KEM AT-610 Operation Manual

Automatic Potentiometric Titrator

AT-610

Operation Manual

Please read this manual thoroughly in advance for the best performance of the equipment.

A/N 69000680148

Ver.01

Table of contents Page

1. Introduction............................................................................................................................................................... 1

1-1. Overview of the instrument ................................................................................................................................ 1

1-2. About the manual ............................................................................................................................................... 2

1-3.

2. Preparations for measurement ................................................................................................................................... 6

2-1. Supplied parts.....................................................................................................................................................6

2-2. Installation and start-up .................................................................................................................................... 12

2-3. Parts configuration and each function.............................................................................................................. 19

Safety symbols.......................................................................................................................................... 3

2-2-1. Protection film ....................................................................................................................................... 12

2-2-2. Assembly of magnetic stirrer ................................................................................................................. 12

2-2-3. Power cable............................................................................................................................................ 13

2-2-4. Connecting cables .................................................................................................................................. 14

2-2-5. Set up the address for measuring unit.................................................................................................... 15

2-2-6. Start-up .................................................................................................................................................. 15

2-2-7. Installation of burette unit ...................................................................................................................... 16

2-2-8. Installation of electrode ......................................................................................................................... 17

2-3-1. Automatic Potentiometric Titrator......................................................................................................... 19

2-3-2. Main control unit (MCU-610) ............................................................................................................... 20

2-3-3. Measuring unit (AT-610) ....................................................................................................................... 22

2-4. Displays and operating buttons ........................................................................................................................ 25

2-4-1. Description of system area and operating buttons ................................................................................. 25

2-4-1-1. Registration of operators ................................................................................................................. 26

2-4-2. Main channel display area and operating buttons.................................................................................. 27

2-4-3. Main channel operating buttons............................................................................................................. 28

2-4-4. Description of how to input characters and numbers............................................................................. 29

2-4-5. Description of date entry........................................................................................................................ 31

2-4-6. Description of numeric entry ................................................................................................................. 32

2-4-7. Description on display for selection ...................................................................................................... 33

3. Basic procedure....................................................................................................................................................... 34

3-1. Basic procedures before starting titration:........................................................................................................ 34

3-1-1. Connecting the electrode ....................................................................................................................... 35

3-1-2. Calibration of detectors (preamplifiers) and electrodes ......................................................................... 36

3-1-3. Operational procedures .......................................................................................................................... 41

3-1-4. Purge the burette .................................................................................................................................... 42

3-1-5. Setting information on reagent .............................................................................................................. 43

3-1-6. Setting Method (measuring conditions)................................................................................................. 44

3-1-7. Selection of Method (measurement parameters and conditions) ........................................................... 48

3-1-8. Preparing a sample for measurement..................................................................................................... 49

3-1-8-1. Preparation of the sample................................................................................................................ 49

3-1-8-2. Setting sample parameters .............................................................................................................. 49

3-1-9. Starting titration..................................................................................................................................... 50

3-1-10. After-titration care ............................................................................................................................... 50

3-2. Usage of titration data ...................................................................................................................................... 51

3-2-1. Re-calculate titration data ...................................................................................................................... 51

3-2-2. Batch processing of titration data .......................................................................................................... 53

3-3. Sample settings ................................................................................................................................................ 55

3-3-1. Sample File Mode ................................................................................................................................. 58

3-3-1-1. Outline of Sample File.................................................................................................................... 58

3-3-1-2. Sample file parameter ..................................................................................................................... 59

3-3-1-3. Sample (list).................................................................................................................................... 61

3-3-1-4. Sample (sample file mode) ............................................................................................................. 62

3-3-1-5. Save CF (sample settings) .............................................................................................................. 64

3-3-1-6. Sample setup after starting titration................................................................................................ 65

3-4. About Setup ..................................................................................................................................................... 66

3-4-1. [Regist operator].................................................................................................................................... 67

3-4-1-1. [Regist] button ................................................................................................................................ 68

3-4-2. [International] ........................................................................................................................................ 69

3-4-3. [Interface] .............................................................................................................................................. 70

3-4-3-1. Printer setting.................................................................................................................................. 71

3-4-3-2. Balance setting................................................................................................................................ 73

3-4-4. [LCD Backlight].................................................................................................................................... 74

3-4-5. [Beep] .................................................................................................................................................... 75

3-4-6. [Maintenance]........................................................................................................................................ 76

3-5. Function ........................................................................................................................................................... 77

3-5-1. [Reagent information] ........................................................................................................................... 79

3-5-1-1. [Edit] − [Reagent information] ....................................................................................................... 80

3-5-1-2. [Edit] − [Reagent alarm] ................................................................................................................. 82

3-5-2. [Results list]........................................................................................................................................... 84

3-5-2-1. [Pickout] ......................................................................................................................................... 86

3-5-2-2. [Statistics] ....................................................................................................................................... 87

3-5-2-3. View of titration results .................................................................................................................. 90

3-5-2-4. [Simulation] .................................................................................................................................... 92

3-5-2-5. [Save (CF)] (Titration results) ........................................................................................................ 98

3-5-3. [Sample mode] ...................................................................................................................................... 99

3-5-4. [Blank list]........................................................................................................................................... 101

3-5-5. [GLP management] ............................................................................................................................. 102

3-5-6. [Auto statistics].................................................................................................................................... 104

3-5-7. [Decimal edit]...................................................................................................................................... 106

3-5-8. [Graph setting]..................................................................................................................................... 107

3-5-8-1. Graph range setup ......................................................................................................................... 109

3-5-9. [Changer Setting] ................................................................................................................................ 111

3-5-9-1. Acting time setup.......................................................................................................................... 113

3-5-10. [Other settings] .................................................................................................................................. 115

3-5-11. [System information]......................................................................................................................... 117

3-5-12. [Memory clear] .................................................................................................................................. 118

3-5-13. [Operation of CF card].......................................................................................................................120

3-5-13-1. [Load/Delete Method].................................................................................................................121

3-5-13-2. [Load/Delete titration results] ..................................................................................................... 124

3-5-13-3. [Load/Delete sample setting] ...................................................................................................... 126

3-6. Burette............................................................................................................................................................ 128

3-6-1. Dosing reagent ..................................................................................................................................... 130

3-6-2. Validation of burette precision ............................................................................................................ 132

3-6-2-1. Parameter settings for burette capacity validation ........................................................................ 133

3-6-2-2. Validation of Burette by precision check...................................................................................... 135

3-6-3. Replacement of burette unit ................................................................................................................. 137

3-7. Calibration...................................................................................................................................................... 138

3-7-1. Calibration condition setup .................................................................................................................. 138

3-7-1-1. [Edit] – [Configure sensor calibration conditions]........................................................................ 139

3-7-1-2. Configure sensor calibration conditions (Ch1/pH, Ch3/pH)......................................................... 141

3-7-1-3. Configure sensor calibration conditions (Ch3/Pol)....................................................................... 144

3-7-1-4. Configure sensor calibration conditions (Ch3/µS)........................................................................ 145

3-7-1-5. Configure sensor calibration conditions (Ch3/%T) ...................................................................... 146

3-7-1-6. [pH table] ...................................................................................................................................... 147

3-7-1-7. [pH table] − [User table] ............................................................................................................... 148

3-8. Method ........................................................................................................................................................... 149

3-8-1. Method list ........................................................................................................................................... 149

3-8-1-1. [Copy] ........................................................................................................................................... 151

3-8-1-2. [Clear] (Method conditions).......................................................................................................... 152

3-8-1-3. [Save (CF)] (Method data) ............................................................................................................ 153

3-8-2. Outline of Method................................................................................................................................154

3-8-3. [Titr. mode, Titr. form] ........................................................................................................................ 155

3-8-3-1. Titration, electrode and preamplifier............................................................................................. 159

3-8-3-2. Preamplifiers ................................................................................................................................. 160

3-8-4. [Predosing parameter].......................................................................................................................... 161

3-8-4-1. [Edit] − [Predosing parameter] ..................................................................................................... 162

3-8-5. [Titration parameter]............................................................................................................................ 165

3-8-5-1. [Dose Parameter] .......................................................................................................................... 169

3-8-6. [Control parameter] ............................................................................................................................. 171

3-8-6-1. EP sense method ........................................................................................................................... 184

3-8-6-2. Data sampling condition ............................................................................................................... 187

3-8-6-3. Control speed mode ...................................................................................................................... 188

3-8-6-4. Other control ................................................................................................................................. 194

3-8-6-5. Volume sampling time .................................................................................................................. 196

3-8-6-6. Initial values of Control parameters..............................................................................................197

3-8-6-7. Input range for potential parameters ............................................................................................. 200

3-8-6-8. Normalized potential..................................................................................................................... 200

3-8-7. [Calculation parameter] ....................................................................................................................... 201

3-8-7-1. Calculation formula ...................................................................................................................... 203

3-8-7-2. Constant........................................................................................................................................ 206

3-8-7-3. Titrant temperature compensation ................................................................................................ 207

3-8-8. [Report parameter] .............................................................................................................................. 208

3-8-8-1. Report format................................................................................................................................ 209

3-8-9. [Reagent parameter] ............................................................................................................................ 212

3-8-10. [Option parameter] ............................................................................................................................ 213

3-8-10-1. Rinse sequence ........................................................................................................................... 214

3-8-11. [Combined]........................................................................................................................................ 216

3-8-11-1. General description ..................................................................................................................... 216

3-8-11-2. [Combined] − [Combined] ......................................................................................................... 217

3-8-11-3. Combine a plural number of method .......................................................................................... 218

4. Others ................................................................................................................................................................... 220

4-1. When a preamplifier other than STD-610 is used.......................................................................................... 220

4-1-1. Preamplifier for photometric titration (PTA-610) ............................................................................... 220

4-1-2. Preamplifier for polarization titration (POT-610) ............................................................................... 223

4-1-3. Preamplifier for conductometric titration (CMT-610)......................................................................... 226

4-1-4. Preamplifier for pH dual input (TET-610) .......................................................................................... 230

4-1-5. How to change preamplifier ................................................................................................................ 231

4-2. Change maximum titration volume................................................................................................................ 232

4-3. Connecting Balance ....................................................................................................................................... 233

4-3-1. How to connect a balance .................................................................................................................... 233

4-3-2. Input sample size on balance ............................................................................................................... 235

4-3-3. Input on balance at the time of burette validation ............................................................................... 236

4-4. Usage of a multiple sample changer .............................................................................................................. 237

4-4-1. Selection of sampler ............................................................................................................................ 237

4-4-2. Standard sequence setup ...................................................................................................................... 237

4-4-3. User sequence setup ............................................................................................................................ 237

4-4-4. Setup sample conditions ...................................................................................................................... 237

4-5. Connecting additional burette ........................................................................................................................ 238

4-6. Connecting a plural number of measuring unit.............................................................................................. 239

4-7. Optional electrode cleaning unit (MW-510) .................................................................................................. 240

4-7-1. Connecting the electrode cleaning unit ............................................................................................... 240

4-7-2. Cleaning the electrode ......................................................................................................................... 241

4-8. Use COD titration unit (COD-510)................................................................................................................ 242

4-8-1. Connecting the COD titration unit....................................................................................................... 242

4-8-2. Parameter setup ................................................................................................................................... 244

4-8-3. Calculation formulas for COD measurement ...................................................................................... 246

4-8-4. Calculation formulas for COD measurement ...................................................................................... 246

4-9. Propeller stirrer (984300036)......................................................................................................................... 247

5. Maintenance.......................................................................................................................................................... 248

5-1. Daily maintenance ......................................................................................................................................... 248

5-1-1. Check the instrument ........................................................................................................................... 248

5-1-2. Check the electrode..............................................................................................................................248

5-1-3. Check the cable.................................................................................................................................... 248

5-1-4. Check the connectors ........................................................................................................................... 248

5-1-5. Check any leaking................................................................................................................................248

5-1-6. Check burette performance .................................................................................................................. 248

5-1-7. Check stirrer performance ................................................................................................................... 249

