1.4

Accident

prevention

regulations

It is forbidden to stand or walk in the crop intake area.

Do not feed crop into the harvester using your hands. Do not

push crop further into the machine using your foot.

Exercise great care when connecting the jointed shafts.

The jointed shaft guard must be kept in good condition at all

Safety instructions

0401

times and the protecting tube must be secured against rotating.

Do not alter the number of fins on the protection on the jointed

shafts.

If necessary, attach counterweights in order to make the tractor

easier to steer, but be sure to observe maximum permitted axle

loads. Adhere to the stipulations made in the individual typeapproval or in the government inspection survey regulations.

Headers should only be detached and removed when the

equipment is standing on a level surface.

Whenever performing any work on the harvester the PTO lever

must be switched to the "off" position; the tractor engine should

be switched off and the ignition key removed.

Caution: The blade rotors are still rotating even after the intake

drums have come to a standstill!

Before investigating the equipment for foreign bodies: Switch off

all drive units; switch off the engine, and allow all moving parts to

come to a complete standstill.

The equipment should be securely supported whenever any work

is carried out underneath the machine.

Ensure that all blades are fixed securely.

Before carrying out any work on the header:

"Wait until the blade rotors have come to a complete

standstill"

Page 12

Chapter 1 Chapter 1

Point 1.4/1.5/1.6 Point 1.4/1.5/1.6

0401

When travelling on the public highway:

Safety instructions

0401

Observe all stipulations made in the extended individual

type-approval (document 'ABE') regarding statutory

highway regulations.

Attach the folding accident protection guard with covers

to the header.

Attach all additional side lamps and indicators.

The additional dipped headlamps should be switched on

when travelling during hours of darkness.

The reflecting hazard warning plates on the accident

protection guard must be in good condition.

The header must be raised so that the front accident

protection guard is approx. 300 mm above the road

surface.

Government inspection survey regulations regarding axle

loads, permitted gross vehicle weights and rear-end

weights must be observed.

Moreover, the general specifications contained in the accident

protection regulations for machinery, equipment, tools, technical

equipment and vehicles issued by the agricultural professional

associations, UVV 3.1 to 3.11 must be observed.

A measurement of the noise level was carried out during the CE

test: max. noise level reaching the driver's ears, in conformity

with regulation 86/188/EWG; measured in accordance with ISO

5131 with the cab closed = 80.0 dB (A).

Only genuine Kemper replacement parts should be used.

1.5 Mechanical safety

Do not place your hands or any other objects inside the

equipment while during operation or while the harvester engine is

still running.

Before carrying out repair and maintenance work, the harvester

engine must be switched off and the ignition key removed.

Safety devices may only be removed in order to perform repair

and maintenance work.

The permitted gross loads, axle loads and tyre pressures must

not be exceeded.

The statutory regulations of the highway code must be observed

when travelling on public highways.

1.6 Safety

instructions

for attaching and

removing the

header

The header may only be removed on firm, level ground.

When removing the header, ensure it is standing securely.

You may only enter the space between the harvesting attachment

and the machine when the engine is switched off and when you

have ensured it is not possible for the machine to roll forwards or

backwards.

Page 13

Chapter 1 Chapter 1

Point 1.8 /1.9 Point 1.8/1.9

0401

1.9 Safety guidelines

when welding and

Hazard from electrical current

Use only welding equipment with electrics which are in

working with

flame

Do not carry out welding where there is an increased

Safety instructions

0401

perfect condition

electrical hazard

(welder standing on a surface which will conduct

electricity, welding in a constrained position, welding in

confined spaces...)

Hazard from optical and UV radiation

Use a face screen with sight glasses appropriate to the

welding procedure in question

(welding goggles, hand or head guard with appropriate

glasses).

Protect your body by wearing clothing appropriate to the

welding procedure.

Hazard from build-up of gases

When components are subjected to heat, layers of paint

and deposits of contamination contained on the

components may combust. This will result in the formation

of noxious vapours.

It is therefore essential that layers of paint and

contamination are removed before heat is applied to the

components in the area to be welded.

(Quite apart from the hazard involved, contamination will

cause faults in the weld bead.)

Weld bead faults will also occur when welding is carried

out where a draft is present (stream of protective gas is

blown away), or when moisture is present (hydrogen

entering the weld bead).

Hazard from heat

Remember that a large amount of heat is applied to the

material when welding, making the parts extremely hot.

Make sure no combustible material is located within your

work area. Wait until all hot tools and equipment have

cooled down before touching them.

Page 14

Chapter 2 Chapter 2

Point 2.0/2.1/2.2 Point 2.0/2.1/2.2

0401

2.0 Declaration of

EC conformity

This product has been tested and marked in accordance with EU

directive 98/37/EC (Communauté européenne / European

Community). A 'Declaration of EC Conformity' is attached to the

Product liability

0401

instruction and should be delivered to the end-customer together

with the instruction.

2.1 Transfer of

ownership of the

equipment

Important! If the customer himself transfers ownership of the

equipment to another party at a later date, the instruction must

also be included in the transfer.

2.2 Obligation to

provide

information about

product liability

Product liability obliges the manufacturer and dealer to deliver the

instruction when equipment is sold and to instruct the customer in the

use of the equipment, referring to relevant operating, safety and

maintenance regulations.

A multi-copy form (A,B,C), as shown below, is attached to every copy

of the instruction. Written confirmation is required as proof of the fact

that the equipment and the instruction manual have been properly

delivered.

To this end, Document A must be signed and returned to Kemper.

Document B is retained by the dealer supplying the equipment, and

Document C is retained by the customer. This also ensure your

warranty rights.

Page 15

Chapter 4 Chapter 4

Point 4 Point 4

0401

4 General

Our patented cutting system enables you to approach the maize stems

from any direction you choose: parallel to the rows, perpendicular to the

rows, or at an angle.

Every single maize stem is fed automatically into a gap in the cutting

head.

