KEM DCU-551 Operation Manual

Auto Clean and Sampling Unit

DCU-551

Operation Manual

Please read this manual thoroughly in advance for the best performance of the equipment.

Ver.09

A/N 98-595-0456

Table of contents Page

1. General...................................................................................................................................................................... 1

1-1. Introduction................................................................................................................................................... 1

1-2. About the manual .......................................................................................................................................... 2

1-3. Safety symbols..................................................................................................................................... 3

2. Preparation ................................................................................................................................................................ 6

2-1. Supplied parts................................................................................................................................................ 6

2-1-1. DCU-551 supplied parts.................................................................................................................... 6

2-1-2. Optional parts .................................................................................................................................... 9

2-2. Installation and start-up preparation............................................................................................................ 10

2-2-1. Supplied power................................................................................................................................ 10

2-2-2. Connecting the cable ....................................................................................................................... 11

2-2-3. Turning on the power ...................................................................................................................... 11

2-2-4. Connecting the tube lines ................................................................................................................ 12

2-2-5. Installation of desiccant tube........................................................................................................... 17

2-2-6. Connecting the drain tube................................................................................................................ 18

2-2-7. Supply of rinse solvent.................................................................................................................... 19

2-2-8. Install the cover ............................................................................................................................... 20

2-3. Parts configuration ...................................................................................................................................... 21

2-4. Function of each key (general).................................................................................................................... 23

2-5. Description of display messages ................................................................................................................. 24

3. Basic procedure of measurement ............................................................................................................................ 25

3-1. Flow of measurement proceedings.............................................................................................................. 25

3-2. Prepare the measuring unit.......................................................................................................................... 26

3-2-1. Typical parameter settings............................................................................................................... 26

3-2-2. Changer setup.................................................................................................................................. 28

3-2-3. Method setup ................................................................................................................................... 29

3-3. Preparation of degassed pure water and sample.......................................................................................... 32

3-4. Setting sample conditions............................................................................................................................ 33

3-4-1. Sample number and ID setup .......................................................................................................... 33

3-4-2. When setting measurement conditions for each sample.................................................................. 33

3-5. Calibrating the measuring cell and how to measure.................................................................................... 37

4. Making the best use of the unit ............................................................................................................................... 38

4-1. Setup function ............................................................................................................................................. 38

4-1-1. Outline............................................................................................................................................. 38

4-1-2. Automatic change-over of sampling speed (Setup 1: Sampling Speed).......................................... 38

4-1-3. Event mode setup (Setup 2: Sequence Mode)................................................................................. 38

4-1-4. Print and external I/O setup (Setup 3: Interface)............................................................................. 40

4-1-5. Beep setup (Setup 4: Beep) ............................................................................................................. 40

4-1-6. Display contrast (Setup 5: LCD Contrast)....................................................................................... 41

4-1-7. Production number and software version (Setup 6: Serial/Version No.) ........................................ 41

4-1-8. Maintenance check (Setup 7: Maintenance).................................................................................... 41

4-2. Optional printer (IDP-100) ..........................................................................................................................44

4-2-1. Connecting printer............................................................................................................................44

4-2-2. Print the parameters .........................................................................................................................45

4-3. RS-232C interface........................................................................................................................................46

4-4. Typical parameter value for using [Rinse/Purge] ........................................................................................48

5. Maintenance ............................................................................................................................................................49

5-1. Daily checkup ..............................................................................................................................................49

5-1-1. Replace silica gel .............................................................................................................................49

5-1-2. Check rinsing solution .....................................................................................................................49

5-1-3. Check and wash Rinsing pot............................................................................................................50

5-1-4. Check and replace nozzle packing ...................................................................................................50

5-1-5. Fasten tube joint more firmly before measurement..........................................................................51

5-2. Other Maintenance.......................................................................................................................................52

5-2-1. Maintenance of Nozzle unit .............................................................................................................52

5-2-2. How to adjust nozzle unit and Rinsing Pot ......................................................................................56

5-2-3. Replace Tubes..................................................................................................................................57

5-2-4. Changing air intake fan filter ...........................................................................................................58

5-2-5. Replace the filter for Rinsing Solution.............................................................................................58

5-2-6. Maintenance of pump unit ...............................................................................................................59

5-2-7. Replacement of pump tube...............................................................................................................62

5-2-8. Chemical resistance of pump tube ...................................................................................................63

6. In Case of Troubles .................................................................................................................................................64

6-1. Error Message-When Auto Operations Stop ...............................................................................................64

6-1-1. Error Messages on Auto Clean and Sampling Unit .........................................................................64

6-1-2. Error Messages on General-purpose concentration meters, Density/specific gravity meters and

Refractometers............................................................................................................................................64

6-2. Troubleshooting...........................................................................................................................................65

6-2-1. When power does not turn on ..........................................................................................................65

6-2-2. When repeatability of measuring results is poor or deviated ...........................................................66

6-2-3. Slow sampling rate or no sampling..................................................................................................67

6-2-4. When the measuring cell is not be dried out ....................................................................................68

7. Others ......................................................................................................................................................................69

7-1. Part list .........................................................................................................................................................69

7-2. System Configuration ..................................................................................................................................74

7-3. Technical Data on the instrument ................................................................................................................75

7-4. Reference .....................................................................................................................................................76

7-4-1. Sample viscosity and sampling time ................................................................................................76

7-4-2. Tube lines flow chart........................................................................................................................77

7-5. Warranty and After-Sale Service.................................................................................................................78

1. General

1-1. Introduction

Your patronage over KEM products is appreciated this time by purchasing the auto clean and sampling unit.

This auto clean and sampling unit automates a series of events including sampling and cleaning the

measuring cell or drying the system lines when connected to a General-purpose concentration meter,

Density/specific gravity meter or Refractometer.

[Features]

1) This unit is equipped with self-diagnostic function by checking keypad function and display screen.

2) The cleaning efficiency is increased by blending air into rinse solvent. By this way, the total amount of

rinse solvent is decreased and saved. In addition, not only inside but outside of the nozzle can be

cleaned very well since the rinse solution is fed from the outside of the nozzle unit.

3) Expensive sample materials like perfume or fragrance can be returned back to sample vials after

measurements are over.

4) The DCU-551 series provides a variety of models with different specifications depending on what type

of sample material is going to be measured; N type as standard model, SS type for small size sampling,

H or HC type for high temperature or C type for low temperature measurement.

Standard model (N type) : 20mL vials for use at ambient temperature.

Small size sampling model (SS type) : 8mL vials for small size of liquid samples. Furthermore,

the sensor, which inhibits over-sampling minimizes required

amount of sample (approximate 5mL).

High temperature model (H type) : For those samples which are softened when heated, the

sampling lines are heated up to 80°C.

* This manual is described on the Standard N type and the Small size sampling SS type.

1

1-2. About the manual

Please keep this manual near your system so that you can easily access to the necessary information you are

looking for while operating or preparing for measurement.

The below three boxed messages show the basis symbols of warning, caution and note that you will see in

this manual from time to time:

1. Where there exists a danger of physical injury or even possible death:

Warning!

There exists the danger of physical injury or even possible death if the

instruction is disregarded.

2. Where there exists a danger of property damage:

Caution!

There exists the danger of property damage if the instruction is ignored.

3. When there exists a possibility of failure of instrument performance:

Note:

There exists the possibility of failure of instrument performance.

If ignored, warranty may not be covered.

* It is prohibited to copy a part or all of this manual without authorization by copyright.

* If you should find any part in this manual not clear to understand or missing article, contact your local

dealer or sales representative.

* Manufacturer will not be liable for any loss or damage directly or indirectly caused by use of the instrument

or its consequences.

* This manual describes the use of instrument when operated as a standard mode.

For use of a model with special feature or specification, please read the manual particular to it.

2

1-3. Safety symbols

Always observe these signs and instructions.

You must observe cautionary messages and warnings in order to protect yourself as well as prevent others

from physical injury or property damages.

Warning

This symbol means "Danger of severe injury

or possible death".

Caution

This symbol means "Danger of injury or

property damage".

WARNING!

You must ground earth wire of power cable.

Ground the green wire of adapter if

power tap is 2-pin outlet.

3-pin plug has earth line to ground

by itself when plugged in.

Danger of electric shock if not grounded to earth.

WARNING!

This symbol means prohibition of an act.

This symbol means mandatory.

Do not use volatile chemical or work in flammable gas.

Danger of explosion inside the instrument.

WARNING!

Wear safety glasses, gloves or protective mask if necessary,and well

ventilate the room.

Danger of injury on your skin or in the eyes by splashing chemical.

Also your windpipe may get hurt if toxic gas is breathed in.

3

CAUTION!

Do not operate in a way other than specified in the manual.

Danger of fire, electric shock or damage to the instrument.

CAUTION!

Do not open housing case or overhaul the unit for repair except by an

authorized service person.

Danger of fire, shock or malfunctioning of the unit.

4

About place for installation

Do not install the instrument under any of the following conditions, which may cause eventual defective

performance and unsured reliability of the system.

z Near or under vibration

z Under direct sunlight

z In corrosive gaseous atmosphere

z Power source of heavy load fluctuation or near strong magnetic field

z High humidity or sharp change in temperature (The ambient condition for this system is 5 to 35°C, below

85%RH.)

z Place not leveled

z Any obstacle in front of the air intake fan

z Installation of DCU-551 in an unlevel location

About power source

z Power for this instrument is AC100-120/200-240V ±10% and 50/60Hz.

z Supply power direct from the outlet, and do not share power from a tap.

z Do not connect the plug of Auto clean and sampling unit to any other equipment than KEM-designated.

z Do not put any obstacle around power outlet just case of need for plugging out power cord to avoid the

possible danger of the whole system in trouble.

