KEMET MULTILAYER CERAMIC CAPACITORS User Manual

© KEMET Electronics Corporation, P.O. Box 5928, Greenville, S.C. 29606, (864) 963-6300 3

MULTILAYER CERAMIC CAPACITORS/AXIAL & RADIAL LEADED

Multilayer ceramic capacitors are available in a

variety of physical sizes and configurations, including

leaded devices and surface mounted chips. Leaded

styles include molded and conformally coated parts

with axial and radial leads. However, the basic

capacitor element is similar for all styles. It is called a

chip and consists of formulated dielectric materials

which have been cast into thin layers, interspersed

with metal electrodes alternately exposed on opposite

edges of the laminated structure.

The entire structure is

fired at high temperature to produce a monolithic

block

which provides high capacitance values in a

small physical volume. After firing, conductive

terminations are applied to opposite ends of the chip to

make contact with the exposed electrodes.

Termination materials and methods vary depending on

the intended use.

TEMPERATURE CHARACTERISTICS

Ceramic dielectric materials can be formulated with

a wide range of characteristics. The EIA standard for

ceramic dielectric capacitors (RS-198) divides ceramic

dielectrics into the following classes:

Class I: Temperature compensating capacitors,

suitable for resonant circuit application or other applications where high Q and stability of capacitance characteristics are required. Class I capacitors have

predictable temperature coefficients and are not

effected by voltage, frequency or time. They are made

from materials which are not ferro-electric, yielding

superior stability but low volumetric efficiency. Class I

capacitors are the most stable type available, but have

the lowest volumetric efficiency.

Class II: Stable capacitors, suitable for bypass

or coupling applications or frequency discriminating

circuits where Q and stability of capacitance characteristics are not of major importance. Class II

capacitors have temperature characteristics of ± 15%

or less. They are made from materials which are

ferro-electric, yielding higher volumetric efficiency but

less stability. Class II capacitors are affected by

temperature, voltage, frequency and time.

Class III: General purpose capacitors, suitable

for by-pass coupling or other applications in which

dielectric losses, high insulation resistance and

stability of capacitance characteristics are of little or

no importance. Class III capacitors are similar to Class

II capacitors except for temperature characteristics,

which are greater than ± 15%. Class III capacitors

have the highest vol

umetric efficiency and poorest

stability of any type.

KEMET leaded ceramic capacitors are offered in

the three most popular temperature characteristics:

C0G: Class I, with a temperature coefficient of 0 ±

30 ppm per degree C over an operating

temperature range of - 55°C to + 125°C (Also

known as “NP0”).

X7R: Class II, with a maximum capacitance

change of ± 15% over an operating temperature

range of - 55°C to + 125°C.

Z5U: Class III, with a maximum capacitance

change of + 22% - 56% over an operating tem-

perature range of + 10°C to + 85°C.

Specified electrical limits for these three temperature

characteristics are shown in Table 1.

