KEM MKA-510N, MKS-510N Operation Manual

Karl Fisher Moisture Titrator

MKA-510N / MKS-510N

Operation Manual

Please read this manual carefully before you use the instrument.!

Ver.10

#595-0246

Table of Contents Page

1. Introduction............................................................................................................................................................1

1-1. Feature........................................................................................................................................................1

1-2. About the manual .......................................................................................................................................2

1-3. Safety symbols ..................................................................................................................................3

1-4. From unpacking till starting titration..........................................................................................................6

1-5. Supplied parts .............................................................................................................................................7

2. Principle of measurement.......................................................................................................................................8

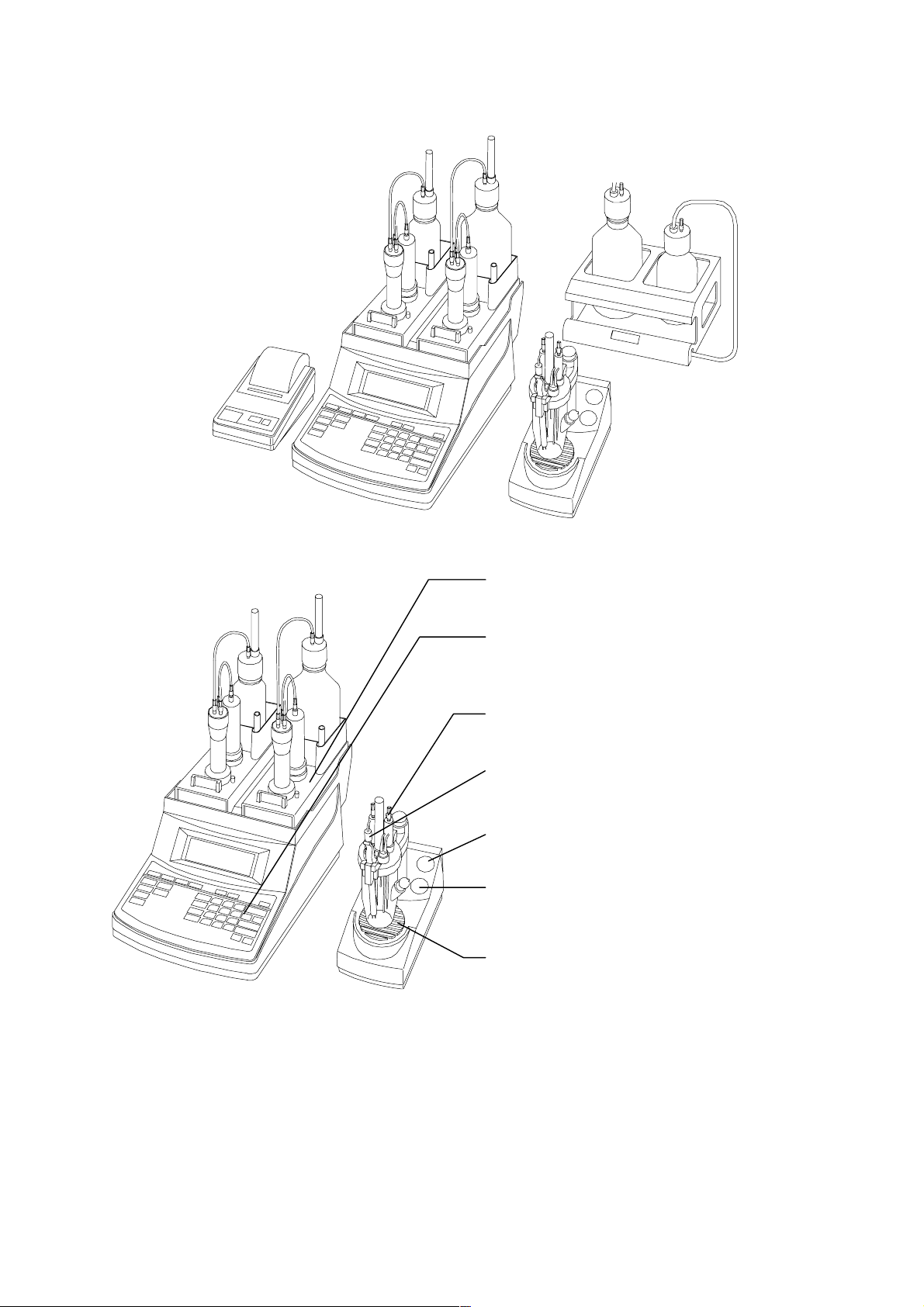

3. Parts name and function .........................................................................................................................................9

4. Power source ........................................................................................................................................................ 13

5. Preparation before measurement..........................................................................................................................14

5-1. Assembly of Stirrer ..................................................................................................................................14

5-2. Setup of titration flask ..............................................................................................................................15

5-3. Setup of Dispenser ...................................................................................................................................16

5-4. Setup of Buret unit ...................................................................................................................................17

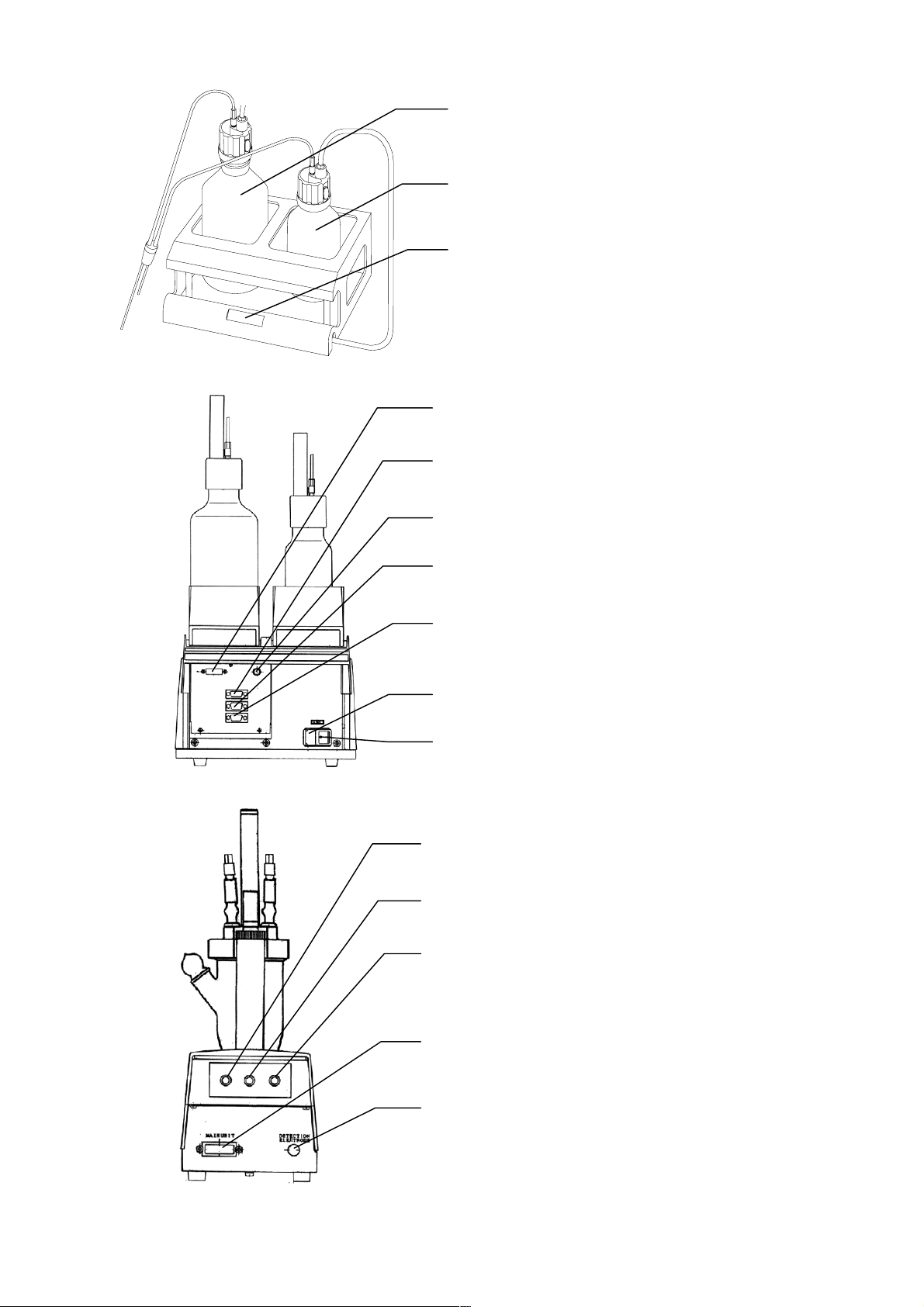

5-5. Initial displays .......................................................................................................................................... 19

5-6. Filling reagent in the buret .......................................................................................................................20

5-6-1. Filling KF reagent.........................................................................................................................20

5-6-2. Filling water-methanol (MKA-510N only) .................................................................................. 20

5-7. Filling and delivering dehydration solvent...............................................................................................21

5-8. Purging the buret ......................................................................................................................................21

6. Key entry and display messages...........................................................................................................................22

6-1. Parameter setup ........................................................................................................................................ 22

6-1-1. General .........................................................................................................................................22

