Operation Manual

MKC-500 KF Moisture Titrator

Ver.04

#595-0006

Contents Page

1. SAFETY MEASURES........................................................................................................................................... 1

2. FOREWORD.......................................................................................................................................................... 2

3. MEASUREMENT PRINCIPLE............................................................................................................................. 3

4. SETTING UP THE SYSTEM................................................................................................................................ 4

4.1 Supplied parts...................................................................................................................................................4

4.2 Parts name and functions.................................................................................................................................. 5

4.3 Checking the operating voltage ........................................................................................................................8

4.4 Turning on the power........................................................................................................................................ 9

4.5 Initial display at start....................................................................................................................................... 10

4.6 How to confirm product version number........................................................................................................ 10

5. INSTALLING THE TITRATION CELL ............................................................................................... .............. 11

5.1 Installation 2-comoponent cell........................................................................................................................ 11

5.2 Installation 1-comoponent cell........................................................................................................................ 12

6. METHOD CONFIGURATION............................................................................................................................13

6.1 General............................................................................................................................................................ 13

6.1.1 Basic structure.......................................................................................................................................... 13

6.1.2 Structure of the parameter configuration ................................................................................................. 14

6.1.3 Initial parameters .....................................................................................................................................16

6.2 Titration parameters........................................................................................................................................ 17

6.2.1 t(stir)[s], t(wait)[s], t(max)[s]................................................................................................................... 18

6.2.2 Drift stop : (rel / abs / off)........................................................................................................................ 18

6.3 Calculation parameters ................................................................................................................................... 20

6.3.1 Calculation formula (by unit)................................................................................................................... 21

6.3.2 Weight : (fix / var)...................................................................................................................................22

6.3.3 Drift comp : (auto / off / manu)................................................................................................................ 22

6.3.4 Blank........................................................................................................................................................ 22

6.3.5 Factor....................................................................................................................................................... 22

6.4 Parameters for Report..................................................................................................................................... 23

6.5 Parameters for Sample.................................................................................................................................... 25

7. EXAMPLE OF ACTUAL OPERATION............................................................................................................. 27

7.1 Status diagram of titration............................................................................................................................... 27

7.2 Titration..........................................................................................................................................................28

7.3 Pretitration ...................................................................................................................................................... 29

7.4 Titration with Balance .................................................................................................................................... 31

8. SETUP.................................................................................................................................................................. 33

8.1 General............................................................................................................................................................ 33

8.2 Interface (Setup 0) .......................................................................................................................................... 35

8.3 Date & Time (Setup 1).................................................................................................................................... 39

8.4 User Name (Setup 2).......................................................................................................................................40

8.5 Serial No. (Setup 3) ........................................................................................................................................ 41

8.6 Cell Type (Setup 4)......................................................................................................................................... 42

9. FUNCTION.......................................................................................................................................................... 43

9.1 General............................................................................................................................................................ 43

9.2 For Reagent life control and Alarm setting (Function 0)................................................................................ 44

9.3 Recalculation (Function 1 )............................................................................................................................. 46

9.4 Factor value setup (Function 2)......................................................................................................................48

9.5 Initialize to default (Function 3).....................................................................................................................49

10. INITIALIZING PARAMETERS AND DEFAULT VALUES.......................................................................... 50

11. SPECIAL KEYS................................................................................................................................................. 51

11.1 The Stirrer Key.............................................................................................................................................51

11.2 The Esc. Key................................................................................................................................................. 51

11.3.The BS. Key.................................................................................................................................................. 51

11.4 The Clr. Key ................................................................................................................................................. 52

11.5 The -/Disp. Key.............................................................................................................................................52

11.6 The Print Key................................................................................................................................................ 52

11.7 The Reset Key............................................................................................................................................... 53

12. MAINTENANCE............................................................................................................................................... 54

12.1 Application of grease.................................................................................................................................... 54

12.2 Septum replacement...................................................................................................................................... 54

12.3 Silica gel replacement................................................................................................................................... 54

12.4 Anolyte replacement..................................................................................................................................... 54

12.5 Catholyte replacement .................................................................................................................................. 55

12.6 Long-term storage measures......................................................................................................................... 55

12.7 Cleaning detection electrode......................................................................................................................... 56

12.8 Cleaning inner burette................................................................................................................................... 56

12.8.1 Cleaning steps........................................................................................................................................ 56

12.8.2 Drying steps........................................................................................................................................... 57

12.8.3 Adjusting the length between anode and membrane.............................................................................. 57

12.9 Cleaning and drying the measuring cell........................................................................................................ 57

12.10 Replacement of power fuse......................................................................................................................... 58

12.11 Backup battery............................................................................................................................................ 58

13. KARL FISCHER REAGENT.............................................................................................................................59

14. TROUBLESHOOTING......................................................................................................................................61

14.1 Error messages and malfunction rectification............................................................................................... 61

14.2 Power switch failure.....................................................................................................................................62

14.3 Stirrer malfunction........................................................................................................................................ 63

14.4 Drift level excessive......................................................................................................................................64

14.5 Excess reagent consumption......................................................................................................................... 65

14.6 Endpoint not reached or reached too late...................................................................................................... 66

14.7 Poor reproducibility of measurement results................................................................................................67

14.8 Glass contact areas jammed.......................................................................................................................... 68

15. DISPLAY MESSAGES LIST............................................................................................................................69

16. PARTS LIST ...................................................................................................................................................... 72

17. SYSTEM CONNECTIONS ............................................................................................................................... 76

18. SPECIFICATIONS.............................................................................................................................................77

19. CONNECTION DIAGRAM..............................................................................................................................78

20. WARRANTY PROVISION FOR TERMS AND CONDITIONS..................................................................... 79

1. Safety measures

Measures for your safety

− Ensure that you plug the supplied power cable into a sock et which is grounded! In the

absence of grounding, a technical fault could be lethal.

− Switch the instrument off and disconnect the power cable if you change blown fuses!

An electrical shock could be fatal.

− Never work in a hazardous area! The housing of the titrator is not gastight (explosion

hazard through spark formation, corrosion by gas diffusion into the instrument).

Measures for operational safety

− Check the set operating voltage before you switch on the instrument (see chapter 4.2)!

The instrument will be damaged if the operating voltage does not match the line voltage.

− Use only fuses of the specified type if you need to change them!

− Let the titrator be opened and maintained by Service only!

− Exclude the following environmental influences:

⋅ Powerful vibrations

⋅ Direct sunlight

⋅ High atmospheric humidity

⋅ Temperatures below 5°C and above 35°C

⋅ Powerful electric or magnetic fields which influence the power supply through large

load fluctuations!

1

2. Foreword

Moisture in sugar or salt influences its pouring properties. Traces of moisture in brake fluid adversely affect the

function of the vehicle brakes. Small amounts of water in aircraft hydraulic oil increase the risk of an emergency.

Traces of moisture usually influence the quality of products and it is therefore often very important to know the

exact value of the moisture content. With the MKC-500 you can easily determine traces of water with a very high

degree of accuracy.

You can change the titration parameters and get the results from computer by RS-232C.

The MKC-500 offers the possibility of entering the sample weight before or after the titration; manually or

transferred automatically from the connected balance.

The MKC-500 has an automatic drift determination, which is reconciled in the result calculation.

The MKC-500 has two kinds of report format, Short/GLP. (Note: Printer is optional )

2

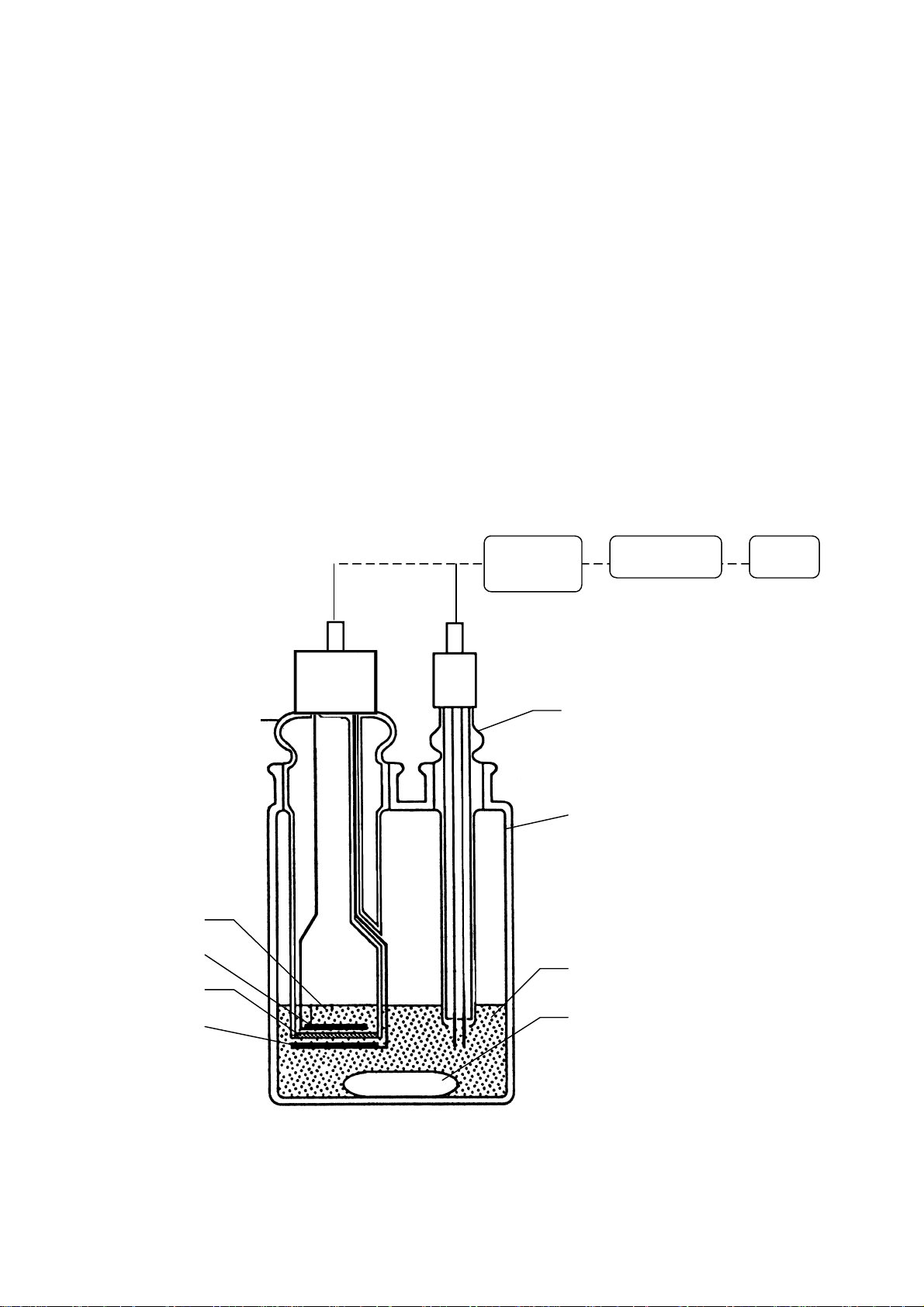

3. Measurement principle

In the Karl Fisher moisture content measurement, water reacts with iodine and sulfur dioxide in the presence of a

base and alcohol.

H

In the volumetric titration, iodine is added as a titrant. In the coulometric technique, iodine is electrolytically

generated in the anolyte, which contains iodide.

2I¯

As long as water is present in the titration cell the generated iodine reacts according to (1).

As soon as all the water has reacts, a small excess of iodine appears in the anolyte. This iodine is detected by the

double platinum pin electrode and the iodine production is stopped. According to Faraday's law, the quantity of

iodine produced is proportional to the current generated. In equation (1), I

proportion 1:1.

Therefore a mole of water (18 g) is equivalent to 296500 coulombs, or 10.72 coulombs/ 1 mg H

of moisture can thus be determined by measuring the total consumption of electricity.

O + I2 + SO2 + CH3OH + 3RN [RNH]SO4CH3 + 2[RNH]I (1)

2

→

I2 + 2 e ¯ (2)

and H2O react with each other in

2

O. The total amount

2

Catholyte

Cathode

Membrane

Detection/

Control unit

Microconputer Display

Detection electrode

(double platinum pin electrode)

Titration cell

Anolyte

Anode

Rotor

3

4. Setting up the system

4.1 Supplied parts

The carton box that has been delivered to you contains the MKC-500 and supplied parts including Operating

manual as per below list. Please identify the supplied parts with the list, and if you should find any part missing

or broken, contact your local dealer.

MKC-500 MKC-500

2-component cell 1-component cell

1. Main unit.................................................................................MKC-500 1 unit 1 unit

2. Power cord with earth wire (AC100/120V area) ....................#320-3198 1 pce 1 pce

(AC220/230/240 area)................#320-3461

(for UK)......................................#320-4199

3. AC 3-pin Adapter (AC100V only)..........................................#320-3199 1 pce 1 pce

4. Earth wire (AC100V only)......................................................#433-3331 1 pce 1 pce

5. Titration cell unit....................................................................#433-0005 1 set ⎯

6. Titration cell unit....................................................................#433-0071 ⎯ 1 set

7. Drain bottle.............................................................................#500-3134 1 pce ⎯

8. Funnel.....................................................................................#500-3159 1 pce ⎯

9. Stirrer spinner (35mm)...........................................................#500-3362 1 pce 1 pce

10. KF grease (5g)......................................................................#433-3138 1 pce 1 pce

11. Septum...................................................................................#523-3161S 10 pcs 10 pcs

12. Anode tool.............................................................................#075-3411 1 pce ⎯

13. Power fuse (T3.15A/250V for AC100/ 120V ).......................#338-5028 2 pcs 2 pcs

(T1.6A/250V for AC220/230/240V) ..................#338-3252 2 pcs 2 pcs

13. Operating manual..................................................................#595-0006 1 copy 1 copy

14. Warranty................................................................................ 1 copy 1 copy

15.Manual solvent exchanger......................................................MLC-500 ⎯ 1 unit

4

4.2 Parts name and functions

g

t

Detection electrode

measures potential

in the cell to detec

endpoint.

Fuse box

where power fuse is replaced

with new one.

Desiccator

keeps air dried.

Inner burette(anode and cathode

electrode combined into one unit)

generates iodine and titrates

moisture content.

Injection port(for syringe)

allows the sample injected into

the cell.

Titration cell

in which iodine and water react

for coulometric titration.

Cell holder

secures the titration cell.