Storage place

z If the instrument is not to be used for a long time, use the attached packing box after cleaning and drying

the tube.

z Avoid the places for storage under inadequate ambient conditions such as extremely high/low temperature,

high humidity or heavily dusty atmosphere.

Use

z Do not touch the nozzle unit when it is in operation.

z When the tube and the connector, be sure to turn off the power before it is checked.

z If the equipment stops during the operation, be sure to discharge the drain. Also, change the line to Drain

for Rinse 1 or 2.

Environmental condition

This instrument is designed for the indoor use under the environmental conditions specified in the Section 1.4

of CE marking (LVD, 73/23/EEC, EN61010-1) and the use of the Category II of Overvoltage and the

Pollution Level 2.

5

2. Preparation

2-1. Supplied parts

The carton box contains the Main unit with its accessories and operating manual. Check the supplied parts

with the below parts list.

If you should find any missing or broken part, contact your local dealer or sales representative.

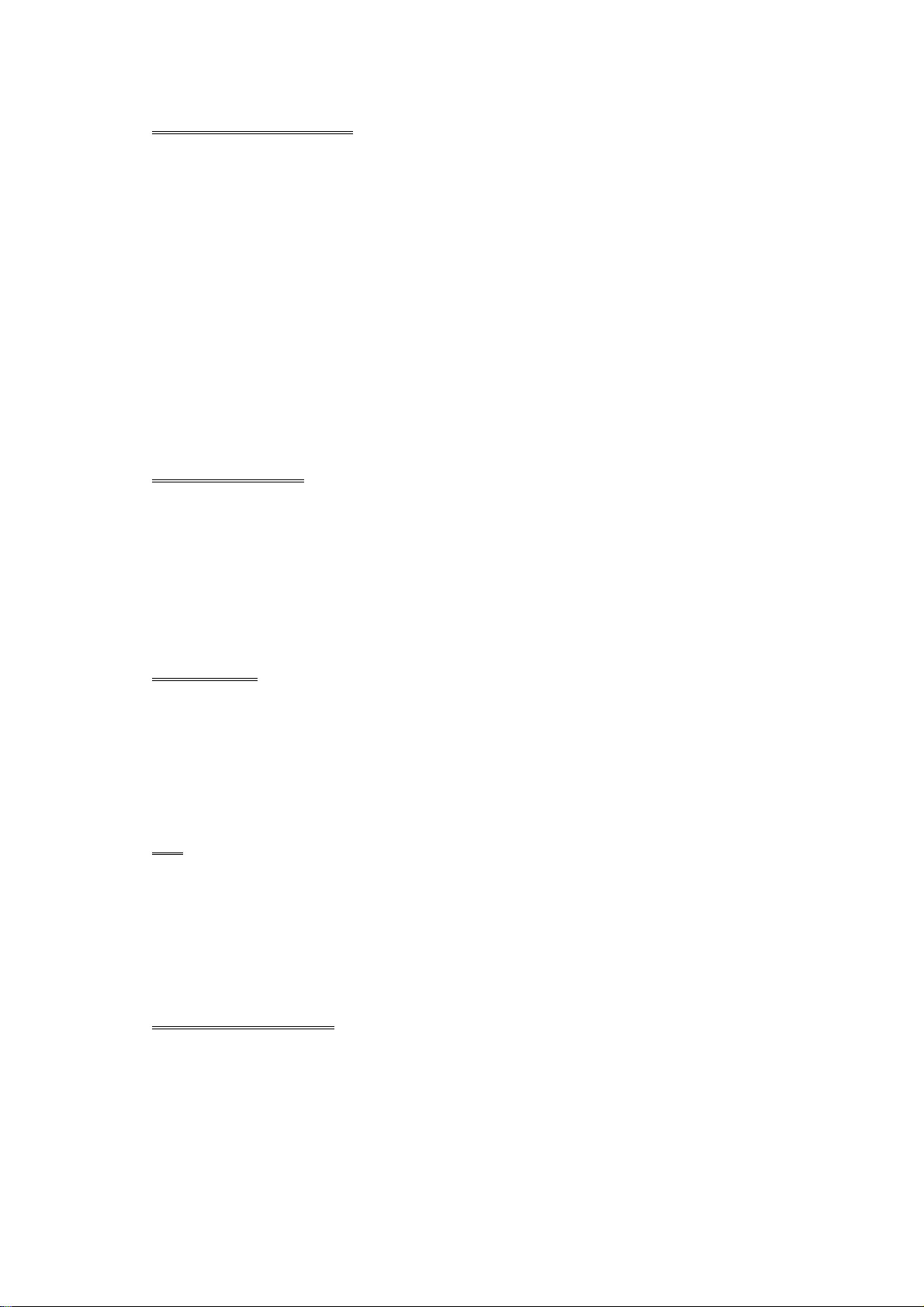

2-1-1. DCU-551 supplied parts

Part name Part code Qty Sketch

Main unit*1 DCU-551 1 Unit

Connecting cable 98-030-3388 1 pce

Tube 98-434-0316 1 pce

(L=1100mm)

Seal 98-551-5109 1 pce

Nut plate 20-035-3600-48 2 pce

Tube 98-434-0251 1 pce

for General-purpose concentration

meter, Density/specific gravity

(L=500mm)

meter

Connection tube 98-434-0238 1 pce

6

for General-purpose concentration

meter, Refractometer

(L=800mm)

Part name Part code Qty Sketch

Tube 98-434-0241 1 pce

for Density/specific gravity meter

(L=800mm)

Cap 98-560-0091 1 pce

PTFE tube 98-521-0050 1 pce

(L=2000mm)

Tube nozzle A 98-550-6520 2 pcs

Tube joint B 98-552-6456 2 pcs

Spiral tube 98-521-6478 1 pce

(L=400mm)

Cover *2 98-560-0068 1 pce

Filter (2 pcs/set) 98-550-0010S 1 set

Tube (with joint) 98-521-0036 2 pcs

(L=1000mm)

Reagent bottle 98-430-5292 2 pcs

Bottle holder 98-560-0017 1 pce

Vial bottle *3 (98-722-0005) 30 pcs

Cap *3 (98-722-0006) 30 pcs

7

Part name Part code Qty Sketch

Packing *3 (98-550-0130) 100 pcs

Hexagonal wrench 98-514-3200 1 pce

Air intake filter (98-501-6864) 1 pce

Operation manual 98-595-0456 1 copy

Operation

manual

Note:

Parts with parenthesized part code have unique order units or packing

forms different from others. Therefore, please refer to the section “7-1.

Part list” when ordering these parts.

*1 For the DCU-551H (High temperature model), please see the corresponding sketch in the Operation

manual for the DCU-551H.

*2 This item is not supplied with DCU-551H (High temperature model).

*3 This item is not supplied with DCU-551SS (Small size sampling model). Supplied parts are shown in

below chart.

Part name Part code Qty Sketch

Vial (98-722-0007) 5 pcs

Cap 98-722-0009S

Packing (98-550-0131) 100 pcs

1 set

(5 pcs)

Note:

Parts with parenthesized part code have unique order units or packing

forms different from others. Therefore, please refer to the section “7-1.

Part list” when ordering these parts.

8

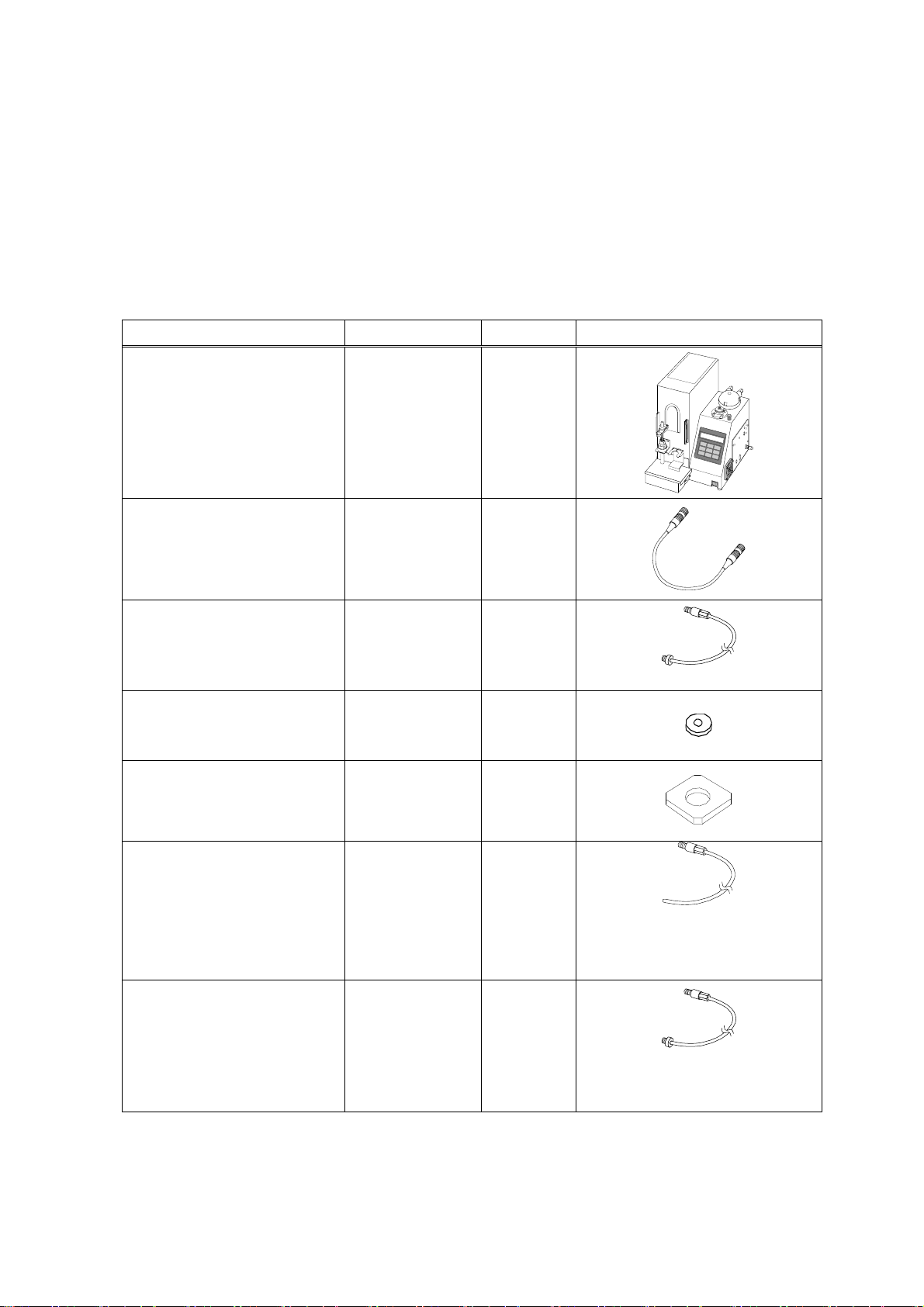

2-1-2. Optional parts

When Refractometer is connected to Main unit, it is necessary to use connection kit shown below.