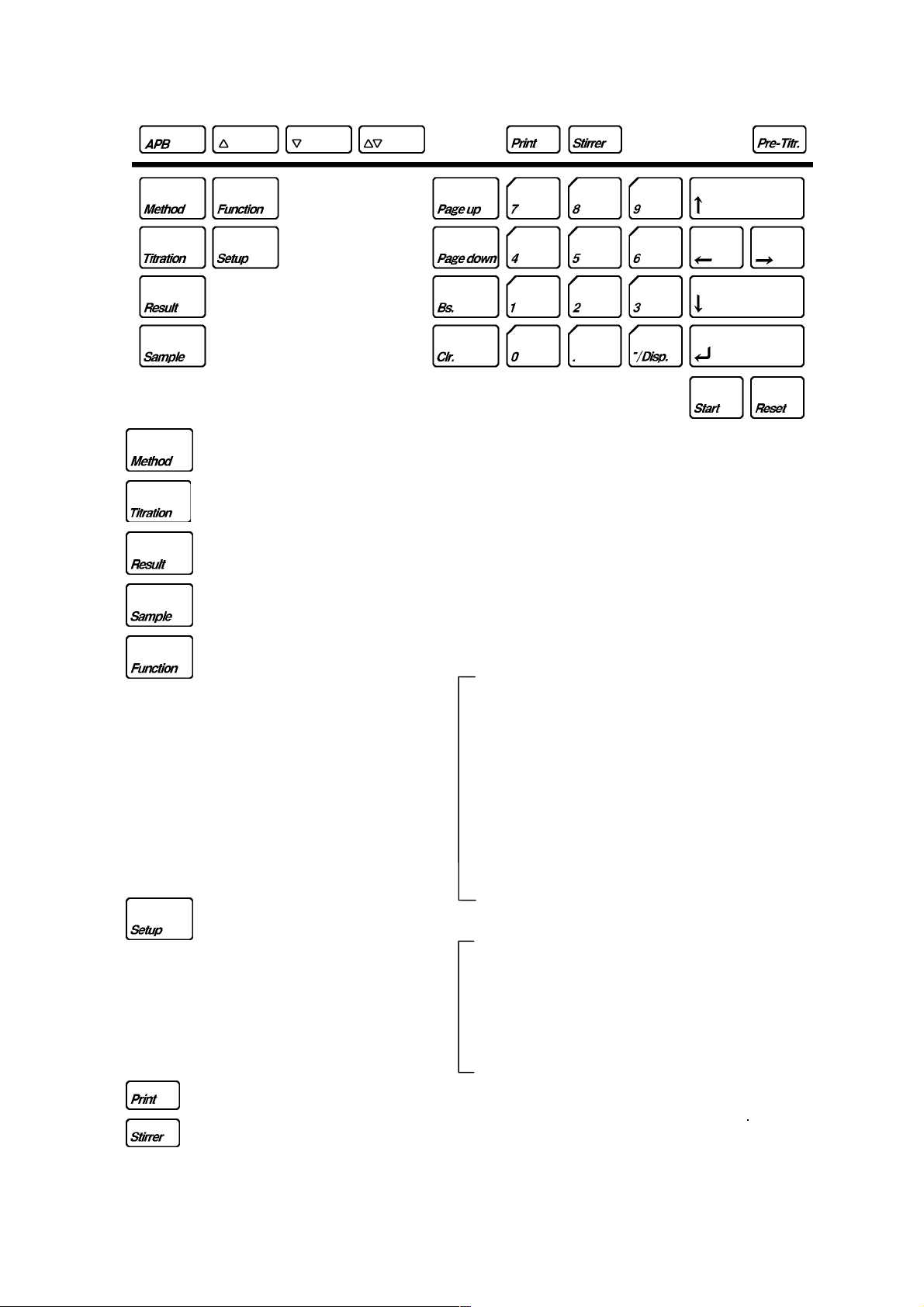

6-1-2. Method parameter.........................................................................................................................22

6-1-3. Titration parameter .......................................................................................................................23

6-1-4. Result parameter ...........................................................................................................................29

6-1-5. Sample parameter .........................................................................................................................39

6-2. Special keys..............................................................................................................................................41

6-2-1. General .........................................................................................................................................41

6-2-2. [Stirrer] key ..................................................................................................................................41

6-2-3. [Print] key.....................................................................................................................................42

6-2-4. [-/Disp.] key..................................................................................................................................43

6-2-5. [APB] key.....................................................................................................................................43

6-2-6. [!],["],[!"] key......................................................................................................................44

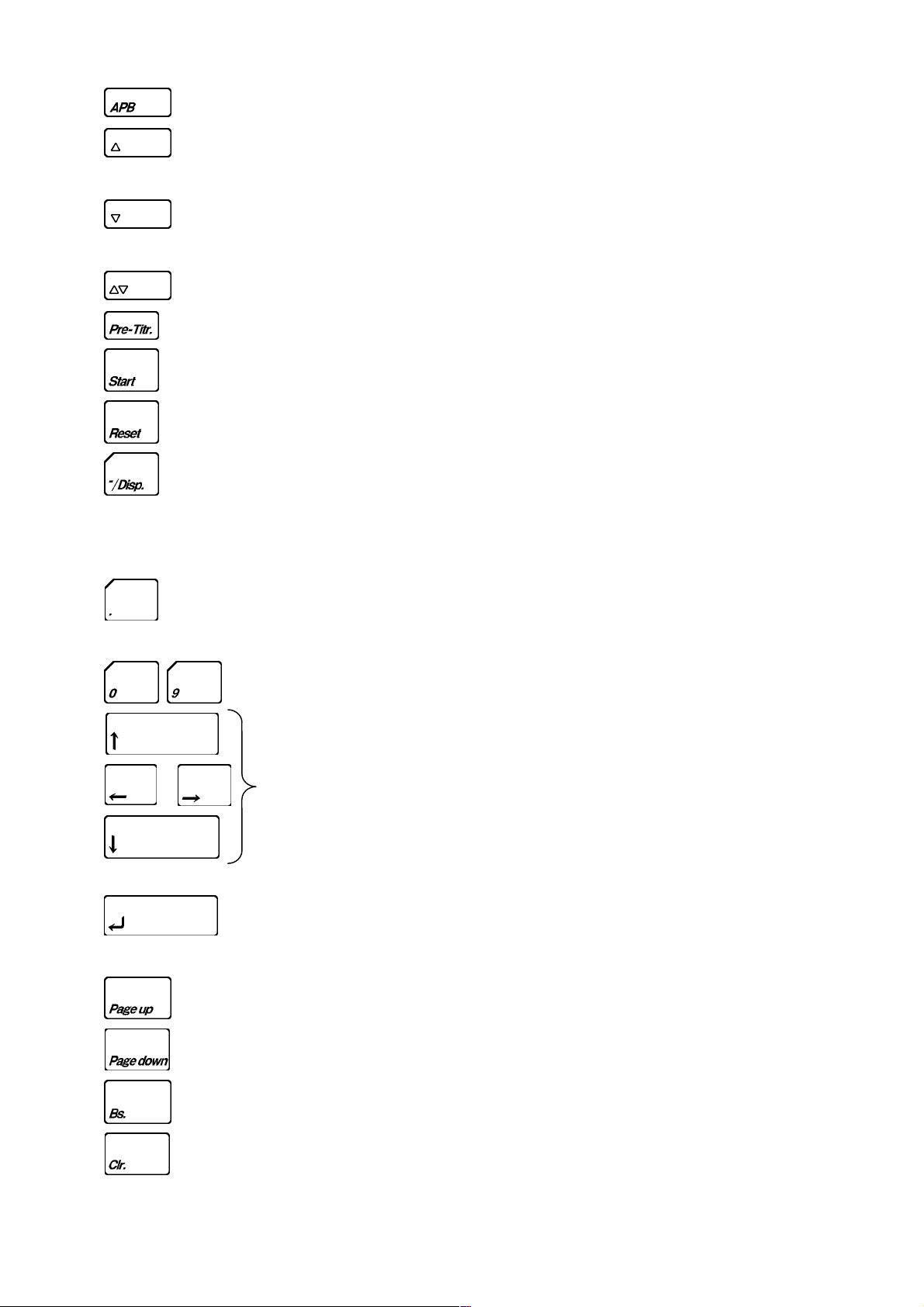

7. Measurement procedure .......................................................................................................................................45

7-1. General .....................................................................................................................................................45

7-2. Measurement sequence.............................................................................................................................45

7-3. Pretitration................................................................................................................................................46

7-4. Factor measurement of KF regent ............................................................................................................48

7-4-1. Introduction ..................................................................................................................................48

7-4-2. Factor measurement with standard water-methanol in buret (MKA-510N only).........................48

7-4-3. Factor measurement by weighing standard ..................................................................................49

7-5. Routine measurement .............................................................................................................................. 50

7-6. When Balance is connected ..................................................................................................................... 53

7-7. When Evaporator is connected ................................................................................................................ 54

8. Setup Function..................................................................................................................................................... 58

8-1. General..................................................................................................................................................... 58

8-2. Interface setup (Setup 0) .......................................................................................................................... 59

8-2-1. RS-232C....................................................................................................................................... 59

8-2-2. Printer........................................................................................................................................... 60

8-2-3. Balance......................................................................................................................................... 61

8-3. Calendar date (Setup 1) ........................................................................................................................... 62

8-4. Register operator’s name (Setup 2) ......................................................................................................... 63

8-5. Serial number and Version number (Setup 3).......................................................................................... 64

8-6. Adjust brightness of LC display (Setup 4)............................................................................................... 64

8-7. Setting display and beep (Setup 5) .......................................................................................................... 65

9. Special function ................................................................................................................................................... 66

9-1. General..................................................................................................................................................... 66

9-2. Input of reagent factor and confirmation (Function 0) ............................................................................ 67

9-3. Recalculation (Function 1)....................................................................................................................... 68

9-4. Statistics (Function 2) .............................................................................................................................. 71

9-5. Deletion of data (Function 3)................................................................................................................... 72

9-6. Auxiliary function for Sample (Function 4) ............................................................................................ 73

9-6-1. General......................................................................................................................................... 73

9-6-2. Sample File .................................................................................................................................. 73

9-6-3. Size only....................................................................................................................................... 75

9-6-4. Sampling amount ......................................................................................................................... 75

9-7. Evaporator and ageing (Function 5) ........................................................................................................ 76

9-8. Auxiliary function for buret (Function 6) ................................................................................................ 77

9-8-1. General......................................................................................................................................... 77

9-8-2. Fixed manual dose ....................................................................................................................... 78

9-8-3. Control reagent dispensing speed ................................................................................................ 79

9-8-4. Select amount for backlash .......................................................................................................... 79

9-9. Check measurement precision ................................................................................................................. 80

9-9-1. Precision check by water standard ............................................................................................... 80

9-9-2. Operating Calibration................................................................................................................... 81

9-10. Setting Check Day and Check record (Function 8) ............................................................................... 82

9-11. Initialization of data (Function 9) .......................................................................................................... 84

10. Initialization of parameter to default ................................................................................................................. 85

11. Connecting Printer............................................................................................................................................. 94

11-1. Printers................................................................................................................................................... 94

11-2. Connecting Printer ................................................................................................................................. 95

12. Maintenance ...................................................................................................................................................... 96

12-1. Application of KF grease....................................................................................................................... 96

12-2. Replacement of silica gel ....................................................................................................................... 97

12-3. Replacement of KF reagent ................................................................................................................... 97

12-4. Replacement of water-methanol (MKA-510N only) ............................................................................. 97

12-5. Cleaning the electrode ............................................................................................................................97

12-6. Cleaning Titration vessel........................................................................................................................98

12-7. Cleaning the buret ..................................................................................................................................98

12-8. Replacement of piston head .................................................................................................................100

12-9. Replacement of Switching valve ..........................................................................................................101

12-10. Replacement of Titration nozzle ........................................................................................................102

12-11. Replacement of tubing........................................................................................................................102

12-12. Drain disposal.....................................................................................................................................103