Display screen

shows measurement results or

mode of the instrument.

Keypad

Enter desired parameters and

controls titration.

Input for inner burette

Plug in the connector from

inner burette.

Input for detection electrode

Plug in the cable end from the

electrode.

Port for Printer

Plug in the printer cable here.

Port for Balance

in the cable from Balance.

Plu

5

Voltage selector

Power switch

RS-232C connector

Interface for communication

with PC or other external

device.

Connector for power cable

Key to enter Titration parameter.

Press the key again when finishing parameter setting.

Key to enter parameters for Calculation or Report.

Press the key again when finishing parameter setting.

Key to enter Sample No., Lot No. or Sample weight.

Press the key again when finishing parameter setting.

Key to set up Function parameter.

Press the key when closing parameter setup.

0.Reagent Capacity

1.Recalculation

2.Factor

3.Memory clear

Key to enter Setup parameter.

Press the key when closing parameter setup.

0.Interface

1.Date & Time

2.Name

3.Serial No.

Key to activate Printer for printing.

Key to control Stirring speed.

Press the key again finishing rotating speed se tt i ng.

Key to perform Pre-titration.

Key to start Titration.

Key to turn the instrument into reset condition.

Key to select menu with ↑ mark or characters, and to show cell potential.

Key to select and reverse dot or character.

6

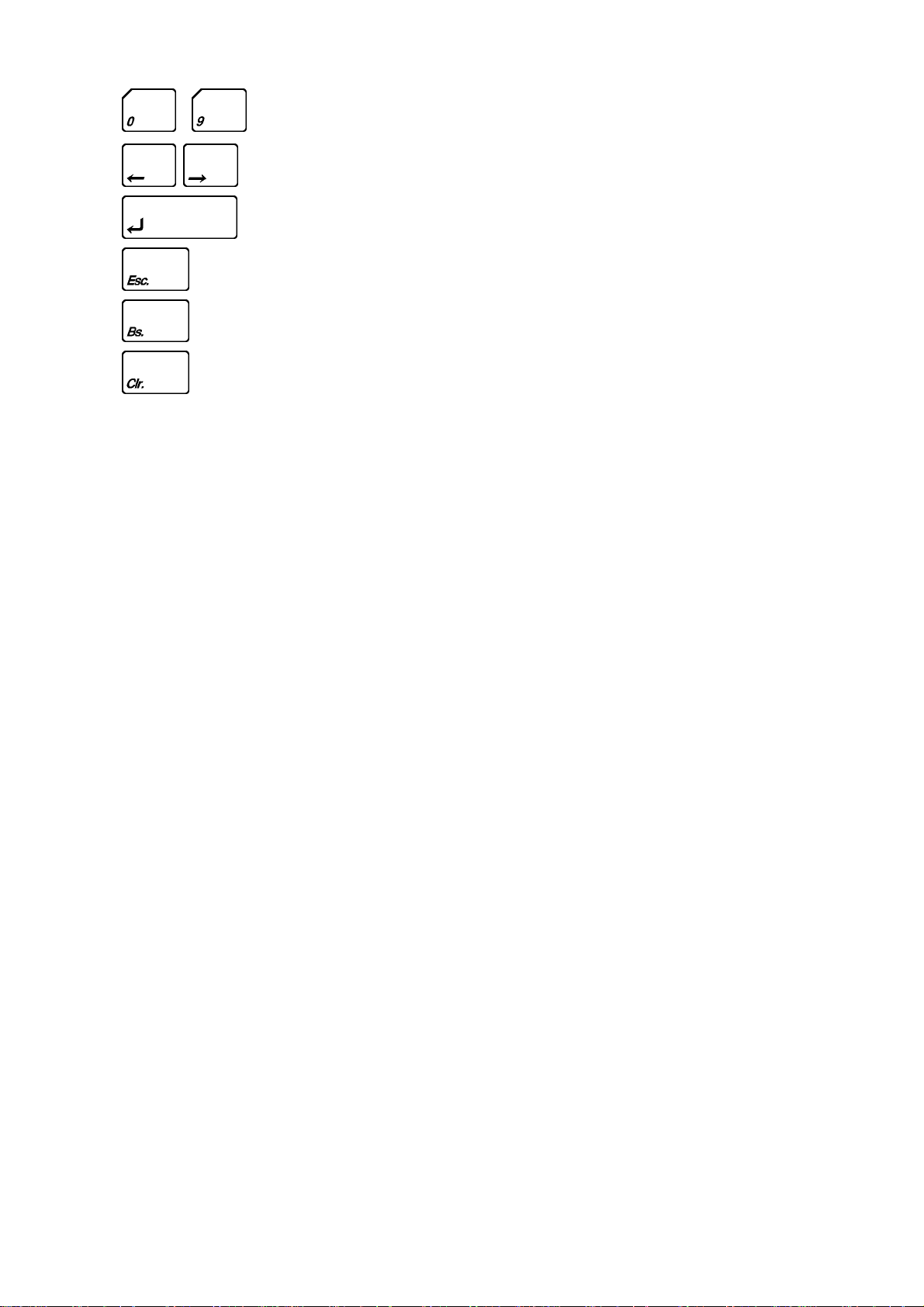

Key to select numerals.

~

Key to move the cursor.

Key to confirm the key entry.

Key to return the parameters on display to the previous screen.

Key to reverse a character or number by one space.

Key to clear the key entry that has been made.

7

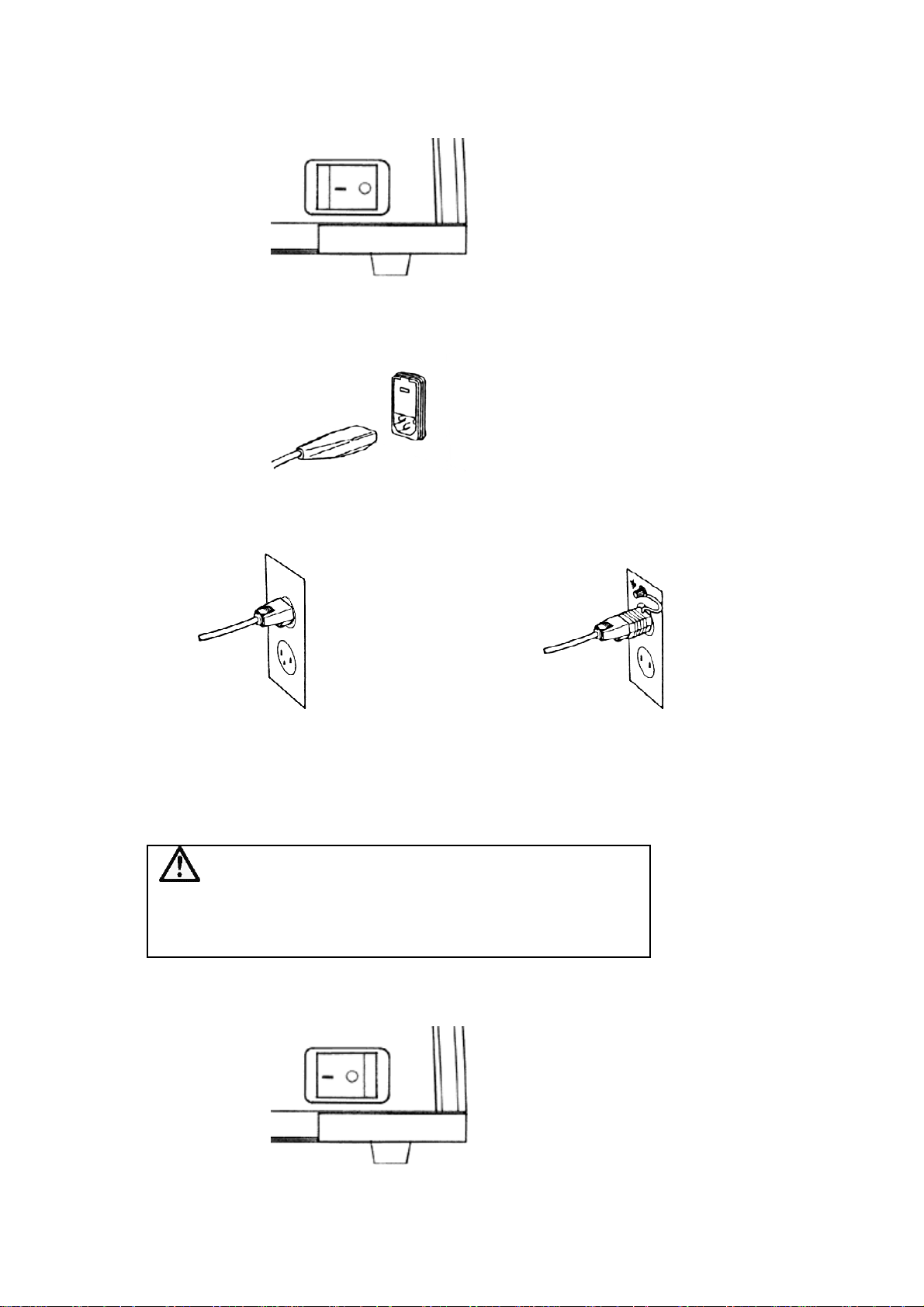

4.3 Checking the operating voltage

Before switching on the instrument for the first time, make sure the voltage selector is set to the appropriate

line voltage. If it should be set to a wrong voltage, correct it by the following procedure:

(1) Open the cover of power inlet using a flat head screw driver.

(2) Pull out the voltage selector wheel, and put it back to the box so that the selected voltage can be seen when

the cover is closed.

(3) Close the cover and recheck the voltage display on the box.

Insert the driver and Pull out the voltage Close the cover.

open the cover. selector wheel.

Voltage selector

Make sure the power fuse conforms to the below rating chart.

For more details, see 12.10 Replacement of Power Fuse.

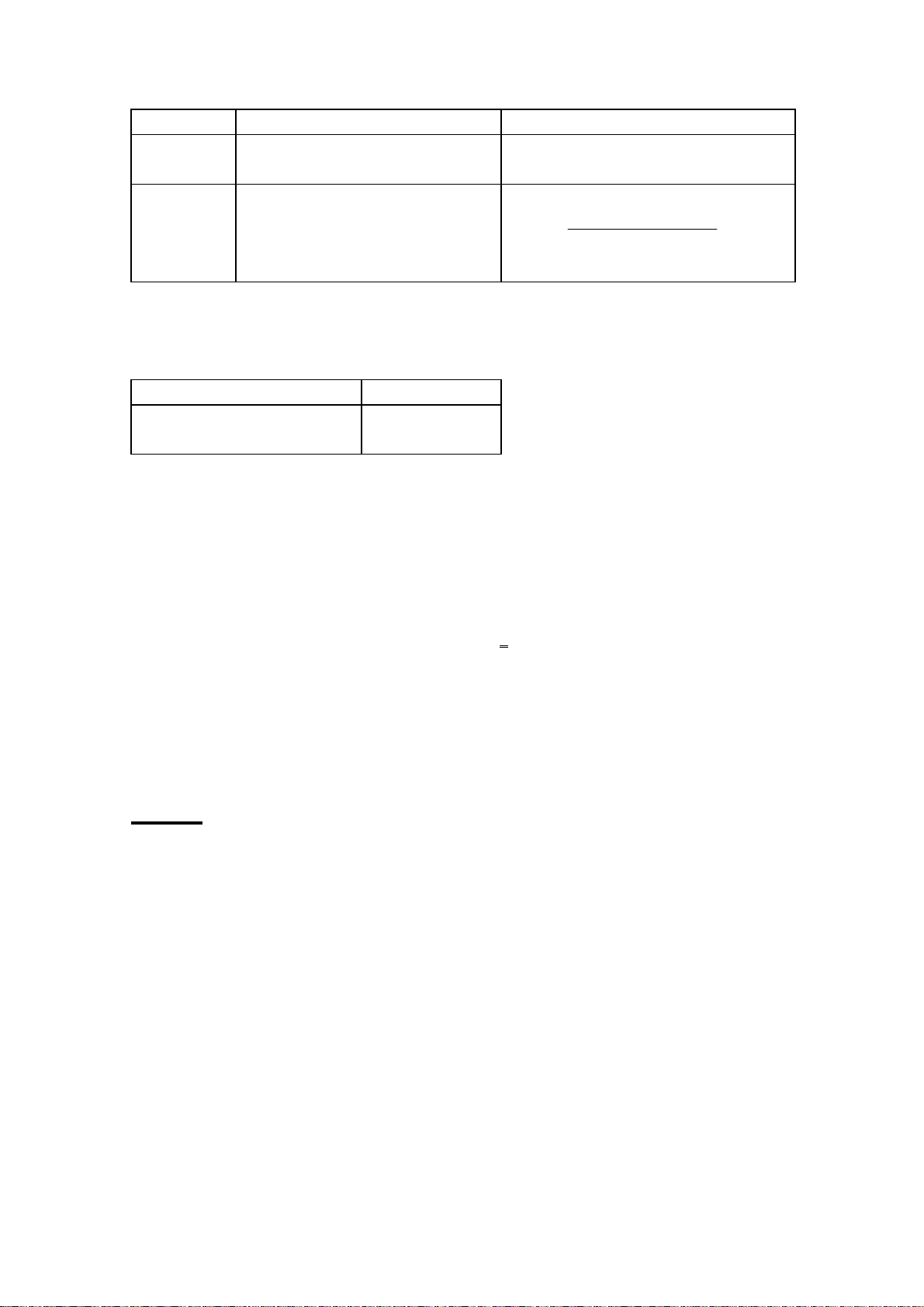

AC Line voltage Fuse Hz

100 V 90 - 120 V T3.15 A/250 V 50/60

120 V 103 - 132 V T3.15 A/250 V 50/60

220 V 198 - 242 V T 1.6 A/250 V 50/60

230 V 207 - 253 V T 1.6 A/250 V 50/60

240 V 216 - 264 V T 1.6 A/250 V 50/60

Voltage can be selected by the selector on the rear panel.

CAUTION

For continued protection against risk of fire,

replace only with same type and ratings of fuse.

Fuse

8

4.4 Turning on the power

(1) Make sure the power switch is in OFF position.

(2) Plug in the connector of supplied power cord to the unit.

(3) Plug in the other end of power cord to the power outlet.

<For 3-P consent> <For 2-P consent>

The 3-pin plug has an earth terminal First, plug in the AC-3P adapter to AC plug,

so that grounding by wire is not necessary. and then ground the green wire to the earth.

(4) Turn ON the power switch of the unit.