In open-cut mode, i.e. without return cut, the crop stem is cut along the

entire working width by the fast-action blade 9. The slow-action intake

drum 1 feeds the stem along the intake bars 110.

A row of teeth 111 grasp the stem securely.

The forward movement of the intake drum pushes the crop up against

the carrier teeth 11, thus allowing the crop to be transported safely past

the guides and scrapers 22 to the intake drum.

Here, the stem is placed against the carrier teeth 51 and is thus cleanly

and evenly gathered lengthways. It is then fed pre-pressed to the

header's pre-compression and intake rollers.

General

0401

Closely spaced rows - High crop yields

Maize cultivation methods have formed the subject of intensive debate

in recent times; there has also been a shift towards increasing crop

yields by placing the individual plants closer together.

However, if this new cultivation method is to be adopted, it is essential

that the existing seed drills be used, and harvest is only possible with a

row-independent harvesting system.

The new cultivation method does not allow us to work with double rows;

instead, the previous row distance of 75 cm must be reduced to 30 cm.

Maintaining the same cultivation density of 10 plants/m

greater distance between the plants in the individual rows.

The advantages of the new cultivation method:

■ More space for each individual plant.

■ Faster overgrowing between rows and hence earlier shading of soil.

■ Less soil erosion.

■ Improved utilisation of nitrogen in the soil.

■ Increased yields by approx. 12 - 17 %.

■ Improved quality.

2

produces a

Page 16

Chapter 4 Chapter 4

Point 4.1 Point 4.1

4.1 Description of

0401

the header

Harvesting implement with integrated interface for self-propelled

forage harvesters.

When fitted with the appropriate interface, the header is suitable

for attachment to a variety of self-propelled forage harvesters.

Power transmission is delivered by the SPFH drive line via oilimmersed transmission and safety clutches.

Row-independent cutting system with fast-running rotors and

freewheel mechanism.

Cutting across the entire working width by closed saw-type rotor

blades with replaceable segments.

Even crop intake to the chopping unit via slow-running intake

drums and clean gathering by two slanting intake drums. Two

mechanically driven crop separators for heavily laid crops, heightadjustable crop lifters.