12-13. Replacement of extracting solvent .....................................................................................................104

12-14. Replacement of print paper and printing cartridge .............................................................................104

13. Karl Fischer reagent ......................................................................................................................................... 105

14. Troubleshooting ............................................................................................................................................... 106

14-1. Error messages and remedies ...............................................................................................................106

14-2. When Stirrer malfunctions ...................................................................................................................108

14-3. When Buret malfunctions.....................................................................................................................109

14-4. When air bubble exists in buret ............................................................................................................110

14-5. When Dispenser malfunctions..............................................................................................................111

14-6. When titration ends in excess of KF reagent........................................................................................112

14-7. When Endpoint is not found or takes a long time ................................................................................113

14-8. When measurement results in poor reproducibility..............................................................................114

14-9. Crystallization of KF reagent and solidification...................................................................................115

14-9-1. When the titration nozzle is clogged ........................................................................................115

14-9-2. When the switching valve is clogged or jammed .....................................................................115

14-10. When glass contact area is solidified .................................................................................................116

14-11. Replacement of filter of Dispenser.....................................................................................................117

14-12. When the buret unit is hard to be mounted. .......................................................................................118

15. Relation of moisture content and sample size ..................................................................................................120

16. Display messages and glossary ........................................................................................................................121

16-1. Display message and meaning..............................................................................................................121

16-2. Glossary................................................................................................................................................ 127

17. Parts list............................................................................................................................................................128

18. System flow chart.............................................................................................................................................134

19. External I/O interface pin configuration ..........................................................................................................135

20. Basic specification ...........................................................................................................................................136

21. Warranty ..........................................................................................................................................................138

1

1. Introduction

1-1. Feature

The instrument you have purchased is Karl Fischer Volumetric Moisture Titrator to determine water content

in liquid or solid sample. It measures moisture content with high precision by easy operation in a short

period of time.

The MKA-510N is twin buret titrator that can perform back titration and automatic factor calibration with

water-methanol standard.

The MKS-510N is single buret titrator designed for normal titration with high cost performance.

Since basic specifications of both models are the same, only different parts of instrumental operations and

measurement procedures are separately described in this manual.

[Feature]

! Easy operation

You can go on routine measurement simply by pressing [Pre-Titr] key and [Start] key.

! Digital display of the results with high reproducibility

It displays reproducibility of "0.01mL by 10mL buret.

! Easy dispensing dehydration solvent

Delivery and draining of dehydration solvent is automated by single button switch by the built-in

solvent dispenser, which is now standard.

! Easy replacement of buret unit

Reagent of different factor can be easily switched by replacing the buret unit.

! Standard built-in interfaces

The interface for personal computer via RS-232C, for Balance and for Printer is now standard and

each is built-in.

It is recommended to peruse this manual so that you can obtain the maximum efficiency and

performance of the instrument for a long duration.

Note:

If you should find any portion in this manual that may differ from the

unit you have purchased, please always refer to the specification that

accompanies your system.

2

1-2. About the manual

You are requested to respect the safety rules and symbols which you will find from place to place in this

manual.

1. Where there exists danger of physical injury or possible death:

WARNING!!

Danger of severe injury or even leading to

death unless the instruction is followed.

2. Where there exists danger of property damage:

CAUTION!

Danger of property damage of yourself and

others unless the instruction is followed.!

3. Where there exists danger of malfunctioning of the instrument:

Note:

May not be covered by warranty unless the

instruction is followed.

! It is prohibited to copy a part or all of this manual.

! If you should find any questions about the description in this manual, please contact your local dealer.

! The manufacturer will not be liable for any damage by use of the measurement results of the instrument.

3

1-3. Safety symbols

Always observe these signs and instructions.

You must observe cautionary messages and warnings in order to protect yourself as well as prevent others

from physical injury or property damages.

Warning

This symbol means "Danger of severe injury

or possible death".

Caution

This symbol means "Danger of injury or

property damage".

This symbol means prohibition of an act.

This symbol means mandatory.

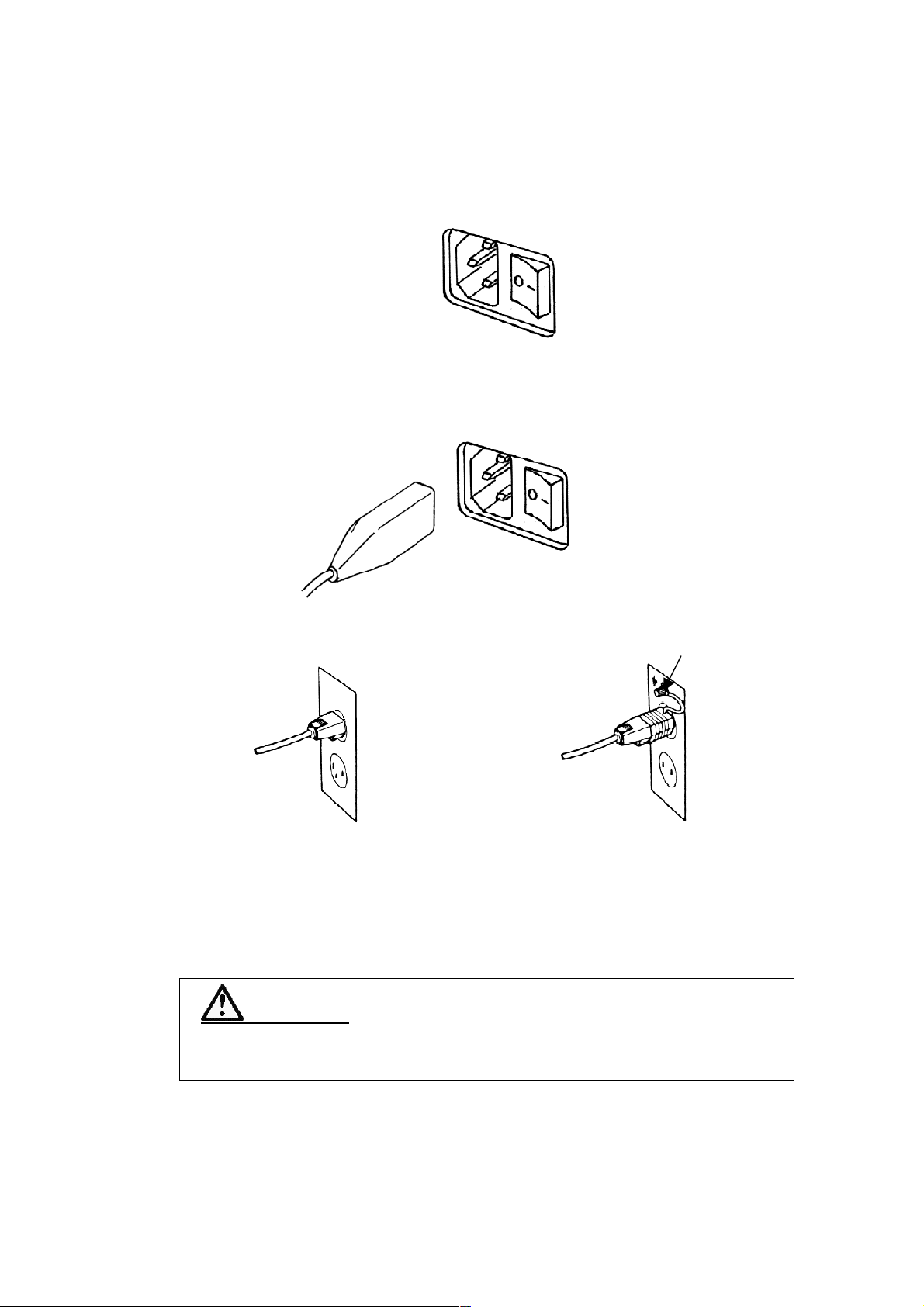

WARNING!

You must ground earth wire of power cable.

Ground the green wire of adapter if

power tap is 2-pin outlet.

3-pin plug has earth line to ground

by itself when plugged in.

Danger of electric shock if not grounded to earth.

WARNING!

Use the same type and rating of fuse. Be sure to plug out power cord before

replace the fuse.

Danger of fire if a wrong fuse is loaded.

Do not use volatile chemical or work in flammable gas.

Danger of explosion inside the instrument.

WARNING!

4

WARNING!

Wear safety glasses, gloves or protective mask if necessary,and well

ventilate the room.

Danger of injury on your skin or in the eyes by splashing chemical.

Also your windpipe may get hurt if toxic gas is breathed in.

Danger of fire, electric shock or damage to the instrument.

Do not operate in a way other than specified in the manual.

CAUTION!

CAUTION!

Do not open housing case or overhaul the unit for repair except by an

authorized service person.

Danger of fire, shock or malfunctioning of the unit.

5

Safety measures!

Place for installation

!" The performance and reliability of the instrument may not be secured if your instrument is used under

excess ambient condition. Avoid a place under any of the following conditions:

#" Under or near vibration

#" Direct sunlight

#" Corrosive gas atmosphere

#" Power source of heavy load fluctuation or strong magnetic field

#" Ambient condition other than 5 to 35$C, below 85% RH, which is normal condition for use of this

instrument.

About power source

!" Available power source for the instrument: AC100 to 120V, AC200 to 240V, 50/60Hz

!" Supply power direct from power outlet.

!" Do not share power from a power tap.

About place for storage

!" Store the disassembled titration vessel after cleaned and dried. It is recommended to use the carton box in

which the unit was first delivered.

!" Avoid a place for storage under dusty condition or excess temperature or humidity.

About use

!" Karl Fischer reagents are toxic chemicals. Therefore, please handle in a well ventilated room and be aware

of its danger.

!" When a reagent etc. is spilt to Main unit or the connectors of magnetic stirrer, there is a possibility of

malfunction.

Other caution

!" Do not use such a solvent as alcohol, acetone, thinner or the like for cleaning this instrument. Doing so

may adversely affect the instrument, e.g. deformation, discoloration or cracks. When cleaning this

instrument, wipe it with a soft cloth or tissue paper, after applying detergent diluted with water to the soft

cloth or tissue paper and adequately wringing out excess water in order not to allow water drops to fall.