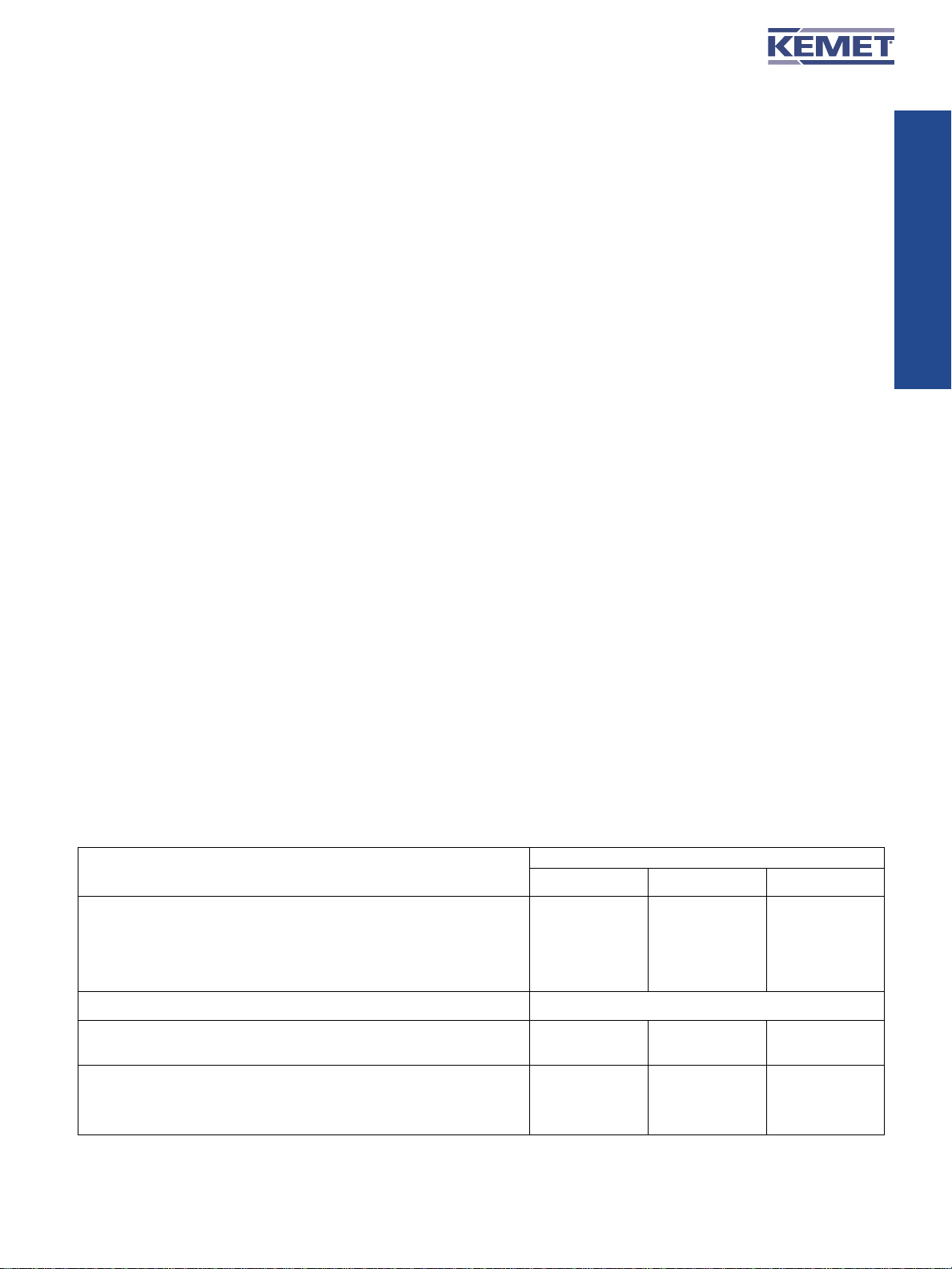

SPECIFIED ELECTRICAL LIMITS

TEMPERATURE CHARACTERISTICS

PARAMETER C0G X7R Z5U

Dissipation Factor: Measured at following conditions:

C0G — 1 kHz and 1 vrms if capacitance > 1000 pF

1 MHz and 1 vrms if capacitance ≤ 1000 pF 0.15% 2.5% 4.0%

X7R — 1 kHz and 1 vrms* or if extended cap range 0.5 vrms

Z5U — 1 kHz and 0.5 vrms

Dielectric Strength: 2.5 times rated DC voltage. Pass Subsequent IR Test

Insulation Resistance (IR): At rated DC voltage, 1,000 MΩ-µF 1,000 MΩ-µF 1,000 MΩ-µF

whichever of the two is smaller or 100 GΩ or 100 GΩ or 10 GΩ

Temperature Characteristics: Range, °C -55 to +125 -55 to +125 +10 to +85

Capacitance Change without 0 ± 30 ppm/°C ±15% +22%, -56%

DC voltage

* 1 MHz and 1 vrms if capacitance ≤ 100 pF on military product.

