Page 1

Inverter Air Conditioner

Installation Manual

KSV25CRF, KSV35CRF, KSV70CRF,

KSV25HRF, KSV35HRF, KSV52HRF,

KSV70HRF, KSV80HRF

Refrigerant R32

Page 2

WARNING

WARNING

TIPS & INFORMATION

ENVIRONMENTAL TIPS

Congratulations Contents

Congratulations and thank you for choosing our Inverter air

conditioner. We are sure you will find your new air conditioner a

pleasure to use. Before you use the air conditioner, we recommend

that you read through the entire user manual, which provides the

description of the air conditioner and its functions.

To avoid the risks that are always present when you use an electrical

appliance, it is important that the air conditioner is installed

correctly and that you read the safety instructions carefully to avoid

misuse and hazards.

We recommend that you keep this instruction booklet for future

reference and pass it on to any future owners.

After unpacking the air conditioner please check it is not damaged.

If in doubt, do not use the air conditioner but contact your local

Electrolux Customer Care Centre.

Meanings of symbols used in this manual are shown below:

warning

This symbol indicates information concerning your

personal safety

caution

This symbol indicates information on how to avoid damaging

the appliance

Important safety instructions ....................................... 3

Notice for installation .................................................. 3

Minimum floor areas .................................................... 4

Components ................................................................ 4

Product description .....................................................5

Installation site instructions ......................................... 6

Rooftop installation ..................................................... 7

Outdoor unit installation .............................................. 8

Indoor unit installation ................................................. 9

Installation ................................................................. 19

Testing the air conditioner ......................................... 23

Installation checklist ................................................... 24

Post installation checks .............................................. 25

Warranty .................................................................... 27

important

This symbol indicates tips and information about

use of the appliance

environment

This symbol indicates tips and information about economical and

ecological use of the appliance

This symbol indicates never to do this

This symbol indicates always do this

2 Contents

Page 3

WARNING

WARNING

R300 refrigerant warning

ENVIRONMENTAL TIPS

Important safety instructions Notice for installation

Please read this installation manual and the user manual before

installation and carefully store in a handy place for later reference.

Inside you will find many helpful hints on how to install and test the

air conditioner properly.

Electrical work must be installed by a licensed electrician. Be sure

to use the correct rating of the power plug and main circuit for the

model to be installed.

Incorrect installation due to ignoring this instruction may cause

harm or damage, which may not be covered by warranty.

R32 REFRIGERANT WARNING

Warning Refrigerant R32, mildly flammable. This product uses

Refrigerant R32, Difluoromethane which is a mildly flammable

gas class 2.2, based on AS1677 and must be handled by a

Refrigeration Mechanic with an appropriate Australian Refrigerant

Gas handling license

environment

Information on disposal for users

• Most of the packing materials are recyclable.

Please dispose of those materials through your local recycling

depot or by placing them in appropriate collection containers.

• If you wish to discard this air conditioner, please contact your

local authorities and ask for the correct method

of disposal.

caution

1. The unit must only be installed by a qualified refrigeration

mechanic and electrical work carried out by a qualified

electrician according to AS/NZS3000 electrical installation

standard and all local and national regulations, and in

compliance with this manual..

2. Before installation, please contact a qualified air conditioner

installer. If the unit is not installed by a qualified air conditioner

installer, the malfunction may not be solved due to faulty

installation.

3. If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in

order to avoid a hazard.

4. The appliance must be positioned so that the plug

is accessible.

5. The temperature of the refrigerant circuit will be high, please

keep the interconnection cable away from the copper tube.

6. This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

7. Children should be supervised to ensure that they do not play

with the appliance.

warning

Before obtaining access to terminals, all supply circuits must be

disconnected.