WARNING

Be sure to ground the earth line.

If not earthed, there will be danger of electric shock.

9

4.5 Initial display at start

When the power is turned on, the message (1) will appear on display for about two seconds. Then, the

message (2) on product version number will be shown for two seconds. Then, the message (3) will blink,

which keeps blinking until pre-titration starts.

(1)

(2)

(3)

C . M o i s t u r e T i t r .

V e r 1 .01

Pre-Tit r

4.6 How to confirm product version number

The product ver. number varies depending on what options and specifications you have selected for your

MKC-500.

Follow the below procedure to check its number:

With power turned on, make sure it shows Initial message or Main display.

Then, press [ 0 ], [ 0 ], [ 0 ] and press [ ↵ ] key.

The product number will appear for two seconds.

( 4.5 (2) )

Note!

This procedure must be worked on Initial display or main display.

10

5. Installing the titration cell

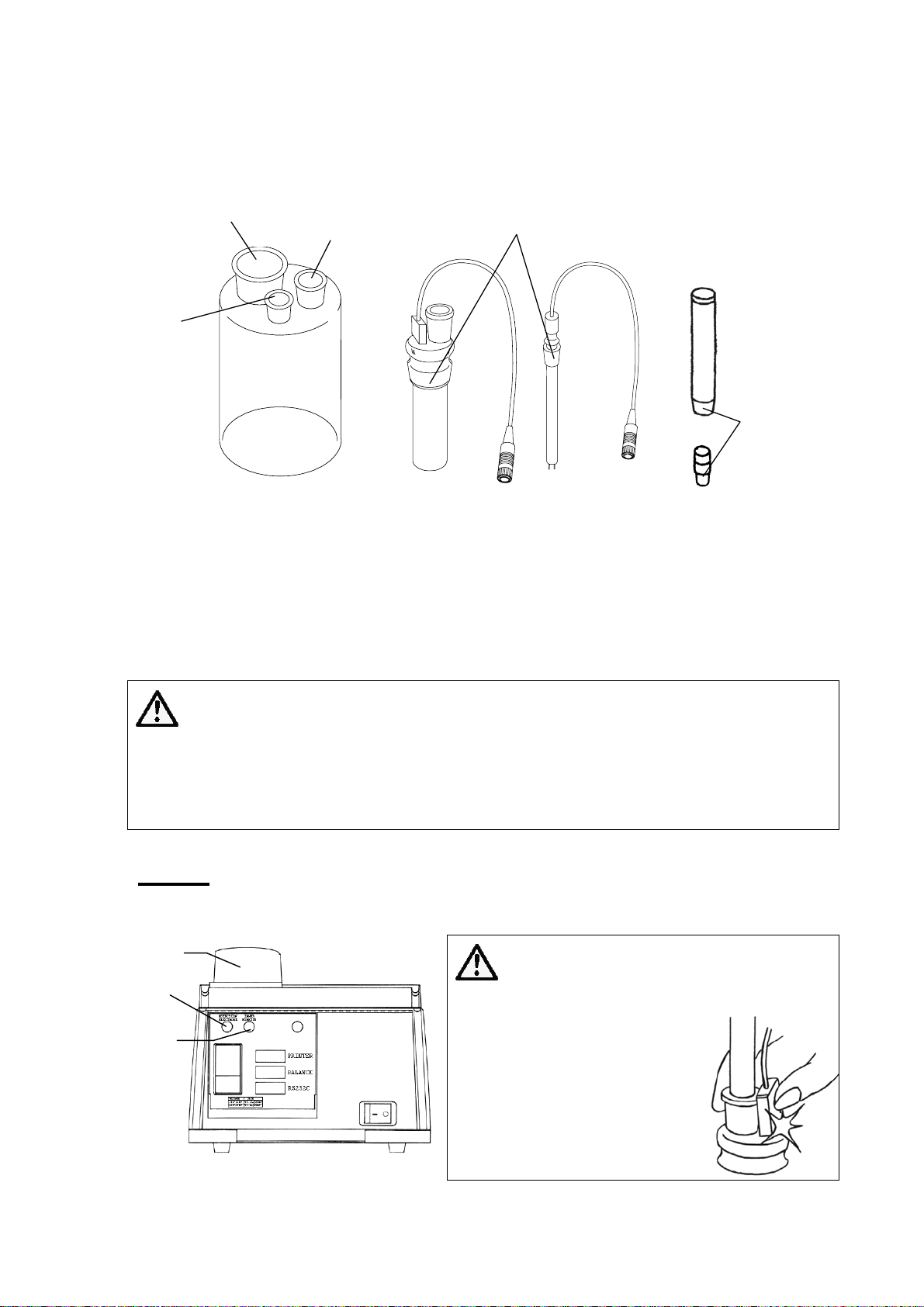

5.1 Installation 2-comoponent cell

(1) Put the stirring spinner in the cell, and insert the inner burette and the detection electrode. Apply KF grease

around jointing parts.

Inner burette port

Detection

electrode port

Sample injection

port

Apply KF grease

Desiccator

Apply

KF grease

Titration cell

(2) Supply 100mL anolyte into Titration cell, and seal it after KF grease is applied around the injection p ort.

(The lower level line outside the titration cell shows 100mL line.)

(3) Supply 5mL catholyte into Inner burette, and seal it by the desiccant tube.

(4) Position the measuring cell in the cell holder.

Then, plug the cables of the electrode and the inner burette to the ports at the rear panel. (See next page)

Inner burette

(with diaphragm)

Detection electrode

Sample port

stopper

CAUTION

KF grease must be applied around all the jointed parts including the inner

burette, the detection electrode, sample port inlet and the low end of

desiccant tube. Check the jointed parts once a week. (See 12.1)

Neglegence of such maintenance will lead to solidification of those parts.

Note!

The protective seal on Desiccator must be peeled off.

Cell holder

Inner burette

holder

Detection

electrode

holder

CAUTION

To prevent the inner

burette from breaking by

handhold, do not snatch

the housing (black resin)

and desiccant tube by

fingers.

You may get hurt if it is

broken.

11

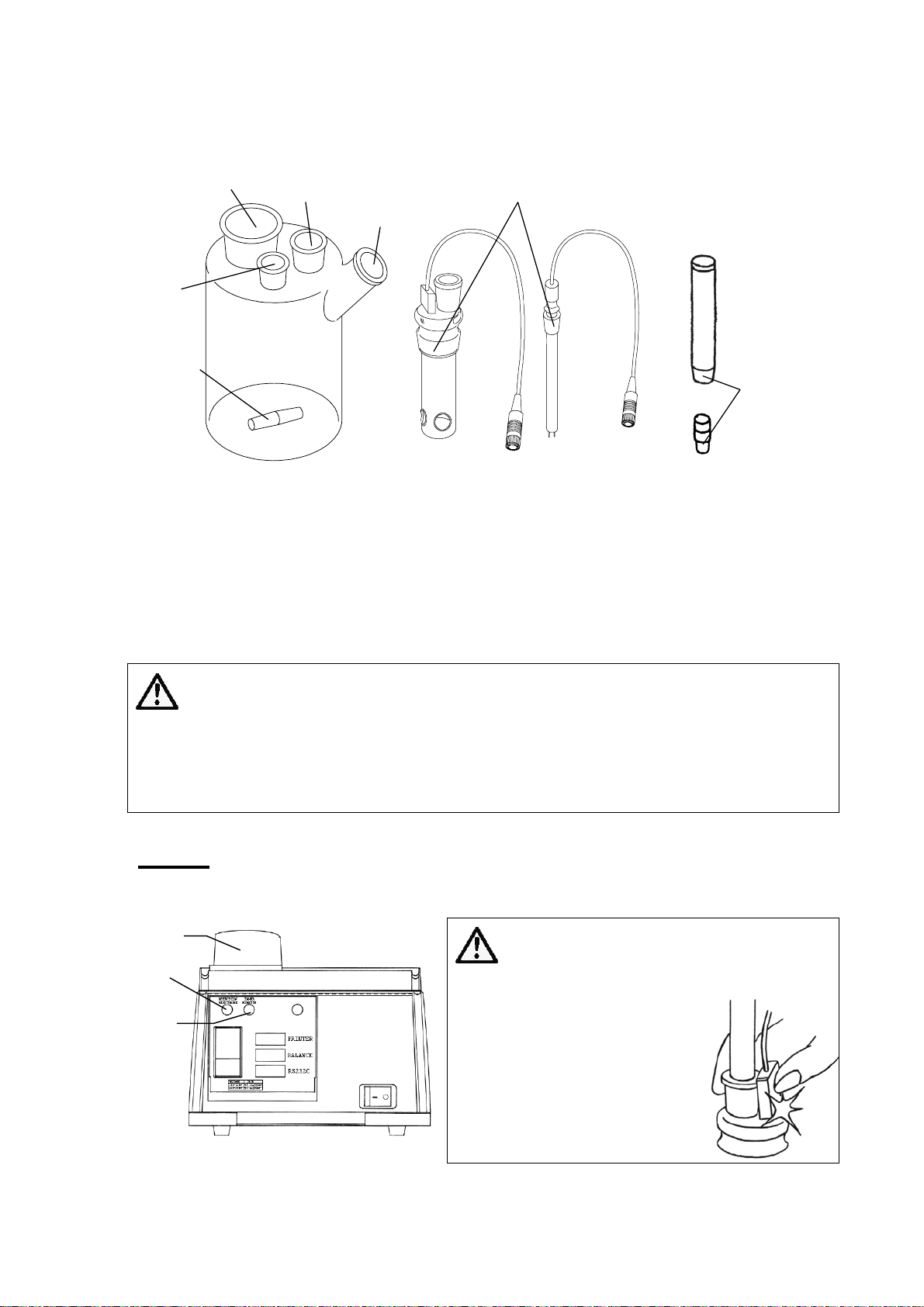

5.2 Installation 1-comoponent cell

(1) Put the stirring spinner in the cell, and insert the inner burette and the detection electrode. Apply KF grease

around jointing parts.

Inner burette port

Detection

electrode port

35mm spinner

Flask stopper port

Sample injection

port

Apply KF grease

Desiccator

Apply

KF grease

Titration cell

(2) Supply 150mL anolyte into Titration cell, and seal it after KF grease is applied around the injection p ort.

(The lower level line outside the titration cell shows 150mL line.)

(3) Position the measuring cell in the cell holder.

Then, plug the cables of the electrode and the inner burette to the ports at the rear panel. (See next page)

Inner burette

(Diaphragmless)

Detection electrode

Sample port

stopper

CAUTION

KF grease must be applied around all the jointed parts including the inner

burette, the detection electrode, sample port inlet and the low end of

desiccant tube. Check the jointed parts once a week. (See 12.1)

Neglegence of such maintenance will lead to solidification of those parts.

Note!

The protective seal on Desiccator must be peeled off.

Cell holder

Inner burette

holder

Detection

electrode

holder

CAUTION

To prevent the inner

burette from breaking by

handhold, do not snatch

the housing (black resin)

and desiccant tube by

fingers.

You may get hurt if it is

broken.

12

6. Method configuration

6.1 General

The MKC-500 has some parameters which are used for the titration, the calculation and the record of a titration.

These parameters can be modified to meet the requirements of individual titrations using the three function

keys, Titration, Result and Sample.

In a new MKC-500 parameters are initialized with default value (see 10.). With these parameters you can start

a titration without any change of parameter configuration.

6.1.1 Basic structure

The parameters can be selected with the three function keys, Titration, Result and Sample.

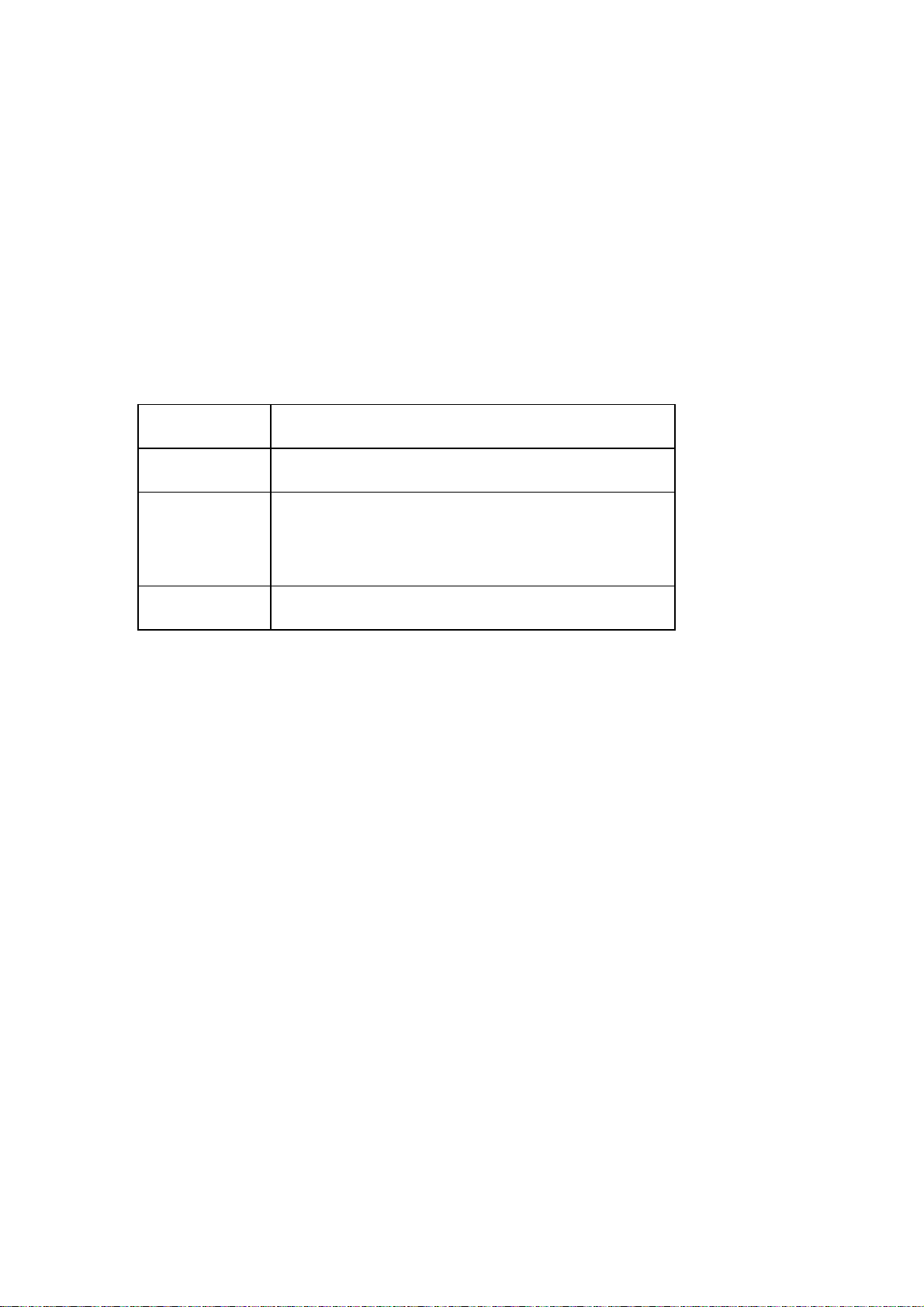

Function key Description

Titration (parameters for controlling the titration)

Result (parameters for the result calculation)

(parameters for the result print out)

Sample (parameters for the sample)

13

6.1.2 Structure of the parameter configuration

For entering and changing these display lines, see the chapters 6.2, 6.3, 6.4, 6.5.