5-1-8. Check the nozzle.................................................................................................................................. 249

5-1-9. Preamplifier ......................................................................................................................................... 249

5-1-10. Replacement of Zeolite (molecular sieves)........................................................................................ 249

5-1-11. How to clean the burette unit ............................................................................................................. 250

5-1-12. Replacement of protection film ......................................................................................................... 251

5-2. Other Maintenance ......................................................................................................................................... 252

5-2-1. Storage of the instrument ..................................................................................................................... 252

5-2-2. Cleaning the electrode ......................................................................................................................... 252

5-2-3. Replacement of piston head ................................................................................................................. 253

5-2-4. Change switching valve .......................................................................................................................259

5-2-5. Replace titration nozzle ....................................................................................................................... 260

5-2-6. Replace tube ........................................................................................................................................261

5-2-7. Changing the blown off power fuse.....................................................................................................262

5-2-8. Replacing the clock battery.................................................................................................................. 262

6. Troubleshooting .................................................................................................................................................... 263

6-1. Error messages and remedies ......................................................................................................................... 263

6-2. Alarm message and remedies .........................................................................................................................266

6-3. Clogging of titration nozzle or switching valve ............................................................................................. 267

6-4. When it is difficult to mount the burette unit ................................................................................................. 268

6-5. Power failure .................................................................................................................................................. 270

6-6. Stirrer does not work properly ....................................................................................................................... 271

6-7. Piston burette does not work properly............................................................................................................272

6-8. Air bubbles are trapped in the piston burette.................................................................................................. 273

6-9. Titration is not controlled properly ................................................................................................................ 274

6-10. Endpoint is not detected by EP Stop or Full titration ................................................................................... 275

6-11. Erroneous endpoint is detected in Full or EP Stop titration ......................................................................... 276

7. Others.................................................................................................................................................................... 280

7-1. Part list ...........................................................................................................................................................280

7-1-1. Consumable parts ⋅ Maintenance parts ................................................................................................ 280

7-1-2. Option .................................................................................................................................................. 287

7-2. System Configuration..................................................................................................................................... 293

7-3. Specification................................................................................................................................................... 294

7-4. Reference ....................................................................................................................................................... 296

7-4-1. Parameter list ....................................................................................................................................... 296

7-4-1-1. Setup parameters ........................................................................................................................... 296

7-4-1-2. Function parameters ..................................................................................................................... 297

7-4-1-3. Method parameters ....................................................................................................................... 300

7-5. Warranty and After-Sale Service ................................................................................................................... 305

7-5-1. Warranty and After-Sale Service......................................................................................................... 305

1. Introduction

1-1. Overview of the instrument

We thank you for your continued patronage of KEM products. The AT-610 Automatic Potentiometric

Titrator you have purchased is the latest titration system to determine concentration of target substance in

liquids or solids, operated easily and resulting quickly with high precision and accuracy. By changing the

electrode and preamplifier, those titrations like acid base, redox and photometric can be equally performed

as well.

[Features]

1) Two (2) measuring units can be connected (simultaneous measurements in parallel)

Addition of another AT-610 as option to this unit allows you to make two measurements

simultaneously. In addition, this unit can be also used in combination with MKA-610 (Volumetric

KF titrator) or MKC-610 (Coulometric KF titrator).

2) A Large color LCD with two languages selective on display

A large 8-inch color LCD provides easy view and operation with language selection of either English

or Japanese on display.

3) Real time titration curve and two potentials are displayed and recorded simultaneously

Titration in progress can be seen in real time, and two potentials of titration and temperature, pH and

transmittance as well as pH and conductivity can now be recorded at the same time, which used to be

unavailable with the existing titration devices. Measurement of transmittance or conductivity requires

optional parts.

4) Operating panel is Touch-on type LCD

You just touch on the display panel following the guiding messages to complete a series of

measurements. The panel is covered with a protection film which is replaceable with a new one

whenever you want a better view in the course of time.

5) Operating unit and measuring unit can be separated

The measuring unit can be detached depending on sample type when so necessary.

6) Data Storage on Compact Flash (CF) Card:

Allow an operator to store Measuring conditions (Method Parameter) and Titration results on CF cards

(option).

7) GLP/GMP conformed

Up to 50 operators names can be registered. Also, check results with standard substances and

calibration records for electrodes can be recorded. Recorded results can be displayed as history.

Further, AT-610 features reminders of the day for replacing reagent and piston.

8) Platinum thermal resistor Pt100 sensor ensures precise measurement of temperature

Pt100 platinum resistance element is quipped for sensing correct measuring temperature.

1

1-2. About the manual

Please keep this manual near your system so that you can easily access to the necessary information you are

looking for while operating or preparing for measurement.

The below three boxed messages show the basis symbols of warning, caution and note that you will see in

this manual from time to time:

1. Where there exists a danger of physical injury or even possible death:

Warning!

There exists the danger of physical injury or even possible death if the

instruction is disregarded.

2. Where there exists a danger of property damage:

Caution!

There exists the danger of property damage if the instruction is

ignored.

3. When there exists a possibility of failure of instrument performance:

Note:

There exists the possibility of failure of instrument performance.

If ignored, warranty may not be covered.

* It is prohibited to copy a part or all of this manual without authorization by copyright.

* If you should find any part in this manual not clear to understand or missing article, contact your local

dealer or sales representative.

* Manufacturer will not be liable for any loss or damage directly or indirectly caused by use of the

instrument or its consequences.

* This Manual is based on the apparatus of standard specification. For details of those of special

specification, see its manual.

2

1-3.

Safety symbols

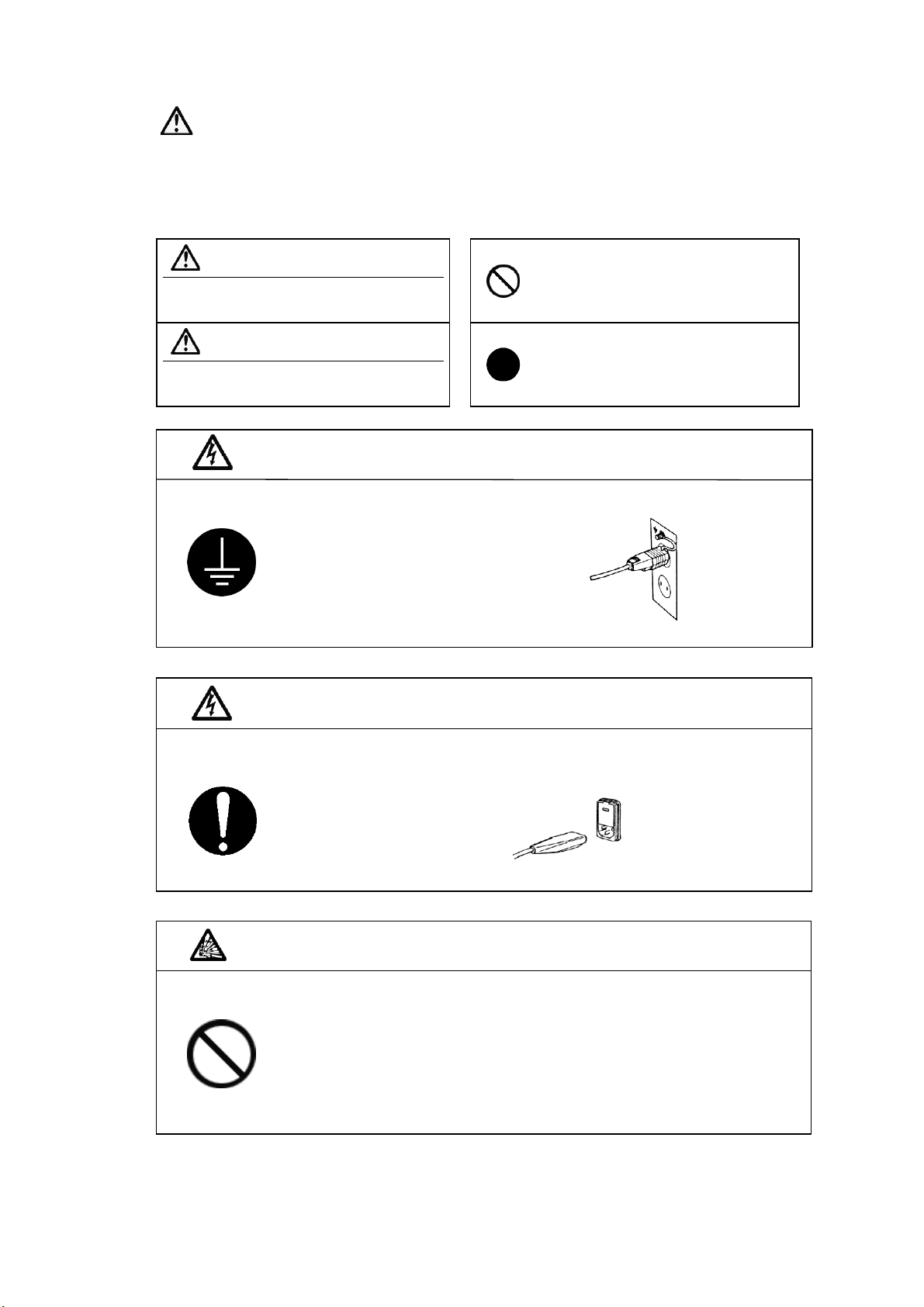

Always observe these signs and instructions.

You must observe cautionary messages and warnings in order to protect yourself as well as prevent others

from physical injury or property damages.

Warning

This symbol means "Danger of severe injury

or possible death".

Caution

This symbol means "Danger of injury or

property damage".

WARNING!

You must ground earth wire of power cable.

Ground the green wire of adapter if

power tap is 2-pin outlet.

3-pin plug has earth line to ground

by itself when plugged in.

Danger of electric shock if not grounded to earth.

WARNING!

This symbol means prohibition of an act.

This symbol means mandatory.

Use the same type and rating of fuse. Be sure to plug out power cord before

replace the fuse.

Danger of fire if a wrong fuse is loaded.

WARNING!

Do not use volatile chemical or work in flammable gas.

Danger of explosion inside the instrument.

3

WARNING!

Wear safety glasses, gloves or protective mask if necessary,and well

ventilate the room.

Danger of injury on your skin or in the eyes by splashing chemical.

Also your windpipe may get hurt if toxic gas is breathed in.

CAUTION!

Unplug the power cord when the unit can be troubled or exposed to a lightning.

Failure to observe this caution may result in a damage to the instrument.

CAUTION!

Do not operate in a way other than specified in the manual.

Danger of fire, electric shock or damage to the instrument.

CAUTION!

Do not open housing case or overhaul the unit for repair except by an

authorized service person.

Danger of fire, shock or malfunctioning of the unit.

4

About place for installation

Avoid the use of this instrument under the environment described below.

(Failure can lead to the degradation of performance and reliability of the system.)

• Operation of devices with strong electric motors using common power source

• Near strong magnetic/electric field

• Use of power source with too variable load

• Location of strong vibration

• Exposure to direct sunlight

• Location with large temperature difference

• Exposure to corrosive gas

• Exposure to extreme heat (Operation temperature: 5 to 35°C (41 to 95°F))

• Exposure to high humidity (Over 85%RH)

About power source

• Power for this instrument is AC100-120/200-240V ±10%and 50/60Hz.

• Supply power direct from the outlet, and do not share power from a tap.

• Do not put any obstacle around power outlet just case of need for plugging out power cord to avoid the

possible danger of the whole system in trouble.

About place for storage

• If the unit is not used for an extended period of time, first clean the electrode and place it for storage.

Also discard the regent in the burette, and clean it with pure water or methanol before storage.

It is recommended to pack the main unit in the carton box in which the instrument was first delivered.

• Avoid the places for storage under inadequate ambient conditions such as extremely high/low

temperature, high humidity or heavily dusty atmosphere.

About use

• Karl Fischer reagents are toxic chemicals. Therefore, please handle in a well ventilated room and be

aware of its danger.

• When a reagent etc. is spilt to Main unit or the connectors of magnetic stirrer, there is a possibility of

malfunction.