General

0401

330

Working width = 3.0 m

Page 17

Chapter 4 Chapter 4

Point 4.2 Point 4.2

0401

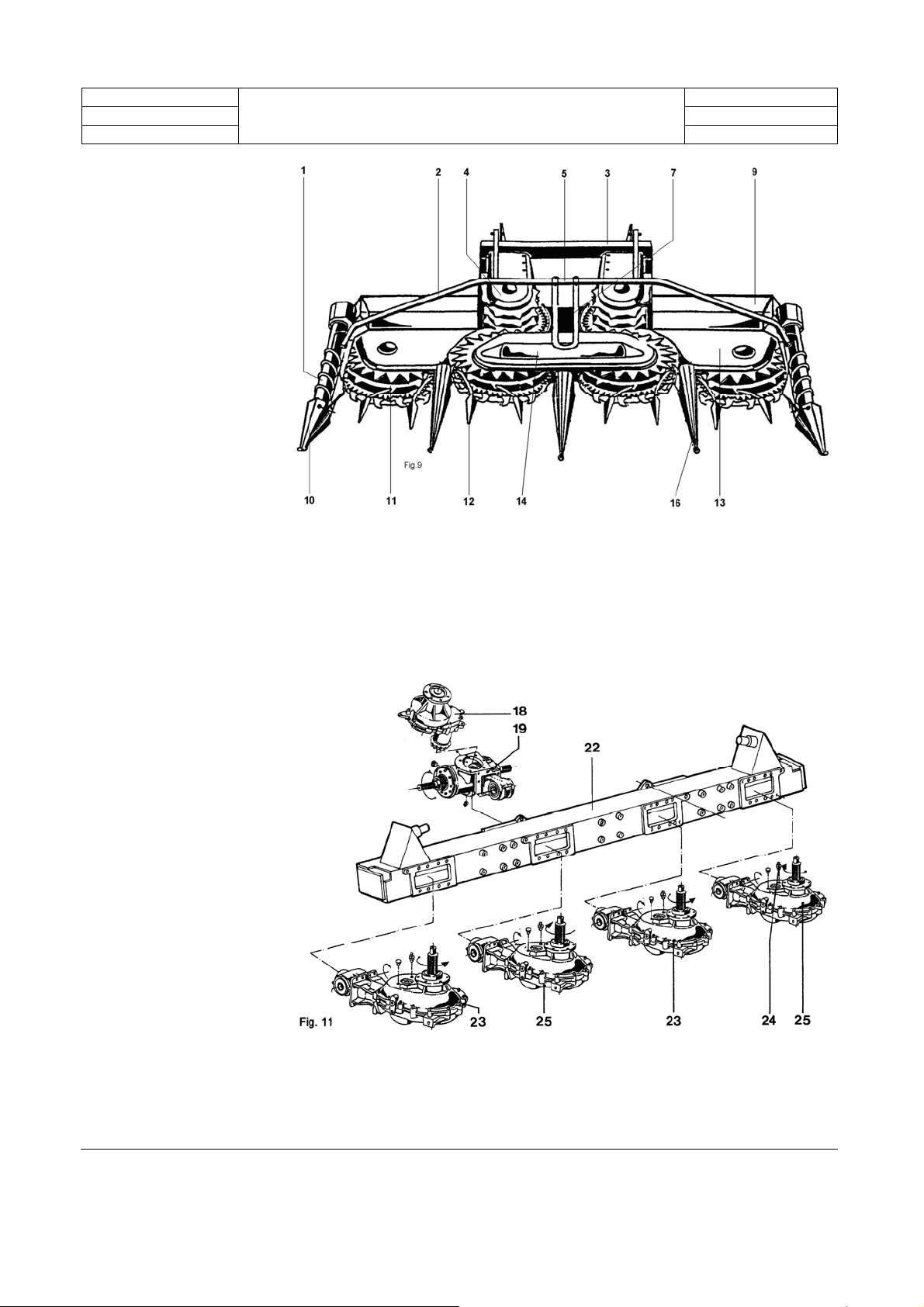

4.2

Design of the

General

0401

harvesting

attachments

with the major

sub-assemblies

Page 18

Chapter 4 Chapter 4

Point 4.2 Point 4.2

0401

Sub-assembly designations

1 Rotating lodged maize auger

2 Outer feed bar

3 Frame

4 Intake drum

5 Central feed bar

7 Centre guide

9 Rear guard

10 Outer crop separator

11 Intake drum, left or right-rotating

12 Small crop separators

13 Shield

14 Central covering plate

16 Large crop separators

18 Spur gear drives - Intake drum

19 Spur gear angle drive left and right

22 Basic frame

23 Spur gear angle drive - Intake drum, left-rotating.

24 Breather - always outside!

25 Spur gear angle drive - Intake drum, right-rotating.

General

0401

Page 19

Chapter 4 Chapter 4

Point 4.3 Point 4.3

0401

4.3 Header

dimensions and

weights

Length

Overall width

Height

Working width

Transport width

Weight of basic version

Height folded in - lowered

4.4 Maintenance

and testing

Maintenance at start of new season

The most important job to be performed before operating the header

General

Unit of

dimensio

n

m

m

m

m

m

Kg

m

0401

Harvester attachment type

330

2.06

3.00

1.36

3.00

3.00

1500

1.36

is to inspect the two friction clutches in the main power unit: remove

both clutches, dismantle, clean or replace.

(See appropriate instructions in the instruction manual)

Before commencing new operation, we recommend star ratchets K 43

in the intake drums be inspected. For lubrication of the star ratchet (1

x year) we recommend a lithium saponified grease, "GLEITMO 805

and 810" made by Gleitmolybdän. This is particularly suitable for

combating frictional corrosion.

Run the machine and check all bearings for overheating or excess

play.

Daily maintenance

Make sure scrapers (2 per rotor) beneath the rotor blade are intact.

This is important as blunt or deformed scrapers can cause blockages

and place an unnecessary strain on the power unit and friction

clutches.

Tighten the bolts after a few days' use when applying from new or

when replacing the blades or scrapers. Check all rotor blades. Heavily

worn blades should be replaced as they will create long stubble and

place unnecessary strain on the power unit.

The entire area surrounding the intake drums, rotor blades and

scraper must be cleaned of husks and stem remains every day.

Carry out a visual check of all transmissions every day to see if there

are any oil leaks.

Carrying out lubrication daily in accordance with the lubrication

schedule merely means greasing the two front bearings on the side

lodged maize augers, or, on certain models, greasing the jointed

shaft.

Weekly maintenance

All bolts and screws should be checked at regular intervals to ensure

they are firmly secured.

Foreign bodies in the cutting area can cause damage to or

deformation of the rotors, the carrier elements on the intake drums or

the crop separators. You should therefore check the entire area.

Page 20

Chapter 4 Chapter 4

Point 4.3 Point 4.3

0401

General

0401

4.5 Torques for

metric bolts

TORQUES FOR METRIC BOLTS in NM

Size

M6 4.8 6 9 11 13 17 15 19

M8 12 15 22 28 32 40 37 47

M10 23 29 43 55 63 80 75 95

M12 40 50 75 95 110 140 130 165

M14 63 80 120 150 175 225 205 60

M16 100 125 190 240 275 350 320 400

M18 135 175 260 330 375 475 440 560

M20 190 240 375 475 530 675 625 800

M22 260 330 510 650 725 925 850 1075

M24 330 425 650 825 925 1150 1075 1350

M27 490 625 950 1200 1350 1700 1600 2000

M30 675 850 1300 1650 1850 2300 2150 2700

M33 900 1150 1750 2200 2500 3150 2900 3700

M36 1150 1450 2250 2850 3200 4050 3750 4750

*“Lubricated“ means that the bolts are supplied with a lubricant such as engine oil, or that

phosphated or oiled bolts are used. "Dry“ means that normal or galvanised bolts without

any lubrication are used.

The torques specified in the table are guidelines only and do NOT apply

Grade 4.8 Grade 8.8 or 9.8

Lubricated

*

Nm Nm Nm Nm Nm Nm Nm Nm

Dry*

Lubrica-

*

ted

Dry* Lubricated* Dry*

Grade 10.9

where a different torque specification is given in this manual for certain

bolts and nuts.

Check that bolts and nuts are securely tightened.

Shearing bolts are designed to shear off when a specific load is applied.

Same grade bolts only should be used when replacing shearing bolts.

When replacing bolts and nuts, ensure that same grade parts or better

are used. Bolts and nuts of a higher grade should be tightened to the

same torque as the parts originally used.

Make sure that the threads engage properly and the bolts are correctly

applied.

This will prevent damage occurring when tightening.

Tighten locknuts (not the bolts) with a plastic insert and flanged steel

locknuts to approx. 50% of the 'dry' value given in the above table.

Tighten hinge / nuts to the full torque value.

Grade 12.9

Lubricated

*

Dry*

Page 21

Chapter 4 Chapter 4

Point 4.6 Point 4.6

0401

General

0401

4.6 Transporting the

equipment

Fold in the outer cutting units for transport (transport width 3.00 m)

Attach the folding accident prevention guard.

(The transport guard is fitted with flashing lights and position

lights.)

When folded, the cutting units may partially cover the headlamps

on some self-propelled forage harvesters.

In this case, it may be necessary to re-position the headlamps to

conform to the prevailing highway regulations, or to fit additional

headlamps.

When loading the equipment with the outer units folded, chains (or

rope) must be used as shown in Fig.7. This will prevent the

machine from toppling over. When loading in this way, you must

exercise great care and use additional securing chains if

necessary.

Fig.