Routine measurement by MKC-500 is simply started by [ Start ] key, and can be aborted by [Reset ] key.

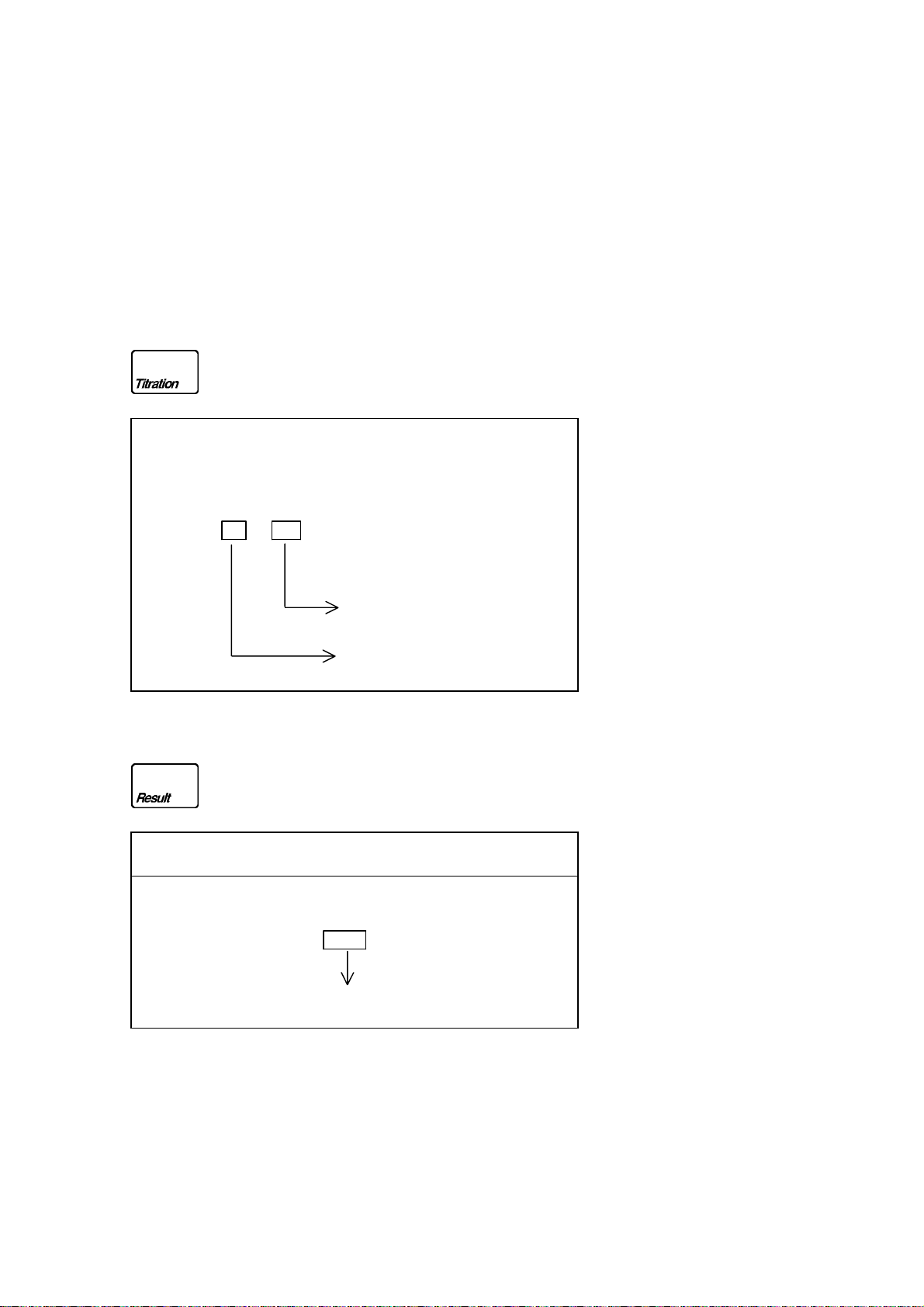

Display messages and key entry are related like this:

Parameters of message ending with "↑" is selected on display by [-/Disp. ] key, and confirmed by [↵ ] key.

For parameters ending with "?", use numeric key and confirm by [↵ ] key.

The contents of each parameter are shown below:

t(stir) [s] ( 0 - 999 s )

t(wait) [s] (15 - 9999 s )

t(max) [s] ( 0 - 999 s )

Drift stop : rel ↑/ abs ↑/ off↑

Calculation↑

Unit : μg↑ /mg↑ /ppm↑ /%↑

Weight : fix↑ /var↑

Drift comp : auto↑ /off↑/ manu

Abs?(0.00 - 9.99)

Rel?(0.00 - 9.99)

↑

Drift?(0.0000 - 999.9)

14

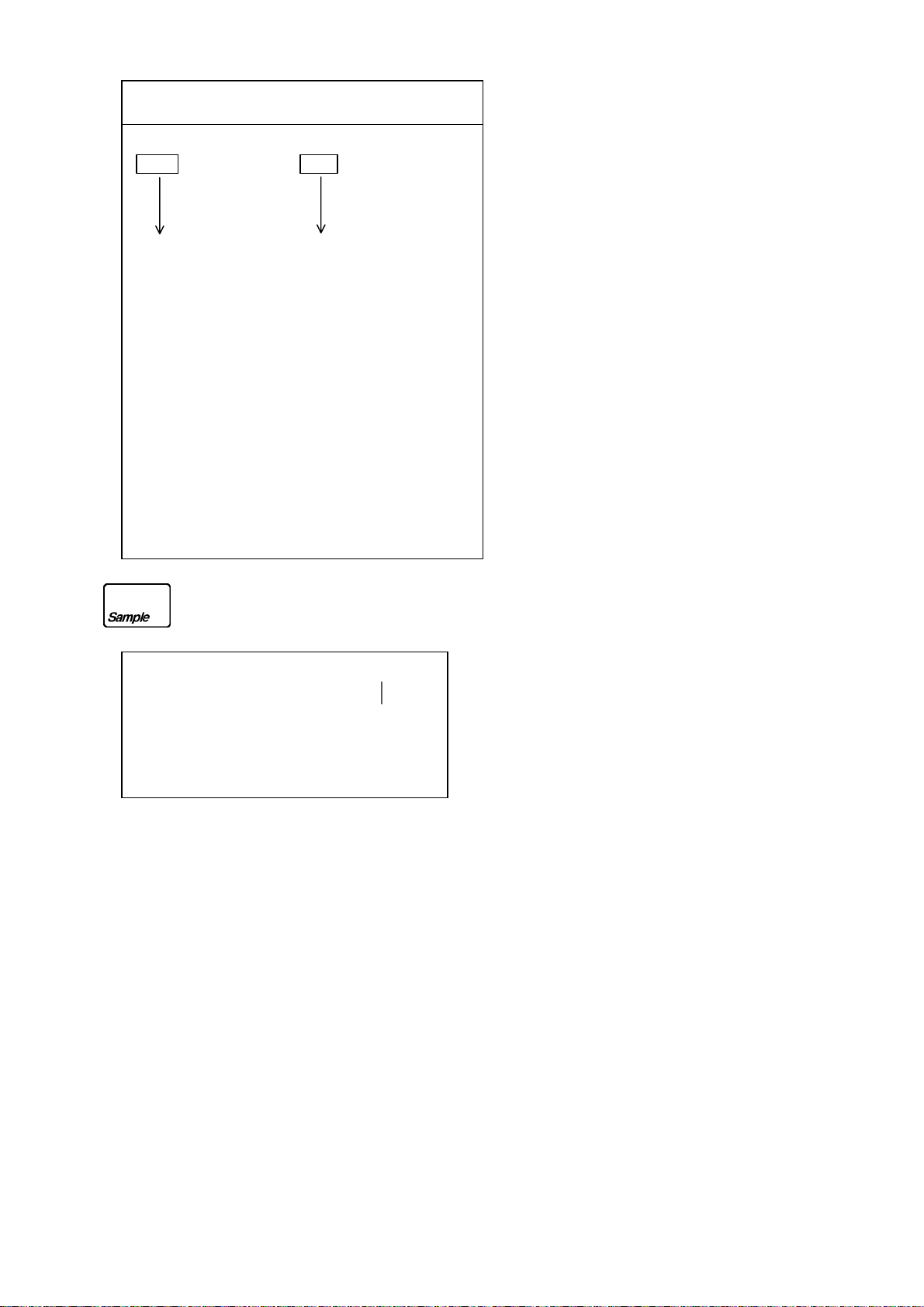

Report ↑

Short

↑/ GLP ↑

Date & Time Date & Time

Sample No. Serial No.

Sample Weight Sample No.

Result Lot No.

Sample Weight

Factor

Result

Titr.Time

Drift

Blank

Name

Sample No. ? (00 - 00

99 - 99)

Lot ? (xxxxxxxxxx)

Wt1 ? (0.000000 - 999.9999)

Wt2 ? (0.000000 - 999.9999)

15

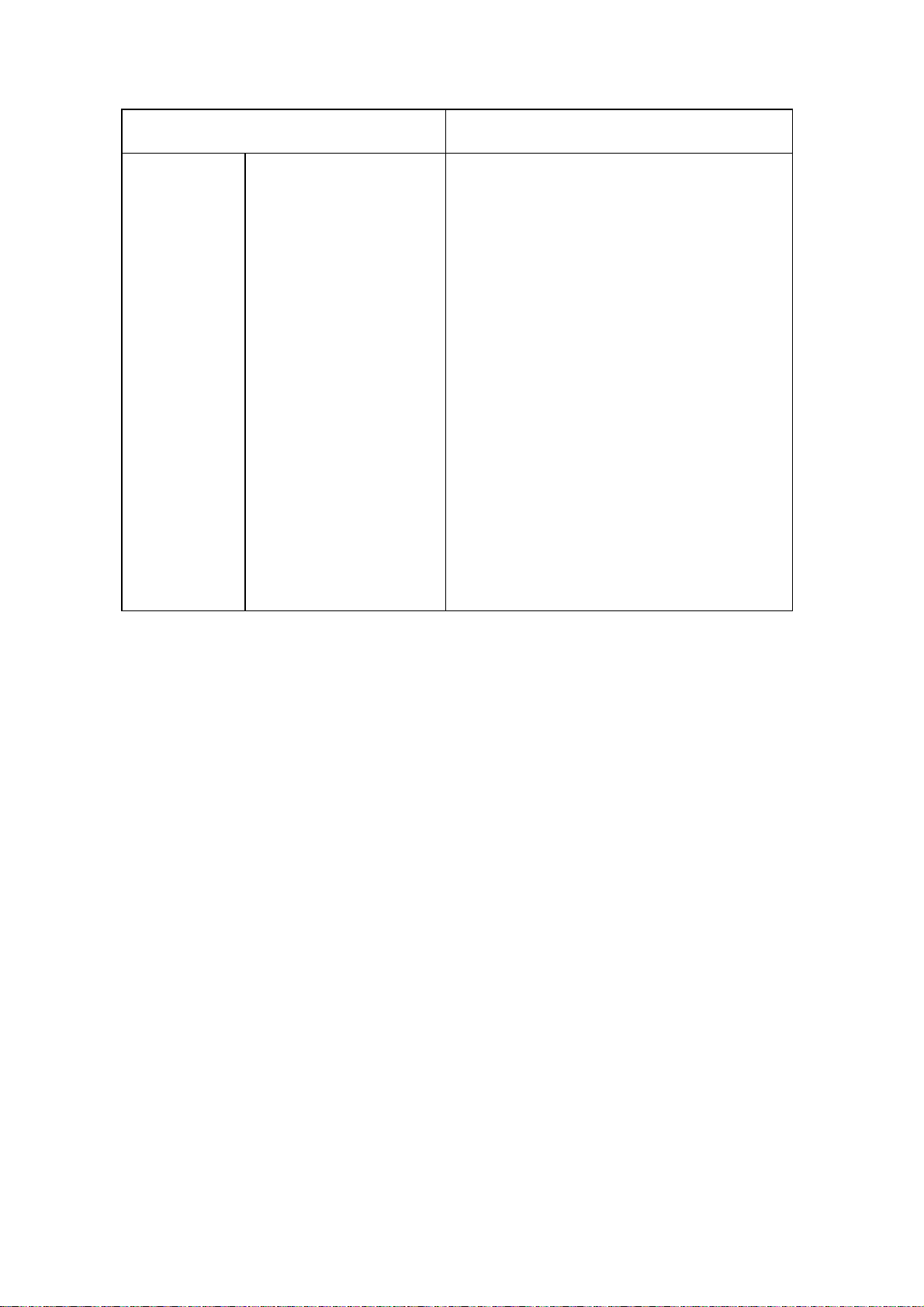

6.1.3 Initial parameters

Parameters Initial value

Titration

Result

Calculation

Report

Sample

t(stir) [s]?

t(wait) [s]?

t(max) [s]?

Drift stop

Unit

Weight

Drift comp

Drift comp:manu↑

Drift ?

Blank ?

Sample No. ?

Lot ?

Wt1 ?

Wt2 ?

0s

15s

0s

rel 0.1μg / s

Calculation↑

μg↑

f ix↑

auto↑

0.0μg / s

0μg

Short↑

00 - 00

5.0000g

0.0000g

16

6.2 Titration parameters

Here you can set the control parameters for the titration.