3Safety

Page 4

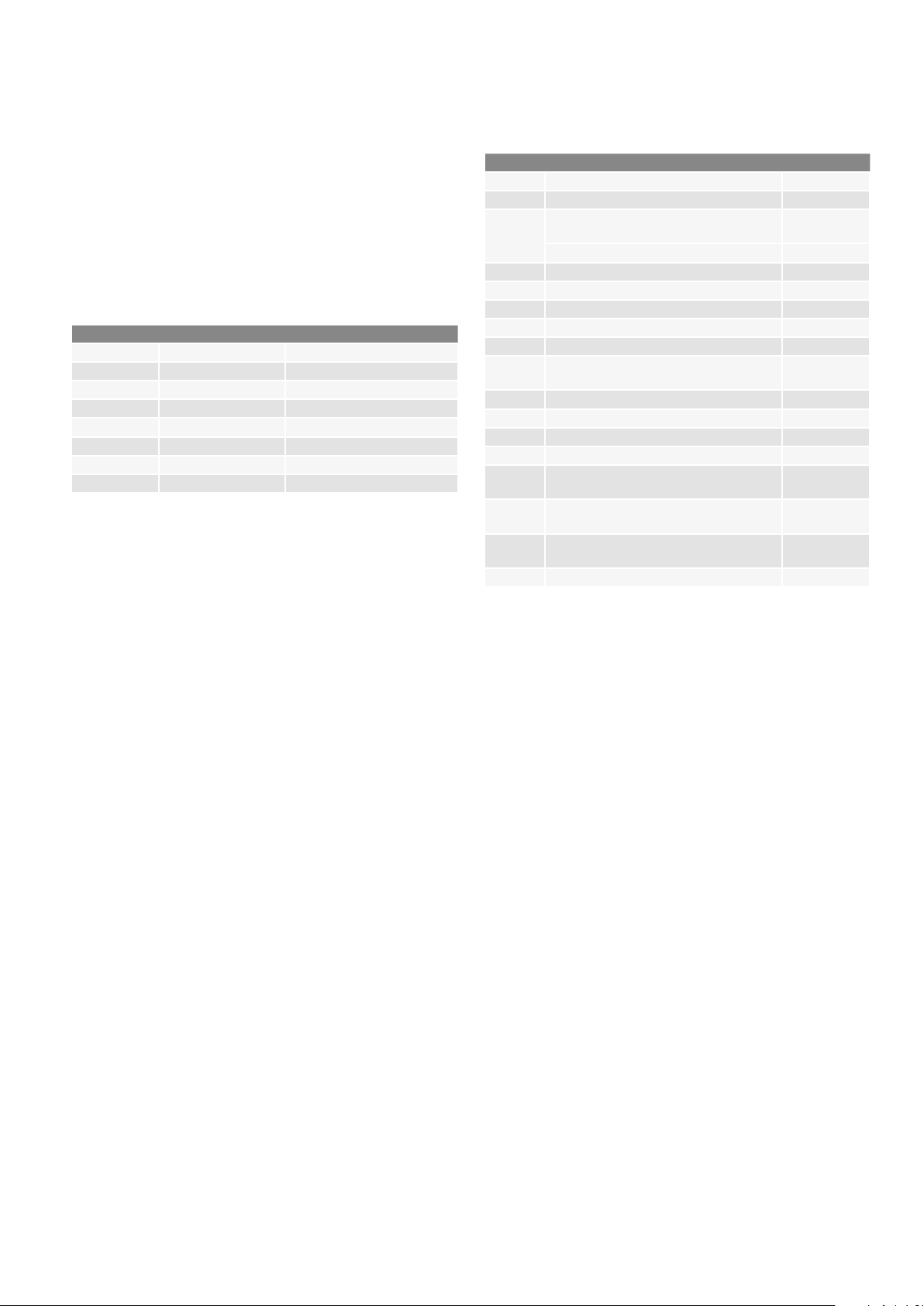

Minimum floor areas

Components

Your air conditioner is designed to condition the air for a certain

range of room sizes, please ensure the selection of your air

conditioner complies with the Kelvinator selection tool available

from www.kelvinator.com.au

This product uses refrigerant R32. Certain levels of refrigerant

require minimum room sizes. Please ensure that these minimum

room sizes are adhered to for standard installations (7.5m pipe

length). If larger refrigerant charges than standard are used then

please consult AS60335.2.40 to determine the safe minimum floor

area for the installation.

Model no. Charge of R32 (g) Minimum floor area (m2)

KSV25CRF 710 n/a*

KSV25HRF 710 n/a*

KSV35CRF 970 n/a*

KSV35HRF 970 n/a*

KSV52HRF 900 n/a*

KSV70CRF 1300 1.87

KSV70HRF 1400 1.87

KSV80HRF 1700 2.76

*no minimum floor area required for this product

Items required for installation

• Level gauge

• Screw driver

• Electric drill

• Hole core drill ( 55mm / 70mm)

• Flaring tool specifically designed for R32 or

R410a refrigerant

• Specified torque wrenches

• Spanner (half union)

• A glass of water

• Hexagonal wrench (6mm)

• Gas-leak detector

• 2 stage vacuum pump

• Gauge manifold

• Users manual

• Thermometer

• Multimeter

• Pipe cutter

• Measuring tape

Number Description Quantity

1 Indoor unit mounting plate 1

2 Clip anchor not supplied

Self-tapping screw ST4 x 25

3

4 Remote control 1

5 Remote control holder 1

6 Screw for remote holder 2

7 Battery (AAA 1.5V) 2

8 Insulation material not supplied

9

10 Insulation hose for refrigerant piping not supplied

11 Wall clamp not supplied

12 Drain hose not supplied

13 Connection power cable not supplied

14

15

16

17 Flare nut 2

NOTE: Other parts necessary for installation besides those

mentioned above must be supplied by the customer/installer.

- for KSV70CRF, KSV70HRF & KSV80HRF 10

- for all other models 5

Connection piping assembly

(refer to page 8)

Drain connector

(heat pump model only)

Drain plug (reverse cycle models with

capacity of over 4500W)