7

Page 22

Chapter 4 Chapter 4

Point 4.7 Point 4.7

0401

4.7 Travelling on

the public

highway

Steering

To ensure proper steering is maintained, the steering axle on the

transport vehicle must be equipped with counterweights, paying

General

0401

due attention to the permitted axle loads.

Counterweight specifications are given in the appropriate

government inspection survey regulations.

Accident prevention

When travelling on public highways the entire area around the crop

separators must be covered with a folding guard.

Assembly sequence:

A After the rotors have come to a complete standstill, fold up

the side cutting units.

B Place the folding guard in a central position and insert the

rubber rings.

C Fold up the protective profiles on the side and insert rubber

rings.

D The runners, blades and other edges are covered with

protective cloths.

Ground clearance

When travelling on public highways the harvesting attachment

must be raised so that the front accident prevention device is

approx. 300 mm above the road surface.

Side lamps and indicators

As the side lamps and indicators on the transport vehicle are

usually covered by the intake drums in raised position, we have

mounted duplicates of these inside the accident protection device.

For the 12 V power supply a 7-pole plug is located on the right side

of the harvester.

Dipped headlamps Fig. 46 Fig. 48

The dipped headlamps (not to be confused with working

headlamps) must be duplicated at another position on the

harvester. This is because the road ahead is not adequately

illuminated when the outside intake drums are in the raised

position.

The TÜV, Germany's technical inspection authority, suggests the

following:

"Additional dipped headlamps "A" of approved design fitted (e.g.

Hella type 1 AB 004231-001, test mark HR HC/R E1 02 24461

R20) with two independent switches, for serial lighting when

travelling without the header and with standard cutting unit and

standard lighting plus additional headlamps when travelling with

Kemper harvesting implement.

The headlamp mountings are attached to the cab posts on the left

and right using appropriate drilled holes. The lower edge of the

headlamp should be approx. 3000 mm above the road surface".

See instructions in the appropriate government inspection survey

regulations.

Moreover, additional side indicators "B" should be mounted at the

front of the harvester on the right and left, in accordance with

statutory traffic regulations.

(e.g. Hella type 2 BM 006 692 - 011 or - 021)

Page 23

Chapter 4 Chapter 4

Point 4.7 Point 4.7

0401

General

0401

Page 24

Chapter 4 Chapter 4

Point 4.10 Point 4.10

0401

General

0401

4.10 Observe Public Road Legislation

CAUTION: Before transporting the machine on public roads, make

sure that the machine conforms to the legislation governing the use

of agricultural vehicles on the road.

Page 25

Chapter 9 Chapter 9

Point 9.0/9.1 Point 9.0/9.1

0501

9

Power transmission

Power transmission

Power is transmitted via jointed shafts, drive shafts and

transmission units.

0501

The individual oil levels have to be checked before

Initial start - up

9.1

Arrangement of

transmissions

330

the initial startup of the device. The header also

has to be subjected to a visual inspection.

How the drive elements interact

The harvesting implement is driven by jointed shafts from

the main chopping unit to the main drives (21 / 22) on the

implement.

The transmissions (20) for the transverse intake drums are

flanged directly to these transmissions.

Page 26

Chapter 9 Chapter 9

Point 9.1 Point 9.1

0401

Fig.

no.

20 Spur gear

21 Spur gear angle drive left

22 Spur gear angle drive right

Description

This gear is fitted with a ratchet clutch. It is filled with 0.5 l of

AVIATICON XRF liquid grease.

Transmission oil: 1.0 litres SAE 90

Transmission oil: 1.0 litres SAE 90

Power transmission

0401

Remarks

Before installing, we recommend you check the direction of

rotation. This is determined by the position of the rear bevel

gear shaft 100. On left-handed transmissions the bevel gear is

on the left. The bore in the bevel gear has one short and one

long projection to the hex form. The bevel gear is situated on

the short projection side.

Transmissions 1,5,6 and 7 = Freewheel for clockwise

Transmissions 2,3,4 and 8 = Freewheel for anticlockwise

Transmission 20 = Ratchet clutch 1150-1250 Nm

Page 27

Chapter 9 Chapter 9

Point 9.1 Point 9.1

Arrangement of

0401

Power transmission

0401

transmissions

330

Fig. 2

Page 28

A

Chapter 9 Chapter 9

Point 9.1 Point 9.1

0401

Direction of rotation

Power transmission

0401

When carrying out assembly and dismantling work on spur

gear angle drives 3-6 it is particularly important that you

observe the direction of rotation.

Freewheel

There are transmissions with anti-clockwise freewheel

and clockwise freewheel. (The number depends on the

type of harvesting implement.)

Basic principle: All transmissions have a fixing bolt

V M12x1.5 DIN 908

and a bleeding bolt E M12x1.5.

"The bleeding bolt is always assembled in the

direction of travel, facing outwards."

In the event of incorrect assembly, oil will escape from

the breather in the raised position!

There are essentially just 2 transmission versions:

Clockwise and

anticlockwise

transmission

L = anti-clockwise freewheel, transmissions items 4 ,6

R = clockwise freewheel, transmission items 3, 5

versions

Oil

The transmissions each have one oil supply system =

4.80 litres SAE 90.

n inspection screw P is located on the left and right

M22x1.5 and a magnetic drain bolt A M18x1.5 is located

at the bottom.

The threads are different to prevent confusion. Drain oil

Direction of rotation

before dismantling the transmissions 12 - 18!

We recommend you check the direction of rotation before

installing. This is determined by the position of the rear

bevel gear 190. On left-handed transmissions the bevel

gear is on the right. The bore in the bevel gear shaft has

one short and one long projection to the hex form. This

bevel gear is on the short projection side.

An additional mark is located on the raised casing area of

transmission 9: L or R at the top.

When assembling from new:

L, top = anti-clockwise transmission.

Split transmissions,

rear

R, top = clockwise transmission.

Transmissions 3-6 can be split to make for fast dismantling

in the event of service being necessary. The rear bevel

gear 9 remains in the basic frame.