Table I

Multlayer Ceramic

Capacitors

CERAMIC CONFORMALLY COATED/AXIAL & RADIAL

PERFORMANCE CHARACTERISTICS FOR STANDARD AND HIGH VOLTAGE

© KEMET Electronics Corporation, P.O. Box 5928, Greenville, S.C. 29606, (864) 963-63004

GENERAL SPECIFICATIONS

Working Voltage:

Axial (WVDC) Radial (WVDC)

C0G – 50 & 100

X7R – 50 & 100

Z5U – 50 & 100 50 & 100

Temperature Characteristics:

C0G – 0 ± 30 PPM / °C from - 55°C to + 125°C (1)

X7R – ± 15% from - 55°C to + 125°C

Z5U – + 22% / -56% from + 10°C to + 85°C

Capacitance Tolerance:

C0G – ±0.5pF, ±1%, ±2%, ±5%, ±10%

X7R – ±10%, ±20%, +80% / -20%, +100% / -0%

Z5U – ±20%, +80% / -20%

Construction:

Epoxy encapsulated - meets flame test requirements of UL

Standard 94V-0.

High-temperature solder - meets EIA RS-198, Method 302,

Condition B (260°C for 10 seconds)

Lead Material:

100% matte tin (Sn) with nickel (Ni) underplate and steel core.

Solderability:

EIA RS-198, Method 301, Solder Temperature: 230°C ±5°C.

Dwell time in solder = 7 ± ½ seconds.

Terminal Strength:

EIA RS-198, Method 303, Condition A (2.2kg)

50, 100, 200, 500, 1k, 1.5k, 2k, 2.5k, 3k

50, 100, 200, 500, 1k, 1.5k, 2k, 2.5k, 3k

ENVIRONMENTAL

Vibration:

EIA RS-198, Method 304, Condition D (10-2000Hz; 20g)

Shock:

EIA RS-198, Method 305, Condition I (100g)

Life Test:

EIA RS-198, Method 201, Condition D.

££

200V

C0G – 200% of rated voltage @ +125°C

X7R – 200% of rated voltage @ +125°C

Z5U – 200% of rated voltage @ +85°C

³³

500V

C0G – rated voltage @ +125°C

X7R – rated voltage @ +125°C

Post Test Limits @ 25°C are:

Capacitance Change:

C0G (£ 200V) – +3% or 0.25pF, whichever is greater.

C0G (³ 500V) – +3% or 0.50pF, whichever is greater.

X7R – + 20% of initial value (2)

Z5U – + 30% of initial value (2)

Dissipation Factor:

C0G – 0.15% maximum

X7R – 2.5% maximum

Z5U – 4.0% maximum

Insulation Resistance:

C0G – 10k Megohm or 100 Megohm x µF, whichever is less.

³1kV tested @ 500V.

X7R – 10k Megohm or 100 Megohm x µF, whichever is less.

³1kV tested @ 500V.

Z5U – 1k Megohm or 100 Megohm x µF, whichever is less.

ELECTRICAL

Capacitance @ 25°C:

Within specified tolerance and following test conditions.

C0G – > 1000pF with 1.0 vrms @ 1 kHz

£ 1000pF with 1.0 vrms @ 1 MHz

X7R – with 1.0 vrms @ 1 kHz

Z5U – with 1.0 vrms @ 1 kHz

Dissipation Factor @ 25°C:

Same test conditions as capacitance.

C0G – 0.15% maximum

X7R – 2.5% maximum

Z5U – 4.0% maximum

Insulation Resistance @ 25°C:

EIA RS-198, Method 104, Condition A <1kV

C0G – 100k Megohm or 1000 Megohm x µF, whichever is less.

£500V test @ rated voltage, ³1kV test @ 500V

X7R – 100k Megohm or 1000 Megohm x µF, whichever is less.

£500V test @ rated voltage, ³1kV test @ 500V

Z5U – 10k Megohm or 1000 Megohm x µF, whichever is less.

Dielectric Withstanding Voltage:

EIA RS-198, Method 103

£200V test @ 250% of rated voltage for 5 seconds with current

limited to 50mA.

500V test @ 150% of rated voltage for 5 seconds with current

limited to 50mA.

³1000V test @ 120% of rated voltage for 5 seconds with current

limited to 50mA.

Moisture Resistance:

EIA RS-198, Method 204, Condition A (10 cycles without

applied voltage.)

Post Test Limits @ 25°C are:

Capacitance Change:

C0G (£ 200V) – +3% or 0.25pF, whichever is greater.