Thermal insulating pipe for extending

drain hose

varies by

country

1

3

1

4 Minimum floor areas / components

Page 5

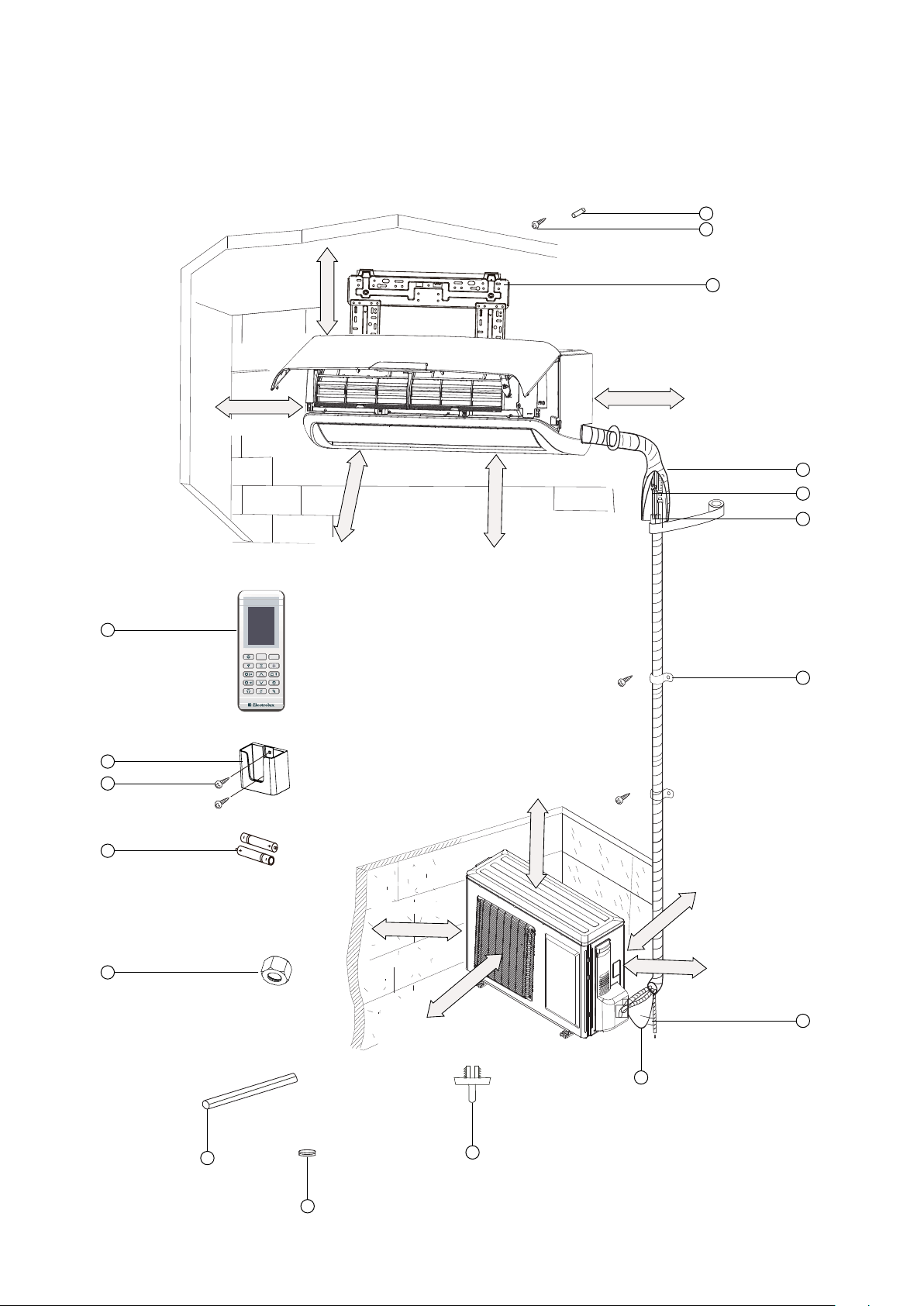

Product description

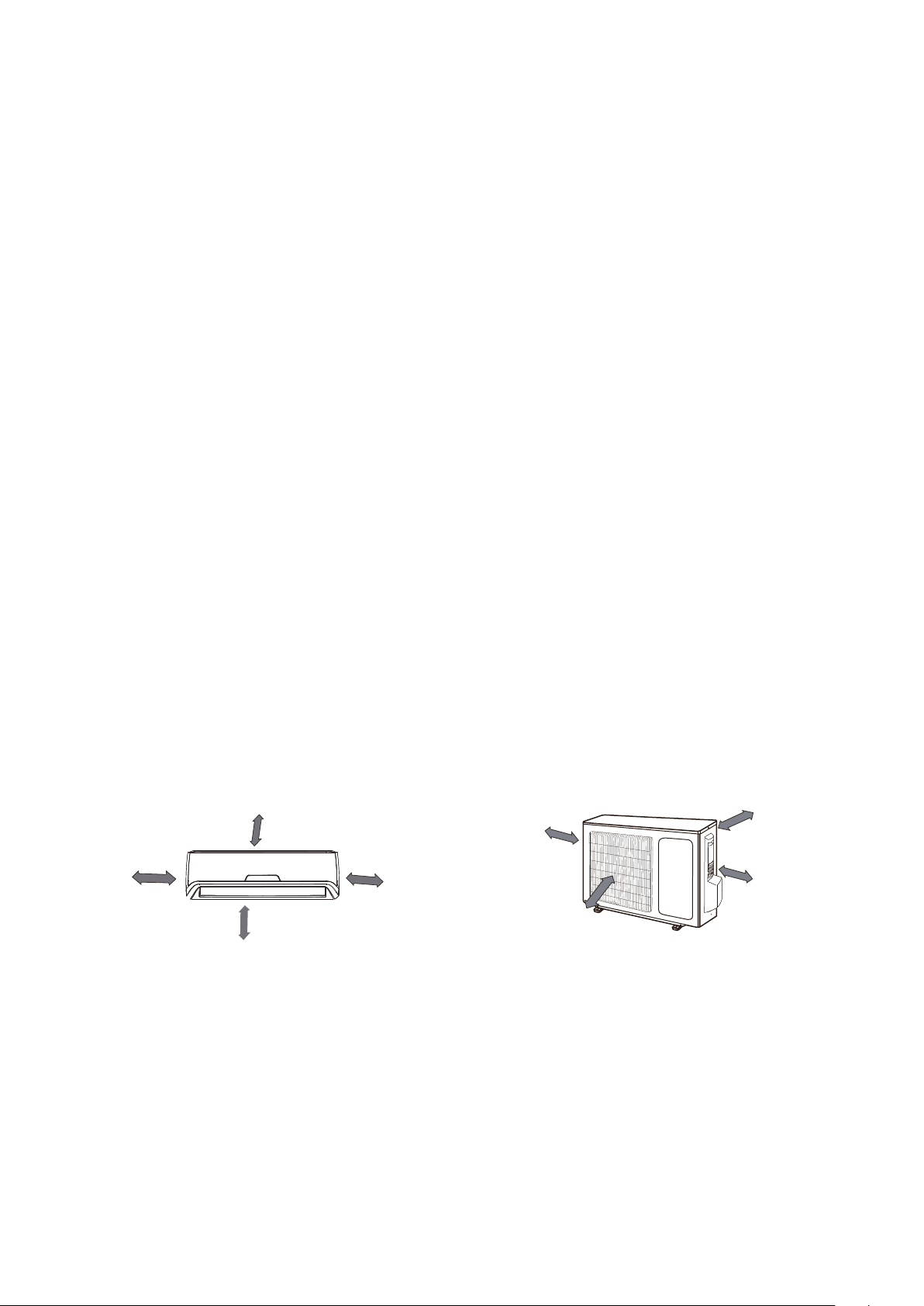

Indoor unit

4

space to the ceiling

15cm or more

space to the wall

Light

Mode

Healthy

Turbo

Fan

Temp

Timer-On

Timer-Off

Clock

Eco

I feel

Swing

15cm or more

250cm or more

air outlet side

200cm or more

space to the floor

2

3

1

space to the wall

15cm or more

8

9

10

11

Outdoor unit

5

6

7

17

space to obstruction

50cm or more

space to the wall

30cm or more

150cm or more

air outlet side

16

14

air inlet side

20cm or more

50cm or more

space to the wall

12

13

15

5Product description

Page 6

Installation site instructions

A proper installation site is vital for correct and efficient

operation of the unit.

Avoid the following sites where:

• strong heat sources, vapour, flammable gas or volatile liquids

are emitted.

• high-frequency electro-magnetic waves are generated by radio

equipment, welders or medical equipment.

• salt-laden air prevails (such as close to coastal areas).

• the air is contaminated with industrial vapours and oils.

• the air contains sulphurous gas such as in hot

spring zones.

• corrosive or poor air quality exists.

Indoor unit

1. The air inlet and outlet should be kept clear of obstructions.

Ensure the air can be blown through the whole room.

2. Select a site where the condensing water can be easily drained

out, and where it is easily connected to the

outdoor unit.

3. Select a place where it is out of reach of children.

4. Select the place where the wall is strong enough to withstand

the full weight and vibration of the unit.

5. Be sure to leave enough space to allow access for routine

maintenance.

6. For optimum performance, the indoor unit should be installed

on the wall at a height of 2 metres or more above the floor and

at least 2.5 metres from the opposing wall.

7. Make sure that the indoor unit is installed in accordance with

installation dimension as below:

more than 15cm from

the ceiling

refrigerant charge.

14. Do not install near a doorway.

15. Note low temperature soldering alloys are not acceptable.

16. Minimum room space requirements as advised on the rating

plate must be complied with.

17. Reusable mechanical connectors may not be used within

indoors or within wall or ceiling cavities where a refrigerant leak

can gather.

18. All refrigerant tubing shall be protected or enclosed to prevent

damage.

Outdoor unit

1. Select a site where noise and outflow air emitted by unit will

not annoy neighbours.

2. Select a site where there is sufficient ventilation.

3. Select a site where there is no obstruction blocking the inlet

and outlet.

4 The site should be able to withstand the full weight and

vibration of the unit.

5. Select a dry place, but do not expose the unit to direct sunlight

or strong wind.

6. Make sure that the outdoor unit is installed in accordance with

the installation instructions, and is convenient for maintenance

and repair.

7. Select a place where it is out of reach of children and far from

animals or plants.

8. Select a place where the unit keeps the horizontal and aligned

position.

9. Select at a place that respects the minimum distances around

the outdoor unit as below:

more than 20cm

more than

30cm

more than

15c m

more than 2m from the floor

more than 2.5m from the opposing wall

8. Select place about 1m or more away from a TV set or any

other electric appliance.