Page 29

Chapter 9 Chapter 9

Point 9.1 Point 9.1

0401

Oil change intervals

Power transmission

First oil change after approx. 100 operating

hours, then every 500 operating hours

0401

Oil level check

Before checking the oil level, place the implement in a

horizontal position and open the check bolt.

Oil should reach the lower edge of the inspection aperture.

Transmissions with

grease lubrication

Item 20 = Spur gears. These two transmissions are each

filled with 0.65 litre of Aviaticon XRF liquid grease and are

lubricated for their entire service life.

Alternative grease options: Gresanat X00 made by

Westfalen or to norm: sodium transmission grease of

consistency grade NL GI 00, e.g. Shell special transmission

grease "H".

Transmission grease

- A comparison

Check interval

Made by Description

Westfalen Gresanat X00

Aral Aralub FDP 00

Shell Special transmission

grease

Esso Liquid transmission

grease

BP Energrease HT 00 EP

Texaco Starfak E 900

Antar Liquid transmission

grease

Daily visual check for oil leaks

H

EPEXELF 00

Page 30

Chapter 9 Chapter 9

Point 9.2 Point 9.2

0401

9.2

Position of openings

on the various

transmissions

Power transmission

0401

Filling, drainage bleeding bolts, grease nipples

A = Oil drainage bolt

E = Filler bolt

L = Bleed

N = Grease nipple

P = Oil level check bolt

Fig. 4

Page 31

Chapter 9 Chapter 9

Point 9.2 Point 9.2

0401

Power transmission

0401

9.3

Oil grade

Capacities, oil-filled

transmissions

Oil grades and capacities

SAE 90 transmission oil

Item 21 = Spur gear angle drive = 1.00 litre

Item 22 = Spur gear angle drive = 1.00 litre

Item 24 = Spur gear angle drive = 4.80 litres

Page 32

Chapter 9 Chapter 9

Point 9.3 Point 9.3

9.3 Oil grades and

0401

Power transmission

0401

capacities

Direction of rotation

When carrying out assembly and dismantling work on Spur

gear angle drive 4 it is particularly important that you

observe the direction of rotation.

We recommend you check the direction of rotation before

installing. This is determined by the position of the rear bevel

gear 100. On left-handed transmissions the bevel gear is on

the right. The bore in the bevel gear shaft has one short and

one long projection to the hex form. This bevel gear is on the

short projection side.

Ratchet clutch

Transmission 20 = Ratchet clutch

1150-1250 Nm

Transmission 24 = Ratchet clutch

570- 630 Nm

Fig.4

Description

no.

20 Spur gear drives 2

21 Spur gear angle drives Left-handed 1

Transmission oil: 1.0 L SAE 90

22 Spur gear angle drives Right-handed 1

Transmission oil: 1.0 L SAE 90

23 Spur gear angle drives Right-handed 2

Transmission for transverse intake drum - left-handed.

24 Spur gear angle drives Left-handed 2

Transmission for transverse intake drum - right-handed.

This gear is fitted with a ratchet clutch. It is filled with 0.5 l

of AVIATICON XRF liquid grease.

This transmission is fitted with a ratchet clutch.

Mark beneath transmission = 07

Transmission oil: 0.85 L SAE 90

This transmission is fitted with a ratchet clutch.

Mark beneath transmission = 08

Transmission oil: 0.85 L SAE 90

Parts

330

Remarks

Page 33

Chapter 9 Chapter 9

Point 9.4 Point 9.4

9.4

0401

Power transmission

0401

Basic machine lubrication schedule

Basic machine

Grease daily

1 = Grease nipple on lower bearing of

lodged maize auger

(left and right)

Grease annually

2 = Star ratchet in all eight intake drums.

We recommend lubrication using a lithium saponified

grease lithium-saponified grease

"GLEITMO 805 and 810" made by Gleitmolybdän.

This is particularly good against friction corrosion.

Page 34

Chapter 10 Chapter 10

Point 10.0 Point 10.0

0401

10 Clutches

Clutches

0401

General inspection of friction clutches

shortly before each new season begins

Page 35

Chapter 10 Chapter 10

Point 10.1 Point 10.1

0401

10.1 Starting clutch

Clutches

0401

800 Nm

Page 36

Chapter 10 Chapter 10

Point 10.1 Point 10.1

0401

The 700 Nm friction clutch in main drive

Clutches

0401

Protective

function

Fig. 55-58

The two friction clutches 50 in the main drive (beneath the

attachment frame) protect the entire machine from unnecessary

loads. Proper maintenance of both clutches and continuous

inspection of proper functioning are

absolutely essential!

Torque The torque setting is M = 800 Nm. The following two chapters

describe the maintenance work necessary to ensure this torque

value is retained. The friction clutch must be "bled" at regular

intervals.

Failure to observe these instructions will render your warranty

null and void!

Simple

inspection

Simple inspection before first time of using and following a

lengthy period out of service:

■ Dismantle protective tube 54.

■ Tighten nuts 12, thus relieving the friction disk,

slip clutch.

■ Loosen nuts 12 to end of thread.

■ Assemble protective tube.

General

Inspection

"bleeding"

General inspection before start of new season:

■ Dismantle protective tube 54 - Dismantle circlip 52 Push aside bushing 51 -

Remove clutch shaft 53 - Remove both friction clutches 50.

■ Tighten nuts 12, thus relieving friction disks 4 and setting ring

2.

■ Remove setting ring 2.

■ Remove spring pack, friction disks, drive plates and hub,

clean or replace if necessary.

In order to maintain torque at M = 800 Nm, the correct

installation of setting ring 2 is important, see Fig. 55

(cam 9 on setting ring 2 inside - cam 9 engages in

depression 1 on housing 8).

New linings When new friction disks have been fitted, the clutch will require

time to run-in before it achieves full torque.

■ Exercise care when driving off. Do not place the clutch under

unnecessary load.

■ Allow a running-in period before driving at full power.