C0G (³ 500V) – +3% or 0.50pF, whichever is greater.

X7R – + 20% of initial value (2)

Z5U – + 30% of initial value (2)

Dissipation Factor:

C0G – 0.25% maximum

X7R – 3.0% maximum

Z5U – 4.0% maximum

Insulation Resistance:

C0G – 10k Megohm or 100 Megohm x µF, whichever is less.

£500V test @ rated voltage, ³1kV test @ 500V.

X7R – 10k Megohm or 100 Megohm x µF, whichever is less.

³500V test @ rated voltage, >1kV test @ 500V.

Z5U – 1k Megohm or 100 Megohm x µF, whichever is less.

Thermal Shock:

EIA RS-198, Method 202, Condition B (C0G & X7R: -55°C to

+125°C); Condition A (Z5U: -55°C to 85°C)

(1) +53 PPM -30 PPM/ °C from +25°C to -55°C, + 60 PPM below

10pF.

(2) X7R and Z5U dielectrics exhibit aging characteristics; there-

fore, it is highly recommended that capacitors be deaged for 2

hours at 150°C and stabilized at room temperature for 48

hours before capacitance measurements are made.

CERAMIC CONFORMALLY COATED/RADIAL

“STANDARD & HIGH VOLTAGE GOLDEN MAX”