9. Select a place where the filter can be easily taken out.

10. Do not use the unit in wet areas such as the laundry or by a

swimming pool.

11. A minimum pipe run of 3 metres is required to minimise

vibration and noise.

12. Use a stud finder to locate studs to prevent unnecessary

damage to the wall.

13. Any variations in pipe length may require adjustment to

6 Installation site instructions

more than

15c m

more than

50cm

more than 1.5m

10. Note low temperature soldering alloys are not acceptable.

11. Reusable mechanical connectors may not be used within

indoors or within wall or ceiling cavities where a refrigerant leak

can gather.

Page 7

Rooftop installation

WARNING

If the outdoor unit is installed on a roof structure, be sure to level

the unit.

Ensure the roof structure and anchoring method are adequate for

the unit location.

If the outdoor unit is installed on roof structures or external walls,

this may result in excessive noise and vibration, and may also be

classed as non-serviceable installation.

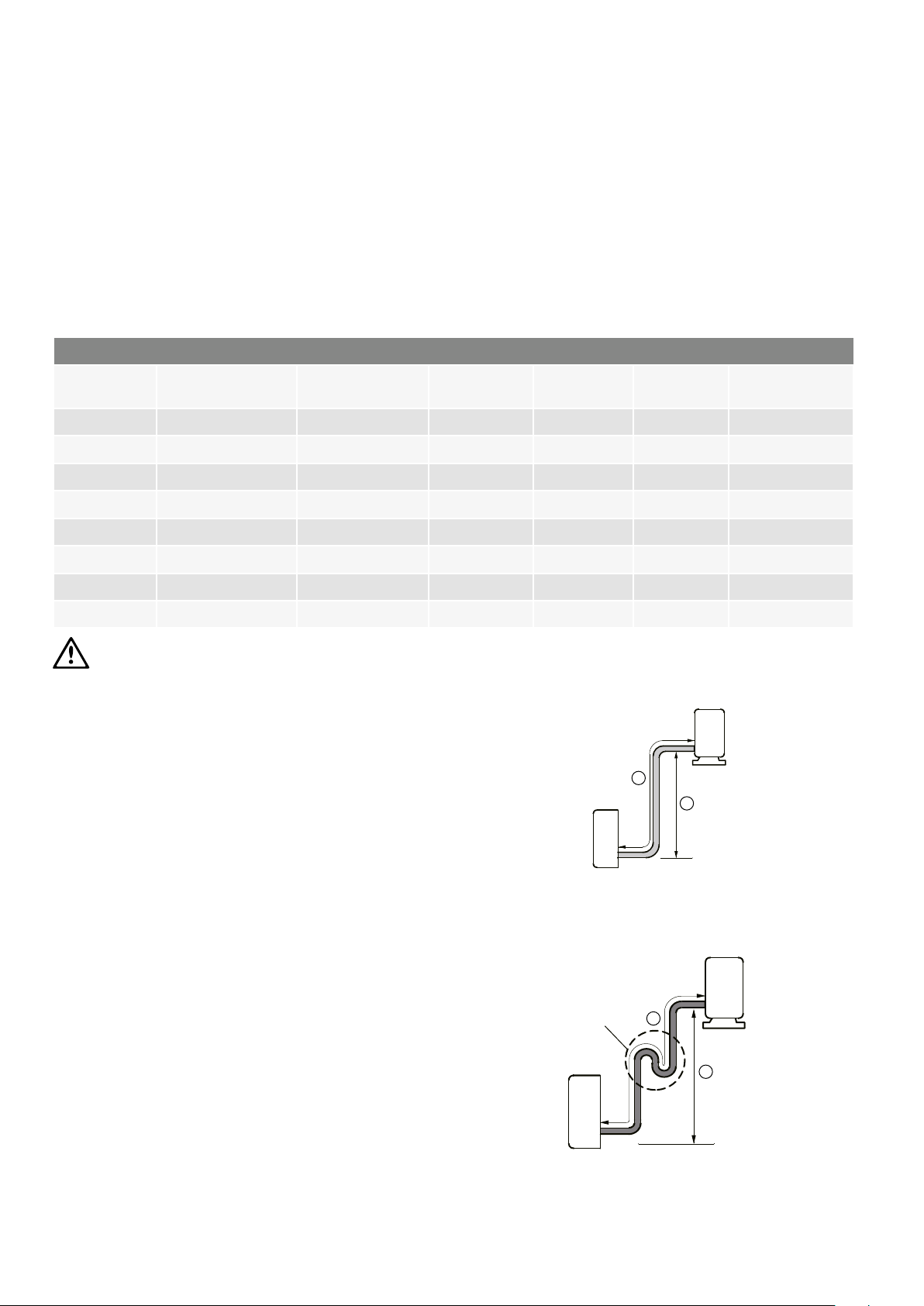

Pipe Length Elevation and Additional Quantity of Gas

Model Number

Discharge Pipe

Diameter

Suction Pipe

Diameter

Standard

Length (m)

Maximum

Length (m)

Maximum

Height (m)

KSV25HRF Ø6.35 mm (1/4”) Ø9.52 mm (3/8”) 7.5 15 10 16

KSV35HRF Ø6.35 mm (1/4”) Ø9.52 mm (3/8”) 7.5 20 10 16

KSV52HRF Ø6.35 mm (1/4”) Ø12.70 mm (1/2”) 7.5 25 10 16

KSV70HRF Ø6.35 mm (1/4”) Ø15.88mm (5/8”) 7.5 25 10 40

KSV80HRF Ø6.35 mm (1/4”) Ø15.88mm (5/8”) 7.5 30 10 40

KSV25CRF Ø6.35 mm (1/4”) Ø9.52 mm (3/8”) 7.5 15 10 12

KSV35CRF Ø6.35 mm (1/4”) Ø9.52 mm (3/8”) 7.5 20 10 12

KSV70CRF Ø6.35 mm (1/4”) Ø15.88 mm (5/8”) 7.5 25 10 12

caution

• The outdoor unit is charged with the refrigerant for standard

pipe length of 7.5m.

• When the connecting pipe length is longer than the standard

length, additional refrigerant should be added into the unit

according to the above table through the service port on 3-way

service valve on the outdoor unit.

• PLEASE MAINTAIN THE SHORTEST DISTANCE (3 TO 5

METRES) AND SHORTEST MISALIGNMENT POSSIBLE

BETWEEN THE INDOOR AND OUTDOOR UNITS.

• The maximum allowance length and height is based

on reliability. Exceeding the maximum may cause poor

performance or malfunction.