• When using the touch panel, just lightly touch it with a finger. Do not touch it with a sharp edge such

as pen tip; otherwise the touch panel can be incapable of normal operations.

About reagents

• The liquid contact part on burette and reagent bottle is made of materials such as glass, ceramics or

PTFE. Refrain from using reagents containing solid medium that may be incompatible with these

materials.

Other caution

• Do not use such a solvent as alcohol, acetone, thinner or the like for cleaning this instrument. Doing so

may adversely affect the instrument, e.g. deformation, discoloration or cracks. When cleaning this

instrument, wipe it with a soft cloth or tissue paper, after applying detergent diluted with water to the

soft cloth or tissue paper and adequately wringing out excess water in order not to allow water drops to

fall.

• Waste liquid should be drained out before the Drain pot is filled with it. Otherwise, waste liquid may

overflow into the stirrer unit, causing its breakdown.

Environmental condition

• This instrument is designed for the indoor use under the environmental conditions specified in the

Section 1.4 of CE marking (LVD, 73/23/EEC, EN61010-1) and the use of the Category II of

Overvoltage and the Pollution Level 2.

5

2. Preparations for measurement

2-1. Supplied parts

Check the supplied parts referring to the following parts list for MKA-610, Reagent Replacement Unit and

MCU-610. If you should find any missing or broken parts including the main unit, accessories or manual,

contact your sales representative or local dealer.

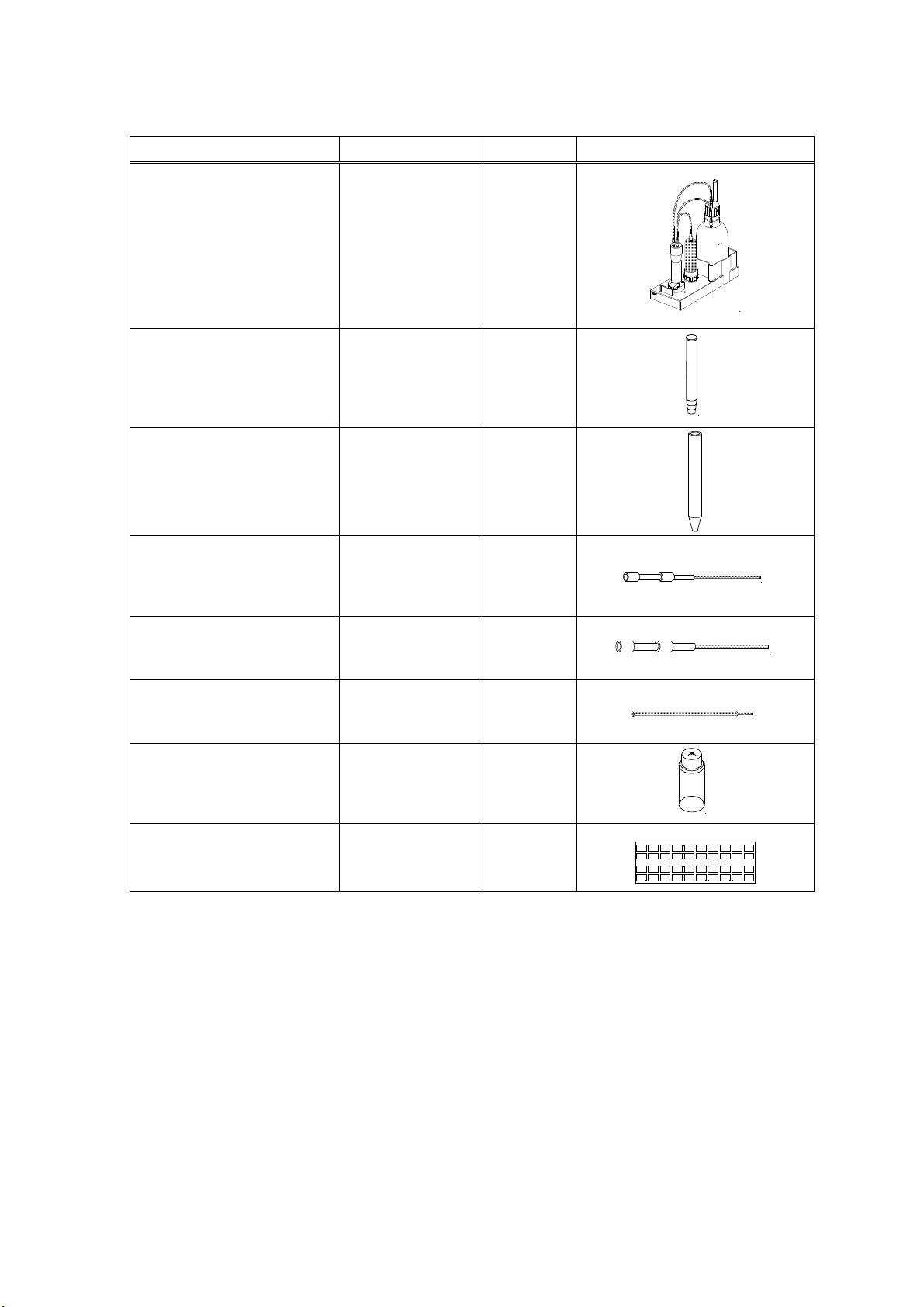

― Automatic Potentiometric Titrator AT-610 ―

Part name Part code Qty Sketch

Automatic Potentiometric unit*1 AT-610 1 unit

EBU-610-50B

Burette unit*2

(Standard unit: EBU-610-20B)

EBU-610-20B

EBU-610-10B

EBU-610-05B

EBU-610-01B

1 unit

E

B

U

6

1

0

K

F

Touch-on panel main control

unit*3

MCU-610 1 unit

Impact dot printer

(AC 100V)

(AC 120V)

(AC 230V)

-11

-12

IDP-100-10

1 unit

Note:

The details of components for above 1, 2 and 3 are shown on the

following pages.

6

― Components of AT-610 (*1) ―

Part name Part code Qty Sketch

Main unit ― 1 unit

Magnetic stirrer

(With a built-in preamplifier)

Stand bar 985500041 1 pce

Electrode holder 984305007 1 pce

Stirrer cable 984280031 1 pce

Connecting cable 32001140048 1 pce

(12001040148) 1 unit

Terminator 984290026 1 pce

Stirrer rotor (985003141) 1 pce

Combined glass electrode 98100C171 1 pce

Connecting cable 984290012 1 pce

(L=25mm)

7

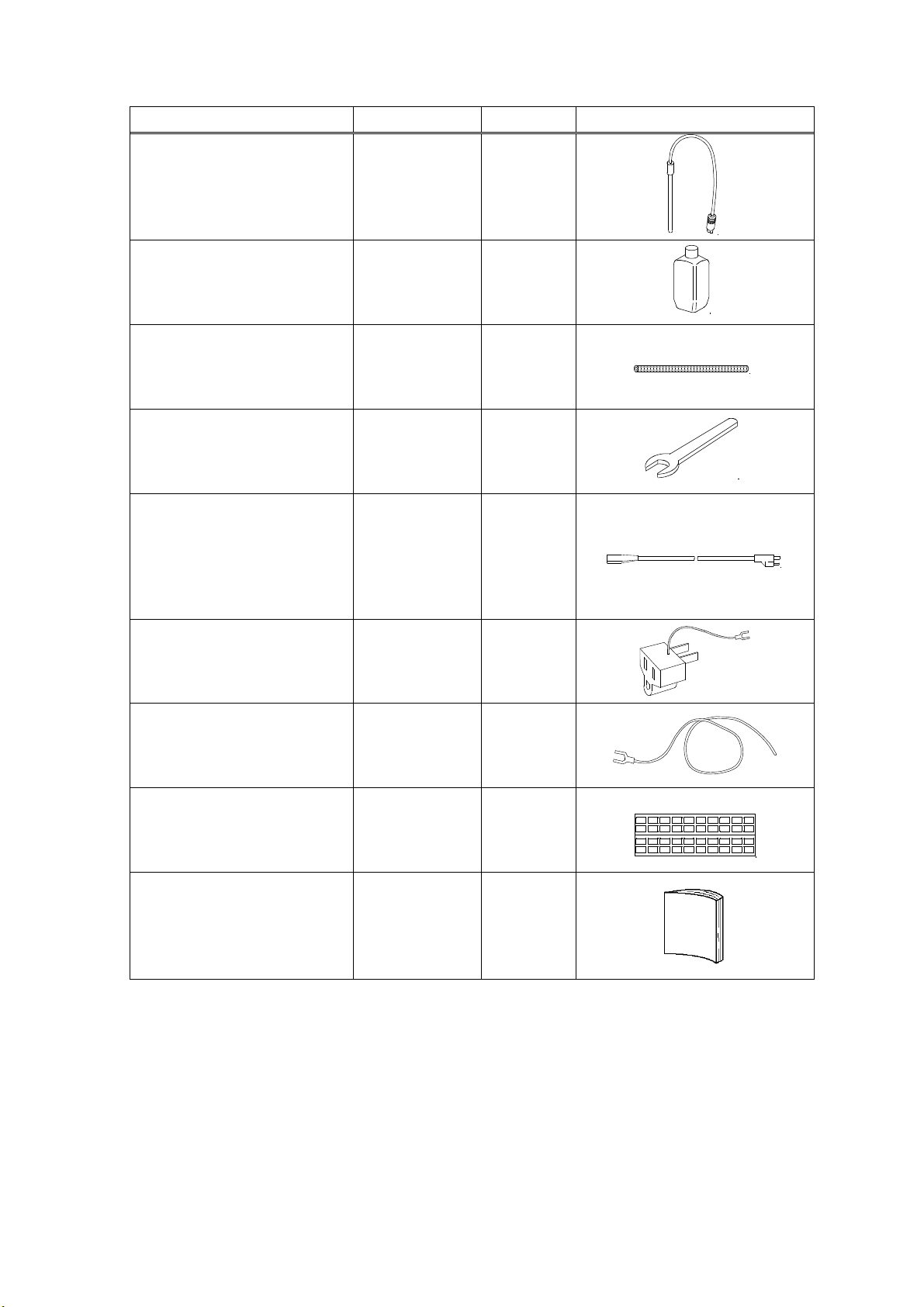

Part name Part code Qty Sketch

Temperature compensation

electrode

98100T171 1 pce

Internal solution for reference

988115001 1 pce

electrode (3.33M-KC1)

Piston extraction rod 985515002 1 pce

Wrench 8mm 985143339 1 pce

Power cord with earth wire

(AC 100/120V area)

(AC 220/230/240V area)

(for UK)

(for China)

983203198

983203461

983204199

64000180048

1 pce

Adapter for power connector

(AC 100V only)

983203199 1 pce

Ground wire (AC 100V only) 984333331 1 pce

CH1

CH1

CH1

CH1

CH1

CH1

7 8 9 10

7 8 9 10

CH1

Seal (985940010) 1 pce

CH1

1

234

5 6

CH2

CH2

CH2 CH2 CH2 CH2 CH2 CH2 CH2 CH2

1

234

5 6

CH1 CH1

Operation

manual

Operation manual 69000680148 1 copy

8

When the photometric titration kit (AT-610-PT) is purchased, the following parts are also included in the kit.

Part name Part code Qty Sketch

Photometric sensor 12001100048 1 set

Connecting cable 984280030 1 pce

5

5

5

5

3

3

3

3

0

0

0

0

n

n

n

n

m

m

m

Interference filter (530nm)* 12001120048 1 pce

m

6

6

6

6

3

3

3

3

0

0

0

0

n

n

n

n

m

m

m

Interference filter (630nm) 12001120148 1 pce

m

Shutter 985505502 1 pce

* Attached to the photometric sensor.

When the polarization titration kit (AT-610-OT) is purchased, the following part is also included in the kit.

Part name Part code Qty Sketch

Twin platinum electrode 98100M511 1 pce

When the conductometric titration kit (AT-610-CT) is purchased, the following part is also included in the kit.