Golden Max

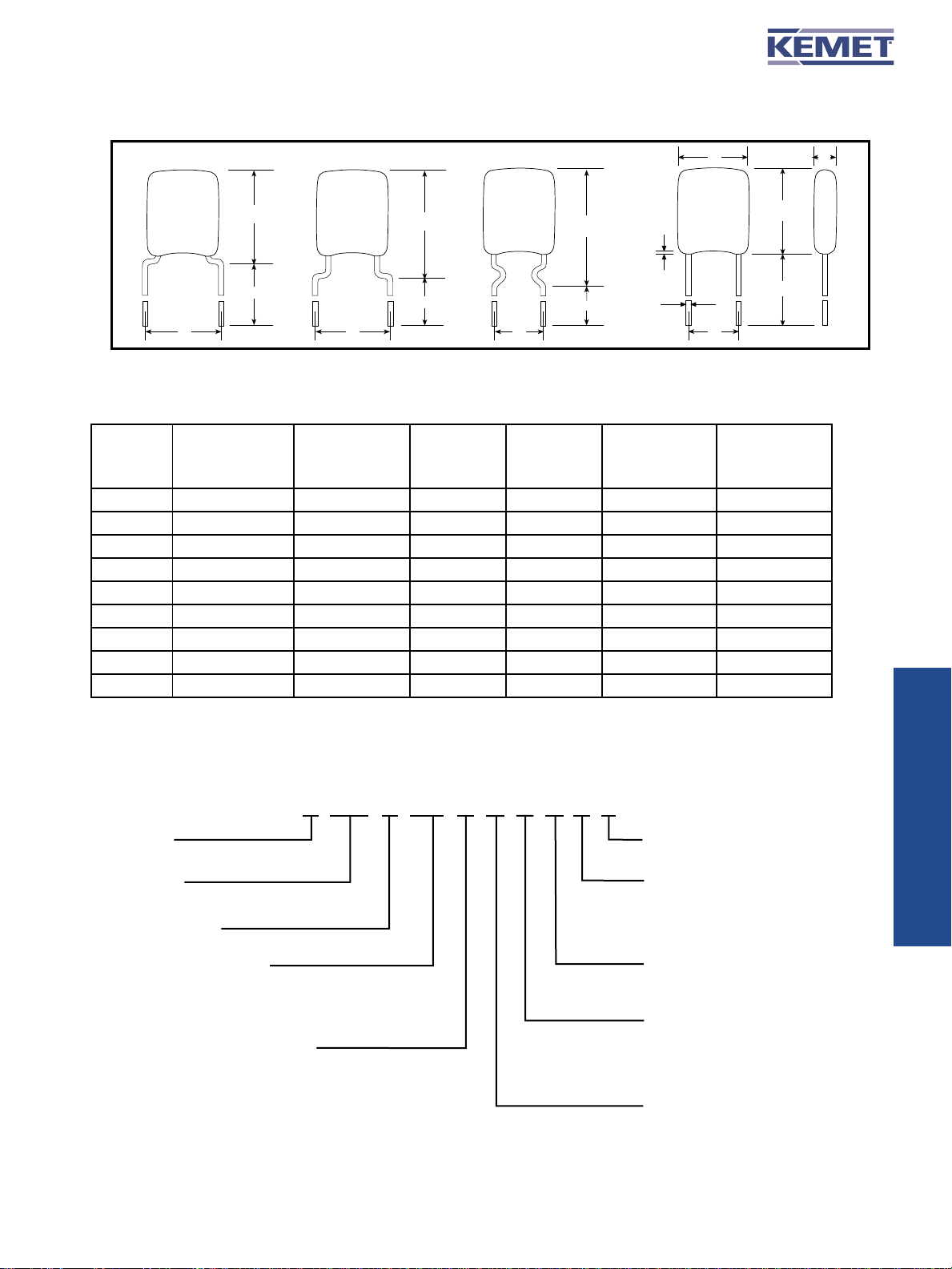

STANDARD LEAD CONFIGURATION — OUTLINE DRAWINGS

*.276 (7.00) MIN.

C317

C322

C330

H

*

S

Drawings are not to scale. See table below for dimensions.

See page 10 for optional lead configurations.

C323

S

C333

H

*

.060

(1.52)

H

MAX.

*

D

S

L

C315

C320

C330

C340

C350

S

H

*

DIMENSIONS — INCHES & MILLIMETERS

CASE L H T S(1) D

Case

SIZE MAX. MAX. MAX. ±.030 (.78)

Size

C315 .150 (3.81) .210 (5.33) .130 (3.30) .100 (2.54) .020 (.51)

C315 0.150 (3.81) 0.210 (5.33) 0.100 0.150 0.100 (2.54) 0.020 (.51)

C317 .150 (3.81) .230 (5.84) .130 (3.30) .200 (5.08) .020 (.51)

C317 0.150 (3.81) 0.230 (5.84) 0.100 0.150 0.200 (5.08) 0.020 (.51)

C320 .200 (5.08) .260 (6.60) .150 (3.81) .100 (2.54) .020 (.51)

C320 0.200 (5.08) 0.260 (6.60) 0.125 0.200 0.100 (2.54) 0.020 (.51)

C322 .200 (5.08) .260 (6.60) .150 (3.81) .200 (5.08) .020 (.51)

C322 0.200 (5.08) 0.260 (6.60) 0.125 0.200 0.200 (5.08) 0.020 (.51)

C323 .200 (5.08) .320 (8.13) .150 (3.81) .200 (5.08) .020 (.51)

C323 0.200 (5.08) 0.320 (8.13) 0.125 0.200 0.200 (5.08) 0.020 (.51)

C330 0.300 (7.62) 0.360 (9.14) 0.150 0.250 0.200 (5.08) 0.020 (.51)

C330 .300 (7.62) .360 (9.14) .200 (5.08) .200 (5.08) .020 (.51)

C333 0.300 (7.62) 0.390 (9.91) 0.150 0.250 0.200 (5.08) 0.020 (.51)

C333 .300 (7.62) .390 (9.91) .200 (5.08) .200 (5.08) .020 (.51)

C340 0.400 (10.16) 0.460 (11.68) 0.150 0.270 0.200 (5.08) 0.020 (.51)

C340 .400 (10.16) .460 (11.68) .200 (5.08) .200 (5.08) .020 (.51)

C350 0.500 (12.70) 0.560 (14.22) 0.200 0.270 0.400 (10.16) 0.025 (.64)

C350 .500 (12.70) .560 (14.22) .250 (6.35) .400 (10.16) .025 (.64)

NOTE: 1 inch = 25.4 mm.

NOTE: (1) Measured at seating plane.

L

Max.

H.

Max

Standard

T

Max.

High

Voltage

T Max.