6

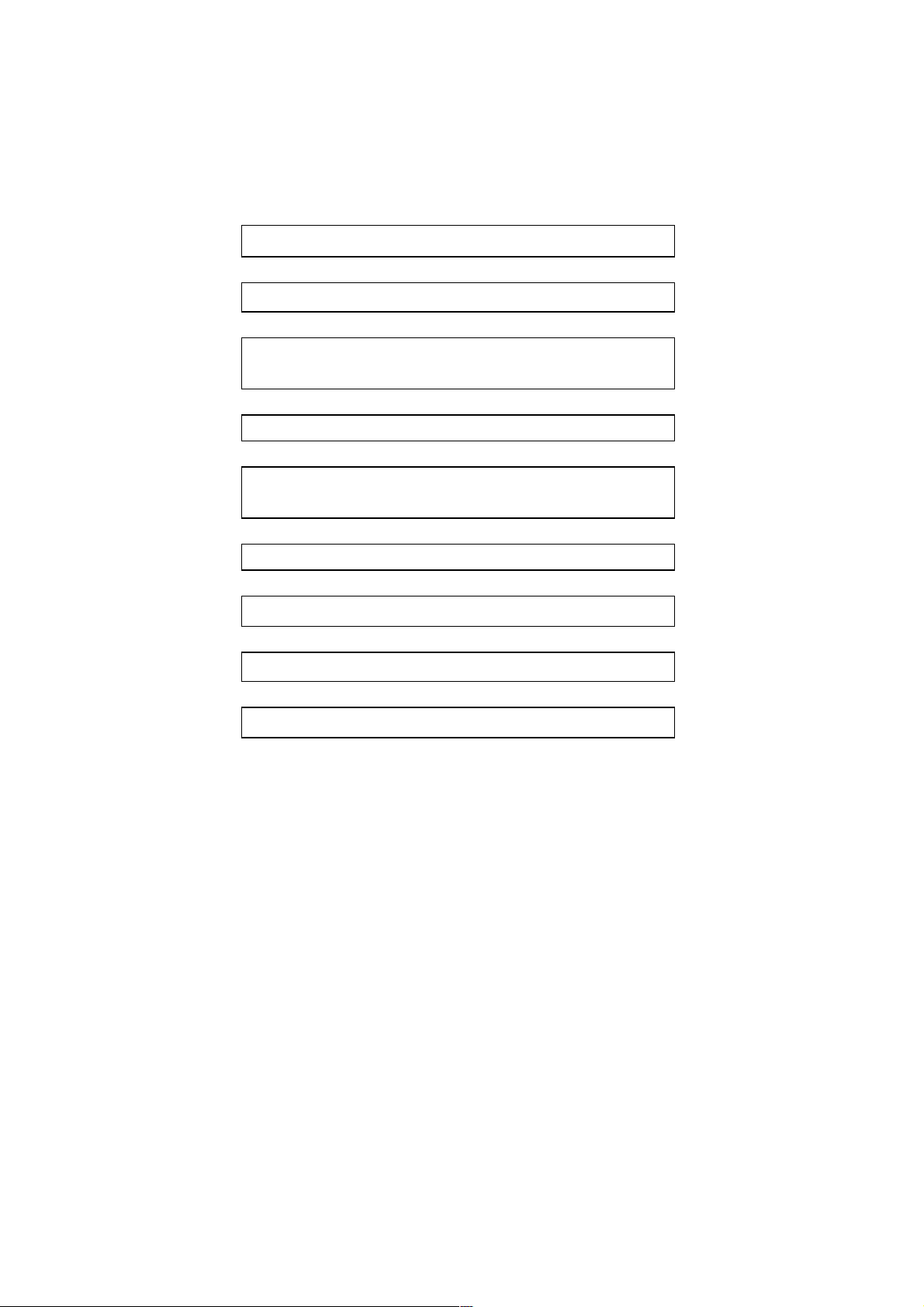

1-4. From unpacking till starting titration

The below chart shows the flow from unpacking the carton box until the first measurement is started.

Check supplied parts. (see 1-5)

%

Prepare power. (see 4)

%

Connect Stirrer, attach titration flask and set up the solvent

dispenser. (see 5-1, to 5-4)

%

Fill reagent in buret. (see 5-6)

%

Set up parameters and Method for the sample. (see 6)

Set up Sample file (10-6) and Factor (10-8).

%

Select on Setup function. (see 8)

%

Start pretitration. (see 7-3)

%

Calibrate KF reagent. (see 7-4)

%

Start titration. (see 7-5)

7

1-5. Supplied parts

The carton box that has been delivered to you contains the following items including the MKA-510N /

MKS-510N, the parts and Users manual. Please check them with the below parts list:

MKA-510N MKS-510N

(1) Main unit..................................................................... 1 unit 1 unit

(2) Magnetic stirrer with Dispenser .................................. #433-0068 1 unit 1 unit

(3) Buret unit (for KF) ...................................................... APB-510-KF 1 set 1 set

(4) Buret unit (for ME) ..................................................... APB-510-ME 1 set &

(5) Stirrer cable................................................................. #030-0006 1 pce 1 pce

(6) Power cord with earth (AC 100V area only) .............. #320-3198 1 pce 1 pce

(AC 100-120V area)............... #320-3194

(AC 220-240V area)............... #320-3461

(UK) ....................................... #320-4199

(7) AC-3P adapter (AC 100V area only) .......................... #320-3199 1 pce 1 pce

(8) Earth wire (AC 100V area only) ................................. #433-3331 1 pce 1 pce

(9) S-type titration flask.................................................... #740-3001 1 pce 1 pce

(10) Titration flask cover.................................................... #433-3435 1 pce 1 pce

(11) Detection electrode (2-pin platinum) .......................... #103-M714 1 pce 1 pce

(12) Stirrer spinner (25mm)................................................ #500-3141 1 pce 1 pce

(13) Ball stopper for titration flask ..................................... #550-3500 1 pce 1 pce

(14) KF grease (5g) ............................................................ #433-3138 1 pce 1 pce

(15) Desiccant tube A......................................................... #433-3116 3 pcs 2 pcs

(16) Piston rod .................................................................... #552-5002 1 pce 1 pce

(17) Wrench (8mm)............................................................ #514-3339 1 pce 1 pce

(18) Bottle holder ............................................................... #560-0017 1 set 1 set

(19) Waste bottle cover ...................................................... #433-0021 2 pcs 2 pcs

(20) Bottle for waste solution ............................................. #500-0022 1 pce 1 pce

(21) Desiccant tube (for solvent)........................................ #444-6542 1 pce 1 pce

(22) Drain tube ................................................................... #433-0025 1 pce 1 pce

(23) Injection tube .............................................................. #433-0024 1 pce 1 pce

(24) Silicone tube (25,40,43cm)......................................... #521-0009 1 set 1 set

(25) Operation manual........................................................ #595-0246 1 copy 1 copy

(26) Operation manual (RS-232C) ..................................... #595-0248 1 copy 1 copy

(27) Warranty ..................................................................... 1 copy 1 copy

8

2. Principle of measurement

Water content in the presence of base and alcohol reacts with iodine and sulfur dioxide quantitatively as

follows:

H

2

O + I

2

+ S O

2

+ C H

3

O H + 3 R N ' [ R N H ] S O 4 C H 3 + 2 [ R N H ] I

Karl Fischer moisture determination is based on this reaction. Add sample solution after the solvent in

titration vessel is dehydrated by KF reagent. Quantitative titration of water is complete with KF reagent,

of which factor is determined in advance (mg H

2

O/mL) by standard water-methanol. Titration is

progressed by detecting polar potential of the electrode while controlling titration speed.