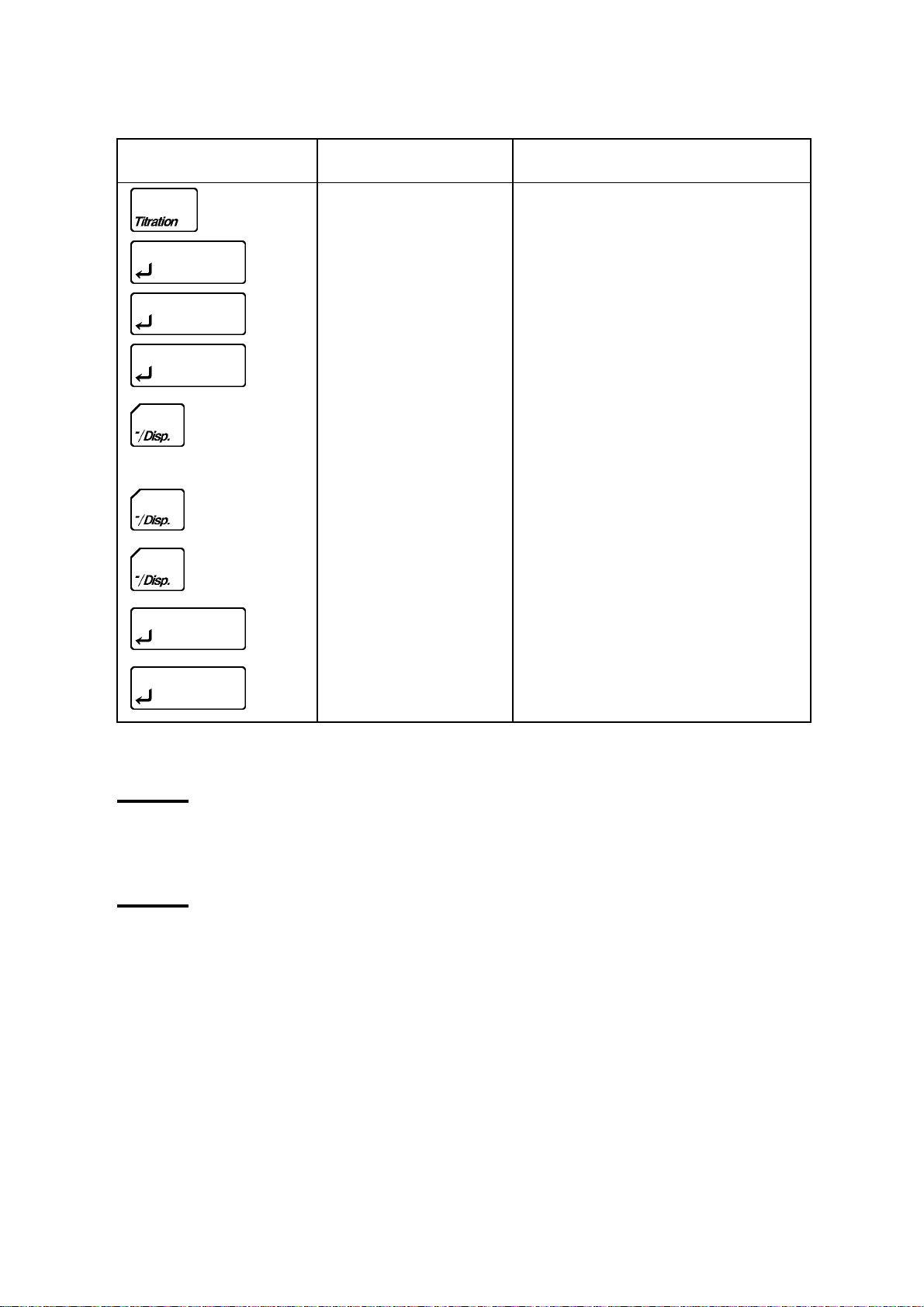

Entry Key Display Description

t(stir)[s]? 0 titration active, stirrer, no I

t(wait)[s]? 15

t(max)[s]? 0 time limit of titration, termination criteria. (0s

Drift stop : rel ↑ rel : stop s when drift is below.

Drift stop : abs ↑

Drift stop : off ↑

Drift stop : rel ↑

rel[μg/s]? 0.1

titration active, no termination during this

time. (more than 15s)

endless)

(entered value + drift value)

abs : stops when drift is below entered value.

off : no drift stop, termination after

{ t(stir) + t(wait) + t(max) }

- generation.

2

Note!

Do not select Drift Stop:off and t(max)=0 at the same time.

If selected, the alarm will beep when titration starts.

Note!

All parameters with the ↑ sign can be changed with the [ -/Disp. ] key.

All parameters with the ? sign require entry of a numeric value.

17

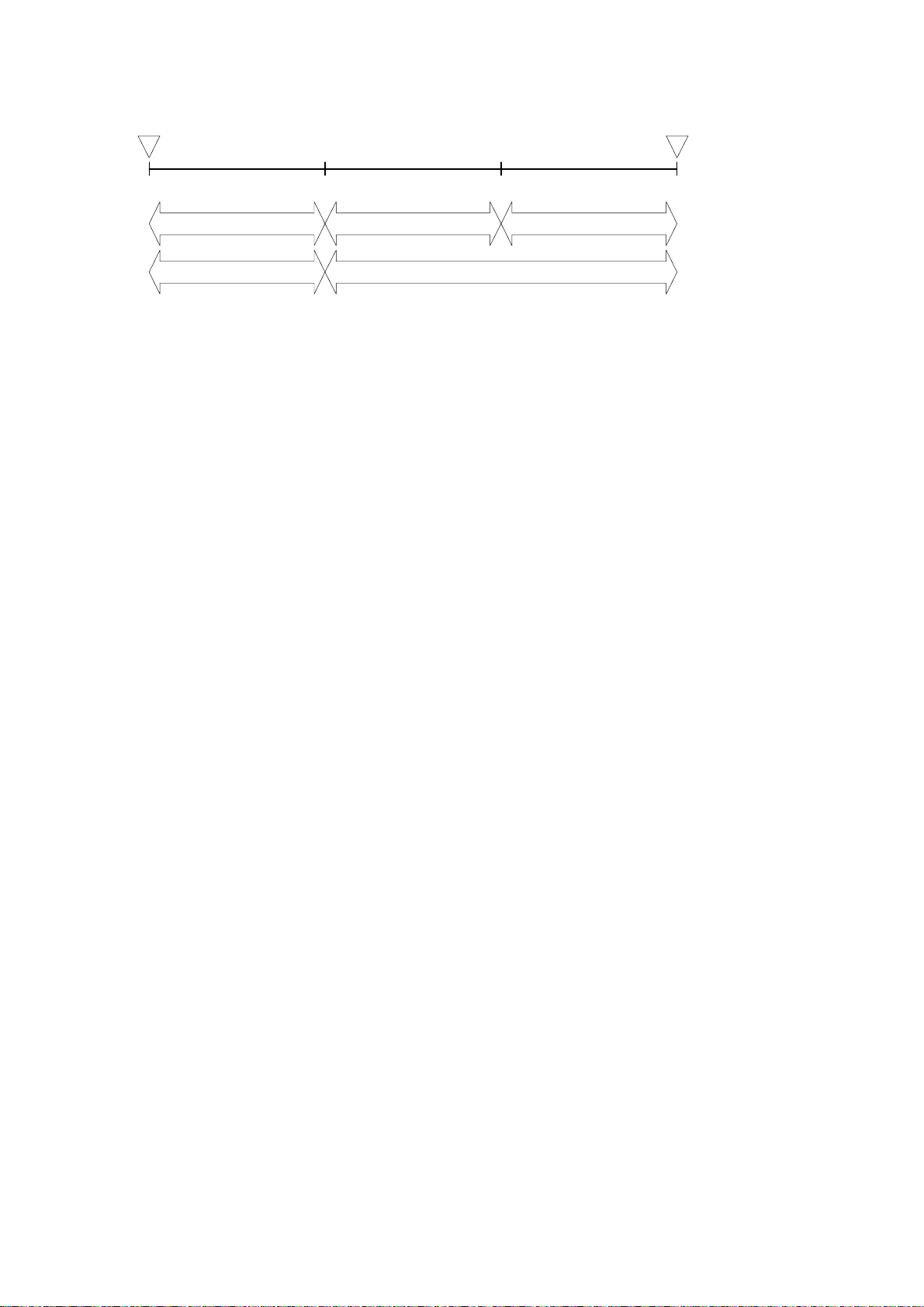

6.2.1 t(stir)[s], t(wait)[s], t(max)[s]

Start End

t(stir) t(wait) t(max)

No I2 generation I2 generation

a) t(stir) is the time that just stirrer is active.

b) t(wait) is the first possible time of titration termination.

Titration terminates here if drift stop level is reached.

c) t(max) is the time limit of titration.

titration time = t(stir) + t(wait) + t(max)

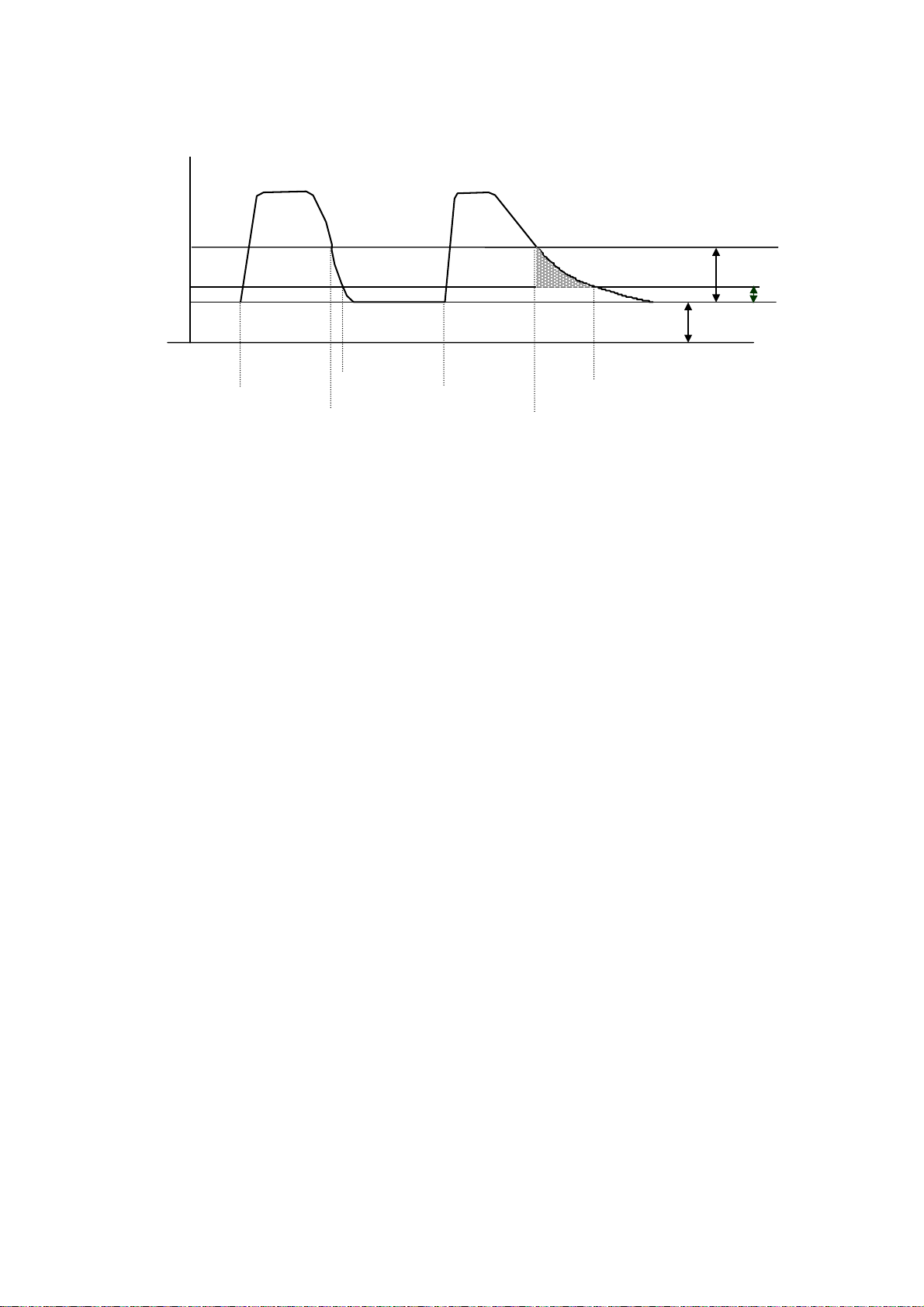

6.2.2 Drift stop : (rel / abs / off)

With the MKC-500 you have two possibilities to determine an endpoint.

a) Time Limit ( t(wait) + t(max) )

You define a fixed titration time. The titration stops after the defined time.

b) Drift stop

You define a drift stop. When the drift stop is reached, and the time "t(wait)"elapses, the titration stops.

You must define t(max) or Drift stop, or both.

If you define nothing, in other words t(max) 0 and Drift stop off, you get an error message: Para set miss!

Remarks regarding Drift stop

A high value of the Drift stop reduces the titration time, but the titration error increases, especially if the sample

releases its moisture slowly.

Repeated analysis of an oil sample sometimes causes a shift to a higher drift. In this case a low Drift stop setting

results in failure to detect the endpoint.

In the case of titrations with a sluggish approach towards the endpoint (due to side-reactions), a higher Drift stop

can help reduce the error.