S(1)

±.030 (.78)

D

+.004(.10)

+.004 (.10)- .001 (.025)

-.001(.025)

T

ORDERING INFORMATION

C

320

C

102

M

R

1

CERAMIC

CASE SIZE

(See Table Above)

SPECIFICATION

C — Standard

CAPACITANCE, CODE

Expressed in Picofarads (pF)

First Two Digits — Significant Figures

Third Digit — Number of Zeros (Use 9 for 1.0

thru 9.9 pF. Example: 2.2pF — 229)

CAP ACIT ANCE T OLERANCE

D — ±0.5 pF

F — ±1%

G — ±2%

J — ±5%

K — ±10%

M — ±20%

P — 0%, +100%

Z — -20, +80%

*Part Number Example: C320C102M1R5CA (14 digits – no spaces)

T

5

For packaging information, see pages 40, and 41.

© KEMET Electronics Corporation, P.O. Box 5928, Greenville, S.C. 29606, (864) 963-6300 9

*

A

FAILURE RATE

A — Not Applicable

TERMINATION MATERIAL

T — 100% Tin

H — SnPb

100% Sn

C —

(

Not recommended for new design)

INTERNAL

CONSTRUCTION

5 — Standard

DIELECTRIC

EIA Designation

G — C0G (NP0) — Ultra-Stable

R — X7R — Stable

U — Z5U — General Purpose

RA TED VOLTA GE

50

1000

F — 1500

G — 2000

Z — 2500

H — 3000

2 — 200

1 — 100

5 —

C — 500

D —

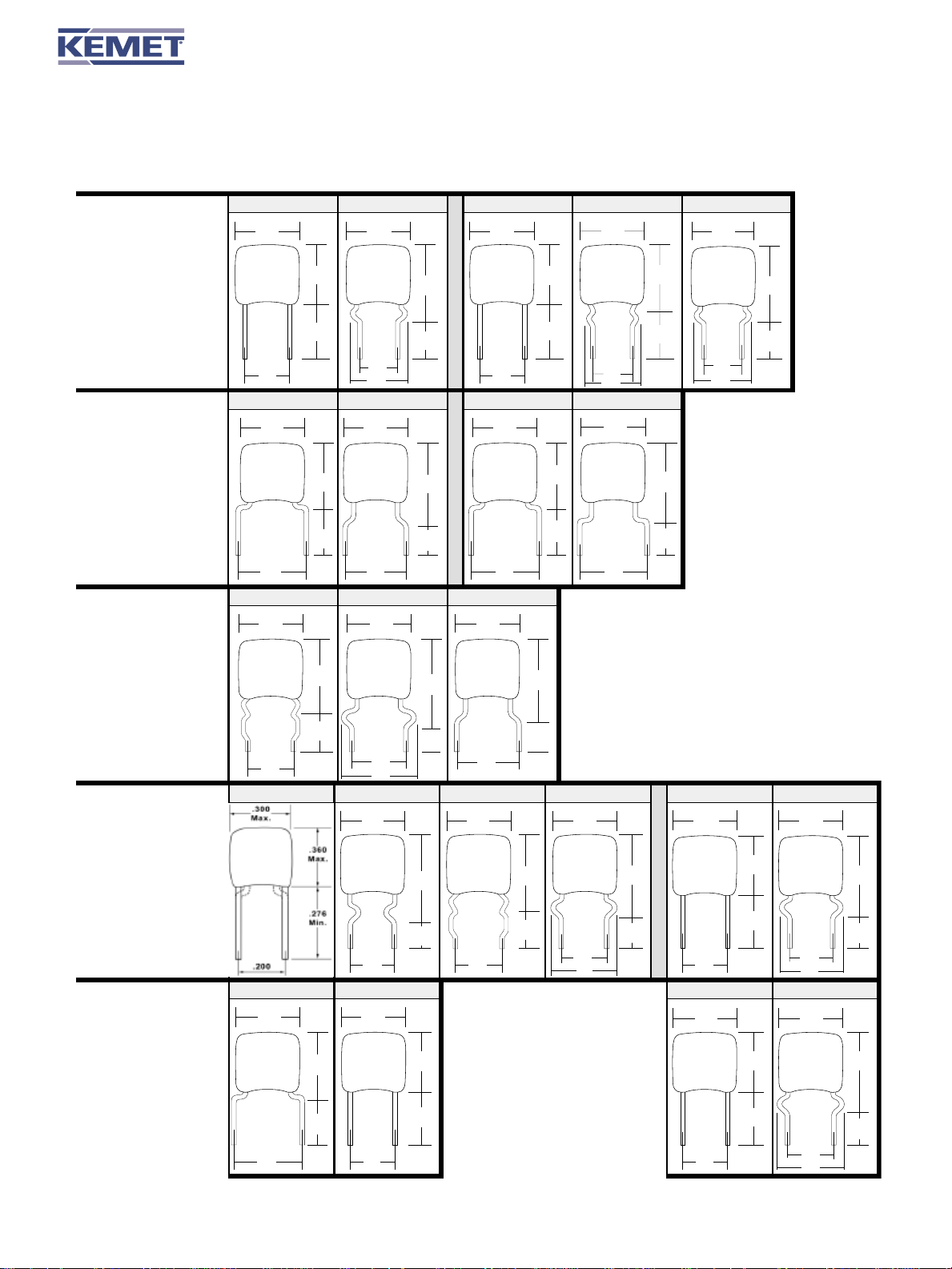

CERAMIC CONFORMALLY COATED/RADIAL

“STANDARD & HIGH VOLTAGE GOLDEN MAX”

© KEMET Electronics Corporation, P.O. Box 5928, Greenville, S.C. 29606, (864) 963-630010

Note: Non-standard lead lengths are available in bulk only.

OPTIONAL CONFIGURATIONS BY LEAD SPACING

The preferred lead wire configurations are shown on page 9. However, additional configurations are

available. All available options, including those on page 9, are shown below grouped by lead spacing.