Note on

assembly:

It is easier to assemble the friction clutch if all the nuts 12 are

tightened. Meshing on the clutch housing and the flange hub can

then be turned.

Page 37

Chapter 10 Chapter 10

Point 10.4 Point 10.4

0401

10.4 Dismantling

Clutches

0401

Page 38

Chapter 11 Chapter 11

Point 11.0 Point 11.0

0401

11

Pre-season

maintenance

Maintenance and inspection

The 'general inspection' of the two friction clutches in the

main drive is the most important task before commencing

Maintenance

0401

operation with the harvesting implement: remove the two

clutches, dismantle them, clean and replace if necessary.

Follow the instructions contained in the chapter "Friction

clutch in the main drive".

Before commencing operation at the start of a new season,

we also recommend the inspection of the star ratchets K 43

in the gathering drums. We recommend the use of a lithiumsaponified grease "GLEITMO 805 and 810" made by

Gleitmolybdän for lubrication of the star ratchet (1 x

annually); this is particularly effective against friction

corrosion.

With the machine running, check all bearings for overheating

and for excess clearance.

Daily maintenance

Make sure the scrapers (2 per rotor) beneath the blades are

intact, as blunt or bent scrapers will cause blockages and

place unnecessary load on the drive system and the friction

clutches.

After a few days' operation or when replacing the blades or

scrapers, the bolts should be re-tightened. Check all the

blades. Replace heavily worn blades, as these will cause

long stubble and place the drive system under unnecessary

load.

The entire area around the gathering drums, the blades and

scrapers must be cleared of husks and stem remnants on a

daily basis.

You should carry out a daily visual inspection of all

transmissions and check for oil leakage.

'Grease daily in accordance with lubrication schedule' simply

means you must grease the two front bearings on the side

lodged maize auger, or the jointed shaft on certain models.

Loose bolts on the blades and scrapers will quickly result in

major subsequent damage such as worn bores. A brief

inspection with the side cutting units raised takes very little

time.

Weekly maintenance

You should check regularly that all screws and bolts are

properly tightened. Torques in Nm:

Foreign bodies in the cutting area can cause damage or

deformations to the blades, the drives on the gathering drum

or on the crop separators. It is therefore essential that you

check the entire area.

Clean the clutches in the hinge.

Page 39

Chapter 11 Chapter 11

Point 11.0 Point 11.0

0401

Maintenance at the

end of the season

Clean and conserve before a lengthy period out of

service. Follow the instructions given on the equipment!

Maintenance

0401

Using high-pressure cleaner : water pressure max. 80 bar,

distance of nozzle from equipment min. 25 cm and water

temperature max. 50° C.

Important : Do not use jets with circular section!

Touch-in minor damage to paintwork immediately.

Clean all spaces 21 above the drum star ratchet K43.

Carry out the first transmission oil change after 100

operating hours, and then every 500 operating hours.

Grease in accordance with lubrication schedule.

Inspect all parts for general wear and tear and order

replacement parts in good time.

The use of replacement parts, accessories and additional

equipment which are not genuine KEMPER parts and have

not been tested and approved by KEMPER can have

negative effects on the design characteristics of the

KEMPER machine or impair its proper functioning, thus

impairing its active and/or passive safety when driving or

when working (accident prevention).

For any damage caused through the use of parts,

accessories and additional equipment which are not genuine

KEMPER parts, KEMPER declines all liability.

Page 40

Chapter 11 Chapter 11

Point 11.1 Point 11.1

0401

11.1

Star ratchet

Maintenance

0401

Information regarding

the star ratchet

The star ratchet as shown in Fig.85 can be removed by

removing the hex bolts S ( 8x ) without the need to

dismantle the gathering drum.

Page 41

Chapter 11 Chapter 11

Point 11.2 Point 11.2

0401

11.2

Blade wear

Blades

The blades have a limited service life. Fig. 94 shows:

Teeth 1 = New condition = 1:1

Teeth 2 = Condition after heavy duty

When the tips are fully worn, the crop may be pushed

forward. Cutting will then require greater power, which will

have a negative effect on the transmissions and clutches.

Maintenance

0401

Replacing the blades

When assembling the coated blades, you should ensure that

green and yellow blades are fitted alternately. Pay attention

to left and right rotation. The coating should face upwards.

The assembly sequence is a safety feature: when the rotor

is turning, a visual effect is created which shows that the

rotor is in operation.

Page 42

Chapter 11 Chapter 11

Point 11.3 Point 11.3

0401

11.3

Maintenance of the intake and cutting area

Maintenance

0401

Intake and cutting

area

The following functional parts are included in the intake and

cutting area:

Small crop separators T - Intake bars E

Driver teeth M - Row of teeth Z

Blades S - Blade scrapers SR

Rotor R - Rotor scrapers RR

The functional interaction of these parts is of major importance for

crop intake, for the safe grasping and cutting of the crop, and for

the further crop transport. Problems occurring in the cutting area

are usually easy to resolve, providing the following instructions

are observed.

Page 43

Chapter 11 Chapter 11

■

■

■

■

■

■

■

■

■

■

Point 11.3 Point 11.3

Small crop separators

0401

Fig. 93

The gap between the rear side of the small crop

separators T and the drive teeth M should be as small as

Maintenance

0401

possible (4-6 mm). The smaller the gap, the better lodged

crop will be picked up.

Drive teeth

For the reason mentioned above, please ensure that any

deformation of the drive teeth M, caused by the presence

of foreign bodies in the system, is rectified immediately.

Intake rods

The intake rods E perform the important task of pressing

the crop into the narrowly spaced row of teeth Z.

Wear to the intake rods E ( 18 ∅ ) can occur after a

lengthy period of use. This wear can be compensated for

by making re-adjustment; alternatively, the parts can be

replaced.

Blades

The blades must be assembled in the direction of cut.

The blades will continue to run after the harvesting

implement has been switched off. The different colour of

the blades provides a visual warning, and the clicking

sound made by the freewheels provides an audible

indication that the blades are still running.