• When the level difference between indoor and outdoor units

is greater than the maximum height of 10 metres, or when

the outdoor unit is installed above the indoor unit, an oil trap

should be installed every 5-7 metres.

maximum length

outdoor unit

A

B

piping length under 7.5m

maximum height

Additional

Refrigerant (g/m)

indoor unit

outdoor unit

maximum length

oil trap

piping length 7.5m or more

A

indoor unit

B

maximum height

7Rooftop installation

Page 8

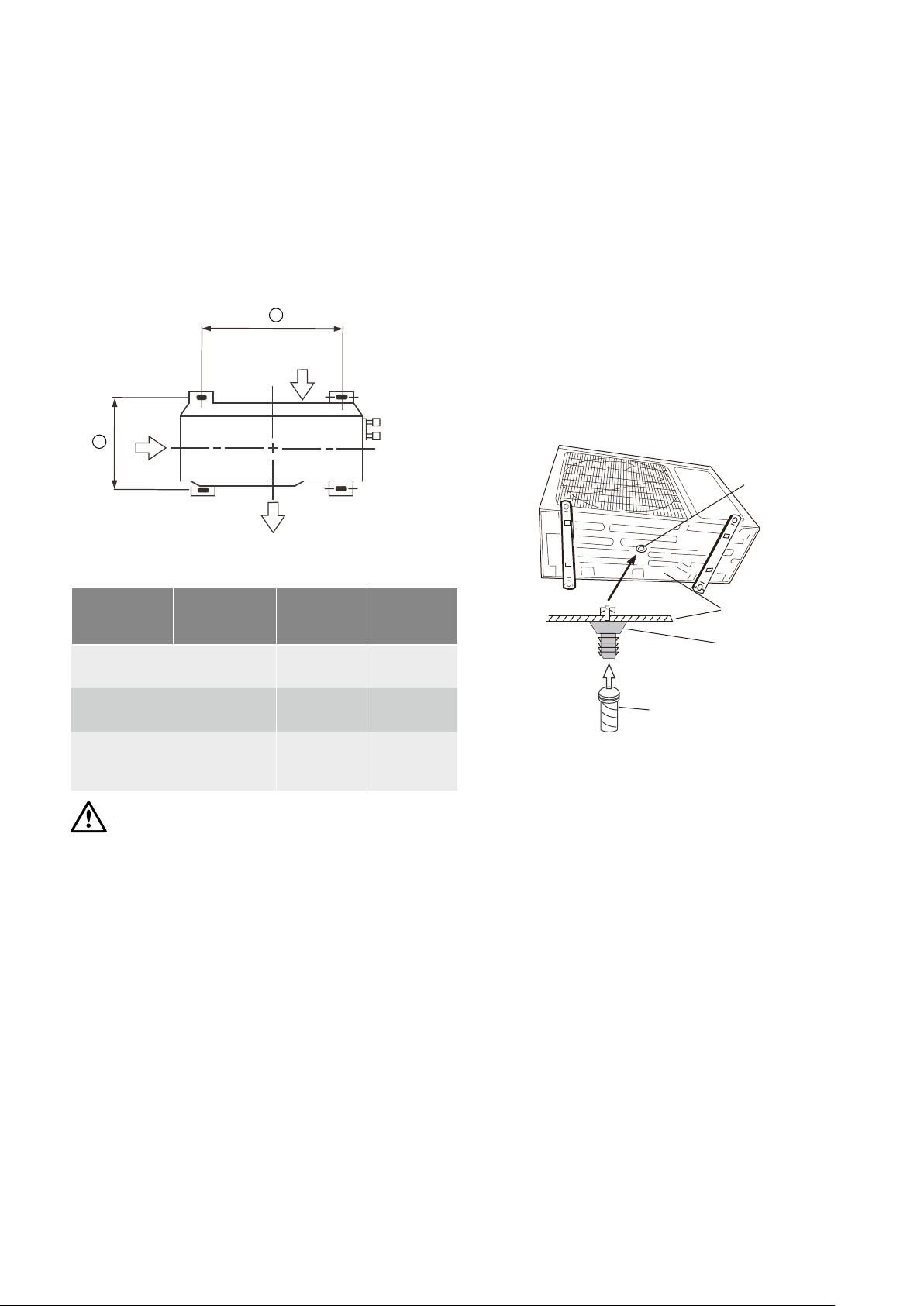

Outdoor unit installation

WARNING

Securing the outdoor unit

Anchor the outdoor unit by fixing the 4 holes existent in its base

with 4 bolts and nuts of φ10 mm tightly (not included).

Place the outdoor unit over a horizontal concrete or rigid surface

(never directly over grass or earth).

A

air inlet

air inlet

B

air outlet

Model

KSV25HRF/

CRF

Outdoor unit

dimensions

W x D x H (mm)

776 x 320 x 540 510 286

Dimension

A (mm)

Dimension B

(mm)

Outdoor condensate drainage

• During heating operation, the condensate and defrosting

water should be drained out reliably through the drain hose.

• The drain-water hole must be plugged. Whether to plug other

holes will be determined by the installer according to actual

conditions.

• Install the outdoor drain connector in the drain-water hole on

the chassis of the outdoor unit, and attach the drain hose to

the connector so that the waste water formed in the outdoor

unit can be drained out.

• In case of a drain hose, the unit must be installed on a base

more than 3cm in height.

drain-water hole

chassis

drain connector

KSV35HRF/

CRF

842 x 320 x 596 540 286

KSV52HRF,

KSV70CRF/

955 x 396 x 700 560 364

HRF KSV80HRF

caution

• If a suspended installation is needed, the installation bracket

must allow the fixation according to dimensions on the figure

above.

• The wall where the unit will be installed must be of solid brick,

concrete or provided with other reinforcement ways to fix the

bracket. The fixation of the bracket to the wall and the bracket

to the air conditioner must be firm, steady and levelled.

hose of inner diameter 16mm

(not supplied)