Part name Part code Qty Sketch

Connecting kit F for combination

of Density and Refractometer

- Connecting kit F for combination of Density and Refractometer -

Part name Part code Qty Sketch

Connection tube A for

Refractometer / CHD-500

Connection tube C for

Density meter / Refractometer

Connection tube D for

Density meter / Refractometer

98-434-0233 1 set

98-434-0102 1 pce

98-434-0133 1 pce

98-434-0134 1 pce

(L=800mm)

(L=1200mm)

(L=1200mm)

Desiccant tube 98-434-0108 1 pce

Silica gel (500g) 98-820-3269 1 pce

Flow Sampling Attachment FCU-520 1 set

9

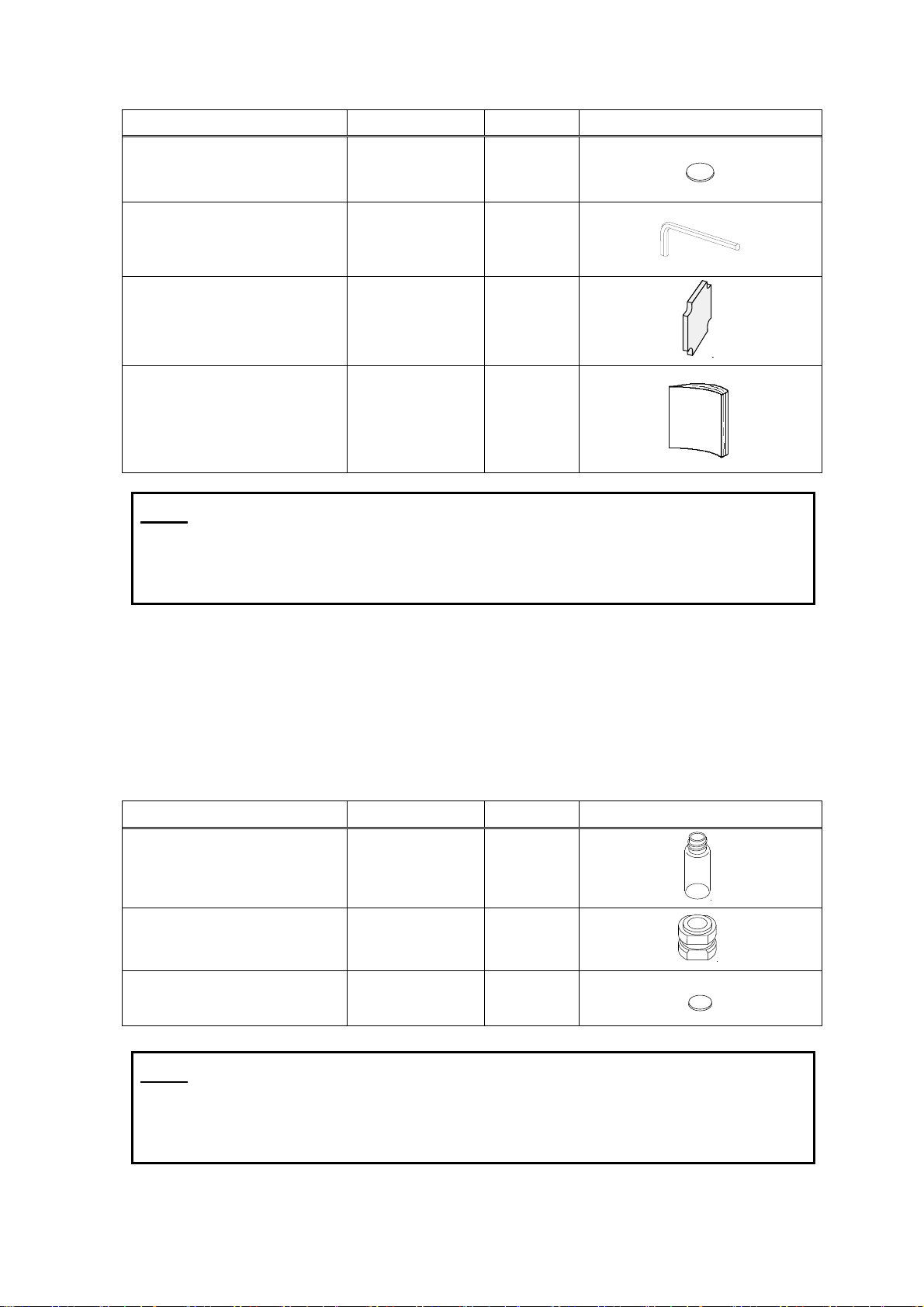

2-2. Installation and start-up preparation

Place DCU-551 on a level and stable surface such as desk or worktable.