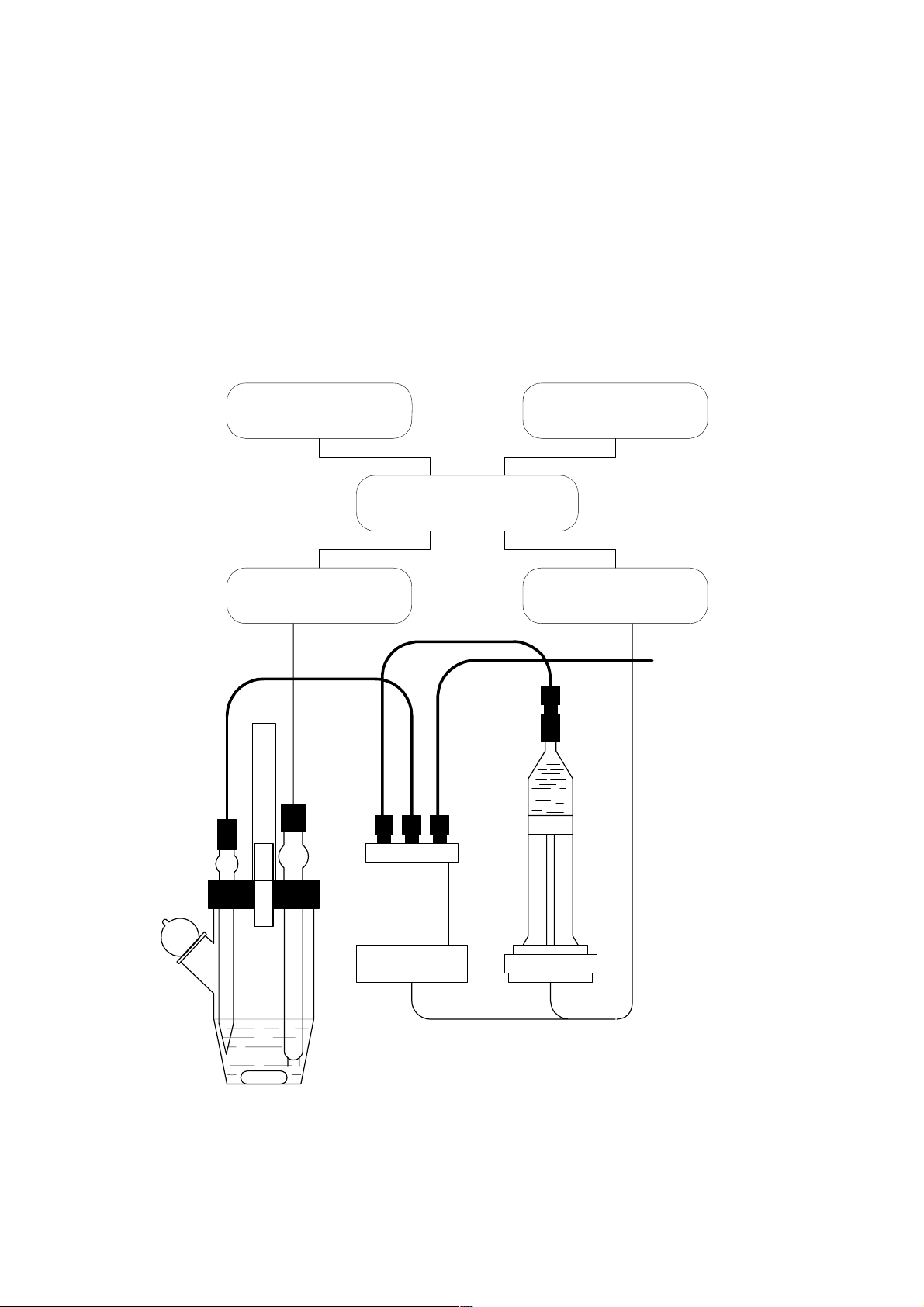

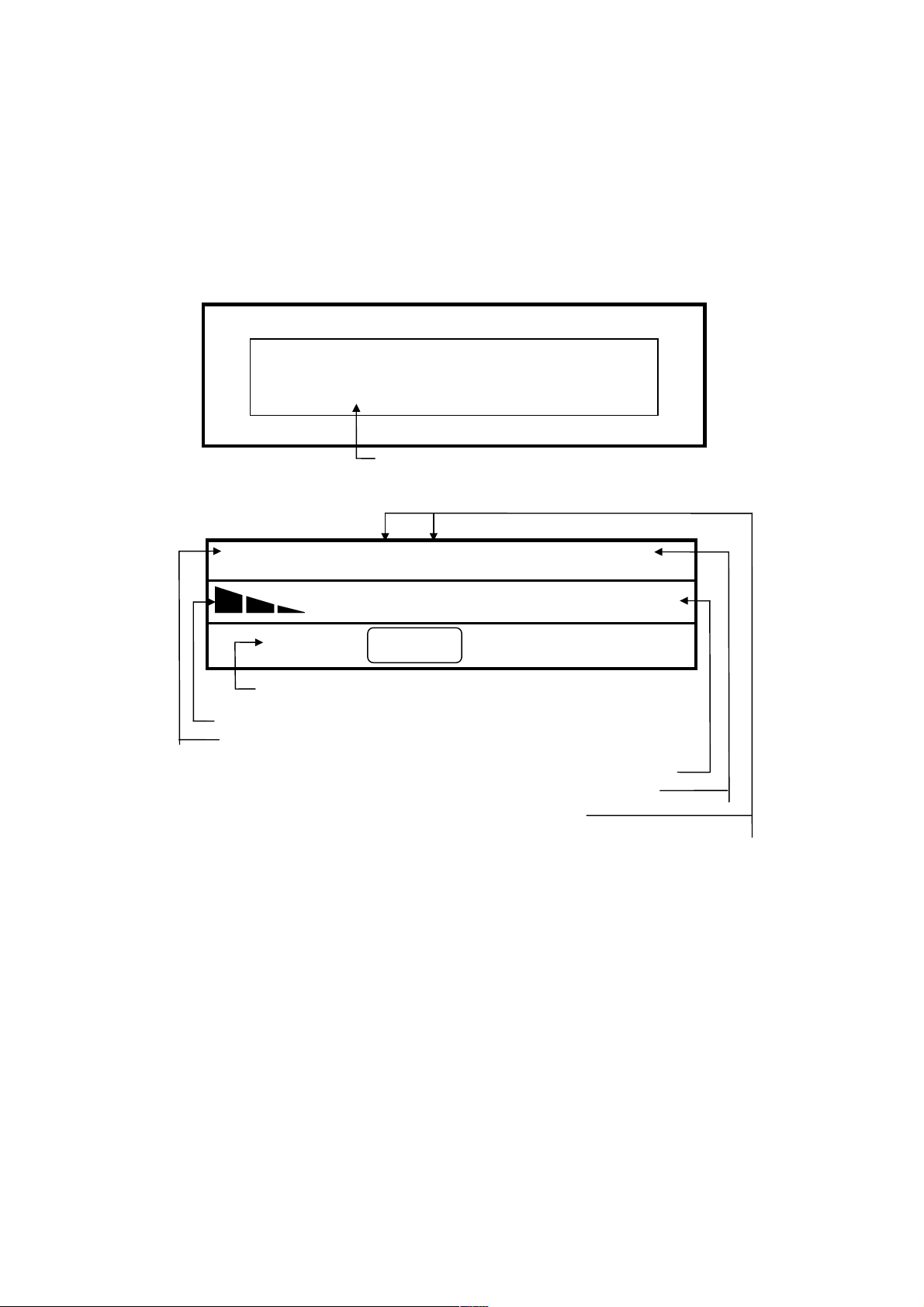

Detection unit Burette control unit

Microcomputer

Display Printer

9

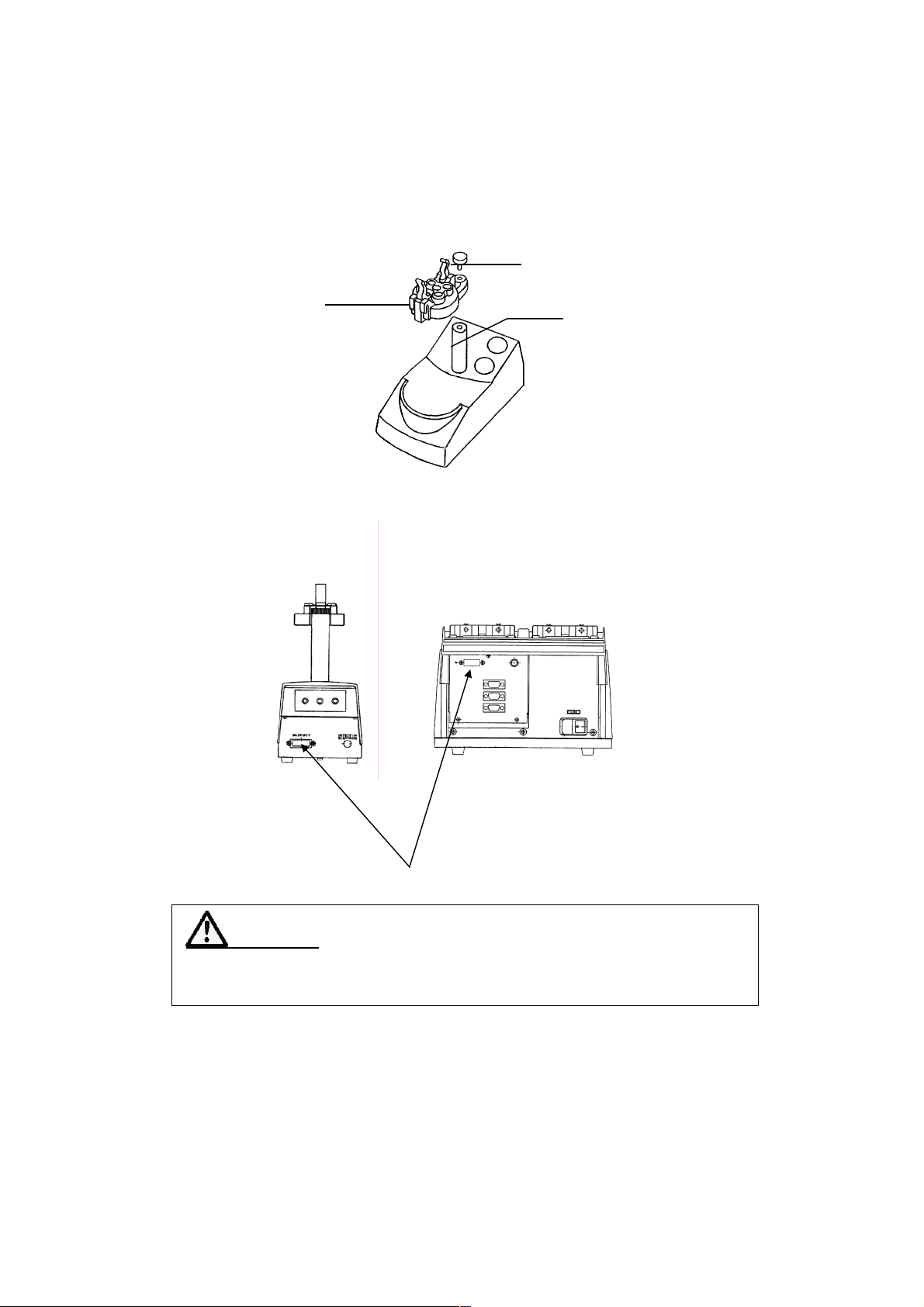

3. Parts name and function

IDP-100 Printer

Stirrer

Bottle holder

MKA-510N/MKS-510N Main unit

This sketch is MKA-510N

!

!

Burette unit

Aspirates reagent and titrates.

Key pad

Start pretitration or measurement

and enter each parameter.

Titration nozzle

Doses reagent.

Detection electrode (Twin Pt electrode)

Detects potential changes.

Drain button

Drains out waste from titration vessel.

Solvent button

Dispense dehydration solvent into

titration vessel.

Magnetic stirrer

Stirrers sample solution.

MKA-510N/MKS-510N Main unit

This sketch is MKA-510N.

10

Waste bottle

Keeps waste solution.

Dehydration solvent

Desiccant tube

Extracts moisture from air going

through the desiccant tube.

Bottle holder

Stirrer cable

Stirrer cable is connected here.

RS-232C connector

RS-232C cable from computer is

connected here.

Rear view of MKA-510N

Printer connector

Printer cable is connected here.

ADP connector

ADP cable is connected here.

Balance connector

Cable from Balance is connected here.

Power receptacle

Power cable is plugged here.

Power switch

Turns ON/OFF power.

Vent hole

Exhausts funs from extracting reagent.

Main connector

Connect Main unit.

Waste outlet

Air intake for waste is connected here.

Pressurized air outlet

Pressurized air to transfer dehydratin

solution is exhausted here.

Electrode connector

11

Key configuration

............................Key to select Method

.............................Key to set up Titration parameter

............................Key to set up parameter for Calculation, Print and Data list

............................Key to enter Sample number, Lot number and Sample weight, etc.

............................Key to set up Function parameter

0. Input reagent factor and confirmation

1. Recalculation

2. Auto statistics

3. Deletion of data

4. Auxiliary function for Sample

5. Ageing Evaporator

6. Auxiliary function for buret

7. Calibration

8. Set up Check day and review Check record

9. Initialize stored data

............................Key for Setup parameter

0. Set up interface

1. Set up date

2. Register Operator's name

3. Confirm serial number and version number

4. Adjust brightness of LC display

5. Set up display and selection of beep

................................Key to print out data

................................Key to turn ON/OFF Stirrer and select stir speed

12

............................ Selection of manual buret (MKA-510N only) and set up number of times of purging.

............................ Dose key

Key to drain by buret manually

............................ Suction Key

Key to aspirate reagent by buret manually

............................ Key to purge manual buret

............................... Key to pretitration

............................... Key to start titration

............................... Key to stop titration

. .............................. Display Key

Key to change page on display or enter alphabetic characters (ABC....Z...) one after

another.

Also to enter a bar "-".

............................... Period key

Key to enter a period "." or characters in reverse order (Z,Y,X...A).