8 Outdoor unit installation

Page 9

Indoor unit installation

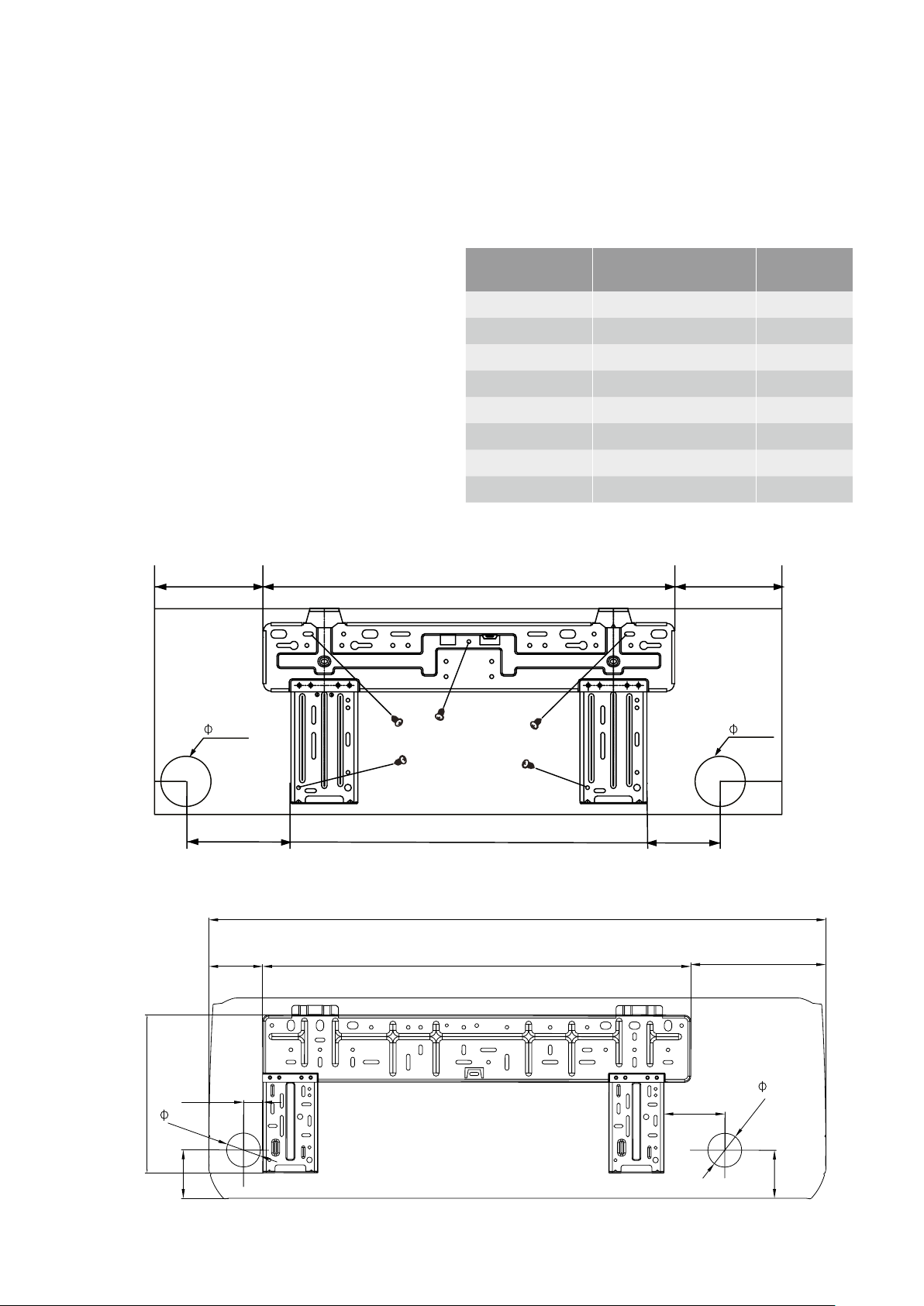

Installing the mounting plate

1. Fit the mounting plate horizontally on the wall with five or

more self-tapping screws (type ST4x25, item 3 on page 3).

2. Be sure that the mounting plate has been fixed firmly enough

to withstand about 60kg. The weight should be evenly shared

by every screw.

3. If the wall is made of brick, concrete or the like, drill five (5)

or more holes of 5mm diameter in the wall. Insert clip anchor

(item 2 on page 3) for appropriate mounting screws.

4. The water tray’s outlet for the indoor unit has two-way drainage

design. During installation, the indoor unit should slightly slant

to water tray’s outlet for smooth drainage of condensate water.

Mounting plate type A

135

Fit the mounting plate and drill holes in the wall according to the

wall structure and corresponding mounting points

on the mounting plate. (dimensions are in mm unless otherwise

stated)

Model no.

Indoor unit dimension

W x D x H (mm)

Mounting

plate type

KSV25CRF 912 x 188 x 290 A

KSV25HRF 912 x 188 x 290 A

KSV35CRF 912 x 188 x 290 A

KSV35HRF 912 x 188 x 290 A

KSV52HRF 1000 x 219 x 326 B

KSV70CRF 1178 x 253 x 326 C

KSV70HRF

1178 x 253 x 326 C

KSV80HRF 1178 x 253 x 326 C

542

235

Mounting plate type B

256

55

78

55mm 55mm

143

87

1000

694

31

80

219

98

55

78

9Indoor unit installation

Page 10

Indoor unit installation

Mounting plate type C

326

253 179746

65 65

50

163 90

6

74 105

indoor

unit

10 Indoor unit installation

Page 11

Indoor unit installation

Drill piping hole

1. Determine hole positions according to the diagram. Drill one (1)

hole (Ф55 or Ф70 mm) in the wall at a slight downward slant to the

outdoor side.

Piping hole Model

55

70

2. The inclination must be between 5mm and 10mm in order to

ensure a good drain of condensed water generated by the

indoor unit.

KSV25CRF, KSV35CRF, KSV25HRF,

KSV35HRF, KSV52HRF

KSV70CRF, KSV70HRF, KSV80HRF

indoor

wall pipe

5-10mm

outdoor

seal putty

55mm or

70mm

Installation of drain hose

1. Connect the drain hose to the outlet pipe of the indoor unit.

Bind the joint with vinyl tape.

outlet pipe of

outlet pipe of

indoor unit

vinyl tape

2. Put the drain hose into insulating pipe.

outlet pipe of

indoor unit

vinyl tape

indoor unit

drain

hose

drain hose (narrow)

insulating pipe

3. Insert the wall pipe into the hole to prevent any wiring from being

damaged when passing through the hole.

4. Always use a wall hole conduit when drilling metal grids, metal

plates or the like.

5. For models with a cooling capacity greater than 4500W, remove

and dispose the two polystyrene lateral rear supports from the

indoor unit before the installation.

remove both supports

3. Wrap the insulating pipe with wide vinyl tape to prevent the

shift of insulating pipe. Slant the drain hose downward slightly

for smooth drainage of condensed water.

vinyl tape

outlet pipe of

indoor unit

connected

insulating pipe

11Indoor unit installation

Page 12

WARNING

Indoor unit installation

caution

1. The insulating tube should be connected reliably with the

sleeve outside the outlet pipe.

2. The drain hose should be slanted downward slightly, without

distortion, bulge or fluctuation.

refrigerant

piping

drain hose

(connected at the

rear left side)

do not block water

flow with a rise

do not put the end

of the hose in water

3. Do not put the outlet in the water.

bulge flooded

The piping can be output from right, rear right, left or

rear left of the indoor unit body.

1. When routing the piping and wiring from the left or right

side of indoor unit, cut off the tailings from the chassis when

necessary (see figure below).

tailing 2

tailing 1

• Cut off the tailings 1 when routing the wiring only.

• Cut off the tailings 1 and tailings 2 when routing both the

wiring and piping.

drain hole

drain cap

Follow the instructions below for exchanging the position of the

drain cap and drain hose from the left to the right side.

a. Pull out the drain cap at the rear right of the

indoor unit.

drain cap

b. Pull out the drain hose at the rear left of the

indoor unit.

drain hose

indoor unit outline

connection piping

43

2. The drain hose can be connected at two different positions.

Use the most convenient position and, if necessary, exchange

the position of drain cap and drain hose.