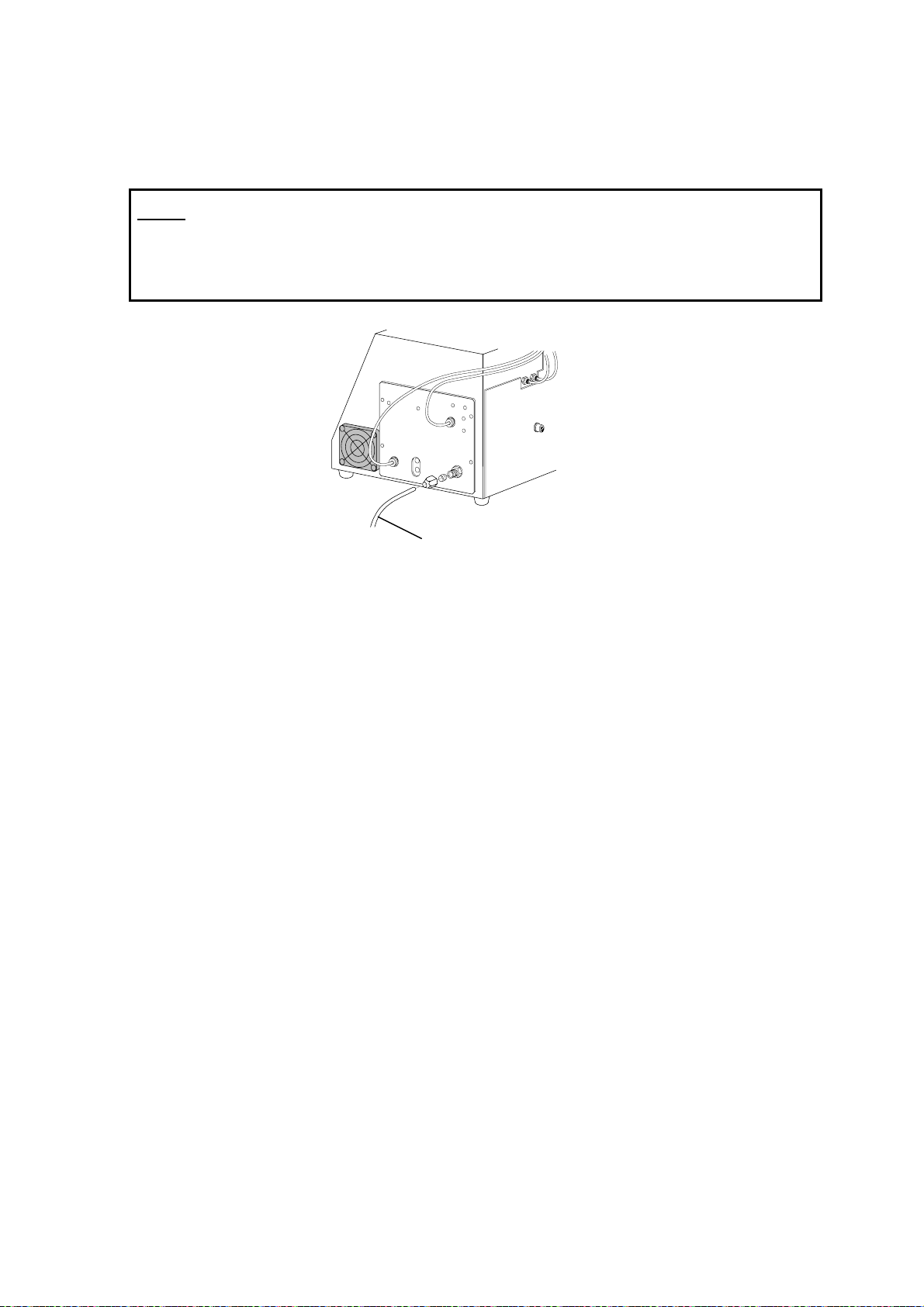

2-2-1. Supplied power

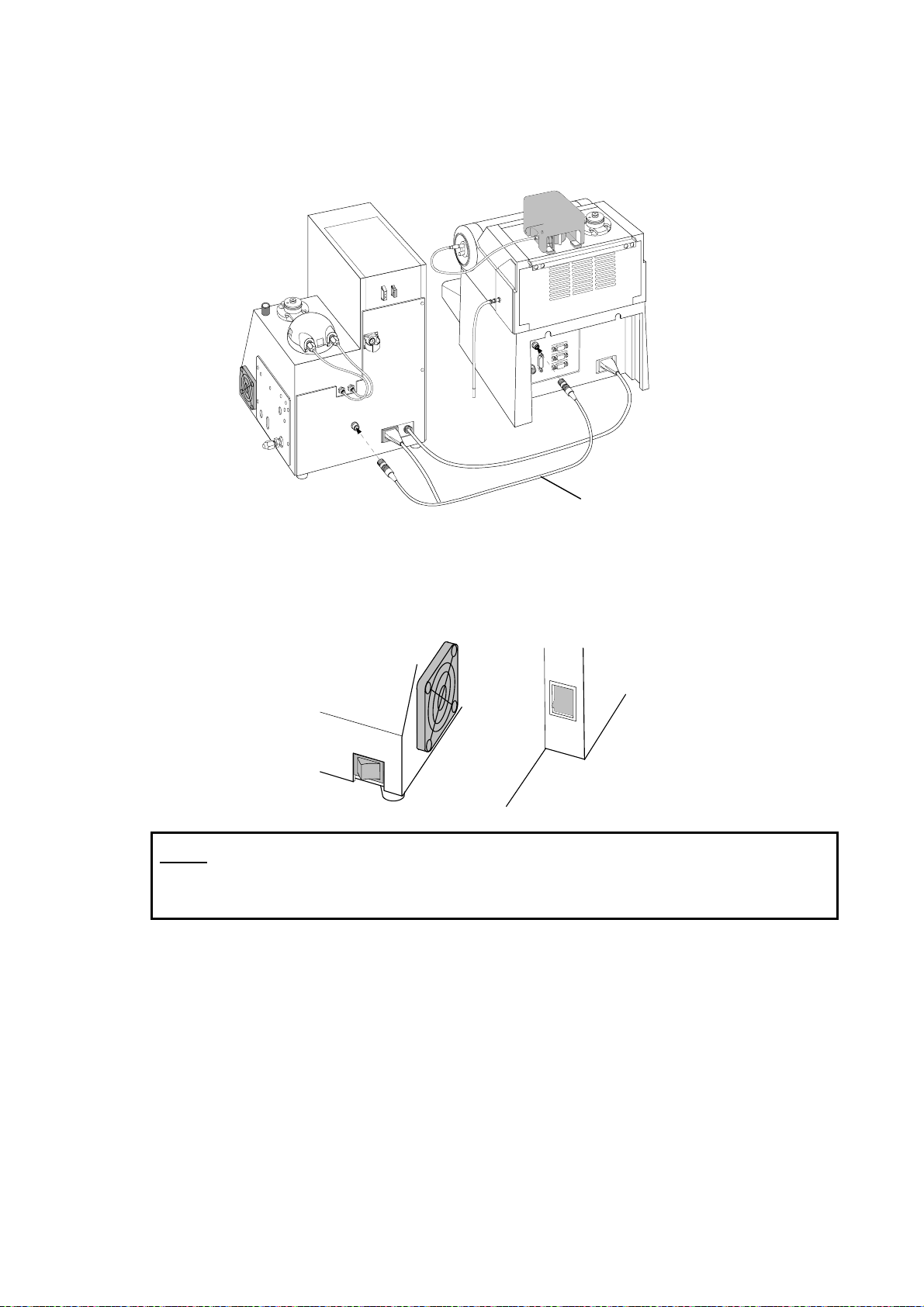

1) Make sure the power switch of Main unit and the measuring unit are in OFF position.

2) Connect the power cord supplied with measuring unit to the power receptacle on the back the Main unit.

The power for measuring unit is supplied by the power cord plug from the rear port of Main unit.

3) Plug in the other end of power cord.

<3-pin plug>

The 3 pins plug has an earth terminal and

grounds to the earth by itself.

Attach an adapter for power connector to

the plug and ground the green wire to the

earth terminal.

<2-pin plug>

Warning!

The earth wire must be grounded. If not, there exists a danger of electric

shock.

10

2-2-2. Connecting the cable

With the supplied cable (98-030-3388), connect each EXT. port on the back of measuring unit and Main unit.

2-2-3. Turning on the power

Turn on the power of the Main unit and the measuring unit.

Note:

Turn on power of the connected instrument only after the cable is

connected.

Connecting cable

11

2-2-4. Connecting the tube lines

The way of connecting tube lines differs according to the type of connected units. Especially when

connecting to a refractometer, the specially designed connecting kit is required.

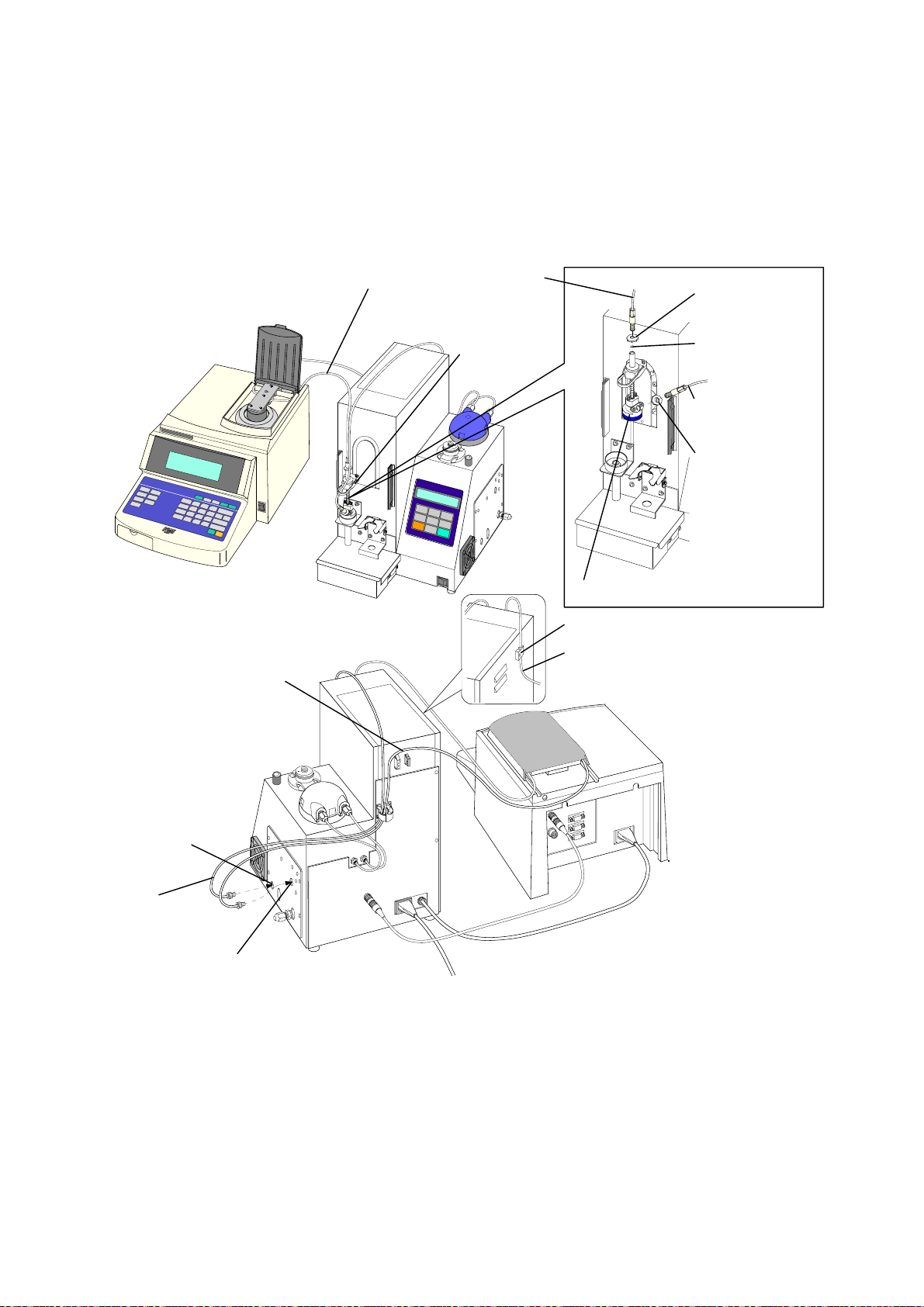

<Connecting to a General-purpose concentration meter>

For this purpose, the tube (98-434-0251) and connection tube (98-434-0238) are required.