18

Titration curves of a rapid and a slow moisture release with two Drift stop :

μgH2O/s

L1

L2

A

End2 End2

Start Start

End1 End1

A : Drift

L1 : High value for Drift stop

L2 : Low value for Drift stop

End1 : Endpoint with L1

End2 : Endpoint with L2

19

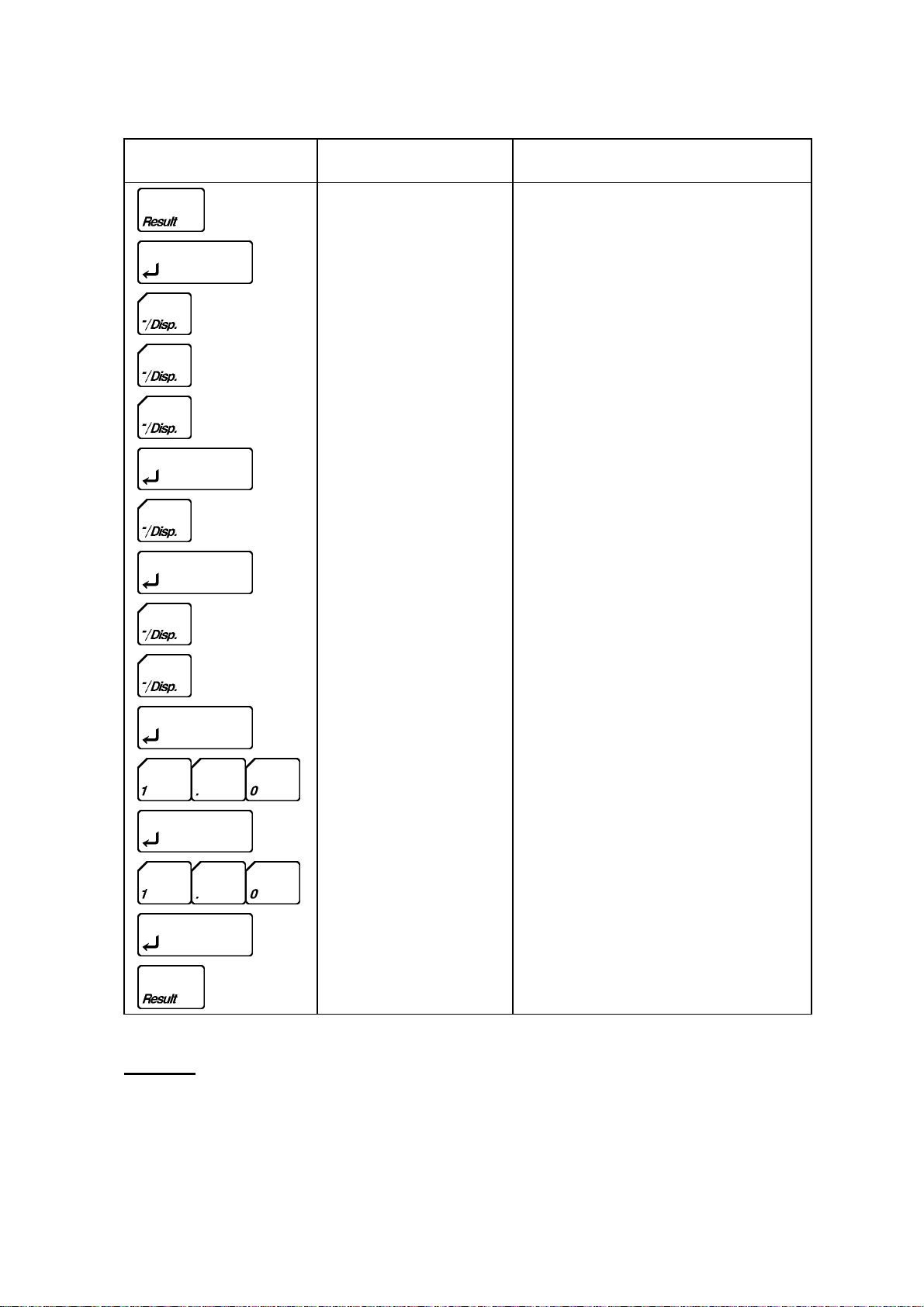

6.3 Calculation parameters

The four calculation parameters are part of the result parameters you can select in a method.

Entry Key Display Description

Calculation ↑

Unit :μg ↑ Set the calculation result unit

Unit : mg ↑

Unit : ppm ↑

Unit : % ↑

Weight : fix ↑ Select fixed or variable

Weight : var ↑

Drift comp : auto ↑ Set the drift compensation

Drift comp : off ↑

Drift comp : manu ↑

Drift? 0

Drift? 1.0

Blank? 0

Blank? 1.0

Calculation ↑

Drift is entered here [μg/s]

Blank is entered here [μg]

Note!

All parameters with the ↑ sign can be changed with the [ -/Disp. ] key.

All parameters with the ? sign require entry of a numeric value.

20

6.3.1 Calculation formula (by unit)

(

(

)

Formula No. Description Formula

1

2 Concent rat ion calculation for weighed

Formula No. is selected automatically by result unit.

Calculation Result unit Formula No.

μg or mg

ppm or %

Data : Result of th e titration (μg)

DL : Drift Level (μg/s)

T : Measurement time (s)

Blank : The value for subtraction of result (μg)

Wt1 : Weight of syringe with sample in it

Wt2 : Weight of empty syringe

Therefore, the sample weight = Wt1-Wt2

Moisture calculation

Result in μg or mg.

liquid or solid samples.

Result in ppm or %

1

2

When Drift comp:auto is selected, this value represents the drift at time [ Start ] key is pressed.

When Drift comp:manu is selected,this is manually input value.

When Drift stop:off ↑ is selected,t=(t(stir)+t(wait)+t(max)) (s)

When Drift stop:rel ↑ /abs ↑ is selected, t=<

Factor Data DL t Blank×−×−

Factor

t(stir)+t(wait)+t(max) (s)

Data DL t Blank

×

−×−

Wt1 Wt2

−

)

(ppm)

Note!

21

Even when ppm or % is selected for calculation results, if Wt1-Wt2=0, the

display will show the results in mg and printout in μg and mg.

6.3.2 Weight : (fix / var)

This parameter is necessary when calculation formula 2 is selected.

fix :

If you choose fix, you can enter fixed sample size by the sample key.

(MKC-500 doesn’t ask you to enter the sample size before or after the titration)

var :

If you choose var, you can enter the sample size by the sample key.

Input sample weight each time at measurement. If it is not input, the message on display will ask Operator for

Wt1 and Wt2 when titration is over.

6.3.3 Drift comp : (auto / off / manu)

auto : ( should be used normally )

The drift is automatically compensated by the measured value of the drift before sample injection.

off :

The drift is not compensated.

manu :

The drift is compensated by the value entered here.

6.3.4 Blank

The Blank is the amount of water that is added with a solvent or an extraction medium, or water that enters the

titration vessel while loading the sample.

This water doesn’t belong to the sample, the blank value has to be subtracted from the result.

6.3.5 Factor

The Factor is the value for multiplication of result. (see 9.4)

22

6.4 Parameters for Report

Net

The report parameters allow you to define the format of your report for a particular method.

With Short format , Date & Time, Sample No., Wt1, Wt2, Net and Result are automatically printed out.

With GLP format, Date & Time, Serial No., Sample No., Wt1, Wt2, Net, Factor, Result, Titration time, Drift,

Blank and Name are automatically printed out.

Entry Key Display Description

Calculation ↑

Report ↑ Set the report parameters

Short ↑

GLP ↑

Report ↑

Note!

You can change all parameters with the ↑ sign using the [ -/Disp. ] key.

Below shows comparison of print format between Short form and GLP:

<Short form>

Date : date and time of measurement

Sample No. : sample number

Wt1 : weight of syringe and sample weight

Wt2 : weight of syringe

Net : weight of sample

Result : amount of water (concentration or weight )

***Result***

Date 95/12/09 11:01

Sample No. 00-34

Wt1 42.5384g

Wt2 42.0213g

0.5171g

Result 1734.8μg

3354.9ppm

23

Net

N

<GLP form>

Date : date and time of measurement

Serial No. : production number of the instrument

Sample No. : sample number

Lot No. : lot number

Wt1 : weight of syringe and sample

Wt2 : weight of syringe

Net : sample weight

Factor : factor value

Result : amount of water(concent rat i o n or wei ght )

Titr. Time : measurement time

Drift : drift value

Blank : blank value

Name : name of operator

***Result***

Date 95/12/09 10:57

Serial No. LCA06202

Sample No. 00-33

Lot No. A960123

Wt1 42.5384 g

Wt2 42.0213 g

0.5171g

Factor 1.00

Result 1728.7μg

3343.0 ppm

Titr.Time 00:01:48

Drift 0.04 μg/s

Blank 0μg

ame KEM.TARO

24

6.5 Parameters for Sample

Desired parameters on the sample can be selected including sample number, lot number and sample size for

concentration calculation.

Entry Key Display Description

Sample No. ? 00 - 00 Enter sample number by numeric key.

Sample No. ? 01 - 00 Enter sample number of high order.

Sample No. ? 01 - 00

Sample No. ? 01 - 01 Enter sample number of low order.

Lot ? Enter lot number by [ -/Disp. ], [ ]and

Lot ? A32-01

Wt1 ? 5.0000

numeric keys.(up to ten characters)

Wt1 ? 4.1235

*Sample parameter can be input during titration.

*If Weight of calculation parameter is var ↑ and sample size is not entered, the display message will ask Operator

for Wt1 and Wt2 after titration is finished.

*Sample number of low order will be added up after each measurement.

Wt2 ? 0.0000

Wt2 ? 4.0173

Enter weight(g) of (syringe+sam pl e).

Enter weight(g) of syringe after sample is

injected.

25

Note!

If Wt1-Wt2 is set to zero(Wt1-Wt2=0) and ppm or % is selected for

calculation results, it will be shown in mg and printed in μg or mg.

Note!

All parameters with the ? sign require entry of a numeric value.

26

7. Example of actual operation

7.1 Status diagram of titration

Power ON

Pre-Titr blinks

Pre-Titr

Pretitration

Ready/Stable

Start

shows the mode of instrument

shows key input on MKC-500

Reset

Samm.In.↔Start

Reset

Start

Titration

27

7.2 Titration

With default parameters in a new MKC-500, you can start a titration without changing parameters.

Start of the first titration:

Set up the MKC-500 as described in chapter 4.3 and 5.

Turn on the power switch. "Pre-Titr" flashes on the display.

Start pretitration:.

Press the [ Pre-Titr ] key ; the pretitration will start.

Wait until the display shows "Stable".

The MKC-500 is now ready for titration.

Start titration:

Press the [ Start ] key.

The display : Samp. In.

Inject a sample using a syringe through the septum (for example 1 mL methanol).

Press the [ Start ] key again then the titration starts.

After the titration is finished, the result is displayed and printed out. (Printer is optional.)

The MKC-500 is now ready to start the next titration. The titration cell is kept free from water by continuous

titration. Press any key, then the display shows "Stable".

←→ Start

Entry Key Display Description

Pre-Titr (flashing) Standby

66 * Pre - Titr Pretitration

15 ⇒ Ready Wait until the display shows "Stable"

3 ⇒ Stable

3 ⇒ Samp.In. Inject the sample into the titration cell

3 ⇒ Start

43 * 45.8 μg

7 50.3 μg The result is displayed and printed

3 ⇒ Ready/Stable MKC-500 is ready for the next titration

28

Note!

The MKC-500 will shift to Reset condition after titration is finished, however,

it is recommended to press [ ↵ ] key after measurement results are recorded

so that the condition of the measuring cell can be checked to see if it is in

Ready or Stable.

Reset condition can be reached by other key than [ ↵ ], and other display

screen can be reached by pressing such keys as Parameter Setup or key for

separate display message screen.

Note!

If Drift Stop:off ↑ is selected and [ Reset ] key is pressed during titration, the

measurement results until [ Reset ] key is pressed will be printed out.

7.3 Pretitration

Turn on the power switch.

On the display "Pre-Titr" flashes (the MKC-500 is in the Standby mode).

Press the [ Pre-Titr. ] key in order to start pretitration.

If the stirrer is not active, press the [ Stirrer ] key and set stirrer speed (see also chapter 11.1)

After the pretitration the MKC-500 switches to the modes "Ready" and then, "Stable"

Status : Pre - Titr The solvent is titrated out.

Status : Ready The value of the drift is 10.0 μg H

Ready for rough measurement.

Status : Stable The change in the drift is 0.1 Δ μg H

Stable drift . Ready for accurate measurement.

The titration cell is kept water-free by continuous titration.

It is possible to start titration in "Ready" or "Stable" mode.

After the titration MKC-500 always returns to in mode "Ready" or "Stable" depending on the drift stability.

O / s or less.

2

O /min or less.

2

Entry Key Display Description

Drift not stable

3 ⇒ Stable High accuracy measurement ready

29

126 * Pre - Titr Pretitration in progress

21 ⇒ Ready Rough measurement ready

Drift stable

Note!

If you reconfigure the MKC-500 or replace the reagents, a high amount of

moisture will enter the titration cell. In this case it may take longer to achieve the

"Ready" and "Stable" status.

Display status Stable :

μg/s status Data

Drift level Status display

(μ gH

Stop Pretitration

In order to exit the status Pre-Titr, Ready or Stable, press the [ Reset ] key.

The status indicated on the display : "Pre-Titr" flashes.

During this time moisture (drift) is not titrated and the instrument is thus not ready to start titration.

To start pretitration, press the [ Pre-Titr ] key.

See also the chapter 7.1, Status diagram of titration.

. 0 3

O/s)

2

⇒

St abl e

30

7.4 Titration with Balance

With the MKC-500 you can enter the sample weight manually using the keypad or automatically when a

balance is connected.

You can activate the weight transfer by pressing the [ -/Disp. ] key

Connect MKC-500 and Balance.

Input sample number and lot number by Sample key, and leave it in waiting condition for Wt1.

Measure the weight of syringe filled with sample for measurement. Place the syringe on Balance and wait until

it becomes stable. Then, press [ -/Disp. ] key. The Wt1 will be read by MKC-500.

Press Start key and inject the sample, and then press Start to titrate. Place the syringe after the sample is injected.

When the display message asks for Wt2 after titration is over, press [ -/Disp. ] key to read Wt2.

Calculation results will be displayed at the end.

Entry Key Display Description

.01⇒Ready/Stable Waiting for titration start.

Sample No. ? 00 - 00 Enter sample number.

Sample No. ? 01 - 00 Enter sample number of high order.

Sample No. ? 01 - 00

Sample No. ? 01 - 01 Enter sample number of low order.

Lot ? Enter lot number by [ -/Disp. ], [ • ] or

numeric keys.

Lot ? A32-01

Wt1 ? 5.0000

31

Wt1 ? 4.3259 Read weight from Balance (syringe+sample)

Wt2 ? 0.0000

Start titration.

Entry Key Display Description

.01⇒Samp. In.

. 01⇒Start

33 * 1124.7μg

Wt2 ? 0.0000 Beep sounds to tell the end of titration with

Wt2 ? 4.0146 Weight of syringe has been read from

.03 4176.2ppm Measurement results are calculated and

.02⇒Ready/Stable Returns to Reset condition.

Now, inject sample into the cell.