(

............... Numeric Key

, .... Key to move the cursor

................ Enter Key

Key to confirm key entry

............................ Key to return the ! marked display to the previous page

............................ Key to move the " marked display to the next page.

............................ Key to erase the preceding character or numeral

. ........................... Key to erase all the entered characters or numerals

13

4. Power source

(1) Make sure the power switch is in OFF position.

(2) Plug in the supplied power cord to the receptacle.

(3) Plug in the other end of the cord to the power outlet.

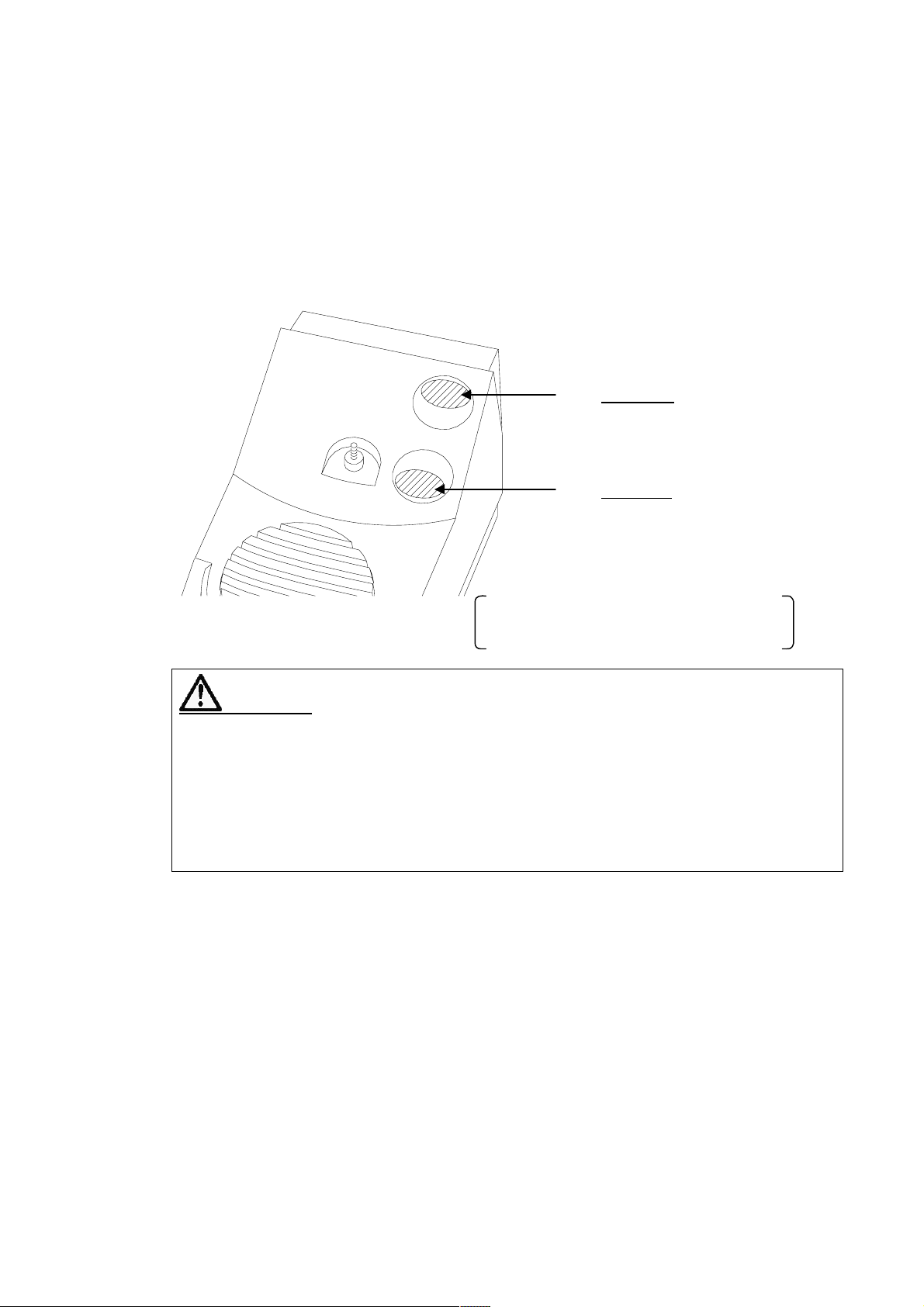

Earth terminal

<3P power outlet> <2P power outlet>

The 3-pin plug has earth terminal Attach the supplied AC-3P

in it and grounding to earth is adapter and ground the green

not necessary. wire to earth.

WARNING!

The earth line must be grounded.

Danger of electric shock if not grounded.

14

5. Preparation before measurement

5-1. Assembly of Stirrer

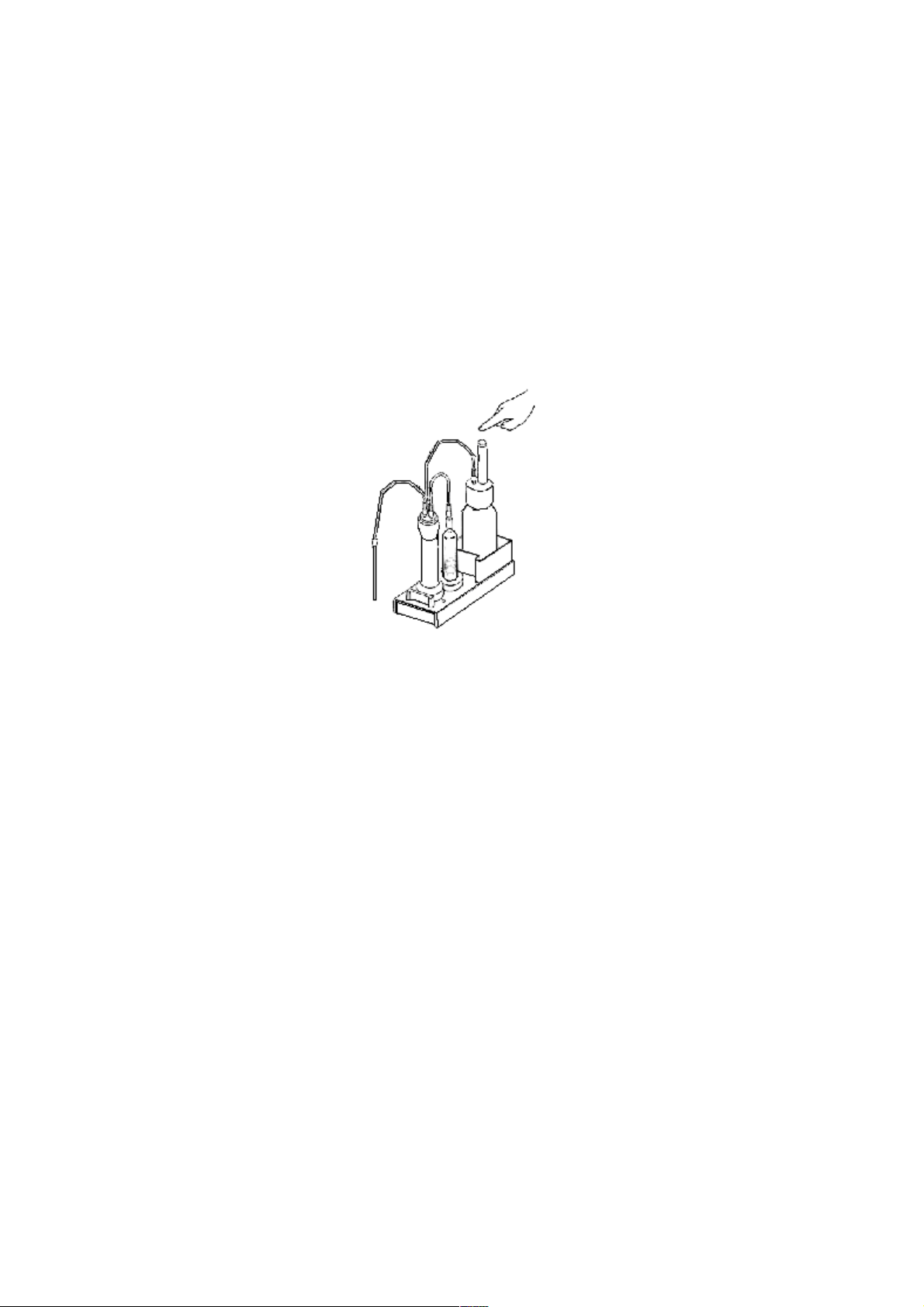

Assemble the magnetic stirrer and connect it to Main unit.

(1) Fasten the titration flask cover to the holder by the screw.

(2) Connect Magnetic stirrer and Main unit by Stirrer cable.

Connect by Stirrer cable

CAUTION!

Turn OFF power of Main unit before plug in Stirrer cable in

order to avoid electric trouble in the unit.

Screw

Holder

Titration flask cover!