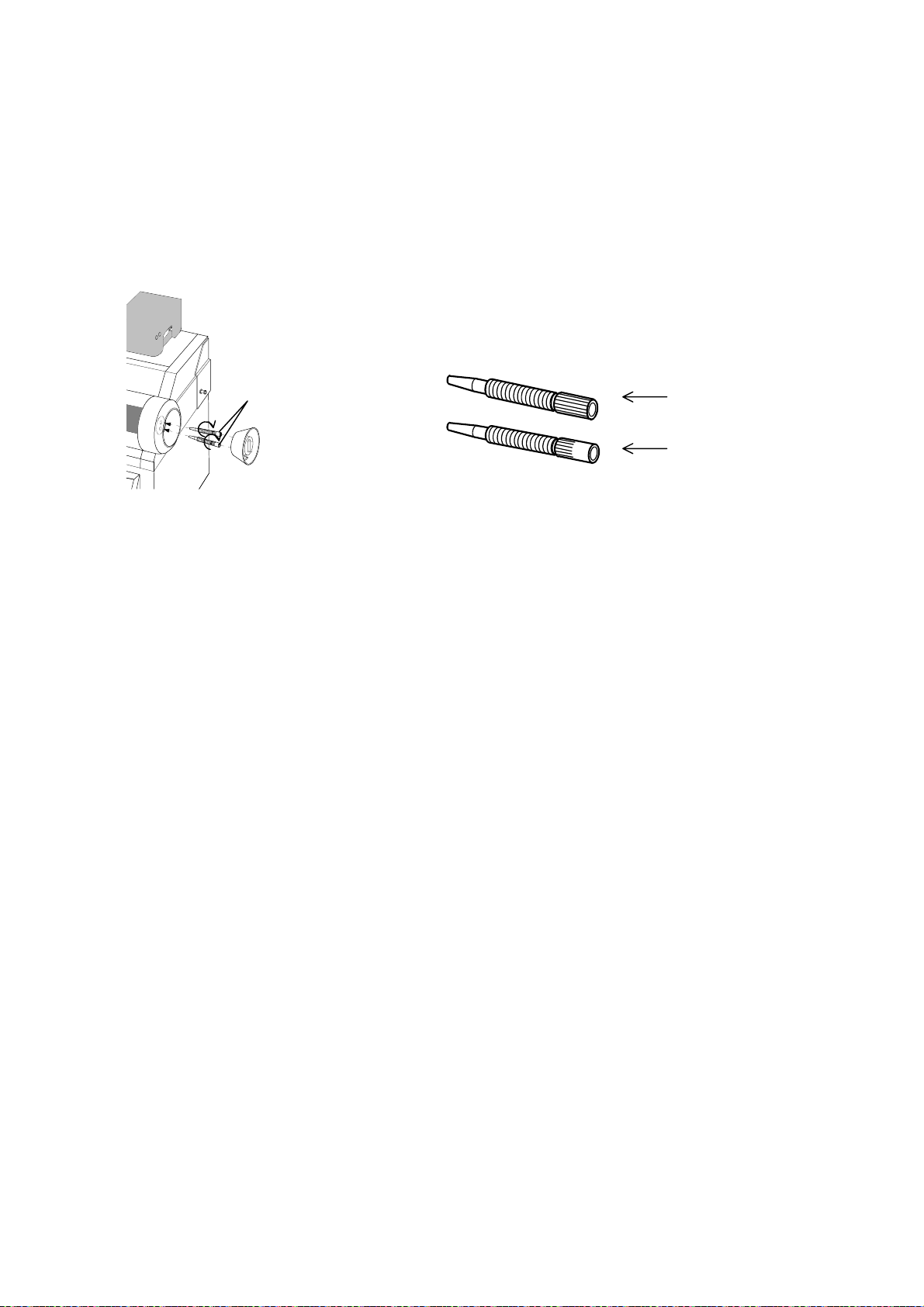

Remove the tube nozzle A-2 (98-550-6564) from the

measuring unit, and replace it with the tube nozzle A

(98-550-6520).

Tube nozzle A

No screw inside

Tube nozzle A-2

Screwed inside

Tube nozzle A

12

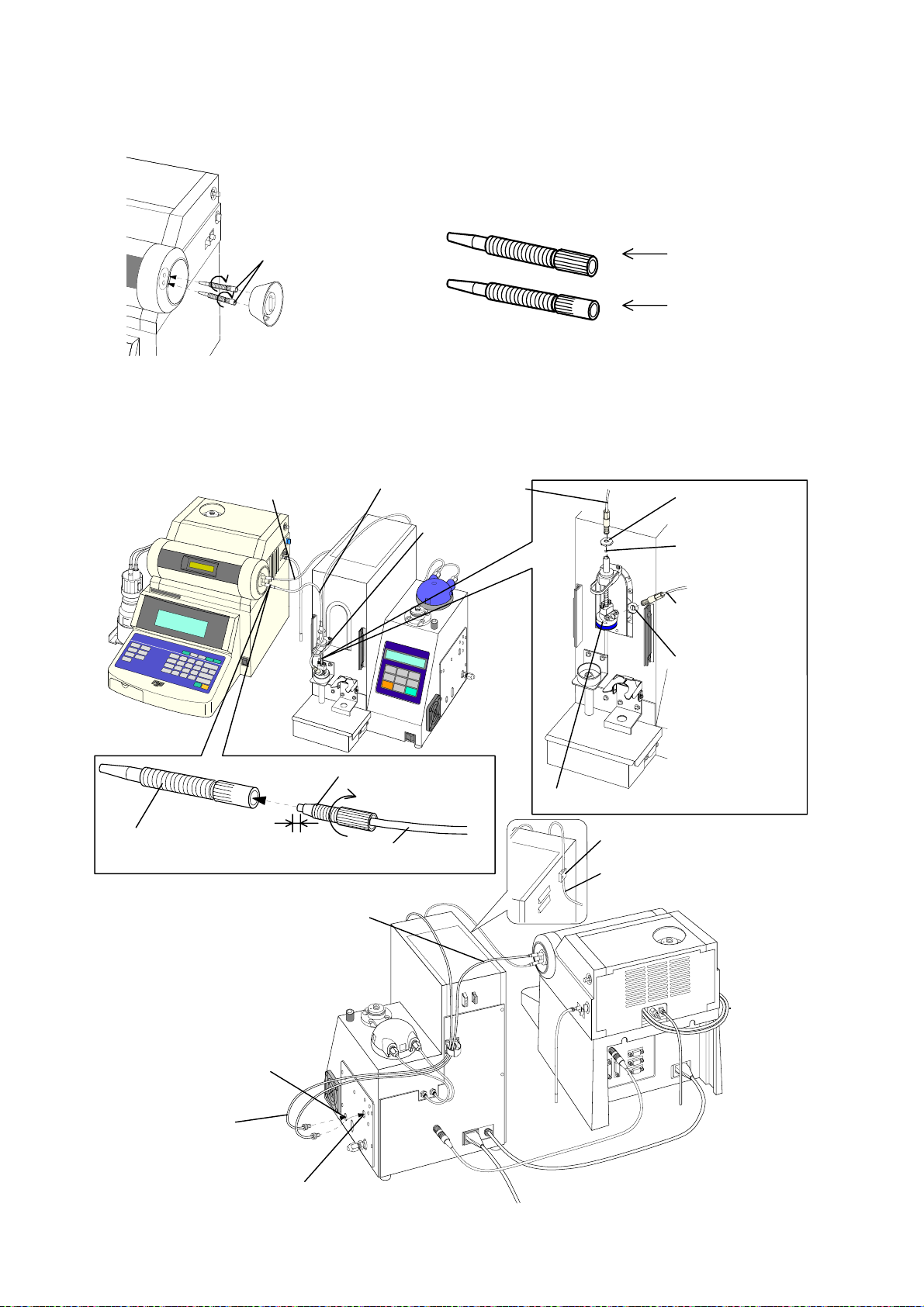

After connecting the nozzle unit with “To Nozzle” through the tube (98-434-0316) fastened with the nut

plate (20-035-3600-48) as shown below, hook the tube on the tube guide. Fix the nut plate

(20-035-3600-48) for the tube (98-434-0251) to connect the measuring unit with the nozzle unit with the seal

(98-551-5109) in. Connect the connection tube A (98-434-0217, with General-purpose concentration

meter) without the joint to the measuring unit. Connect the connection tube (98-434-0238) with both the

measuring unit and the “Meas. Cell”. Secure the tube (98-434-0251) with the tube holder.

Connection tube A

(98-434-0217)

Tube (98-434-0251)

Nut plate

Tube guide

(20-035-3600-48)

Seal

(98-551-5109)

Tube

(98-434-0316)

Nut plate

(20-035-3600-48)

Tube nozzle A

"To Nozzle"

Tube

(98-434-0316)

About 2mm

Connection tube

(98-434-0238)

"Meas. Cell"

Tube joint B

Nozzle unit

Tube holder

Tube (98-434-0251)

Tube (98-434-0251)

Note:

Squeeze in Tube joint B into Tube nozzle A with its tip approx. 2mm

extended. If the connection is loose, the tube may come off and sample

liquid or solvent may flush out.

13

<Connecting to a Density/specific gravity meter>

For this purpose, use the tubes (98-434-0251 and 98-434-0241).

Remove the tube nozzle A-2 (98-550-6564) from the

measuring unit, and replace it with the tube nozzle A

(98-550-6520).

Tube nozzle A

After connecting the nozzle unit with “To Nozzle” through the tube (98-434-0316) fastened with the nut plate

(20-035-3600-48) as shown below, hook the tube on the tube guide. Fix the nut plate (20-035-3600-48) for

the tube (98-434-0251) to connect the measuring unit with the nozzle unit with the seal (98-551-5109) in.

Connect the connection tube (98-434-0241) with both the measuring unit and the “Meas. Cell”. Secure the

tube (98-434-0251) with the tube holder.

Tube (98-434-0251)Tube (98-434-0241)

Tube guide

No screw inside

Tube nozzle A-2

Screwed inside

Tube nozzle A

Nut plate

(20-035-3600-48)

Seal

(98-551-5109)

Tube

(98-434-0316)

Nut plate

(20-035-3600-48)

Tube nozzle A

"To Nozzle"

Tube

(98-434-0316)

About 2mm

Tube (98-434-0241)

"Meas. Cell"

Tube joint B

Nozzle unit

Tube holder

Tube (98-434-0251)

Tube (98-434-0251)

14

Note:

Squeeze in Tube joint B into Tube nozzle A with its tip approx. 2mm

extended. If the connection is loose, the tube may come off and sample

liquid or solvent may flush out.