Electrolysis begins and titration starts, and

the display will show the amount of water per

unit time and then titrated amount of water.

message asking for Wt2.

Balance.

displayed.

Note!

Even if the amount of Wt1-Wt2 becomes in minus, its absolute value will be

read.

32

8. Setup

8.1 General

The MKC-500 has 5 functions for additional possibilities, such as Interface, data & time, Name, Serial No.

Setup No.

0.Interface

1.Date & Time

2.Name

3.Serial No.

4.Cell Type

Setup [ 0-4 ] ?

↓

0. Interface

Interface : RS-232C / Printer / Balance

KEM/Mettler/A&D/Shimadzu/Sartorius

Printer: IDP-/DP-/Other

Baud rate: 300/600/1200/2400/4800/9600

Parity: even/odd/none

Data bits: 7/8

Stop bits: 1/2

(Caution: The parameters of IDP-and

DP-are fixed.)

Baud rate: 300/600/1200/2400/4800/9600

Parity: even/odd/none

Data bits: 7/8

Stop bits: 1/2

Soft HS: off/on

33

1. Date & Time

YY MM DD ? ( 6 numbers )

HH MM ? ( 4 numbers )

2. Name

Name ( 15 characters )

3. Serial No.

Serial No.

4. Cell Type

With Diap h r agm ↑

Diaphragmless ↑

Note!

Press the key when closing parameter setup. The display will return to the

screen for selection of Setup number. To return to the previous display from

Selection of Setup number, press [ Setup ] or [ Esc. ] key.

Note!

All parameters with the ↑ sign can be changed with the [ -/Disp. ] key.

All parameters with the ? sign require entry of a numeric value.

34

8.2 Interface (Setup 0)

The MKC-500 has three interface for the connection, RS-232C, Balance and Printer.

With this function you can set the configuration of the interface.

RS-232C

MKC-500 can communicate with external device via RS-232C cable. Here you will set up necessary protocol to

match digital configuration.

Entry Key Display Description

Setup [ 0-4 ] ?

Setup [ 0-4 ] ? 0

Interface

RS232C↑ Select the RS-232C.

Baud rate : 4800↑ Select the Baud rate.

Baud rate : 9600↑ Choose fr om 300, 600, 1200, 2400, 4800 and

Parity : none↑ Select the Parity.

Parity : even↑ Choose from even, odd and none.

Data bits : 8↑ Select the Data bits

Data bits : 7↑ Choose from 7 and 8

Stop bits : 1↑ Select the Stop bits

Stop bits : 2↑ Choose from 1 and 2

Soft HS : off↑ Select the Soft Hand Shake.

Soft HS : on↑ Choose from off and on

9600 Baud.

Setup [ 0-4 ] ?

Note!

For details of data communication via RS-232C, refer to MKC-500 Serial

Communication Manual.

35

Balance

When an electronic balance is connected to MKC-500, sample weight from Balance can be read automatically to the

MKC-500. Here is how to enter keys to match your Balance.

Entry Key Display Description

Setup [ 0-4 ] ?

Setup [ 0-4 ] ? 0

Interface

RS-232C↑

Balance↑

Bal : KEM↑

Bal : A & D↑

Setup [ 0-4 ] ?

Select the RS-232C.

Select the Balance.

Select the type of Balance.

Choose from KEM,Mettler, A & D,

Shimadzu and Sartorius

Printer

Optional printer can be connected as follows.

Entry Key Display Description

Setup [ 0-4 ] ?

Setup [ 0-4 ] ? 0

Interface

RS232C↑ Select the RS-232C.

Balance↑ Select the Balance.

Printer↑ Select the Printer.

Printer : IDP-↑ Select the type of printer.

36

Entry Key Display Description

Printer : DP-↑ Choose from IDP-,DP-, and Other

Printer : Other↑

Baud rate : 4800↑

Baud rate : 9600↑ Choose from 300, 600, 1200, 2400,4800 and

Parity : none↑ Select the Parity.

Parity : even↑ Choose from even, odd and none.

Data bits : 8↑ Select the Data bits

Data bits : 7↑ Choose from 7 and 8

Select the Baud rate.

9600 Baud.

Stop bits : 1↑ Select the Stop bits

Stop bits : 2↑ Choose from 1 and 2

Setup [ 0-4 ] ?

Note!

The parameters of IDP- and DP- are fixed.

37

MKC-500 interface pin assignment

RS-232C

(1) (2) (3) (4) (5)

(6) (7) (8) (9)

GND

DTR

TXD

RTS

RXD

DSR

Balance

(1) (2) (3) (4) (5)

(6) (7) (8) (9)

GND

DTR

TXD

RXD

Printer

(1) (2) (3) (4) (5)

(6) (7) (8) (9)

GND

TXD

BUSY

38

8.3 Date & Time (Setup 1)

With this function you can set Date and Time.

Once date and time is input on MKC-500, the measurement date and time will be automatically printed out on

Printer. The stored date and time will be kept in good time by clock function of MKC-500 unless backup battery

runs down or the date and time is changed otherwise.

Entry Display Description

Setup [ 0-4 ] ?

Setup [ 0-4 ] ? 1

Date & Time

YY MM DD? 950601 Enter year, month and day

YY MM DD? 960204

HH MM? 1000

HH MM? 1330

Enter hour and minute

Setup [ 0-4 ] ?

39

8.4 User Name (Setup 2)

With this function you can set User name.

Entry Display Description

Setup [ 0-4 ] ?

Setup [ 0-4 ] ? 2

Name

_ Enter User name

A

Use the [ -/Disp. ], [•] and numeric keys.

A_

AB

Setup [ 0-4 ] ?

Note!

Characters can be shifted automatically by keeping [ -/Disp ] and [ • ] keys

pressed.

40

8.5 Serial No. (Setup 3)

With this function you can check the serial No.

Entry Display Description

Setup [ 0-4 ] ?

Setup [ 0-4 ] ? 3

Individual serial number of the unit is input in plant before shipment.

Serial No.

LC60420 The serial number is displayed

Setup [ 0-4 ] ?

Note!

Serial number can only be checked and confirmed but not for changing the

number itself.

41

8.6 Cell Type (Setup 4)

Set the cell type for measurement (2-component or 1-component).

Press [Setup] key.

Entry Display Description

Setup [ 0-4 ] ?

Setup [ 0-4 ] ? 4

Cell Type

Select “Setup 4”.

With Diap h r agm

Diaphragmless

With Diap h r agm

Setup [ 0-4 ] ?

Select the cell type with [←] [→] key.

* With Diaphragm: 2-component cell (with diaphragm)

Selected when two reagents, Anolyte and Catholyte,

are used.

* Diaphragmless: 1-component cell (without diaphragm)

Selected when only Anolyte is used.

Note!

Characters can be shifted automatically by keeping [ -/Disp ] and [ • ] keys

pressed.

42

9. Function

9.1 General

The MKC-500 has 4 functions for additional possibilities, such as reagent capacity, recalculation, factor, memory

clear.

Function No.

0. Reagent capacity

1. Recalculation

2. Factor

3. Memory clear

Function [ 0-3 ] ?

↓

0. Reagent capacity

A . Capa. [mg] ? ( 4 numbers )

C . Capa. [mg] ? ( 4 numbers )

Alarm Set : off / o n

A . Alarm [mg] ? ( 4 numbers )

C . Alarm [mg] ? ( 4 numbers )

1. Recalculation

Unit:μg / mg / ppm / %

Wt1 ? ( 8 numbers )

Wt2 ? ( 8 numbers )

Drift ? ( 5 numbers )

Blank ? ( 5 numbers )

2. Factor

Factor ? (5 numbers )

3. Memory clear

Memory clr. off / on

43

Note!

Press the key when closing parameter setup. The display will return to the

screen for Selection of Setup number. To return to the previous display from

Selection of Setup number, press [ Setup ] or [ Esc. ] key.

Note!

All parameters with the ↑ sign can be changed with the [ -/Disp. ] key.

All parameters with the ? sign require entry of a numeric value.

9.2 For Reagent life control and Alarm setting (Function 0)

The Karl Fischer reagent for coulometric titration has reagent capacity for measurement of water content.

Generally, 1000mg H

capacity for moisture measurement.(For details, see Instruction of the reagent you have purchased.) Exhausted

overdue reagent will lead to longer titration time, too low in the results or too high in the drift.

The MKC-500 can show you update reagent capacity that has been calculated from coulomb used in

electrolysis during moisture titration, and will let you know by alarm when the reagent has reached its preset

limit of capacity.

Function 0 provides the following functions:

* Displays reagent capacity both anolyte and catholyte.

* Clear incremented capacity to zero when reagents are replaced.

* Enter limit value for capacity. (Beep alarm can be switched by off/on.).

O for 100mL anolyte and 300mg H2O for 5mL catholyte are the approximate limit of

2

44

Entry Key Display Description

Function [ 0-3 ] ?

Function [ 0-3 ] ? 0

Reagent capacity

A. Capa. [mg]? xxxx Accumulated electrolytic current (moisture-

A. Capa. [mg]? 0 Enter 0 on anolyte replacement to delete

C. Capa. [mg]? xxxx

C. Capa [mg]? 0 Enter 0 on catholyte replacement to delete

Alarm set : off↑ Select alarm/no-alarm status for

Alarm set : on↑

A.Alarm [mg]? 1000 Enter alarm limit (mg H

A.Alarm [mg]? 500

C.Alarm [mg]? 300 Enter alarm limit (mg H

C.Alarm [mg]? 200

converted) of anolyte is displayed (mg H

accumulated value (reagentcapacity)

Accumulated electrolytic current

(moisture-converted) of catholyte is

displayed (mg H

accumulated value (reagent capacity).

reagent capacity.

capacity.

capacity.

2

O)

O) of anolyte

2

O) of catholyte

2

O)

2

Function [ 0-3 ] ?

Note

How to cancel alarm and display when Alarm set: on ↑ is selected:

when preset moisture-converted reagent life is reached, alarm by beep and

blinking message will be activated. To cancel the alarm, press any key (eg; [ ↵ ]

key, [ Esc. ] key, Numeric key, etc.) just like for ordinary operation after

measurement is finished. It is recommended to replace the reagents

immediately after the alarm has been turned off.

45

9.3 Recalculation (Function 1 )

If expected measurement results have not been obtained due to wrong parameter settings or erroneously input

sample weight, the measurement can be recalculated with correct parameters.

The recalculated results are printed out with (#) mark.

Entry Display Description

Function [ 0-3 ] ?

Function [ 0-3 ] ? 1

Recalculation

Select Function 1 for recalculation

Unit : μg↑ Select result unit.

Unit : ppm↑

Wt1 ? 5.0000 To correct sample weight, use [ • ] or numeric

Wt1 ? 4.37

Wt2 ? 0.000

Wt2 ? 3.86

keys for Wt1, Wt2.

(μg, mg, ppm, %)

Drift ? 0.03 The first display is for drift value.

Blank ? 0 Then, enter Blank value.

1325.4ppm

Function [ 0-3 ] ?

Recalculated results are displayed and

printed.

46

Note!

Net

N

Even when ppm or % is selected, if Wt1-Wt2 is zero(Wt1-Wt2=0), the

recalculated results will be shown in mg, and printed in μg or mg.

Note!

For recalculation with new factor value, enter the corrected factor before

recalculation.

Shown below is an example of recalculated results in ordinary print format.

Printed in short form Printed in GLP form

[ Recalculation ]

Date 95/12/09 11:01

Sample No. 00-34 (#)

Wt1 42.5384 g

Wt2 42.0213 g

Net 0.5171 g

Result 1734.8 μg

3354.9 ppm

[ Recalculation ]

Date 95/12/09 10:57

Serial No. LCA06202

Sample No. 00-33 (#)

Lot No. A960123

Wt1 42.5384 g

Wt2 42.0213 g

0.5171 g

Factor 1.00

Result 1728.7 μg

3343.0 ppm

Titr. Time 00:01:48

Drift 0.04 μg/s

Blank 0 μg

ame KEM.TARO

47

9.4 Factor value setup (Function 2)

The MKC-500 is Karl Fischer Moisture Titrator and does not require Factor valu e unlike volumetric titration,

however, the factor can be set up in order to adjust measurement according to the effect of sample or the syringe

that is used for sampling.

This factor value will be added in the equation for calculation.

Entry Display Description

Function [ 0-3 ] ?

Function [ 0-3 ] ? 2

Factor

Factor ? 1.00 Enter factor value by [ • ] and numeric

Factor ? 0.998 Confirm the factor value.

Select Function 2 for factor entry.

keys.

Function [ 0-3 ] ?

48

9.5 Initialize to default (Function 3)

All the stored parameters can be cancelled and reversed to default values initially input in plant before shipment

by Function 3.

Entry Display Description

Function [ 0-3 ] ?

Function [ 0-3 ] ? 3

Memory clr.

Memory clr. : off↑

Memory clr. : on↑ Select to clear memory.

Function [ 0-3 ] When beep sounds, turn off the

SRAM Init. Press any key (eg; [↵] key). It beeps.

Select Function 3 to clear saved data.

switch, and then, turn it on after five

(5) seconds.

Note!

C. Moisture. Titr. This message turns on for two (2)

Pre-Titr

seconds.

All the data has been cleared, and it

returns to initial display.

Setup function will not be affected by initializing the parameter.

49

10. Initializing parameters and default values

The procedure of initialization of parameters to default is described in 9.5. All the data of parameters are reversed to

default values, which are preset in plant before shipment.

Parameter Default value

Titration t(stir) [ s ] ? 0s

t(wait) [ s ] ? 15s

t(max) [ s ] ? 0s

Drift stop rel 0.1μg/s

Result Calculation↑

Calculation Unit μg↑

Weight fix↑

Drift comp auto↑

Drift comp : manu↑

Drift ? 0.0μg/s

Blank ? 0μg

Report Short↑

Sample Sample No. ? 00-00

Lot ?

Wt1 ? 5.0000g

Wt2 ? 0.0000g

Function

Reagent capacity A.Capa. [mg] 0mg

C.Capa. [mg] 0mg

Alarm set off↑

Alarm set : on↑

A.Alarm [mg] ? 1000mg

C.Alarm [mg] ? 300mg

Recalculation Unit μg↑

Wt1 ? 5.0000g

Wt2 ? 0.0000g

Drift ? 0.0μg/s

Blank ? 0μg

Factor 1.00

Memory clr. off↑

Stirrer Speed [ 0-9 ] 4

Note!

The Setup function is not affected by the initialization.