15

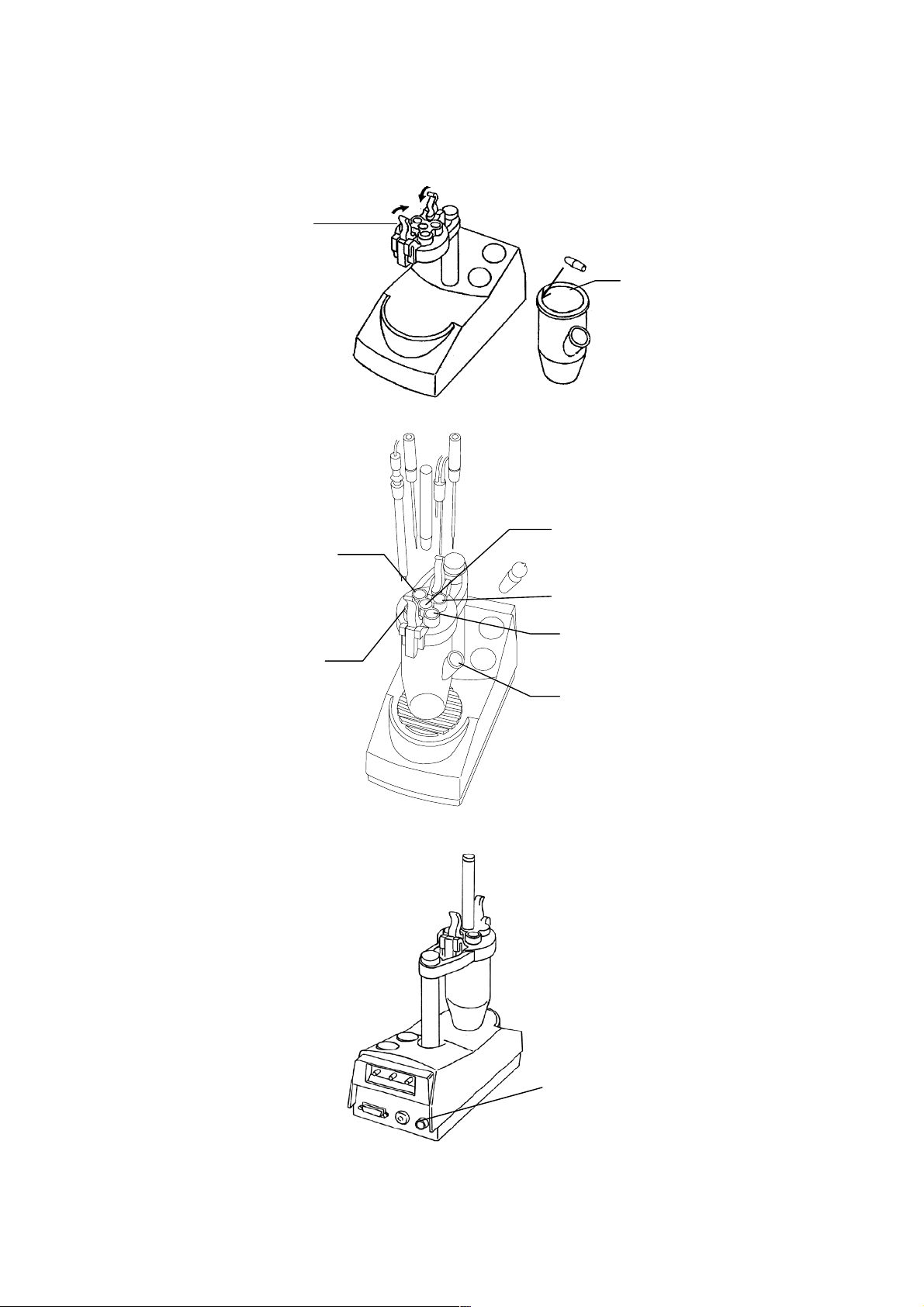

5-2. Setup of titration flask

(1) Apply KF grease around the flask-cover contact area and put the stir spinner, and then, attach the flask

by opening the holding levers.

(2) Apply KF grease around the contact area with electrode, desiccant tube and ball stopper.

Ball stopper

Titration nozzle

Flask stopper

Desiccant tube

Electrode

Titration nozzle

(Ball stopper for MKS 510N instead of nozzle)

(3) Plug in the electrode cable into the connector and fasten by the screw.

Apply KF grease

Holding lever

Electrode connector

16

5-3. Setup of Dispenser

Connect the dispenser to the magnet stirrer.

(1) Set the bottle each for dehydration and waste solution to the attachment, and screw them securely.

Note:

If the bottles are not securely fixed in the bottle cap, pressurized air may

leak out and the solvent may not be well dispensed.!

(2) Set extracting solvent and waste bottle on the bottle holder.

(3) Insert the flask holder into the position on the titration flask.

Apply KF grease thinly around contact area.

(4) Connect the solvent transfer tube to SOLVENT and the drain/air intake tube to DRAIN on the rear of

Stirrer.

EXHAUST DRAIN SOLVENT

EXHAUST

Exhaust fume from dehydraion

solvent

DRAIN

Connect the drain/air intake tube

SOLVENT

Connect the pressurized air tube

for dehydration solvent

!

! WARNING!

Toxic fume of dehydrating solvent and KF reagent will be exhausted

from EXHAUST.

Vent it out by a tube away far enough for safety.!

Attachment (bottle cap)

Flask stopper

(to titration flask)

Drain/air intake tube

Solvent transfer tube

Bottle for waste

solution

Extracting solvent bottle

(not standard accessory)

17

5-4. Setup of Buret unit

Place the reagent bottle on buret unit and then, mount it on the titrator.

Use the KF reagent bottle as it is with reagent in it.

(1) Remove the joint and packing of the reagent bottle cover and insert the reagent tube through the bottle

cover. Remove the seal of desiccant tube during this job.

Seal

Desiccant tube

Joint

Packing

Reagent bottle cap

Note:

1. Seal of desiccant tube must be removed before operating the

instrument.

2. The reagent bottle cover has two kinds, one is KF for KF reagent

and the other is ME (MKA-510N only) for water- methanol.!

for KF for ME

Stop switching valve

and pull out to release

for use

18

(2) Place the buret on top of Main unit, and fasten by pulling it to the front. The buret to the right is Burret

1 for KF reagent and the buret to the left is Burret 2 for water-methanol. (for MKA-510N). Then,

insert the lock pin.

(3) Insert the titration nozzle into the position(“5-2.”).

Apply KF grease thinly around contact area.

Note:

If the buret unit is hard to be mounted, follow the steps 14-12.

19

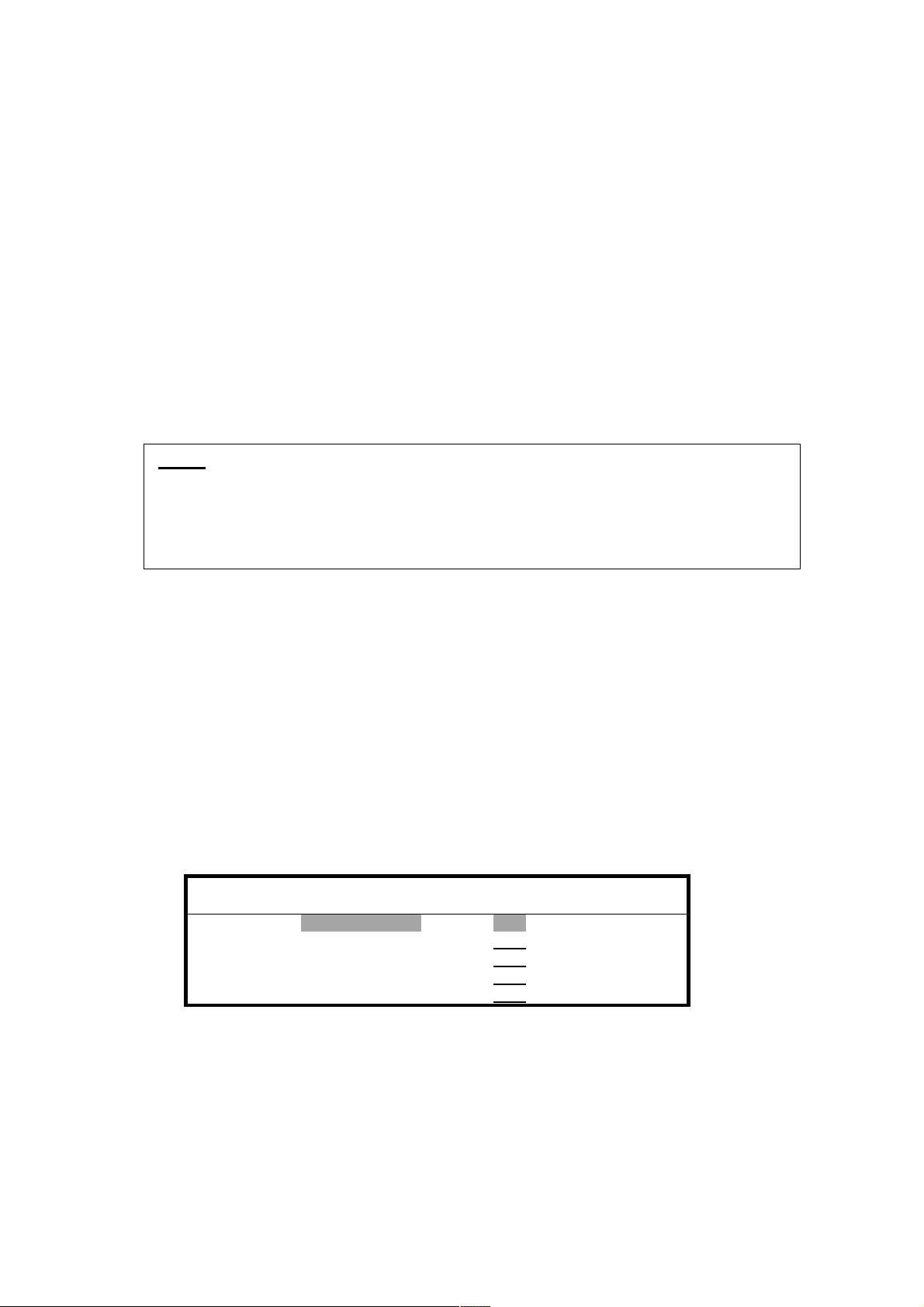

5-5. Initial displays

When the power of MKA-510N / MKS-510N is turned on, the initial displays will appear in the following

sequence:

The below display appears for two seconds and the product version number can be checked during the

display. Then, the second display will appear as follows until pretitration starts.

(1)

K a r l - F i s c h e r

M o i s t u r e T i t r a t o r

M K A - 5 1 0 N V e r 1 . 0 0

“MKS-510N” will appear if the unit is MKS-510N.

(2)

N o . 0 1 - 0 1 [ " ] [" ] [ M E T H O D 1 ]

H

2

O / R e a g e n t P o t e n t i a l ( m V )

654

Press Pre-Titr. K e y

Mode of the unit or dialog message

Shows level of excess water

Sample number during or waiting for measurement

Potential of detection electrode

Method number

Status of buret unit (detachable or not)

“" " appears when the buret is detachable.

20

5-6. Filling reagent in the buret

Fill KF reagent and water-methanol in the buret. (Water-methanol is for MKA-510N only)

5-6-1. Filling KF reagent

(1) Press [APB] key and enter the working buret number. (for MKA-510N only)

(2) Press [!] key to lift the piston to the upper limit.

(3) Press ["] key to fill the reagent.

(4) Press on [!] key to push out the air to Titration flask until the reagent comes out of the nozzle tip.

Then, press [!] key again to stop the piston.

(5) Close the top of desiccant tube by a finger and then, press ["] key to remove the air sticking around

piston head.

(6) Press [!] key and push out air bubble in the buret into Titration flask.

(7) Press ["] key to fill reagent in the buret.

5-6-2. Filling water-methanol (MKA-510N only)

The water-methanol standard solution to calibrate KF reagent is filled in the buret as follows:

(1) Press [APB] key and enter the working buret number.

(2) Press [!] key to lift the piston to the upper limit

(3) Press ["] key to fill the reagent.

(4) Further press [!] key to push out the air and reagent in the buret towards Titration flask.

(5) Close stop switching valve of reagent cap(for ME), and press ["] key to degas air bubbles sticking

around piston head.