<Connecting to a Refractometer>

For this purpose, use the connecting kit (98-434-0233).

Put the connection tubes (98-434-0102 and 98-434-0238) through the gap with the lid as shown below:

Connection tube

(98-434-0238)

Connection tube A for

Male joint

Refractometer/CHD-500

(98-434-0102)

Squeeze the male joint into FCU-520 to fix it on the Refractometer.

Presser bar

Note:

There is a direction of tubing to FCU-520. Connection in a wrong

direction may result in failure of Auto sampling or Drying.

15

After connecting the nozzle unit with “To Nozzle” through the tube (98-434-0316) fastened with the nut

plate (20-035-3600-48) as shown below, hook the tube on the tube guide. Fix the nut plate

(20-035-3600-48) for the connection tube (98-434-0102) to connect FCU-520 with the nozzle unit with the

seal (98-551-5109) in. The connection tube (98-434-0238) from FCU-520 is then connected with “Meas.

Cell”. Secure the connection tube (98-434-0102) with the tube holder.

Connection tube A for

Refractometer/CHD-500

(98-434-0102)

Nut plate

(20-035-3600-48)

Connection tube

(98-434-0238)

Tube guide

Seal

(98-551-5109)

Tube

(98-434-0316)

Nut plate

(20-035-3600-48)

Nozzle unit

Tube holder

Connection tube A for

Refractometer/CHD-500

(98-434-0102)

"To Nozzle"

Tube

(98-434-0316)

16

"Meas. Cell"

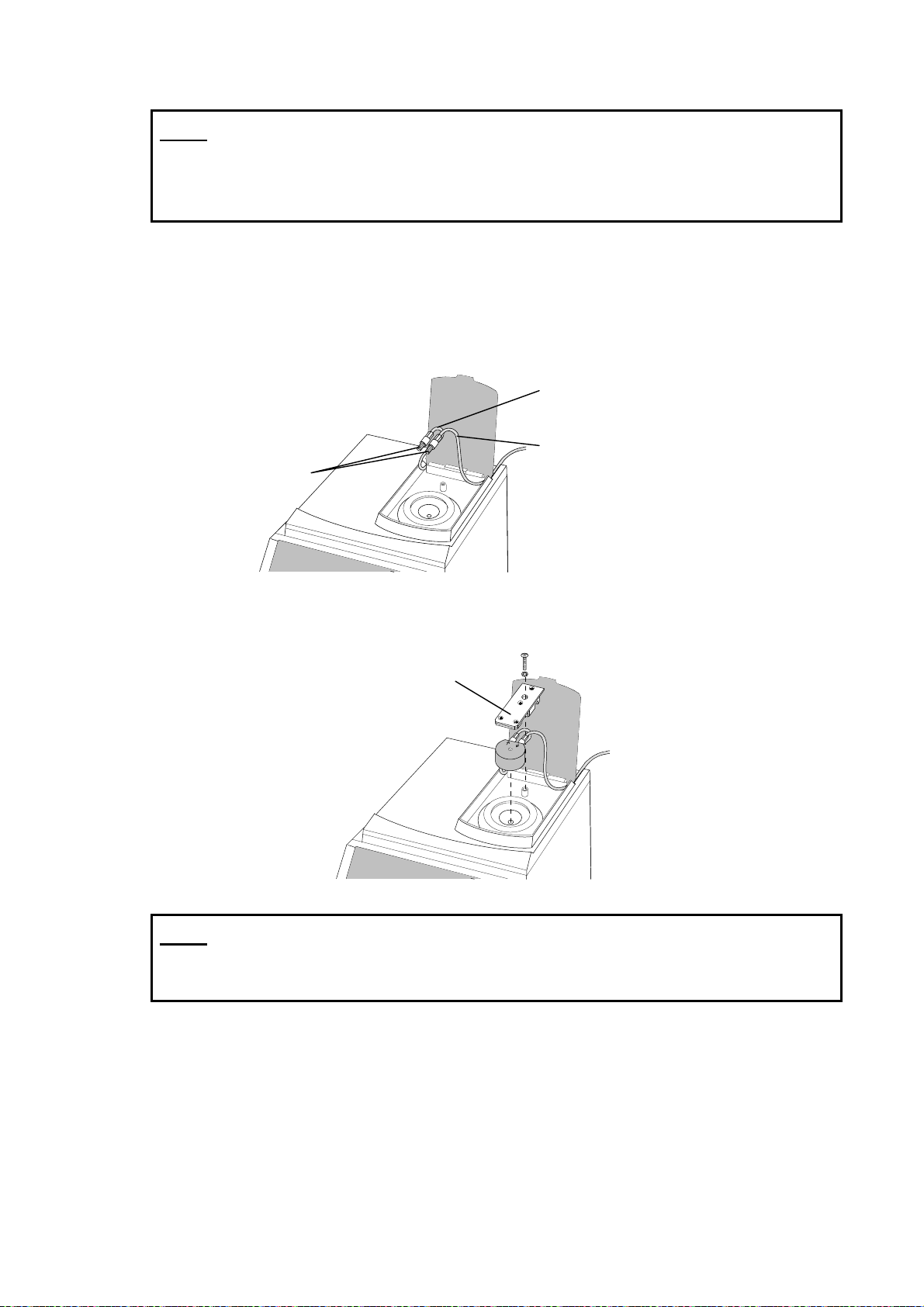

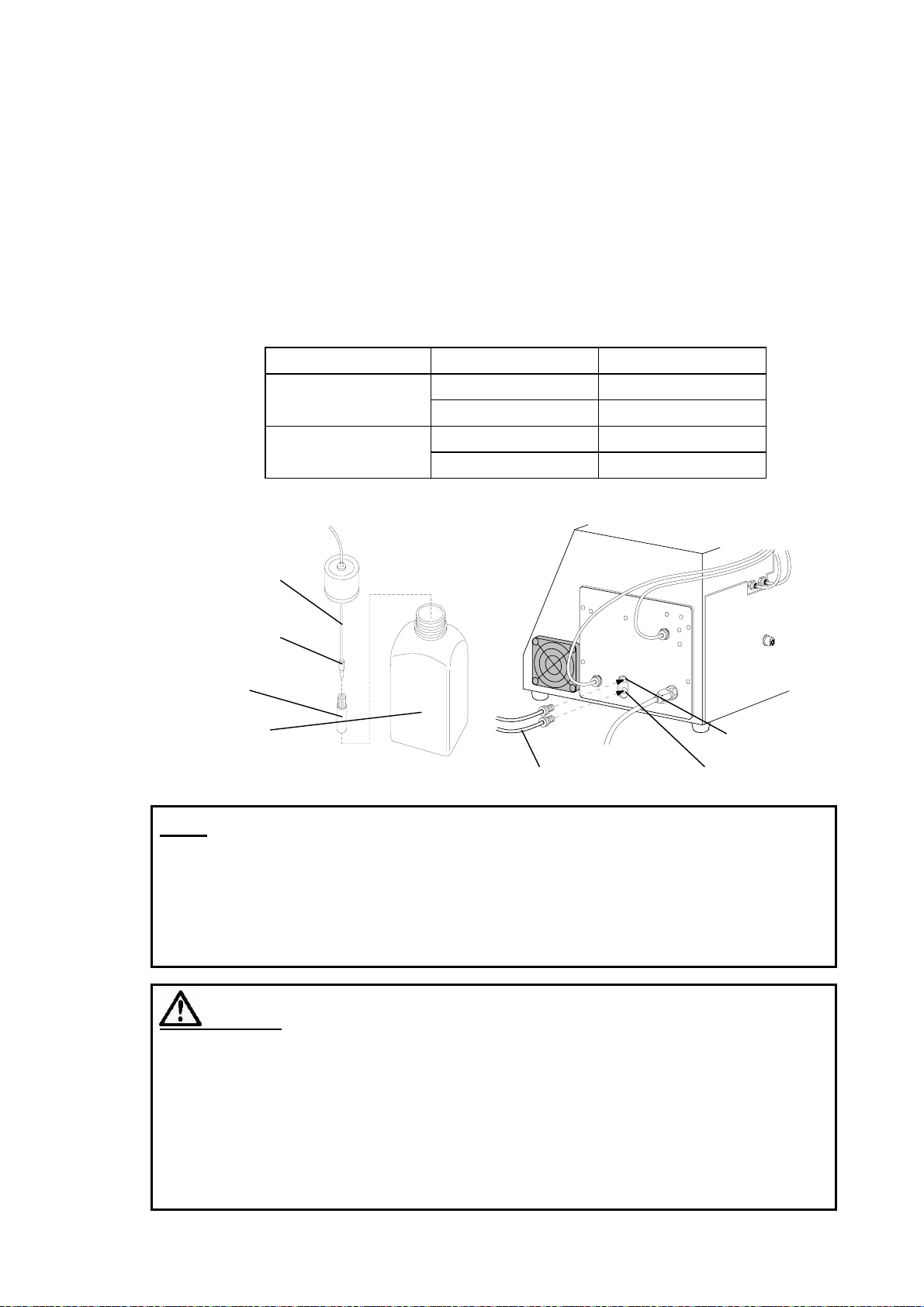

2-2-5. Installation of desiccant tube

<Connecting to a General-purpose concentration meter or a Density/specific gravity meter>

1) Install the Desiccant tube (98-434-0108) attached to the measuring unit and the cap on the measuring

unit and the main unit, respectively. The desiccant tube and the cap can be smoothly installed by

screwing it in the measuring unit.