Part name Part code Qty Sketch

Conductivity cell 98101K321 1 pce

9

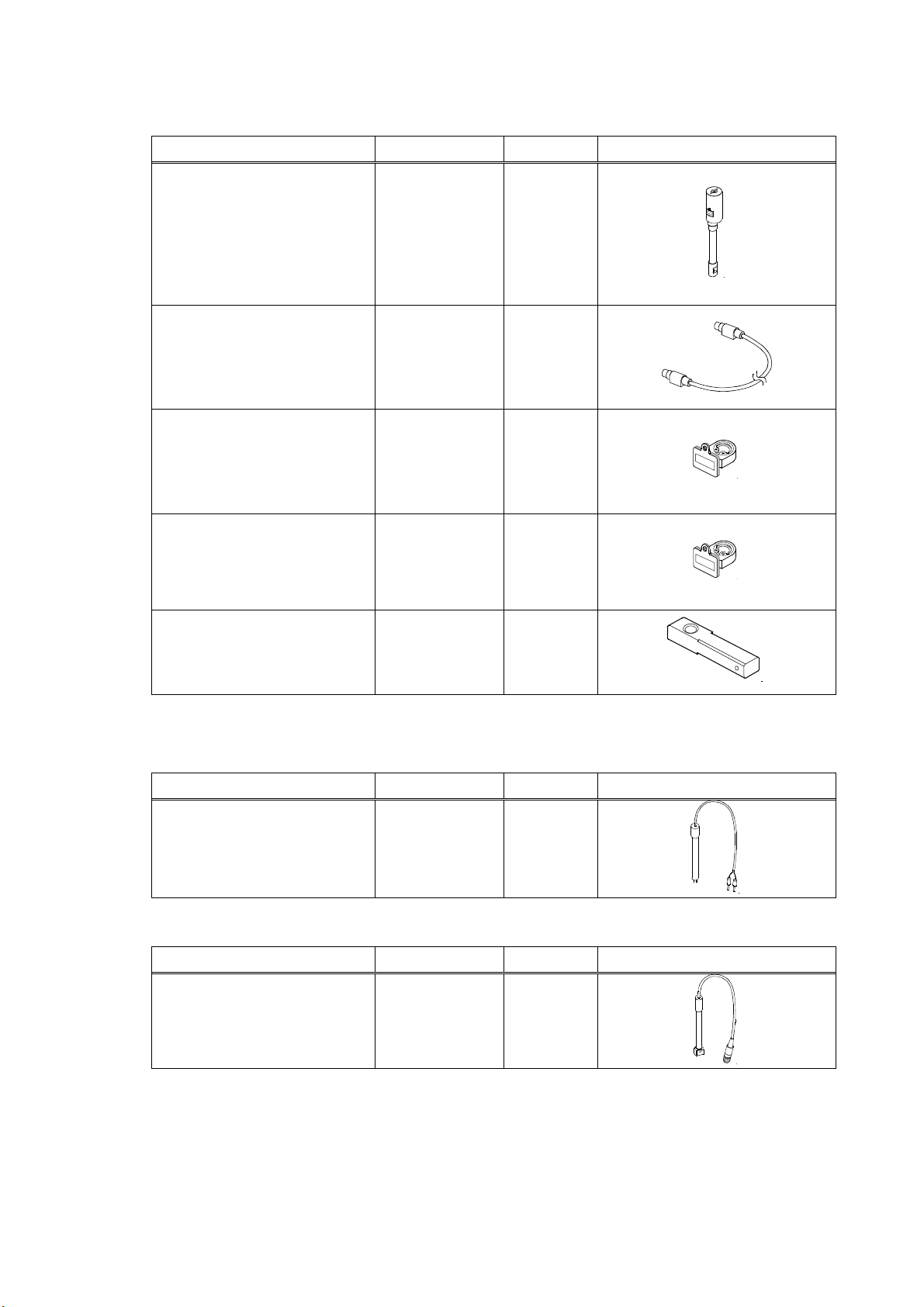

― Components of EBU-610-01B, 05B, 10B, 20B, and 50B (*2) ―

Part name Part code Qty Sketch

Burette unit*

―

1 set

Zeolite tube 984300053 1 pce

Nozzle pocket (984300051) 1 pce

Diffusion proof nozzle / STD

(For EBU-610-01B, 05B, 10B,

12001690248 1 pce

and 20B only)

Titration nozzle / 50mL

(For EBU-610-50B only)

12001690148 1 pce

E

B

U

6

1

0

-

2

0

B

Titration nozzle tip 985210027 1 pce

Degas vial (with septum) 987220003 1 pce

CH1

CH1

CH1

CH1

1

Seal (985940010) 1 pce

234

CH2

CH2

CH2 CH2 CH2 CH2 CH2 CH2 CH2 CH2

1

234

* The burette unit comes with a reagent bottle cap (with a rubber plug)(984300052) and a polyethylene

bottle (69000280048).

CH1

5 6

5 6

CH1 CH1

CH1

CH1

7 8 9 10

7 8 9 10

CH1

10

11

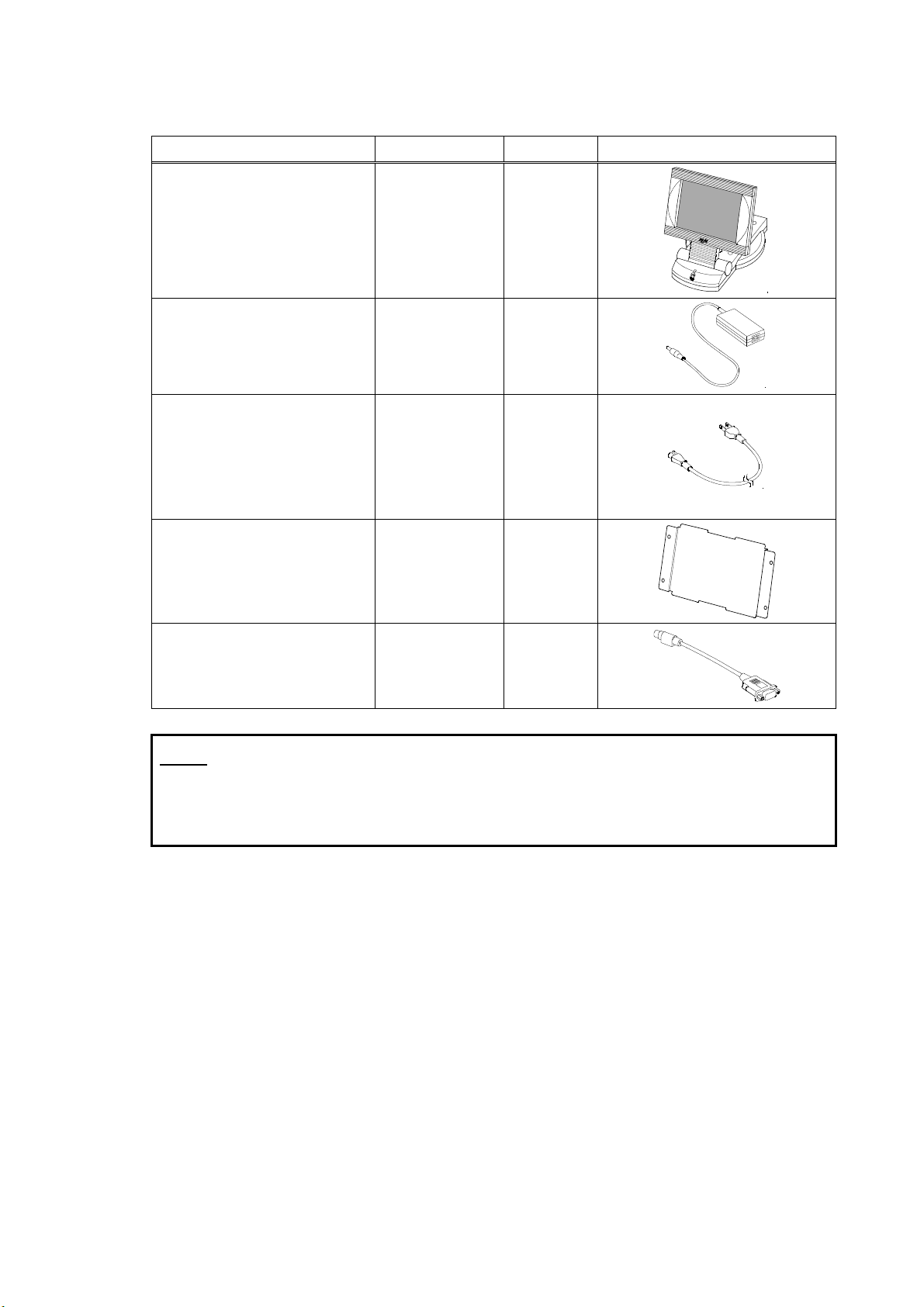

― Component of MCU-610 (*3) ―

Part name Part code Qty Sketch

Main control unit ― 1 unit

AC adapter 984030052 1 pce

Power cable

(AC 100V/120V area)

(AC 220/230/240V area)

(for UK)

(for China)

984290035

984290034

984290036

64000350048

1 pce

Protection film (985600093) 2 pce

Connecting cable

(Mini DIN-D Sub)

984280032 1 pce

Note:

Parts with parenthesized part code have unique order units or packing

forms different from others. Therefore, please refer to the section “7-1.

Part list” when ordering these parts.

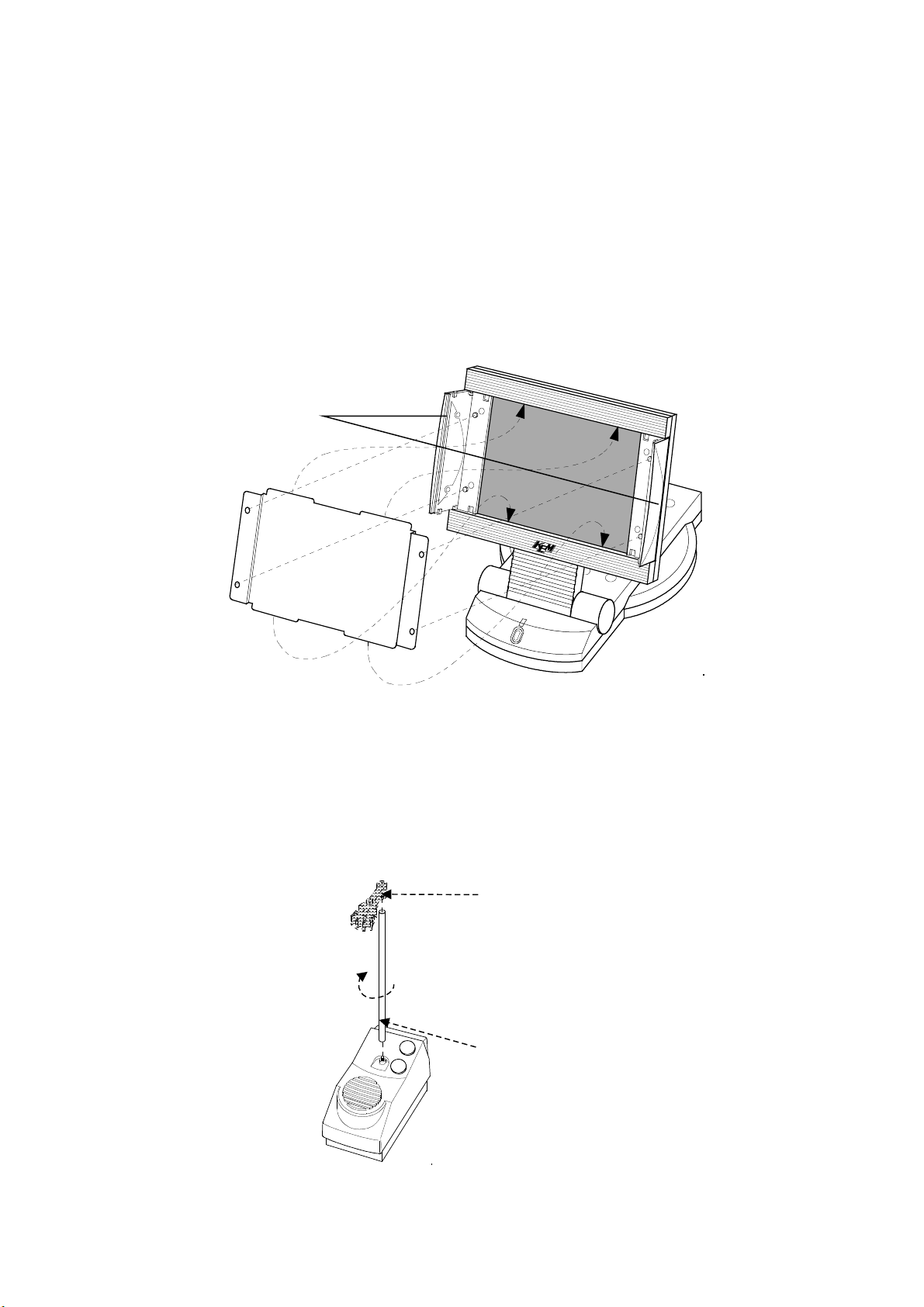

2-2. Installation and start-up

2-2-1. Protection film

Attach the protection film on the display panel of Main control unit (MCU-610):

1) Make sure the power of Main control unit is turned off.