Lead Spacing

.100" ± .030

Lead Spacing

.200" ± .030

Lead Spacing

.200" ± .030

C 3 1 5

.150

MAX.

.100

C 3 1 7

.150

MAX.

.200

C 3 2 5

.200

MAX.

.210

MAX.

.276

MIN.

MAX.

.320

MAX.

.230

.276

MIN.

C 3 1 6

.150

MAX.

.100

.200

C 3 1 8

.150

MAX.

.200

C 3 2 7

.200

MAX.

.230

MAX.

.230

±.030

.235

MAX.

.276

MIN.

.350

MAX.

C 3 2 0

.200

MAX.

.260

MAX.

.276

MIN.

.100

C 3 2 2 C 3 2 3

.200

MAX.

.260

MAX.

.276

MIN.

.200

C 3 2 8

.200

MAX.

.325

MAX.

C 3 2 4 C 3 2 6

.200

MAX.

.100

.125

.200

MAX.

.200

.260

MAX.

.276

MIN.

.320

MAX.

.276

MIN.

.200

MAX.

.100

.200

.350

MAX.

.230

± .030

Lead Spacing

.200" ± .030

Note: C330 Shoulder

bend leads:

X7R/50V 683-105

Z5U/100V 683-334

Lead Spacing

.250" ± .030

(Available in

bulk only)

.200

C 3 3 0

.300

MAX.

.200

C 3 2 1

.200

MAX.

.250

.276

MIN.

.360

MAX.

.276

MIN.

.260

MAX.

.276

MIN.

.200

.270

C 3 3 3

.300

MAX.

.200

C 3 3 1

.300

MAX.

.250

.390

MAX.

.276

MIN.

.360

MAX.

.276

MIN.

.230

±.030

.276

MIN.

.200

C 3 3 5

.300

MAX.

.420

MAX.

.276

MIN.

.200

Lead Spacing

.400" ± .030

(Available in

C 3 3 6

.300

MAX.

.450

MAX.

.230

±.030

.200

.300

bulk only)

C 3 4 0

.400

MAX.

.200

C 3 5 0

.500

MAX.

.400

.460

MAX.

.276

MIN.

.560

MAX.

.276

MIN.

C 3 4 6

.400

MAX.

.200

.320

C 3 5 6

.500

MAX.

.400

.520

.590

MAX.

.230

±.030

.670

MAX.

.230

±.030

Loading...

Loading...