(6) Open the stop switching valve.

(7) Press [!] key to push out the bubble and reagent in the buret into Titration flask.

(8) Press ["] key to fill reagent in the buret.

21

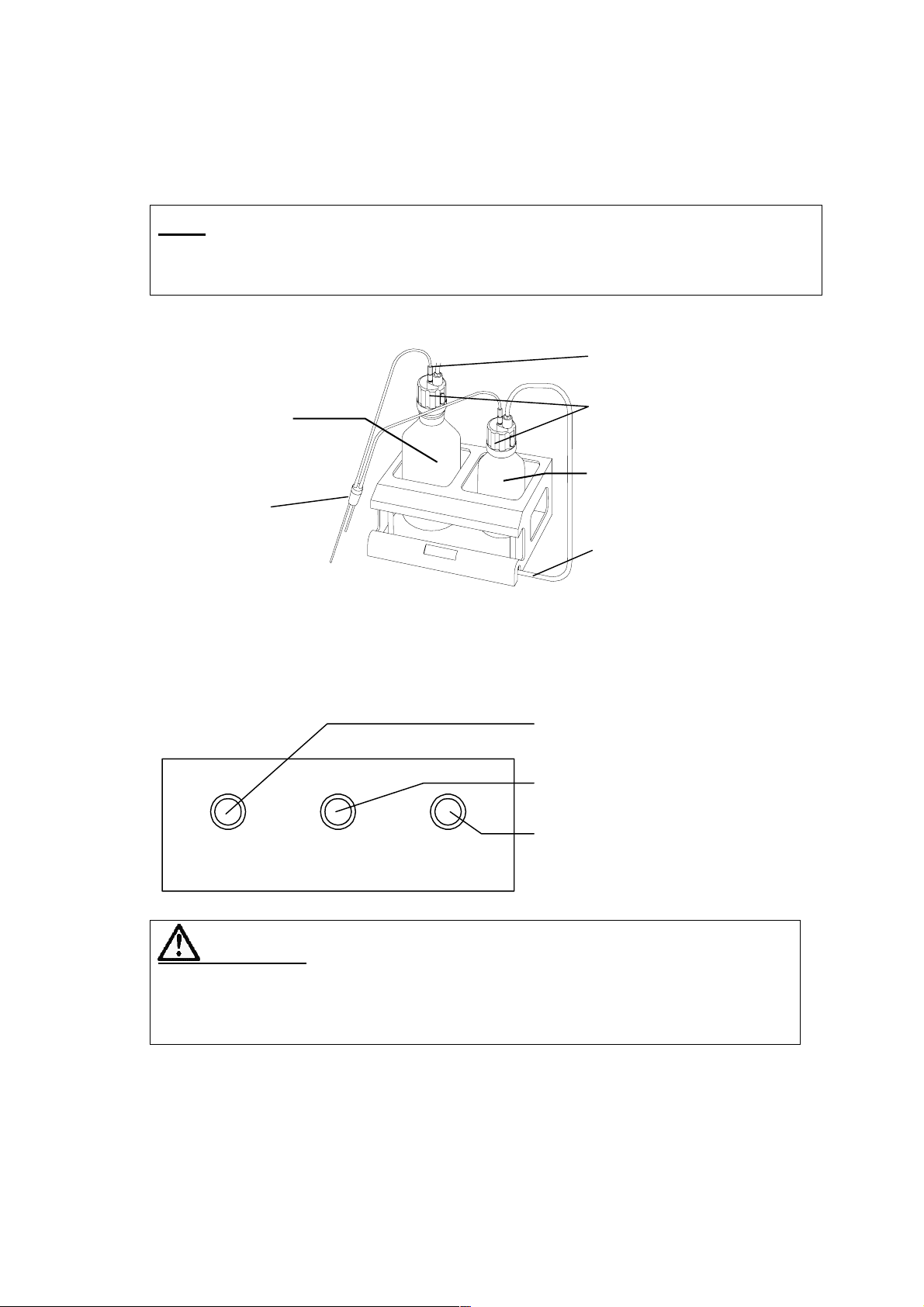

5-7. Filling and delivering dehydration solvent

For volumetric moisture measurement, the solvent to dehydrate the sample is necessary for effective reaction

of extracted water with KF reagent. The MKA-510N/MKS-510N has the built-in dispensing unit within

magnet stirrer that can deliver or aspirate extracting solvent to/from the titration flask by a button.

(1) Press “DRAIN” button of Stirrer to drain out remaining solvent in Titration flask.

If dosing speed is slow, push the button further in to speed it up.

(2) Press “SOLVENT” to deliver approximately 30mL solvent into titration flask.

Push upper part of the button.

Push lower part

of the button.

!

"

#

$

%

&

'

(

)

*

%

+

If other part of the button is pressed,

it may not work properly.

CAUTION!

Drain tube of Dispenser will be clogged if such sample as insoluble or

hard to be dissolved in extracting solvent is drained out after titrated

directly.

Do not use Dispenser to drain out such sample.

When a reagent etc. is spilt to Main unit or the connectors of magnetic

stirrer, there is a possibility of malfunction.

5-8. Purging the buret

The reagent filled in the buret will absorb minute moisture through the joint and piston head as the time

elapses. This will cause the different concentration of reagent between the buret and the bottle.

Purging is necessary to eliminate this difference of concentration.

(1) Press [APB] key and enter the working buret number (MKA-510N only) and the desired number of

times of purging, and then press [APB] key again. (see 6-2-5)

(2) Press [!"] key to start purging. After purging for the preset number of times is finished, it will set

in standby mode.

22

6. Key entry and display messages

6-1. Parameter setup

6-1-1. General

The MKA-510N / MKS-510N can measure water content by the initial parameters, however, if adequate

parameters and method are set up according to the sample, the measurement can be made faster and at

higher precision.

(1) Press the name of desired parameter.

(2) Point the desired item by cursor using [)][%][*]['] key.

(3) Selection of condition is confirmed by [+] key, and when letters and numerals are entered, also confirm

by [+] key.

(4) To exit from the settings, press the key used in (1).

Note:

1. Some parameters are set up in a different way from the above. Refer

to the description for each parameter.

2. Just pointing an item by the cursor does not activate the entry.

Selection or key entry must be confirmed by [+] key.

6-1-2. Method parameter

Method can be selected out of five methods 1 to 5, and each parameter including calculation, print, data list

etc. is stored in memory according to the selected Method individually. The default values differ from

Method 1 to 5 and CALIBRATION, (see “10.Initialization of Parameter and Default”), however,

parameters of each Method can be changed to your need.(except Calibration) If you wish to protect the

preset parameters from erroneous key entry, it can be protected by using Protect Function.

Press [Method] key:

Display changes as below. Select Method number by [)],[%] key and choose Protect or not by [*],[']

key and confirm by [+] key.

< M E T H O D >

Protect

M E T H O D 1 : O f f O n

M E T H O D 2 : O f f

O n

M E T H O D 3 : O f f O n

M E T H O D 4 : O f f O n

M E T H O D 5 : O f f O n

After setup, press [Method] key. When the cursor stays at "METHOD 1", the display returns to the

previous page by [)] key.

23

6-1-3. Titration parameter

Set up parameters to control titration including EP detection method, titration speed, etc.

Press [Titration] key:

The display changes as below to <TITRATION> first display for setting each

parameter. Point the item by cursor using [)][%][*]['] key and confirm by [+] key after desired

values and conditions are entered.

MKA-510N

< T I T R A T I O N > [ M E T H O D 1 ] "

T i t r . M o d e : N o r m a l

B a c k

T i t r . B u r e t N o . ( 1 ( 2 ) [ 1 ]

E n d T i m e [ 3 0 ] s

F i n a l V o l u m e [ 0 . 0 1 ] m L

T i t r . S p e e d ( 1 ( 6 ) [ 3 ] ,

MKS-510N

< T I T R A T I O N > [ M E T H O D 1 ] "

E n d T i m e [ 3 0 ] s

F i n a l V o l u m e [ 0 . 0 1 ] m L

T i t r . S p e e d ( 1 ( 6 ) [ 3 ]

,

Titr. Mode (Normal Back) : Select Titration mode. (“Titr. Mode” is not displayed for MKS-510N)

Normal : Normal titration for routine measurement

Back : Back titration (MKA-510N only) for slow water extraction by

dehydration solvent or slow reaction of KF reagent and water.

Titr. Buret No. (1to2) : Select buret number for titration (MKA-510N only)

End Time : Select time length to end titration. Endpoint is determined when titration

continues around in flection point in excess of reagent past preset time.

(Normal 30s according to JIS)

Final Volume : Select minimum amount of KF reagent to be dosed when approaching

endpoint.

If the selected amount is larger, the more measurement error will be

encountered, though titration time can be shorter. If smaller, the less

measurement error is expected but in the longer measuring time.

24

Titr. Speed : Titration speed (1&6(Titr. Mode: Normal), 1&3(Titr. Mode: Back))

Slow down speed if it overtitrates. Appropriate speed differs according to

the reagent, sample and solvent. Below chart shows general tendency of

Maker's reagent and titration speed:

1 Fast Merck

2 Mitsubishi

3 Riedel-de Haen (Composite)

4 Riedel-de Haen (Titrant)

5

6 Slow

Press [Page down] key.([%][+] will work when the cursor stays at the bottom line):

The display changes as below. Select each parameter on "#$#%&#$'() second display. Select the item

by cursor using [)][%][*]['] key, and confirm by [+] key after conditions or value are entered.

< T I T R A T I O N > [ M E T H O D 1 ] !"

D e t e c t o r M o d e ( 1 ( 2 ) [ 1 ]

t ( s t i r ) [ 0 ] s

t ( w a i t ) [ 0 ] s

t ( m a x ) [ 0 ] s

t ( i n t e r v a l ) [ 0 ] s

D r i f t T i t r a t i o n : O f f O n

,

Detector Mode (1 to 2) : Select detection mode. Select the amount of current to be loaded on the

detection electrode.

It differs depending on type of extracting solvent and the sample.

1 : EP detection for routine measurement

2 : Select this mode when titrating oil samples using CM solvent or when

titration does not end in excess of KF reagent.

t (stir) : Stirring time before titration starts Set up time from starting measurement

after sampled until titration starts, for a sample which is hard to dissolve in

dehydration solvent. You can not set up t(stir)>t(max).

t (wait) : Waiting time to reach EP

It will not reach EP within the preset time. However, if t(wait)>t(max) is

selected, it ends by t(max).

This parameter is necessary when, for example, there are two inflection

points but endpoint is determined in between the two points since

dehydration is maintained between the two peaks.

Loading...

Loading...