• The drain hose is connected at the rear left side of the

indoor unit when you receive the product.

12 Indoor unit installation

c. Put the drain cap into the drain hole at the rear left of the

indoor unit.

drain cap

Page 13

d. Insert the drain hose into the drain hole at the rear right of the

WARNING

indoor unit.

drain hose

3. Arrange the pipe in the most convenient direction

and position.

piping on the rear

right side

piping on the left

rear side

drain hose from

the left side

piping on the

left side

piping on the rear

right side

drain hose from

the right side

piping on the

right side

drain hose from

the left side

drain hose from

the left side

drain hose from

the left side

caution

When refrigerant pipes and the drain pipe are fitted to the same

side, ensure that the bulk does not push the unit away from the wall

when in its final position.

drain hose from

the right side

Piping and cable

from the right side

piping on the

right side

drain hose from

the right side

13Indoor unit installation

Page 14

4. Take out the piping from body case, wrap the piping, power

WARNING

cords, drain hose with the tape and then make them pass

through the piping hose.

Do not put any object in the drain pan located in the rear of

the indoor unit, as the condensed water is gathered there and

piped out of the room.

5. Hang the mounting slots of the indoor unit on the upper hooks

of the mounting plate and check if it is firm enough .

To ease the piping installation, put a spacer between the

indoor unit and the wall. Remove the spacer once finished.

upper hook

mounting plate

indoor unit

liquid pipe

connecting

cable

drain hose

gas pipe

piping

insulation

caution

• Connect the indoor unit first, then the outdoor unit.

• Do not plug the cable to the indoor unit. That must be done

at a later stage.

• Turn the cable lightly to make the connection easier.

• Be careful not to let the drain hose become slack.

• Heat insulate the connecting pipe.

• Be sure that the drain hose is located at the lowest side of

the bundle. Locating at the upper side can cause drain pan to

overflow inside the unit.

• Never cross connect or interwind the power wire with any

other wiring.

• Do not allow the piping to be exposed out from the back of

the indoor unit.

• If part of the drain hose is positioned inside the room, wrap

it with insulating materials so as to prevent condensed water

from dropping.

spacer

6. Press the lower left and right sides of the unit against the

mounting plate until the lower hooks engage into their slots.

Ensure the unit is firmly fitted.

upper hook

connecting

cable

drain hose

mounting plate

fixing lower hook

7. The installation site should be 2 metres or more above

the floor.

14 Indoor unit installation

Page 15

WARNING

Indoor unit installation

Refrigerant pipe connection

The main cause of refrigerant leakage is due to defects in the

flaring work. Carry out flaring work using the following procedure:

Note: When using refrigerant R32, a reusable flared connection is

the only allowed pipework on the outside of any building.

Hence the supplied "once only" flare fitting must be used unless all

welded connections are used. If welded connections are used, no

low temperature solder is permitted.

a. Cut the pipes and the cable

Use the piping kit accessory (if applicable) or pipes purchased

locally. Measure the distance between the indoor and the outdoor

unit. Cut the pipes a little longer than the measured distance. Cut

the cable 1.5m longer than the pipe length.

pipe

caution

It is not possible to put them on after flaring work.

d. Flaring work

Carry out flaring work using flaring tool as shown below.

handle

bar

Firmly hold copper pipe in a die according to the dimension shown

in the table below.

A

copper pipe

clamp handle

bar

yoke

cone

90°

oblique roughness burr

b. Burr removal

Completely remove all burrs from the cut cross section of pipe/

tube. Face the end of the copper pipe/tube in a downward

direction as you remove burrs in order to avoid burrs dropping into

the tubing.

pipe

reamer

face down

c. Put the flare nut on

Remove flare nuts attached to indoor and outdoor unit, then put

them on pipe/tube having completed burr removal.

flare nut

Outer diameter (mm)

6.35 (1/4”)

9.52 (3/8”)

12.70 (1/2”)

15.88 (5/8”)

A (mm)

Max. Min.

1.3 0.7

1.6 1.0

1.8 1.0

2.4 2.2

e. Check

Compare the flare work with the adjacent diagram.

If the pipe has any defect, cut off the enlarged section and redo the

work.

smooth all around

incorrect flaring

inclined

damaged

even length all

around

Make an independent covering for each pipe with the appropriate

tubular isolation.

surface

cracked

uneven

thickness

copper tube

15Indoor unit installation

Page 16

Piping connection - indoor unit

WARNING

a. Connecting the indoor unit tubing to the connection piping:

Align the centres of the pipes and sufficiently tighten the flare

nut with your hands first.

b. Wrap the insulation material around the connecting portion:

Cover the indoor unit pipe and the connection pipe with the

heat insulation material. Bind them together with vinyl tape so

that there is no gap.

insulating material

indoor unit tubing

spanner (fixed)

indoor unit piping

torque

wrench

flare nut

flare nut

piping

piping

Isolate the suction pipe from the liquid pipe.

heat insulation

suction line pipe liquid line pipe

Wrap the insulated pipes with vinyl tape in the rear section for pipe

housing. Fasten the power cable to the pipes with vinyl tape.

connection pipe

vinyl tape (wide)

wrap with vinyl tape

indoor unit pipe

Then tighten the flare nut with spanner and torque wrench referring

to the following:

Outer diameter (mm) Torque (N.m)

6.35 (1/4”)

9.52 (3/8”)

12.70 (1/2”)

15.88 (5/8”)

19.05 (3/4”)

15-20

35-40

50-55

60-65

70-75

caution

Excessive torque can break the nut depending on installation

conditions.

16 Indoor unit installation

pipe

vinyl tape (narrow)

connection

cable

Wrap the piping, drain hose and power cable tightly with vinyl tape

so that they can fit into the rear piping housing section.

pipe

drain hose

connection

power cable

vinyl tape (narrow)

wrap with vinyl

tape (wide)

Page 17

Indoor unit installation

c. Positioning the indoor unit:

Remove the spacer.

Hook the indoor unit onto the upper portion of the mounting plate

(engage the hooks of the mounting plate into the openings at the

rear top of the indoor unit). Ensure that the hooks are properly

seated on the mounting plate by moving the indoor unit in all

directions.

outdoor unit

2-way

valve

discharge pipe

(suction pipe for

KSV52HRF)

suction pipe

(discharge pipe

for KSV52HRF)

upper hook

mounting plate

spacer

Press the lower left and right sides of the unit against the mounting

plate until the hooks engage into their slots (clicking sound).

upper hook

connecting

cable

mounting plate

fixing lower hook

Piping connection - outdoor unit

a. Align the centres of the pipes and sufficiently tighten the flare

nut with your hands.