2) Open the control panel.

3) Attach the supplied film as follows: Insert the film into the vertical gap, and match the film holes and

raised portions on panel.

4) Close the panel.

Panel

2-2-2. Assembly of magnetic stirrer

1) Squeeze the stand bar into the designated position on the stirrer as shown in the figure.

2) Install the electrode holder on the top of the stand bar. The height of electrode holder can be adjusted

with the clip under the electrode holder.

Electrode

holder

Stand bar

12

13

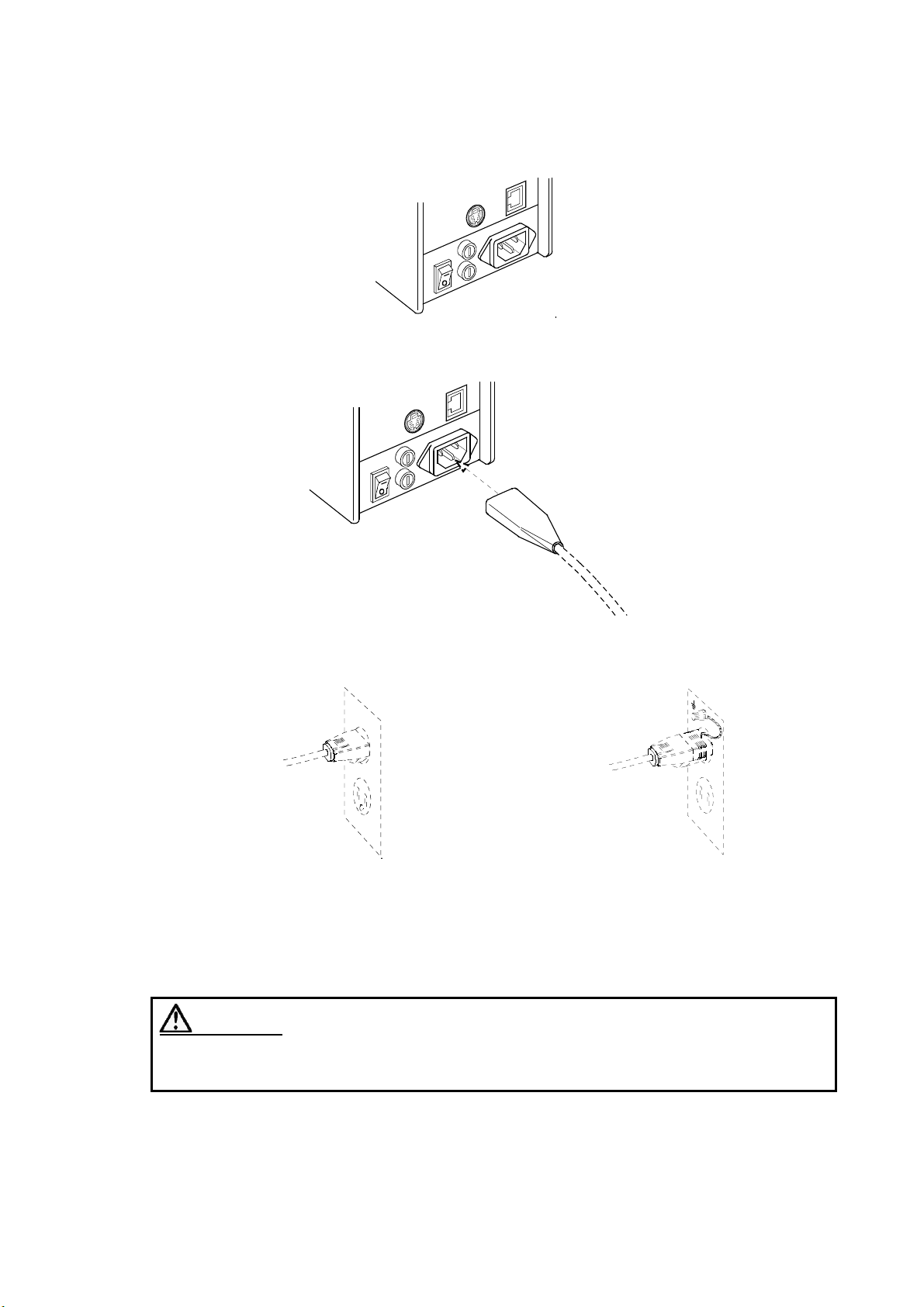

2-2-3. Power cable

1) Make sure the power switch is in Off position.

2) Plug in the supplied power cable on the back of unit.

3) Connect the power cable to the power outlet.

< 3-pin plug >

The 3 pins plug has an earth terminal and

grounds to the earth by itself.

Warning!

The earth wire must be grounded. If not, there exists a danger of

electric shock.

< 2-pin plug >

Attach an adapter for power connector to the

plug and ground the green wire to the earth

terminal.

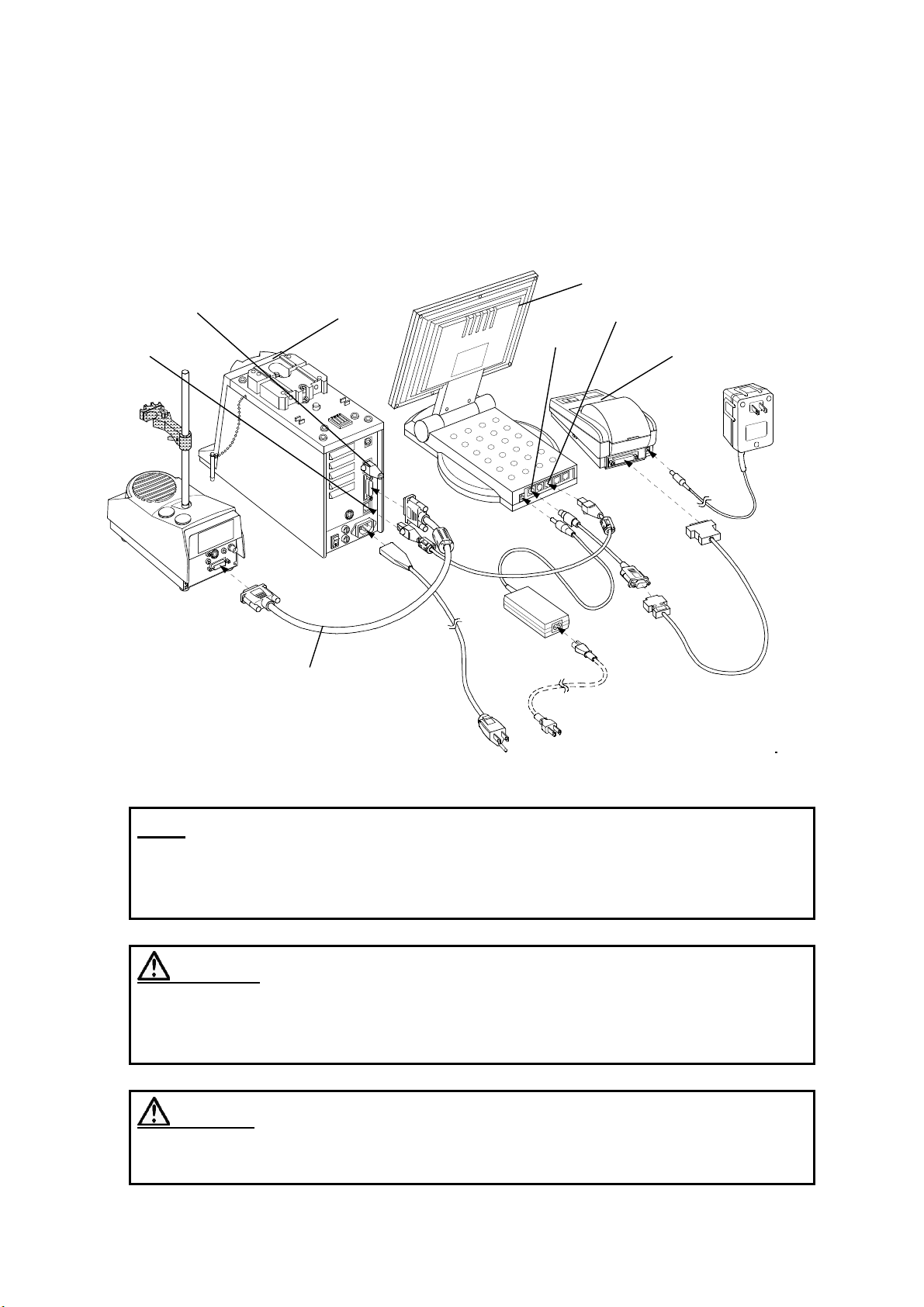

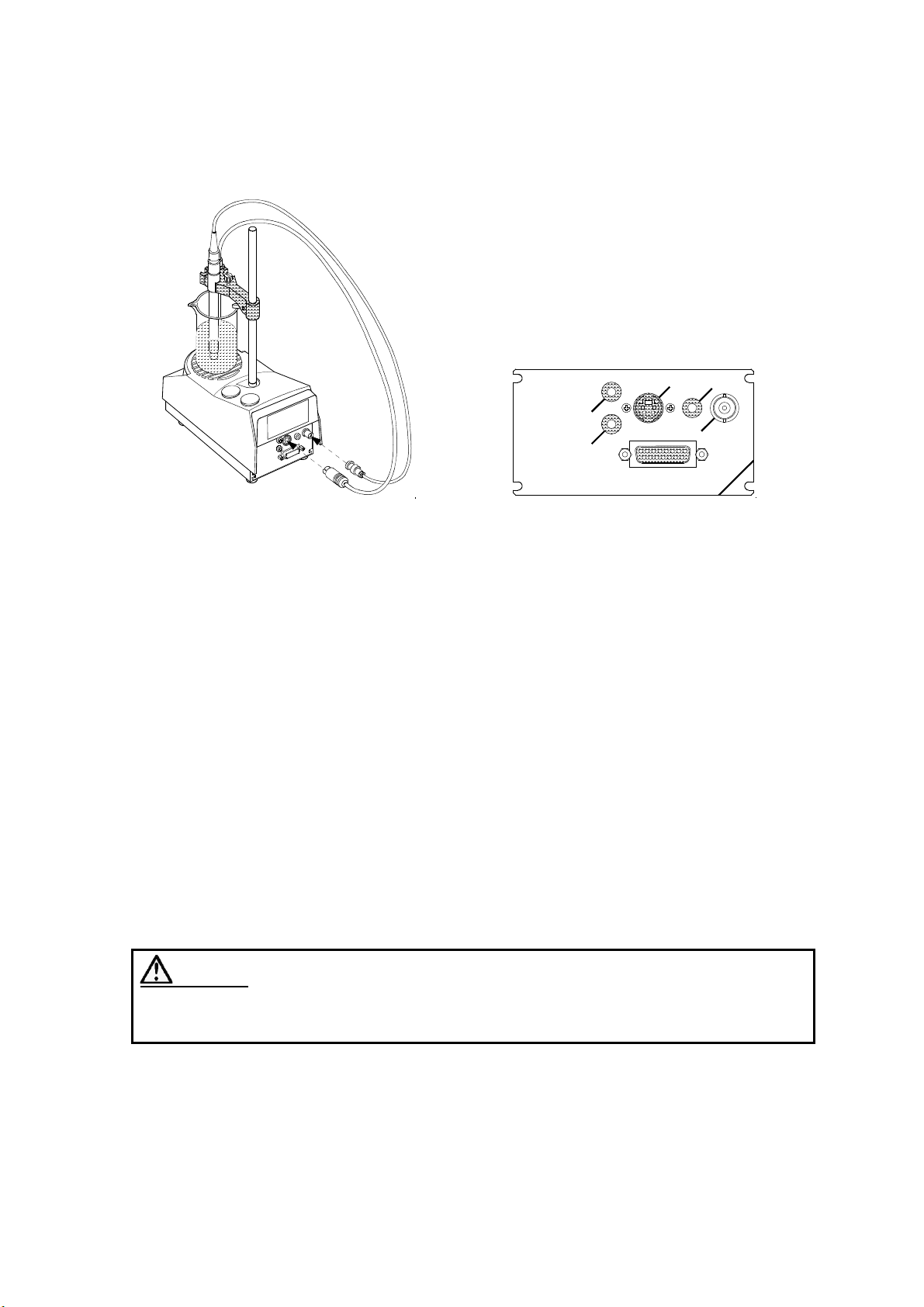

2-2-4. Connecting cables

Connect the cables as shown below.