2) Attach the tube (98-434-0135) to the measuring unit and connect it with the cap that is installed on the

main unit in 1).

Desiccant tube

Cap

Tube

Note:

When installing the Desiccant tube and the cap, be sure to insert them as

far as they will go.

<Connecting to a Refractometer>

Install the Desiccant tube (98-434-0108), attached to the Connecting kit F for combination of Density and

Refracto meter, on the main unit. In this event, the Desiccant tube can be smoothly installed by screwing it

in the measuring unit.

Desiccant tube

Note:

In installing Desiccant tube to Main unit, firmly plug it in.

17

2-2-6. Connecting the drain tube

Connect the PTFE tube (98-521-0050) to “Drain”, and insert the other end of tube into the waste container.

Note:

Always leave the end of the drain tube open to the air or dipped about

5cm in solution.

A waste container is not supplied for this unit.

PTFE (98-521-0050)

18

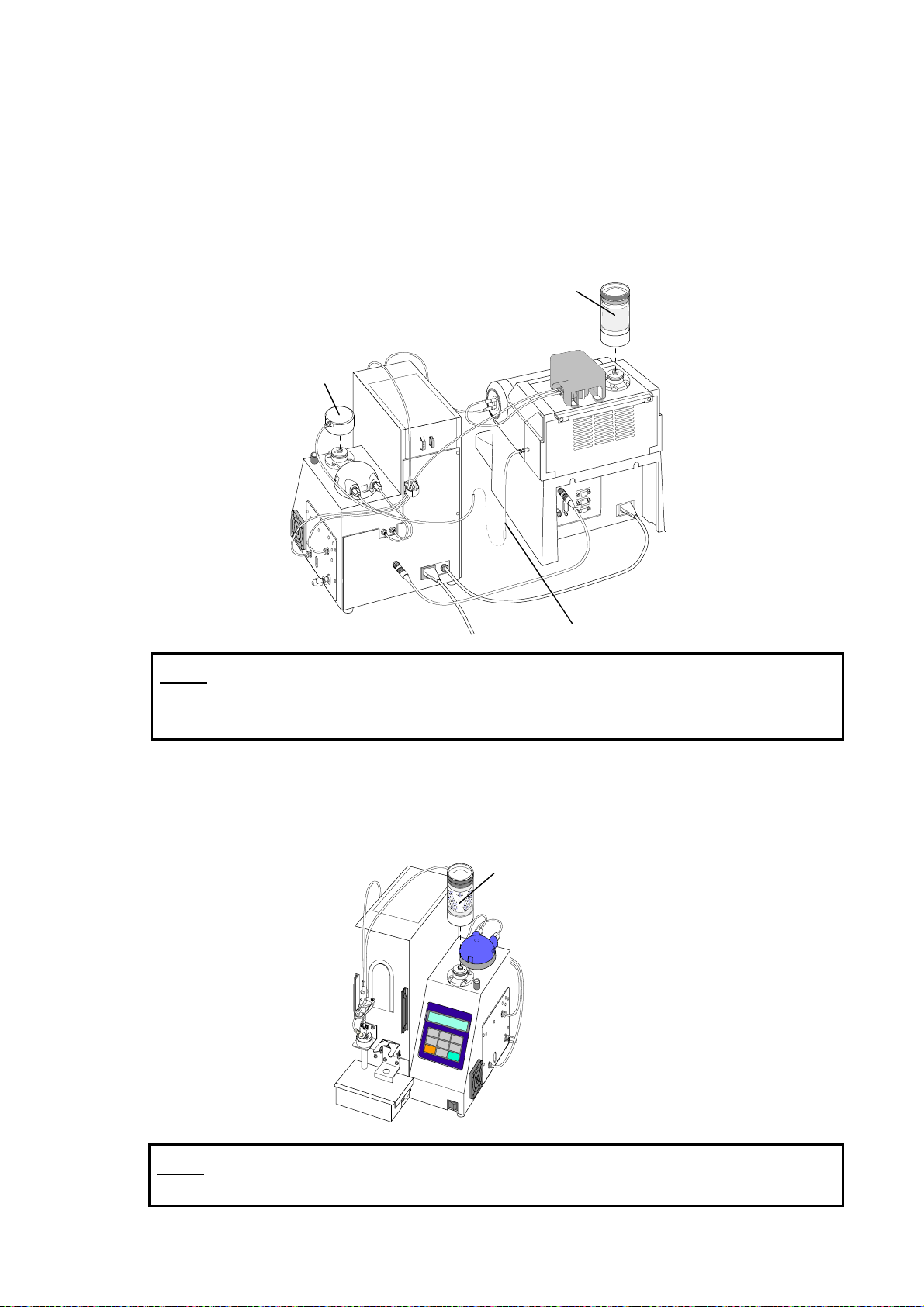

2-2-7. Supply of rinse solvent

1) Insert the tube (with joint) (98-521-0036) into the cap of reagent bottle (98-430-5292), and attach the

filter (98-550-0010) using tube joint B (98-552-6456) of the composition article of filter (98-550-0010S).

In screwing the tube joint B in the filter, the tube should stick out from the tube joint B by 1 to 2 mm.

2) Insert the tube into the rinse inlet of Main unit.

3) Fill the supplied bottle (98-430-5292) each with Rinse 1(RINSE-1) and Rinse 2(RINSE-2).

Use solvent for Rinse 1 which will dissolve the measurement sample or wash it away.

Use solvent for Rinse 2 which will dry the measuring cell. When the ambient temperature is below

15°C and purge-drying with Ethanol does not work well, use Acetone instead.

Measured Sample Rinsing Solution 1 Rinsing Solution 2

Heavy Oil Toluene Acetone

Toluene Ethanol

Saccharine Solution Pure Water Acetone

Pure Water Ethanol

4) Place the reagent bottle filled with rinse solvent in bottle holder (98-560-0017).

Tube(with joint)

(98-521-0036)

Tube joint B

(98-552-6456)

Filter

Reagent bottle

(98-430-5292)

Tube (with joint)

Rinse 2 inlet

Rinse 1 inlet

Note:

Make sure in advance of possible chemical reaction between sample and

solvent or between different kinds of solvent. Some solvent may react

with sample and other solvent and solidifies or generates heat. Avoid

such combination. Place the reagent bottle holder (reagent bottle) at

the same height as Main unit.

Warning!

Splashing of the rinsing solution may cause troubles with skin or eyes

and suction of the vapor may cause bronchial malfunctions. For some

rinsing solution, wear gloves, protective glasses, protective mask and

the like, and have good ventilation.

The materials of the joint for rinsing solution are PTFE, SUS304,

fluorocarbon rubber and glass. Do not use any solvent to which these

materials are sensitive. That will cause troubles.

19

2-2-8. Install the cover

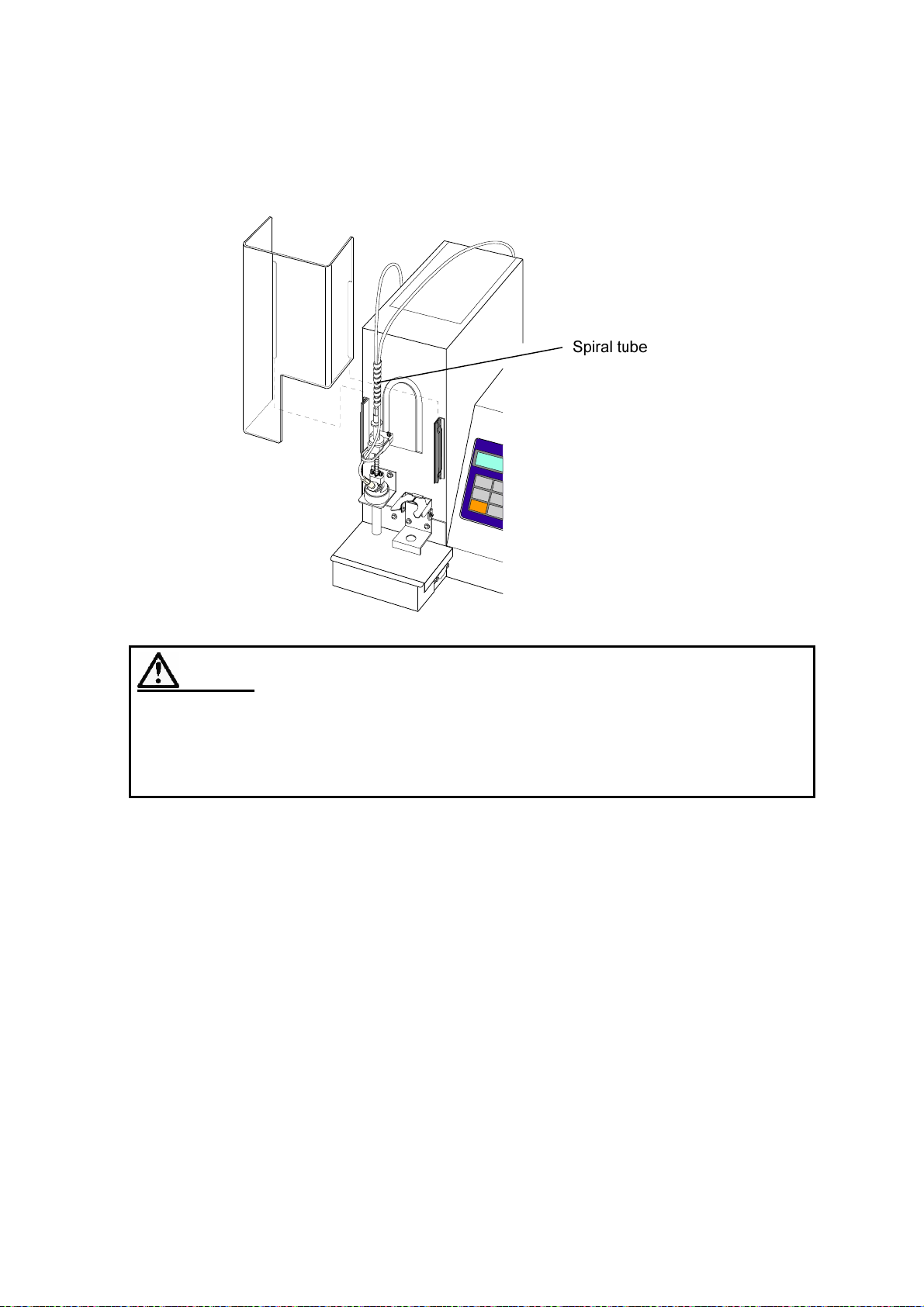

Tube is boundled by using the spiral tube cut in adequate length as shown in figure.