Caution! Do not touch any parts while they are moving!

Wait until the rotors have first come to a complete

standstill.

Blade scrapers SR

Intact blade scrapers SR keep the cutting area free of

fowling by weeds and husks. They are secured on the rotor

by a fixing screw M 10 x 25 and a shearing screw M 8 x 25.

Both screws are special-type screws because of the degree

to which they are tightened ( 8.8 ).

Blunt or bent scrapers will cause blockages. We therefore

recommend they are inspected on a daily basis.

The tungsten carbide coating on the scrapers SR must

face forwards in the direction of rotation.

The two scrapers RR on each rotor keep the space between

rotor R and the transmission clear of husks and

contamination.

Rotor scrapers RR

Intact scrapers protect the drive system from overloading.

The front edge in the direction of rotation should be as

sharp as possible. We therefore recommend daily

inspection. By loosening the special nut 20 and

dismantling the blade scrapers SR, you can remove the

scraper RR and hone its leading edge using a right-angle

grinder.

Page 44

Chapter 11 Chapter 11

Point 11.4 Point 11.4

0401

Maintenance

0401

11.4

Inspecting the crop guide track

Page 45

Chapter 11 Chapter 11

Point 11.4 Point 11.4

0401

Scrapers and

guides

All the scrapers and guides inside the crop guide track require

special attention and should be carefully examined in the event of a

Maintenance

0401

fault occurring. Faults can occur (e.g.) when foreign bodies enter

this track.

Faults can also occur following assembly work in this area.

Should you notice any faults in the flow of the crop, you must

examine the entire scraper and guide track.

Scrapers 7

Fig.96

The basic setting is correct if all the teeth in the gathering drum 5

run through the centre of the slot.

The scraper ends A should also be as close as possible against the

wall of the gathering drum 5. The distance should not be greater

than 5 mm. The teeth on the gathering drum 5 should all pass at

the same height through the guide slot B.

Guide

Fig. 95

Here, too, two important points should be observed. The scraper

ends F should be set as close as possible to the wall of gathering

drum 6.

A maximum distance of 5 mm should not be exceeded.

The lower drive teeth G should not pass more than 4 mm away

from the guide plate.

Scraper 8

Fig.95

In connection with the intake plate 20, the scraper 8 can be turned

about the feed drum 9 depending on the channel width on the

harvester. You should ensure that the H are also set as close as

possible to the feed drum wall 9 (max. 5 mm distance).

Page 46

Chapter 11 Chapter 11

Point 11.5 Point 11.5

11.5

0401

Scrapers

Maintenance

0401

Scrapers

Fig. 98

Intake drum

Feed drum 9

Intake drum

Gathering

drum 6

The scrapers on the teeth of gathering drum 6 and feed drum 9

have the important task of keeping the scrapers 2,3,7 and 8 free

of husk accumulations.

Feed drum 9 is fitted with 5 scrapers.

The three rows of teeth on all the gathering drums are each fitted

with a scraper. One set of driver teeth M is also fitted with a

special flat scraper.

Fig.98

Page 47

Chapter 11 Chapter 11

Point 11.6 Point 11.6

0401

Inspection The scrapers are made of heavy-duty special steel. They are

11.6

subject to continuous wear and tear and should therefore be

inspected at regular intervals.

An accumulation of husks in the scrapers A is usually a sign of

incorrect adjustment or faulty scrapers.

Any wear of the cleaner points can be compensated by build-up

welding with steel electrodes.

Attachment frame

Maintenance

0401

Attachment

frame

Check for proper tightening of all screws after the first 10 hours of

service, and from then on at regular intervals.

When assembling the attachment frame 1, you should first tighten

the screws 14. Then tighten the screws on the struts 8 at top and

bottom.

Page 48

Chapter 11 Chapter 11

Point 11.7 Point 11.7

0401

11.7

Fault Possible cause Remedy

Fault - Causes

Heavy running cutting

rotors

Vibration of implement

Husks accumulate on

scrapers

Stubble is bent forwards

before it is cut Long stubble

Maintenance

Blunt blades Replace blades Greater power required

Faulty scrapers Replace scrapers

Blockage of leaves

beneath rotors

Contamination in rotor

area

Faulty scrapers Replace scrapers

Imbalance caused by

uneven blades

Scrapers torn off Replace scrapers

Imbalance caused by

contamination in rotor

Height at which blades

pass too great

Scrapers have moved See chapter

Small crop separators are

full of leaves

One scraper is torn off Replace both scrapers

Blunt blades Replace blades

0401

Clean rotor area daily

Clean rotor area

Replace blades in pairs

Clean rotor

Adjust – replace if

necessary

"maintenance and

inspection of scrapers"

Clean crop separators

Drives heat up

Intake drum or feed

drum stops

(Cutting rotor is running)

Intake drum and cutting

rotor stop

Entire right or left-hand

side stops

Backlog in hydraulic

system in outer folding

cutting unit

Faults upstream of precompression rollers

Too much oil in the drive Check oil level

Bunch or ball of crop

lodged in intake channel

Clutch transmits speed Repeat procedure if

Damage to drive Replace parts

Faulty claw clutch

(selector sleeve)

Left and right friction

clutch

Faulty (starting-off clutch)

Foreign bodies, e.g. grain

of sand in front of throttle.

Incorrect gear

combination

Springs on precompression rollers

incorrectly set

Reverse a short

distance

necessary

Replace faulty parts

See "Friction clutch in

main drive"

Clean throttle: located in

screwed joint at cylinder

input

Select new gear

combination in acc. with

table of cutting lengths.

Adjust:

Green maize = slacker

Dry maize = tighter

Page 49

Drum speed

40 – 44 min1−

38 - 44 min1−

48 - 52 min1−

Page 50

Starting

Driving into the

crop

fahren

Direction of travel

Driving speed

Turning

Changing the

forage wagon

Eliminating

problem

Working with the Harvesting Header

Starting – Turning – Changing Forage Wagon - Reversing

The header may only be used, serviced and repaired by

personnel familiar with the operation of the machine or trained and instructed

about the dangers and risks associated with the machine!