Connect MCU-610 and AT-610 with connecting cable via K-NET port on the back.

Connect MCU-610 and Printer with the cable via COM1 or COM2 port on the back of MCU-610 and the

printer port.

MCU-610

Terminator

K-NET

AT-610

COM1

K-NET

Option printer

(IDP-100)

Stirrer cable

Note:

Turn on the power only after all of the cables are connected. Work on

the stirrer cable only when the main power switch is off in order to avoid

malfunction of the main unit.

Warning!

Use an AC adapter appropriate to the power line voltage. Make sure of

the rating of the AC adapter before plug it in to avoid malfunction of the

unit or breakout of a fire.

Caution!

Operating the unit without plugging Terminator may cause a

communication error (halt) due to susceptibility to noise.

14

15

2-2-5. Set up the address for measuring unit

Set MCU No. switch on the back of measuring unit to “1” position.

C

D

B

E

A

F

0

9

1

8

2

7

6

3

5

4

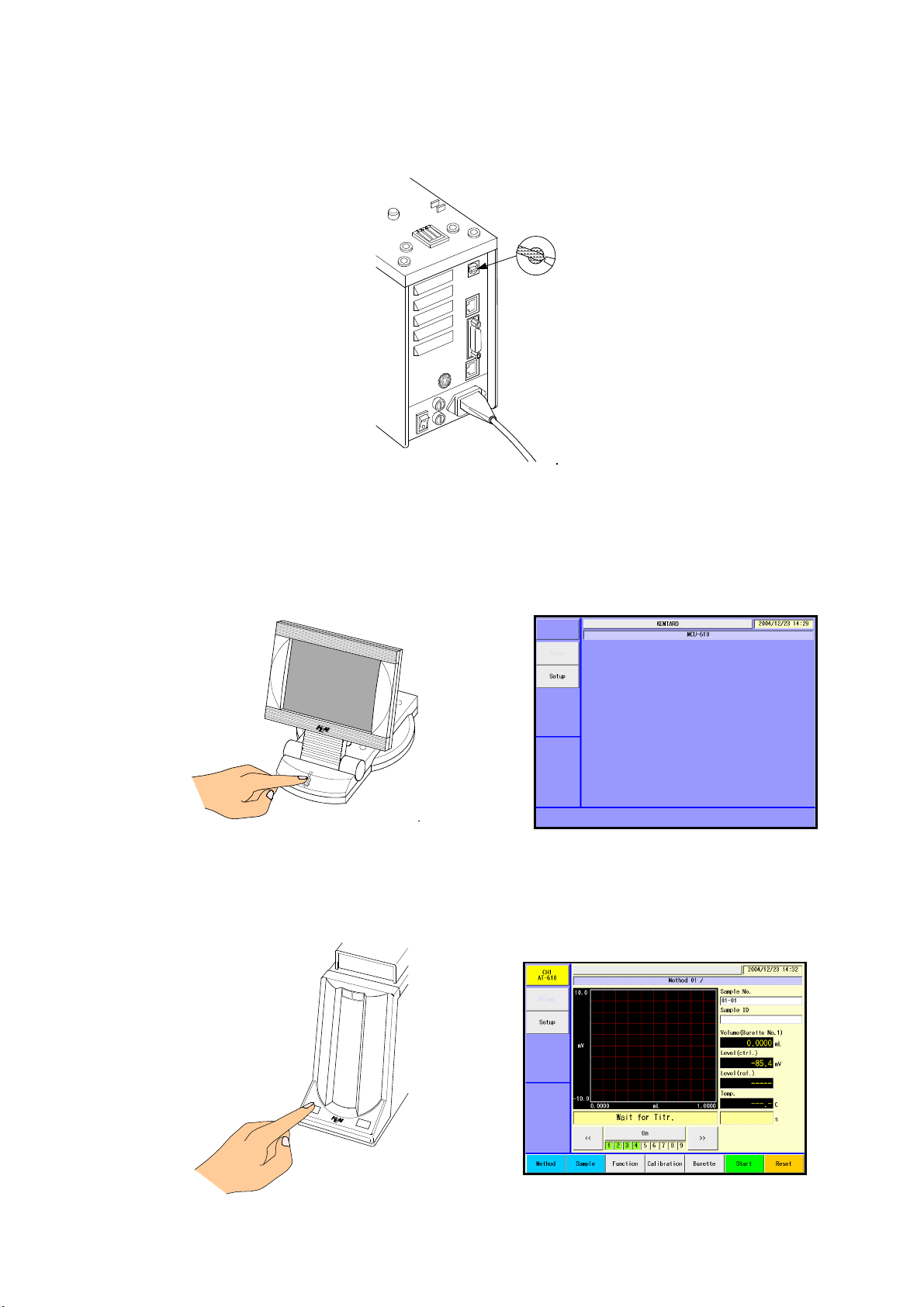

2-2-6. Start-up

1) Make sure the power of measuring unit is off, and then turn on the power of Main control unit. The

screen will show the initial display when first power is turned on after the unit is delivered and

unpacked.

2) Turn on the power of measuring unit by turning on “Power” switch on the back of unit, and then, press

[Power] button in front. The screen of Main control unit will show the below display, which will first

appear from the next time on.

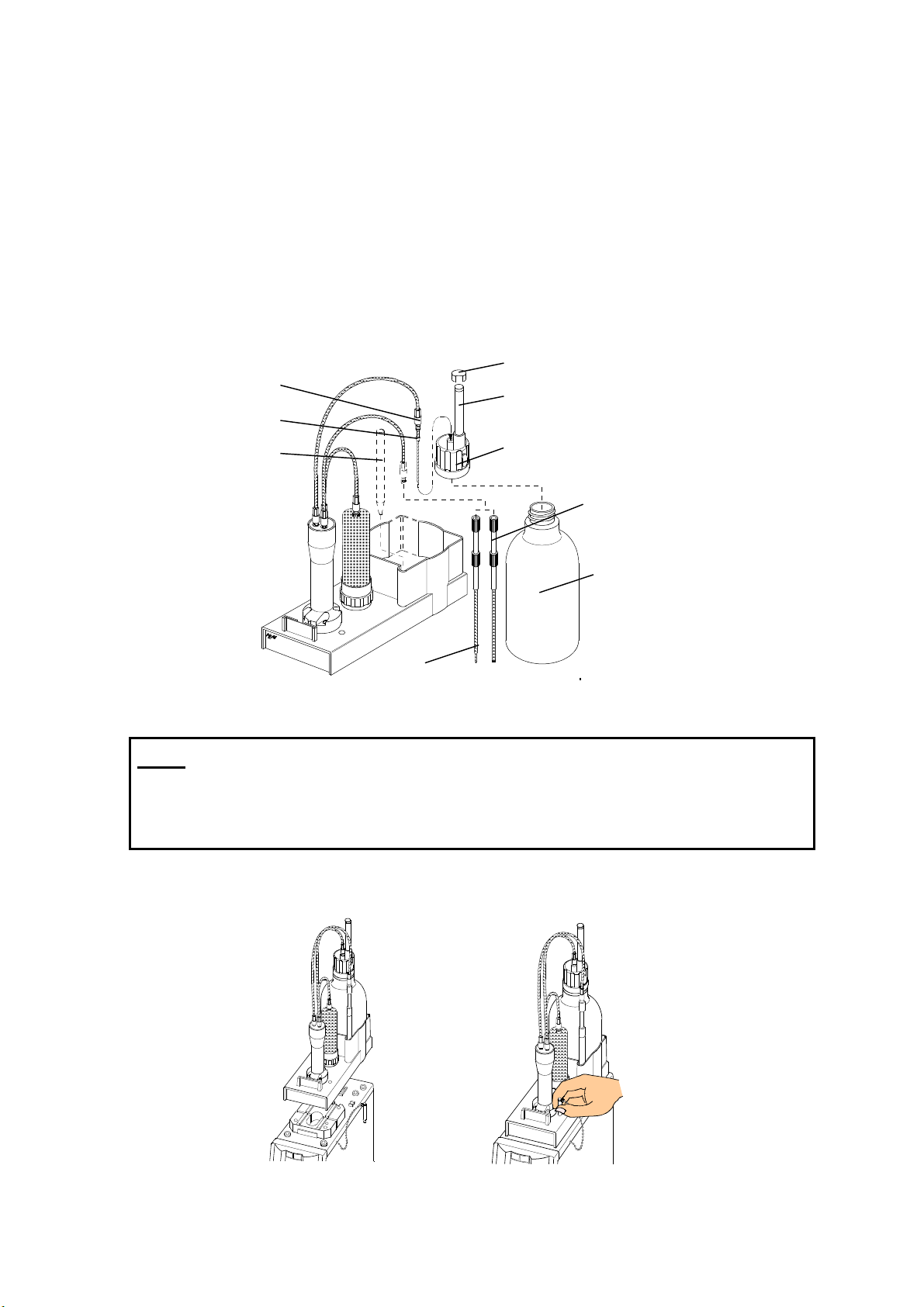

2-2-7. Installation of burette unit

1) Insert the tube from burette unit through the reagent bottle cap, and settle the bottle it in place as shown

below. (Please check that the joint and the stopper are attached to the tube.)

2) Peel off the seal on Zeolite tube, and install it onto the reagent bottle cap.

3) Put the nozzle pocket on burette unit.

4) Connect the diffusion proof nozzle with the tube as shown below.

When using the titration nozzle in order to perform constant dose, change the tip of diffusion proof

nozzle (P/N: 12001690248; with defoaming feature) to the titration nozzle tip before connecting it with

the tube. (See Section 5-2-5. “Replace titration nozzle”.)

Seal

Joint

Stopper

Zeolite tube

Nozzle pocket

EB

U

-

6

1

0

-

2

0B

Reagent bottle cap

Titration nozzle

Note:

Remove the seal on the Zeolite tube first.

When a bottle other than supplied one is used and its outside diameter is

smaller than that of the burette unit, use the optional bottle holder.

5) Place the burette unit onto the main unit, and push it towards you to set it in.

6) Insert the lock pin into the unit until it reaches the bottom.