50

11. Special Keys

The MKC-500 has several special keys.

These Keys are :

the Stirrer Key stirrer speed control

the Esc. Key reverse parameters to previous settings

the BS. Key reverse key entry by one space

the Clr. Key erase all key entries

the -/Disp Key switch function

the Print Key printer operation

the Reset Key interruption of a titration

11.1 The Stirrer Key

With the [ Stirrer ] key you can control the magnet stirrer in the titration cell.

You can set the speed of the magnetic stirrer. You can choose stirring speed from 0 to 9 (0 stops the stirrer).

For a titration under normal conditions use stirrer speed 4-6.

Entry Key Display Description

Speed [0-9] ? 3 The stirrer runs with speed 3

Speed [0-9] ? 4 The stirrer runs with speed 4

Speed [0-9] ? 5 The stirrer runs with speed 5

11.2 The Esc. Key

With the [ Esc. ] key you can quit the parameter entry.

If you want to change only the first parameter of a list, you can quit the parameter list with the [ Esc. ] key after

you have changed the parameter.

You can not interrupt a printout with the [ Esc. ] key.

11.3.The BS. Key

By this key, you can erase the key entry by reversing one space.

51

11.4 The Clr. Key

With the [ Clr. ] key you can clear the numbers and characters that have been entered.

11.5 The -/Disp. Key

1. Switch function in the parameter setting

Many parameters do not require entry of a value but have to be chosen from a given list, for example :

Drift stop : rel↑/ abs↑ / off↑

Weight : fix↑ / var↑

Printer : IDP- ↑/ DP- ↑/ Other↑

With the [ -/Disp. ] key you can change these parameters.

General : All parameters with the ↑ sign can be changed with the [ -/Disp. ] key.

2. Switch to automatic weight transfer from a connected balance

The sample weight can be entered manually or by pressing the [ -/Disp. ] key. The weight will then be

transferred from the connected balance.

3. Toggle between μg and mV

While a titration is running the information on the display can be toggled with the [ -/Disp ] key.

It toggles between μg and mV.

11.6 The Print Key

With the [ Print ] key you can print out parameters.

Entry Key Description

Printout of the titration parameters.

Printout of the calculation and

Press key, display

"Calculation↑" then

Press key, display

"Report↑" then

and then

and then

reportparameters.

Printout of the calculation parameters

Printout of the report parameters

Printout of the Setup parameters

Printout of the Function parameters

(within 1 s)

Printout of all of parameters

(titration, result, fanction and setup

parameters)

52

11.7 The Reset Key

With the [ Reset ] key you can interrupt a titration.

If you press the [ Reset ] key the titration will immediately be interrupted and the MKC-500 will return to the

"ready" or "stable" mode. No results will be calculated or printed.

Note!

If you have defined Drift Stop "off" (you have defined a titration time limit),

a result will be calculated with the titrated water until the interruption and

the entered weight ; the results are displayed and printed out. There is thus

a possibility to terminate a titration before the defined time limit is reached.

53

12. Maintenance

Please follow the below instructions in order to maintain the MKC-500 in good working condition.

12.1 Application of grease

Apply KF grease over the glass contact areas. Turn the parts approximately once a week to ensure they rotate

smoothly ; if not, apply a thin coating of grease.

Parts may otherwise stick and be difficult to separate. Do not apply too much grease as it may penetrate the

titration cell and increase the background owing to the water content of the grease.

Check the glass joints from time to time so that applied grease will not

solidifies. If it should stick to the glass, follow the instruction in 14.8.

12.2 Septum replacement

Change the syringe inlet port septum occasionally. An old septum is easily broken and allows air to enter the

titration cell thereby increasing the background.

12.3 Silica gel replacement

CAUTION

Replace the desiccator silica gel from time to time. When the silca gel in the titration vessel turns reddish, its

hygroscopic properties are impaired and it must be replaced immediately.

Also apply KF grease over the contact areas of the titration cell desiccator.

12.4 Anolyte replacement

Replace about 100mL of anolyte in the following cases :

• when the reagent capacity ( mg H

• if the liquid ( with added sample ) in the titration cell has exceeded the level mark "150",the diluted anolyte

will cause poor sensitivity and extended measurement time,

• when the drift level becomes too high.

O ) has reached 1000 mg H2O as indicated using Setup 1 "A.Capa",

2

Note!

Add 20 mL of ethylene glycol when measuring vaporized moisture or

gaseous samples.

Note!

After the replacement, enter "0" in Function 0 "A.Capa" to delete the

accumulated electrolytic current ( moisture-converted ) of anolyte ( reagent

capacity). ( See page 9.2)

54

12.5 Catholyte replacement (Not necessary for 1-component cell)

Replace about 5mL of catholyte in the following cases:

⋅ when the reagent capacity ( mg H

⋅ when about 5mL of background level is excessive,

⋅ one week after replacement of a reagent.

Periodic catholyte replacement is important. Otherwise the drift level will increase and the membrane could

become contaminated with foreign matter causing measurement errors.

O ) has reached 300 mg H2O as indicated by Setup 1 command,

2

Note!

Adjust the catholyte level to the lower mark on the titration cell.

Note!

After replacement, select Function 0, enter "0" up to "C.Capa",

accumulated electrolytic current ( moisture-converted ) of catholyte is set

to zero. ( See 9.2)

Caution

Karl Fischer Reagents are potentially hazardous. Do not inhale or allow skin

contact.

Replacement should be performed in a fume hood. Reagent should never be

poured down the drain.

12.6 Long-term storage measures

Plug out the power cord, and store the instrument in a room dry and cool without direct sunlight nor

vibration.It is recommended to pack in the unit in the box in wh ich the MKC-500 was delivered when you

purchased.

It is advisable to clean and dry the titration cell unit and keep it disassembled in a desiccator.

For cleaning and drying details, see chapter 12.7~12.9.

55

12.7 Cleaning detection electrode

f

When sample impurities have adhered to the platinum pins of the electrode, first wash with concentrated nitric

acid, then with methanol.

12.8 Cleaning inner burette

12.8.1 Cleaning steps

(1) Clean using alcohol

⋅ Press the [ Reset ] key.

The "Pre-Titr" display flashes.

⋅ Remove the inner burette from the titration cell and drain the catholyte.

⋅ Remove grease from contact areas with methanol.

⋅ Inject methanol into the cathode of the inner burette two or three times, then inject about 10 mL of

methanol. Place the inner burette in a beaker.

⋅ Add methanol to the beaker until it reaches the methanol level in the cathode. Let stand for about 30

minutes.

⋅ Follow the Drying Instructions below.

(2) Clean using chromic acid ( when foreign matter has built up on the membrane and the platinum surface ).

⋅ Use chromic acid instead of methanol in the steps above. Let stand overnight.

⋅ Drain the liquid out of the cathode. Repeat 5 or 6 times : Wash the cathode with pure water until the

yellowish color disappears. ( Rinse the chromic acid off the membrane.)

⋅ Follow the Drying Instructions below.

Note!

Chromic acid cleaning dissolution. Prepare by dissolving about 1.5 g of

potassium dichromate in 100 mL of sulfuric acid.

Chromic acid mixture is a highly reactive oxidizer. It is recommended to

wear protective gloves and glasses while you handle the acid. If it should

contact your skin, wash it away with abundant running water.

Chrome is a toxic heavy metal. Do not discard waste chrome or its solvent

into the sewer.

Dilute chromic acid mixture to 1% for reduction, and after no more existence

of Cr

For more details, please refer to documentations on how to dispose o

heavy metals.

CAUTION About chromic acid mixture

+6

is confirmed, adjust it to pH7.5 to 8.5, and filter it for storage.

56

12.8.2 Drying steps

(1) Warm air drying with a hair dryer.

• Blow warm air on the membrane until dry ( about 10 minutes).

(2) Drying with a vacuum dryer

• Place in a vacuum chamber for 2 hours or longer. This is more effective than using a hair dryer. A vacuum

dryer is very effective.

Low Pressure Dryer Vacuum Constant-temperature Dryer

12.8.3 Adjusting the length between anode and membrane

When the length between anode and membrane in inner buret is too close, it is impossible to electrolyte

correctly. In this case, insert the anode adjuster between anode and membrane on a level.

12.9 Cleaning and drying the measuring cell

* Remove Detection electrode, Inner buret and Sampling port stopper, and then drain out the reagent.

* Wipe off the grease around jointed parts with methanol.

* Rinse by neutral detergent under run ni n g water.

* After drying the glass ware in a heater dryer, either cool them in desiccator or dry them according to 12.8.2.

Note!

If the measuring cell is not dried well, the drift will show higher value.

Do not clean the inner cell in an ultrasonic cleaner because the inner cell is

precision made and it may break.

CAUTION About cleaning inner cell

57

12.10 Replacement of power fuse

(1) Turn off the power and plug out the cord.

(2) Open the box cover above power inlet by a flat screw driver.

(3) Pull out the two fuse holder using the screw driver.

(4) Replace the broken fuse by inserting new fuse to the same arrow direction of cover and holder, and close

the cover.

Open cover by driver Pull out fuse Same arrow direction Close cover

Danger of electric shock.

Before you replace the fuse, turn off power and plug out the cord.

WARNING

12.11 Backup battery

If the built-in backup battery energy runs down, the built-in clock will not keep correct time. When the b attery

needs to be replaced, please contact your local dealer or distributor.

58

13. Karl Fischer reagent

t

p

For Karl Fischer titration, appropriate reagent must be selected to the sample that you are going to analyze. Belo w

chart shows the type of sample and its corresponding reagents available on the market.

• For 2-component cell

Riedel-de Haën

Corresponding

Coulomat Aquamicron

General titration

Alcohols

Hydrocarbons

Ethers

Esters

Ketones Coulomat AK

Gases Coulomat AG

Fats and Oils Coulomat AG-H

Amines Coulomat AG

Karl Fischer

Sam

le

reagen

Coulomat AG

Coulomat CG

Coulomat CG-K

Coulomat AK

Coulomat CK

Coulomat CG

Coulomat CG

Coulomat CG

To use Coulomat AG,

add acetic acid, salicylate

or benzoic acid to 20% of

100mL of Coulomat AG.

MITSUBISHI

Aquamicron AX

Aquamicron CXU

Aquamicron AX

Aquamicron CX

Aquamicron AKS

Aquamicron CXU

Aquamicron AKS

Aquamicron CKS

Aquamicron AX

Aquamicron CXU

Aquamicron AX

Aquamicron CX

Aquamicron AX

Aquamicron CXU

Aquamicron AX

Aquamicron CX

Aquamicron AX

Aquamicron CXU

To use Aquamicron

AX, add 10g salicylate

acid to 100mL

Aquamicron AX.

Remarks

Coulomat AG/CG,

Aquamicron AX/CXU

are non-organic chlorines.

Formaldehyde can only be

titrated among other

aldehydes.

Coulomat CG-K

Aquamicron CXU are

non-organic chlorines.

Coulomat AG-H/CG,

Aquamicron AX/CXU are

non-organic chlorines.

To add, neutralize a basic

amine with an acid.

59

• For 1-component cell

t

p

Riedel-de Haën

Corresponding

Coulomat

General titration

Alcohols

Hydrocarbons

Ethers

Esters

Ketones Coulomat AK Formaldehyde can only be titrated

Gases Coulomat AG

Fats and Oils Coulomat AG-H

Amines Coulomat AG

Karl Fischer

Sam

le

reagen

Coulomat AG

To use Coulomat AG, add acetic

acid, salicylate or benzoic acid to

20% of 100mL of Coulomat AG.

Remarks

among other aldehydes.

To add, neutralize a basic amine with an

acid.

60

14. Troubleshooting

14.1 Error messages and malfunction rectification

Error message Cause Rectification

A.Capacity Over!

C.Capacity Over!

Current Error!

Elect Open!

Elect Short!

Meas. Over!

Over Titr.!

Para set miss!

Pre Amp Err-XX Inside Pre Amp of instrument is not

Accumulated electrolytic current

(moisture-converted)of anolyte has

exceeded anolyte capacity limit.

Accumulated electrolytic current

(moisture-converted)of catholyte has

exceeded catholyte capacity limit.

No electrolytic current flows.

No current to Detection electrode. • Check electrode for breakage or poor

Detection electrode is shorted or cell

potential is very low.

Moisture content measured has exceeded

100 mg H

Over-titration.

Excessive iodine is generated by anolyte

with time.

time(max):0s and Drift stop off ↑ have

both been set.

working correctly.

2

O.

• Replace anolyte.

• Reset A.capacity value.

• Replace catholyte.

• Reset C.capacity value.

• Sample liquid resistance is too great.

• Check anode and cathode for breakage

or poor contact.

• Make sure connectors are plugged in.

contact.

• Make sure connectors are plugged in.

• Check electrode connector for short-

circuit.

• Check cell potential and add water to

raise above 200mV.

Replace catholyte (anolyte if necessary),

make background level stable and

remeasure a smaller quantity sample.

• Clean anode if stained with foreign

matter.

• Move unit to another place if exposed

to direct sunlight.

• In case of pre-titration, add a little water

to cell.

• Set Drift stop rel ↑or abs ↑.

• Set t(max).

Please contact your local dealer or

distributor.

Note!

Press [ Reset ] key to exit from error message.

If the error message remains after all, contact your local dealer or distributor.

61

14.2 Power switch failure

START

Power outlet OK ?

YES

Fuse OK ?

YES

Voltage select OK ?

YES

Repair by

Manufacturer

NO

Collect power outlet

NO

Replace voltage selector fuse

NO

Set voltage selector properly

NO

AC Line voltage Fuse Hz

100 V 90 - 121V T3.15 A/250V 50/60

120 V 103 - 132V T3.15 A/250V 50/60

220 V 198 - 242 V T1.6 A/250V 50/60

230 V 207 - 253 V T1.6 A/250V 50/60

240 V 216 - 264 V T1.6 A/250V 50/60

We accept no responsibility whatsoever for any fault in or damage to the electrical circuit caused by wrong setting of

the voltage selector.

For continued protection against risk of fire.

Replace only with same type and ratings of fuse.

Everything OK ?

YES

END

CAUTION

62

14.3 Stirrer malfunction

START

Setting stirrer speed

with Stirrer key possible?

YES

Stir speed correct?

YES

Stirrer motor working?

YES

Rotor size OK?

YES

Foreign substance

in the titration cell?

NO

Rotor hopping?

NO

NO

Stirrer control impossible.

Repair by manufacturer.

NO