These instructions only serve to make some general recommendations. Your

experiences as well as compliance with the following instructi ons and

own

notes are certain help avoiding major problems.

• You should be familiar with the machine before you start!

Start the forage harvester, engage the chopping unit and the header as well as

reverse with the engine running at idling speed the engine running at idling

speed. Reversing causes the gathering drums to rotate in the opposite

direction. The cutting rotors stop. Switching the gathering drums to forward

movement should also take place at

of the friction clutches.

• Always start and shift into first at idling speed to save the

drive units!

When the chopping unit and the cutting blades have come up to speed, drive at

a sufficient speed into the crops to obtain from the beginning a compact stream

of fodder. This applies especially

handling short-stemmed maize.

• Always drive smoothly and steadily into the crops!

The row-independent harvesting system allows selection of any direction of

travel. In difficult conditions (e.g. down crops) there is always one direction

which provides better results. This must be determined by trial and error.

• Use the free choice of the travel direction for your advantage!

The driving speed is determined by the type and density/volume/mass of the

crops and the available engine power. The shorter the crop and the lower the

crop density, the faster you should drive to ensure satisfactory operation of the

gathering elements.

• The driving speed is based on the existing mass, the type of crops and the

harvester capacity.

• To protect the header drive, maintain your speed when turning and steadily

turn back into the crops when negotiating headlands.

• Maintain rpm when turning!

Due to the short conveyor distances of the header, it is not advantageous to

actuate the instantaneous stop at the forage harvester when changing the crop

wagon. Stopping and restarting the unit would only cause loss of time and

expose the drive units to unnecessary stresses.

• When changing the forage wagon, allow all drive units to continue to run!

To clear blockages in the channel openings caused by weed -infested crops or

long and sticky husks, stop and operate in reverse for a short period (idling

speed, repeat if necessary).

• It is important that the quick reversal process does not allow the cutting

blades to come to a stop!

Should you find it necessary to use your hands to remove any material, be sure

to switch off the combine harvester motor and turn the PTO shaft shift lever to

OFF.

Even though the gathering drum may have stopped rotating, the cutting blades

may still be rotating! Wait for all moving parts to come to a complete stop!

idling speed to avoid unnecessary slipping

in case of difficult crop conditions or when

Page 51

Down maize

Fig. 1

Fig. 2

Page 52

Down maize

Down crops vary widely, because the effects of nature differ greatly.

Despite the successful cultivation of new varieties and the use of new growing

methods, it will never be possible to overcome the problem of down crops. This is

why we have equipped the header with standard design features and technical

solutions, which allow contractors to offer a machine which can deal with any

situation. The most important requirement is here the row-independent operation

so that crops can be approached from the optimal side.

Standard equipment for the header consists of two driven maize augers for down

crops as well as height adjustable crop separators. With the aggressive toothed

element at the gathering drums, the stems frequently positioned crisscross on the

ground are pulled apart, lifted by the traverse auger for down crops and height

adjustable crop separators, and then safely rioted to the blades of the forage

harvester.

Here are some things to consider in spite of the standard universal equipment:

• Walk around the field to determine the best possible driving direction.

• In most cases, it is best to approach crops at a crosswise angle to the

• When starting the harvest, observe exactly how well the machine is handling

• Quickly drive at a very low rpm of the gathering drums into the crops so that

• In case of jams: stop, reverse briefly and repeat the process if necessary.

• Extensive reversing is usually always disadvantageous.

• Mount rigid stalk lifter (fig. 1, optional equipment); kit containing 4 lifters

330 = Sets of 2

Never use your hands or feet to "help"!

direction in which the stalks are positioned. See Fig. 2

the crops.

a material flow is created.

Renewable

resources

Ornamental

grasses

(Maiden Gras,

Zebra Gras,

Elephant Grass)

Always select a high forward speed to obtain an immediate flow of material when

harvesting short-stemmed maize. The feed bars also have to be lower so that the

maize stalks do not enter the compression rollers vertically.

• Drive quickly and apply more pre-pressure to the maize stalks.

The header is currently the only production machine which allows elephant grass

to be harvested and chopped in a single operation. The chopped crop has to

feature an even structure due to the subsequent further processing.

This is only possible with the unique lengthwise transport and bundling provided

by the header.

Page 53

Chapter 15 Chapter 15

Point 15 Point 15

0610

Attachment to forage harvester

0610

15 Attachment to forage harvester

Interface Rigid frame for firm attachment of header to harvester

Notes When attaching a header, always adhere to the following instructions:

• Slowly drive the forage harvester to the header.

• Attach the header to the pre-compression roller housing.

• Lift the header.

• Lock the support feet at the highest position.

• Ensure that the header is fully engaged in the receptacle so

that it cannot become dislodged.

• Close the locking mechanisms.

• Mount the safety devices.

For detailed mounting instructions, please refer to the

respective chapter in the section covering your forage harvester

model in this manual!

Page 54

Chapter 15 Chapter 15

Point 15 Point 15

0610

Attachment to forage harvester

0610

Removing header from forage harvester

.

2. 1.

1. Lower the header onto the level ground.

2. Pull out the two support feet and engage them.

3. Remove the jointed shaft.

4. Open the locking mechanism.

5. Disconnect the hydraulic hoses.

6. Slowly lower the mounting device of the forage harvester until

the frame is released and the harvester can be moved away

from the header.

7. Slowly drive the harvester away from the header.

Some header models require a third support foot below the centre

separator tip. For details, please refer to the section covering your

harvester model in this manual.

Page 55

Serial number The serial number identifying the harvesting header is engraved into

the type plate of the machine, which is attached at the position shown

below.

stamped number

Type plate Please enter here the serial number of your harvesting header.

Loading...

Loading...