Diffusion proof nozzle

Polyethylene bottle

16

17

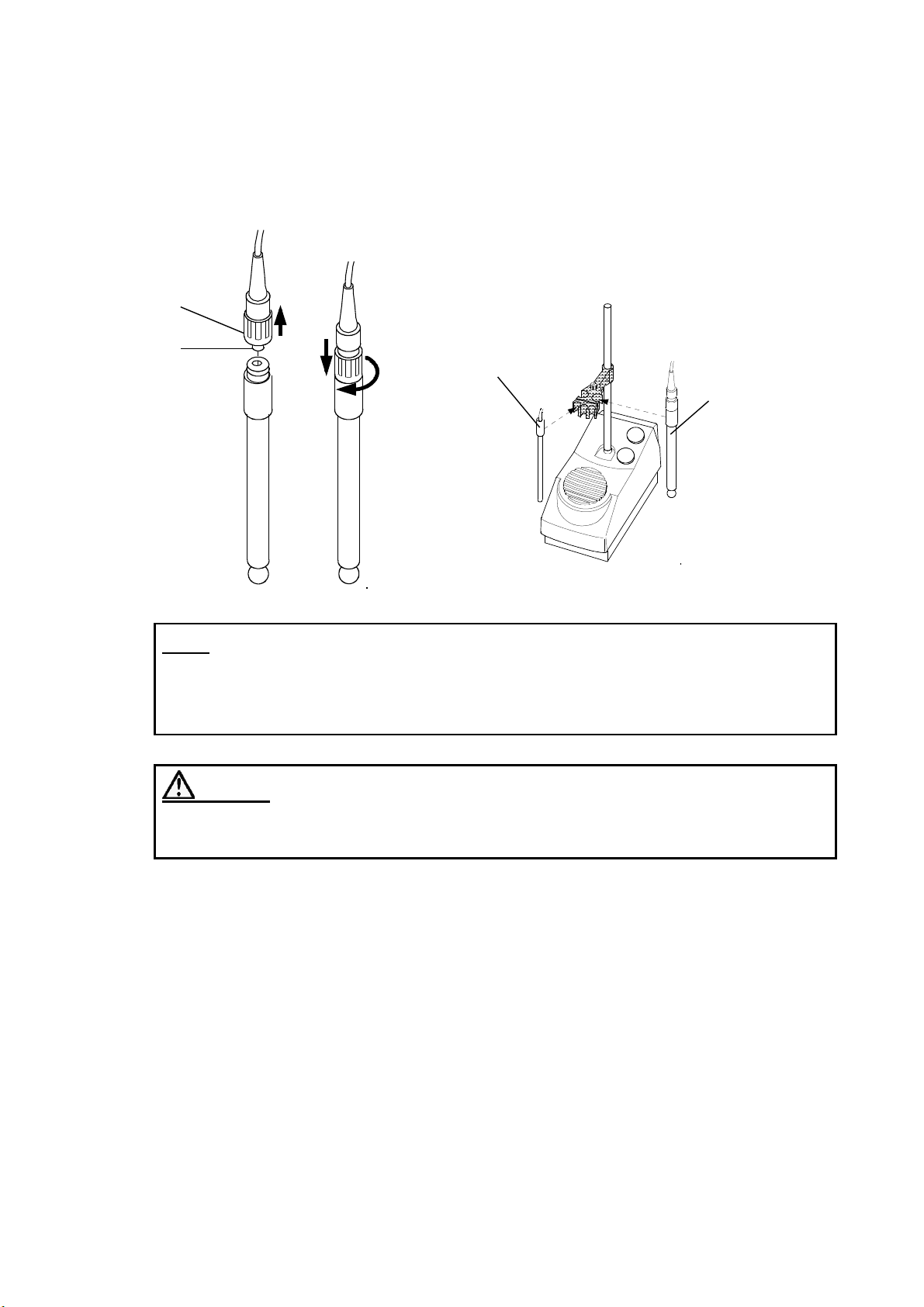

2-2-8. Installation of electrode

1) Connect the cable with an electrode. While watching the tip of electrode cable (pin as shown in the

figure), insert it into the connector until it clicks in it. Then, tighten the cap. An electrode with the

lead already connected does not require this step. Fix the electrode to the holder as shown.

Cap

Pin

Note:

The electrode cable must be securely connected to the electrode

connector until it clicks in, and then tighten the cap. Loose connection

may result in abnormal signal detection.

Caution!

If you give excessive force to the electrode, it may break. Slowly turn

the electrode to connect the holder to it.

Temperature

compensation electrode

Ex.)

Combination

electrode

(98100C171)

2) Ensure that the power switch is in OFF position.

3) Connect the electrode lead with the preamplifier. Connect one for temperature compensation with T1

jack and the combination glass electrode (98100C171) lead with G1 jack.

2

M

R2

T1

MAI N UNI T

< pH glass electrode (98100H1xx) or Ion electrode (981001xx) >

Connect the lead from an electrode with G1 jack and the clear cable (984290014 or 984290017) for

reference electrode (98100Rxx) with R1.

< Metal electrode (98100M2xx or 98100M3xx) >

When connecting an electrode with detector 1, insert the electrode cable to G1, and for reference

electrode (98100Rxx) plug the clear connecting end of the electrode cable (984290014 or 984290017)

in R1.

When connecting an electrode with detector 2, plug the clear connecting end of the electrode cable

(984290014 or 984290017) in M2, and for reference electrode (98100Rxx) plug the clear connecting

end of the electrode cable (984290014 or 984290017) in R2.

< Combination electrode (98100C2xx, 98100C7xx or 98100C8xx) >

When connecting the electrode with detector 1, connect it with G1 jack.

When connecting the electrode with detector 2, plug the clear connecting end of the electrode cable

(984290014 or 984290017) in M2 jack and the black end in R2 jack.

1

R

G1

0

61

-

TD

S

18

Caution!

The electrode is made of glass. If given excessive force, it may break

and hurt your hand. Care should be taken when handle the electrode.

9

2-3. Parts configuration and each function

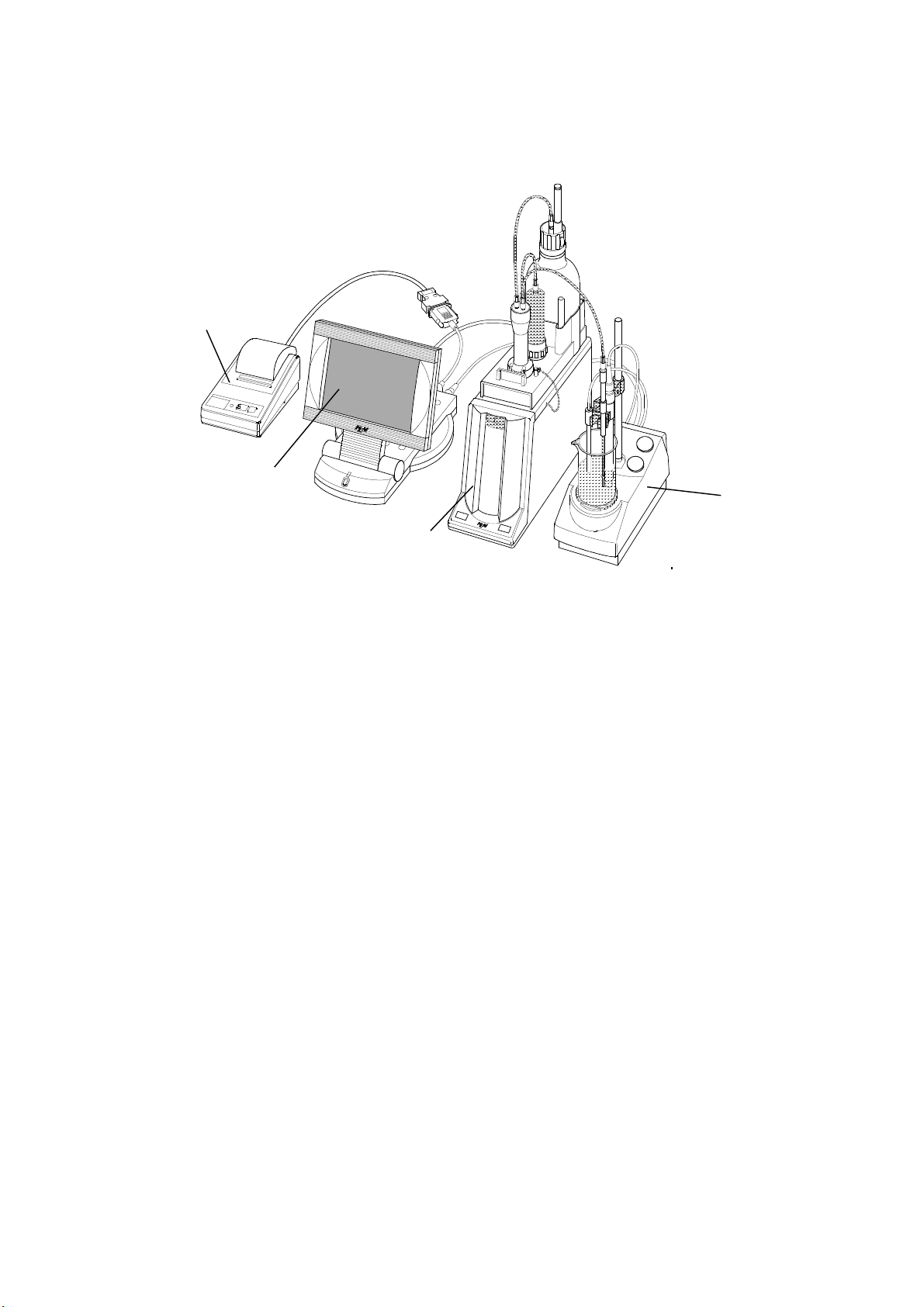

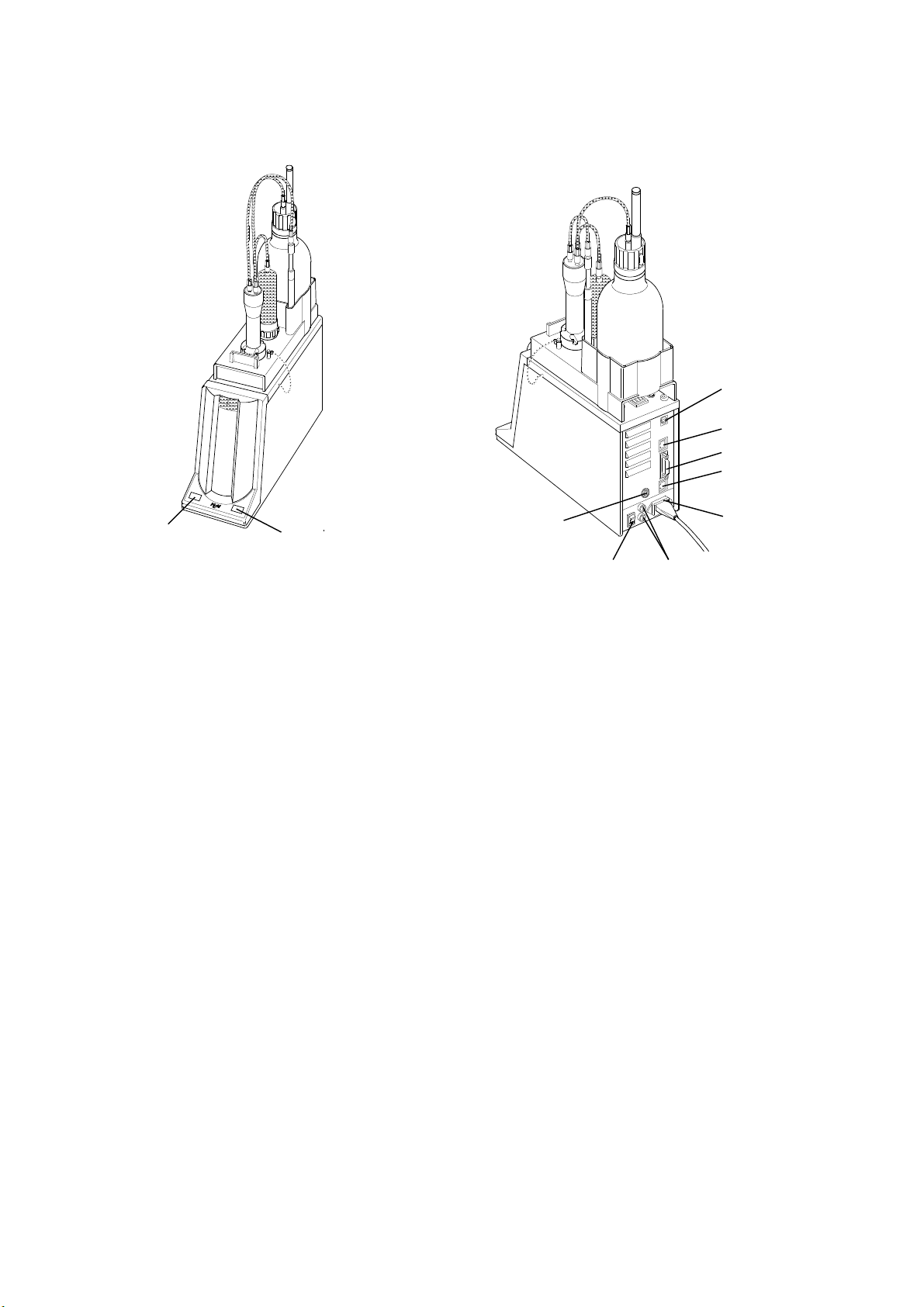

2-3-1. Automatic Potentiometric Titrator

4)

1)

2)

3)

1) Main control unit (MCU-610)

Operating unit Automatic Potentiometric Titrator.