Install cover onto Main unit.

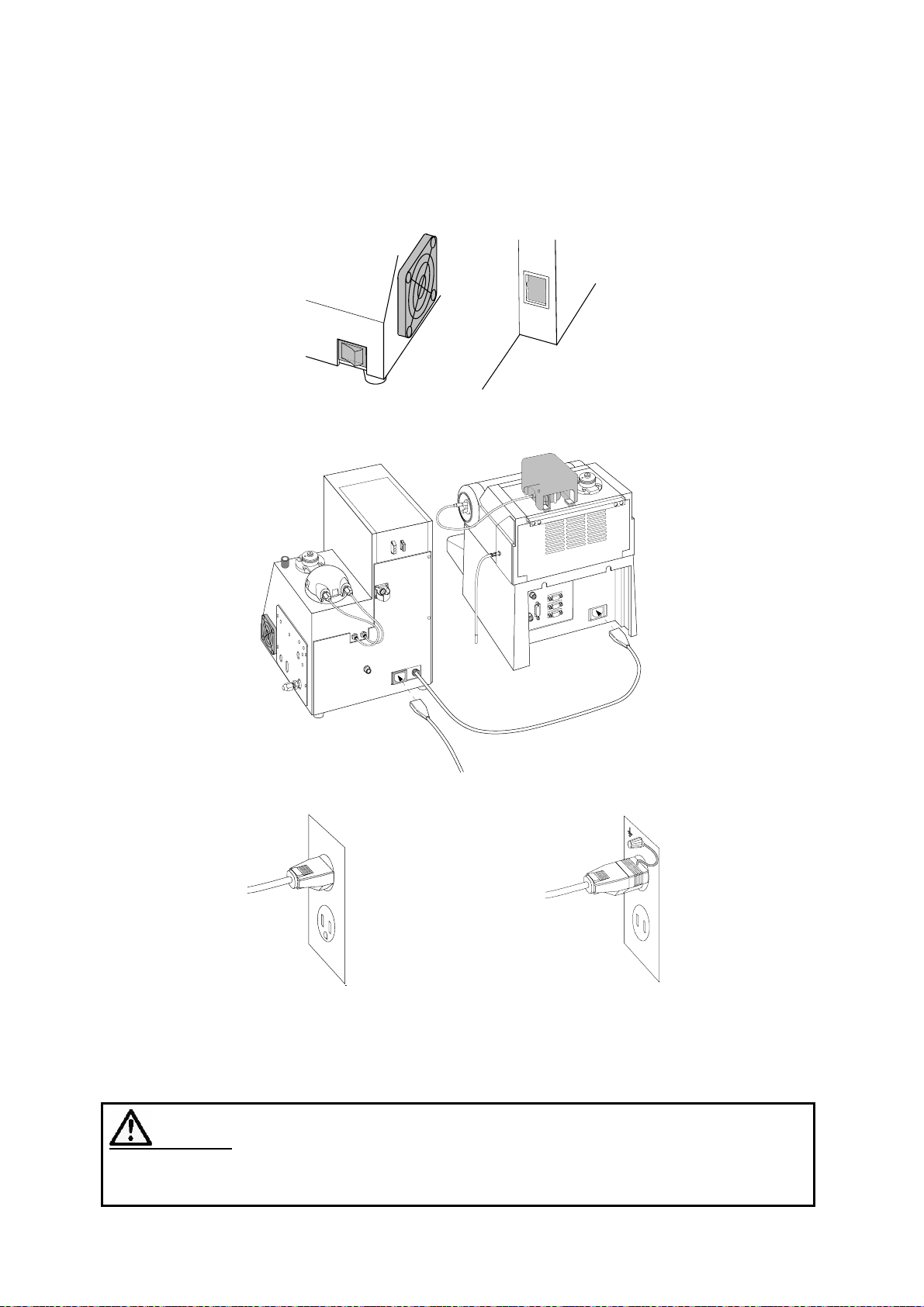

Caution!

You may get hurt if you touch the drive unit while the nozzle unit is in

motion.

Always install the covers to protect yourself in order to avoid injury by

touching those parts without paying much attention.

20

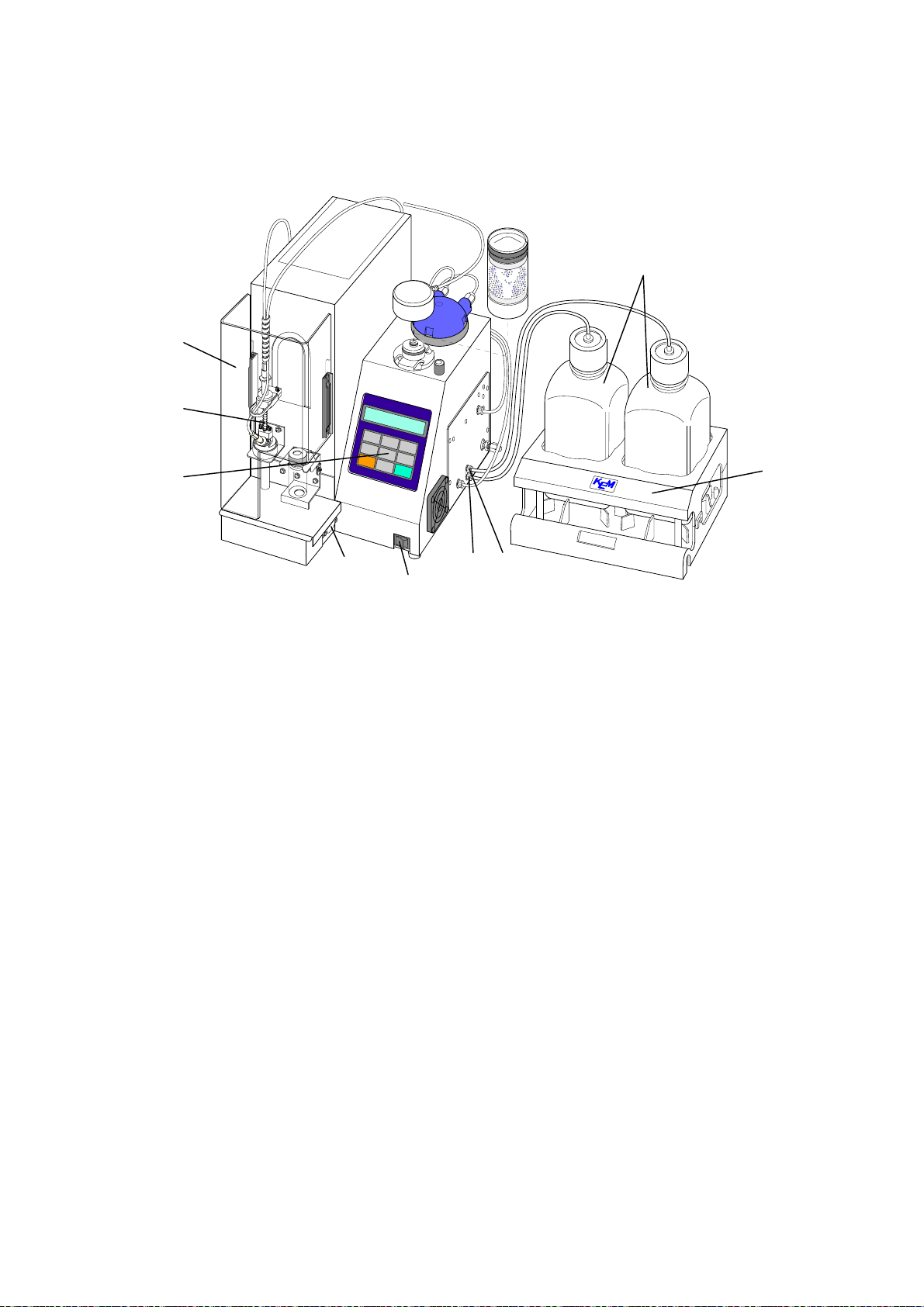

2-3. Parts configuration

< layout in front >

2)

8)

3)

1)

1) Operating panel:

The keypad and display screen are provided here.

2) Cover:

This is a protective cover to avoid human contact while the nozzle unit is moving or the measurements

on sample vials are completed.

3) Reagent bottle:

This is the bottle filled with solvent for rinsing.

4) Bottle holder:

This holder protects the bottle 3) from falling off.

5) Rinse solvent 2 inlet:

The tube to the rinse bottle for drying the line is connected here.

9)

7)

4)

5)6)

6) Rinse solvent 1 inlet:

The tube to the rinse bottle to dissolve or drain out reagent is connected here.

7) Power switch:

Main power switch for the unit.

8) Nozzle unit:

This is the nozzle for sampling, which moves the rinsing pot to sampling position.

9) RS-232C port:

This port is D-sub 9-pin male type for the cable to communicate with a printer or an external PC.

21

Loading...

Loading...