2) Measuring unit (AT-610)

Control unit for Automatic Potentiometric Titrator.

3) Stirrer

Measuring unit for Automatic Potentiometric Titrator. Magnetic stirrer and Preamplifier are

integrated.

4) Impact dot printer (IDP-100)

Print out measurement results and parameters.

1

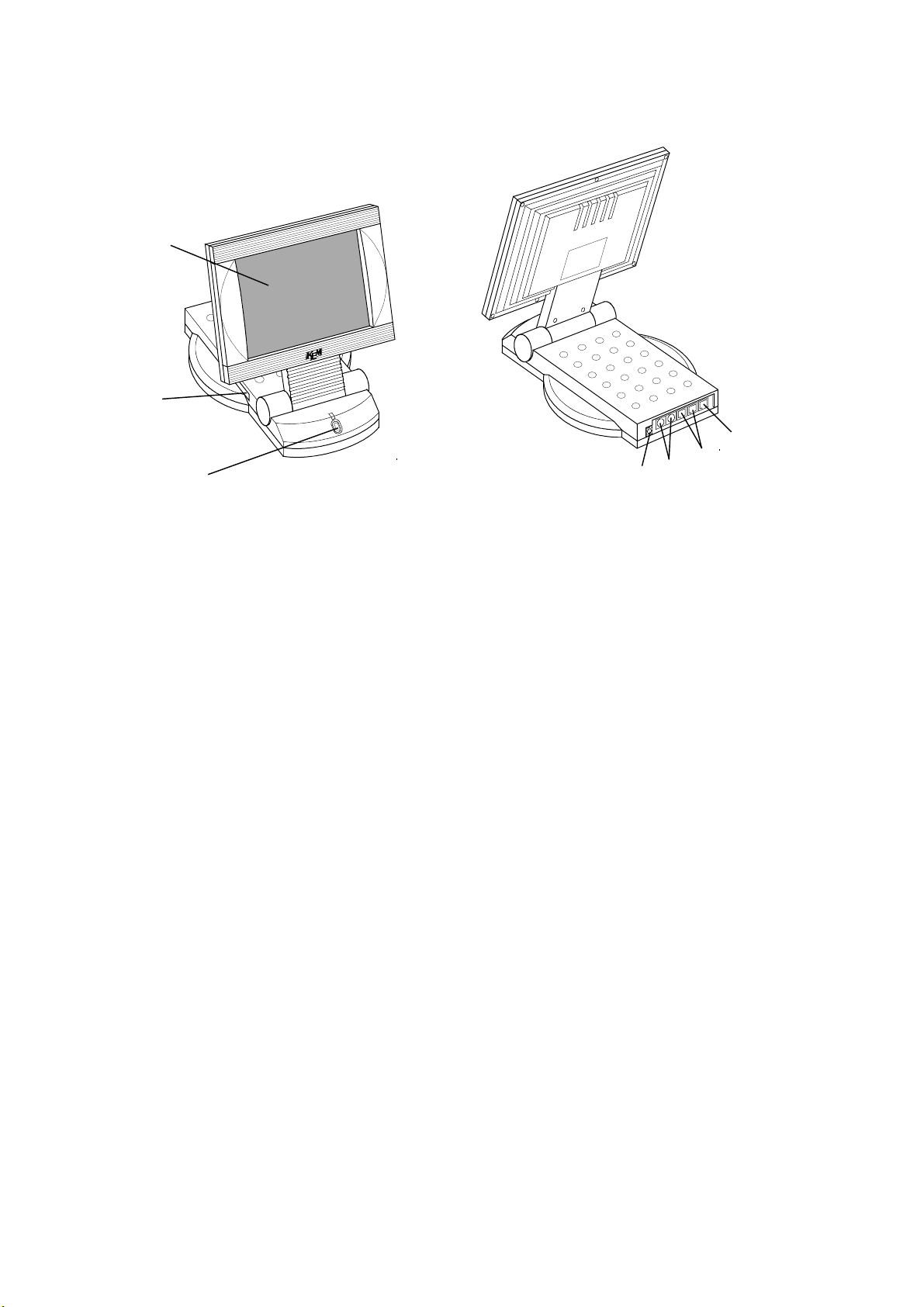

2-3-2. Main control unit (MCU-610)

1)

2)

3)

1) Touch-on panel display

This panel displays operating buttons and measurement results as well as configured parameters.

With these buttons on screen, you can maneuver the sequence for measurement by just touching on the

necessary buttons on display.

4)

5)

7)

6)

2) Card slot

Insert the CF card (option).

3) Power switch

This switch turns on or off the power of Main control unit. It should be noted the power must be

turned on again at least 10 seconds interval.

4) ∼ LINE

Connector for power cord.

5) COM1 and COM2 port

These ports are for connections to Printer, Balance or Personal computer. The printer prints out

measurement results as well as selected parameters. When an electronic balance is connected, the

sample weight is automatically input for measurement. Personal computer is connected to this port

for data acquisition using the optional software.

6) K-NET connector

Connecting port for measuring unit.

7) PC connector

This connector is not used in this system.

20

21

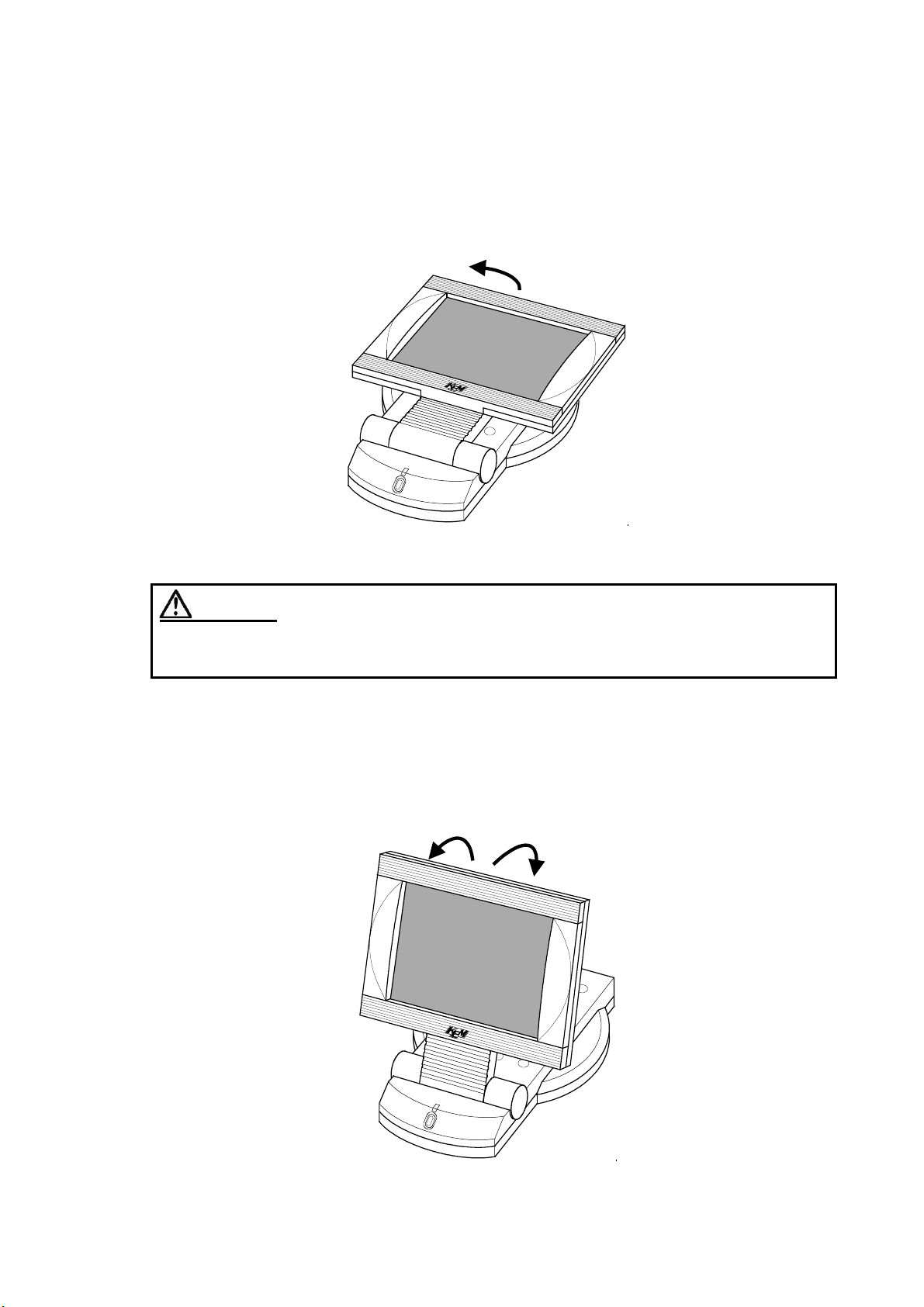

< Adjust the Touchpanel >

Lift the Touchpanel slowly as shown below until you hear it click and stop. Then tilt and sit it to the point

where you can see the monitor well. When lifting it up too much, once lift it to the upright position

according to the instructions in < How to tilt the Touchpanel of MCU-610 >, followed by folding the panel.

Then tilt it again to adjust the angle.

Caution:

Do not force the Touchpanel when tilting it.

Failure may break the joint for tilting the Touchpanel.

< How to tilt the Touchpanel of MCU-610 >

Once lift the Touchpanel to the upright position as shown below.

Then tilt the panel backward.

1111

2222

2-3-3. Measuring unit (AT-610)

< Main unit >

9)

8)

7)

6)

1)

1) [Power] button

It turns on or off the power. The power is turned off when pressed for more than 5 seconds. This

button works only when the power switch on the rear panel of measuring unit is in On position.

2) [Reset] button

On-going measurement can be aborted with this button, and the unit sets in standby mode.

3) Power switch on rear

This switch turns on or off the measuring unit. This is the main switch for measuring unit, and

[Power] switch in front works only when this switch is in On position.

4) Fuse box

Power fuse rated for T3.15A/T250V is housed here.

5) Power connector

Connecting port for power cable.

6) K-NET connector

Connecting port for communication with Main control unit.

2)

10)

3)

4)

5)

7) Stirrer port

Magnetic stirrer is connected to this port.

8) S-Bus port

Connector designated for connecting with the optional External burette unit (APB-600, APB-610 or

APB-620) or Multiple sample changer (CHA-600).

9) MCU No. switch

The main unit group number (MCU No.) connected to measuring unit is selected here.

10) Temp. Comp. connector

Connector designated for connecting with the optional titrant temperature compensation sensor.

22

Loading...

Loading...