3-way

valve

Make sure to follow the torque table value as below:

Outer diameter (mm) Torque (N.m)

6.35 (1/4”)

9.52 (3/8”)

12.70 (1/2”)

15.88 (5/8”)

19.05 (3/4”)

15-20

35-40

50-55

60-65

70-75

Piping formation

a. Form the piping by wrapping the connecting portion of the

indoor unit with insulation material and secure it with narrow

vinyl tape and wide vinyl tape.

If you want to connect an additional drain hose, the end of the

drain hose outlet should be routed above the ground. Secure

the drain hose appropriately.

b. In cases where the outdoor unit is installed below the indoor

unit level:

Wrap the piping, drain hose and connecting cable from the

bottom to the top. Secure the wrapped piping along the

exterior wall using saddle or equivalent.

seal small openings

around piping with a

gum type sealer

wrapping

b. Then, tighten the flare nut with torque wrench until the

wrench clicks.

pipe

drain hose

connection cable

drain hose

trap is required to prevent water from entering electrical parts

NOTE: all piping must be protected against mechanical damage.

17Indoor unit installationV

Page 18

Safety precautions

c. In cases where the outdoor unit is installed above the indoor

unit level:

Wrap the piping and connecting cable from bottom to top.

Form a trap to prevent water from entering the room.

Secure the wrapped piping along the exterior wall using

saddle or equivalent.

seal small openings

around piping with a

gum type sealer

trap

trap

drain hose

Note: all refrigerant piping must be protected against

mechanical damage

Electrical safety rules before starting the installation:

1. A dedicated power supply circuit and breaker should be

provided for the products which are not supplied with a

service cord and plug in accordance with local electrical safety

regulations.

2. The circuit breaker must have the functions of magnetic tripping

and heat tripping to prevent short circuit and overload.

3. The appliance shall be installed in accordance with national

wiring regulations.

4. A circuit breaker with proper capacity must be installed according

to AS3000 and applicable local electrical safety regulations.

5. In case of problems in power supply, the air conditioner must not

be installed before the customer fixes the problem.

6. Be sure the power supply matches the air conditioner.

7. Ensure the live wire, neutral wire and earth wire in the power

socket are properly connected.

8. Inadequate or incorrect electrical connections may cause electric

shock, fire or some electrical parts to malfunction.

9. Before performing any electrical work, turn off the main power to

the system.

Earthing requirements

1. Air conditioners are type 1 electric appliances. The unit must be

reliably earthed and connected by a qualified electrician.

2. The yellow-green wire in the air conditioner is the earthing wire

which cannot be used for any other purposes. Improper earthing

may cause electric shock.

3. The earth resistance must comply to national wiring regulations.

4. The user’s power must have reliable earthing terminal. Do not

connect the earthing wire with the following:

• Water pipe

• Gas pipe

• Contamination pipe

18 Safety precautions

Page 19

N(1) 2 4 5

N(1) 2 3

Installation

WARNING

Indoor electric wiring

Note: for correct operation of the air conditioner and standby

power modes the mains power should be supplied to the

indoor unit.

1. Open the front panel and remove the wiring cover by

loosening the screw.

wiring cover

2. Route the power connection cable from back of the indoor

unit and pull it toward the front through the wiring hole for

connection.

3. Connect and screw the wires onto the terminal block as

identified by their colours.

warning

All wires between indoor and outdoor units must be connected

by a qualified electric contractor.

If the length of the power cord is not enough, please contact your

installer for new a power cord. Lengthening the power cord by

yourself is dangerous and illegal.

NOTE: Powered accessories cannot be connected to these

wiring points

After tightening the screws, pull the wire slightly to confirm whether

it’s firm or not.

Do not connect two power cables together to supply power to the

air conditioner.

Do not extend the power cable conductor by cutting or splicing.

blue

black

brown

4. Wrap wires that are not connected with insulating tape so that

they do not touch any electrical or metal parts.

5. Secure the wires firmly with the cable clamp.

6. Put the wiring cover back and screw it.

7. Reinstall the front panel.

earthing wire

(green and yellow)

19Installation

Page 20

N(1) 2

N(1) 2 3

WARNING

Installation

Outdoor electric wires

1. When required, remove the handle on the right side plate of

outdoor unit by loosening the screw.

handle

terminal

block

2. Take off wire cable clamp. Connect and screw the power

connection cable and signal control wire (for reverse cycle

models only) onto the terminal block following corresponding

identification numbers and colours on the terminal blocks of

indoor and outdoor units.

3. To prevent water from entering, make a trap (“U”) in the

connection wires (see page 16).

4. Wrap wires that are not connected with insulating tape so that

they do not touch any electrical or metal parts.

5. Fix the power connection wires with wire clamps.

6. Reinstall the handle.

caution

After confirming the above conditions, prepare the wiring as

follows:

• The screws which fasten the wiring to the terminal block may

come loose from vibrations during transportation.

• Check and make sure all screws are well fixed. Otherwise, it

could cause burn-out of the wires.

• Be sure the circuit capacity is sufficient.

• Ensure the starting voltage is maintained at over 90% of the

rated voltage marked on the nameplate.

• Confirm that the cable thickness is as specified in the power

source specification.

• Always install a Residual Current Device (RCD).

• The following may be caused by voltage drop: vibration of a

contactor, which will damage the contact point, fuse blowing,

disturbance of the normal function of the overload.

• The means for disconnection from a power supply shall be

incorporated in the fixed wiring and have an air gap contact

separation of at least 3mm in each active (phase) conductor.

NOTE: Powered accessories cannot be connected to these

wiring points.

blue black brown

earthing wire

(green & yellow)

cable clamp

to outdoor unit

20 Installation

Page 21

Checking the drainage

WARNING

Do not place drain piping as indicated below:

1. Open and lift the indoor unit front panel.

Hold the lower part of the left and right sides of the panel, pull it

against you and lift it stops with a full support from

the bracket.

panel bracket

2. Check the drainage

Carefully pour a glass of water on the evaporator.

Ensure the water flows through the drain hose of the indoor unit

without any leakage and goes out the drain exit.

do not rise

water

leakage

accumulated

drain water

water

leakage

water

leakage

tip of drain

hose dipped

in water

space less

than 50mm

Air purging and leakage test

Note: Any brazed connections must be completed before

evacuation and prior to the release of any refrigerant into the

refrigerating components.

Air and moisture in the refrigeration system have undesirable

effects as indicated below:

• System pressure increase

• Rise of the operating current.

• Cooling or heating efficiency drops.

• Moisture in the refrigeration circuit may freeze and block the

capillary tubing.

• Water may lead to corrosion of parts in the

refrigeration system.

Therefore, the indoor unit and tubing between the indoor and

outdoor units must be tested for leakage and evacuated to remove

any non-condensables and moisture from the system.

drain hose

c. Drain piping

The drain hose should point downward for easy

drain flow.

downward slope

Air purging with a vacuum pump

Preparation

Check that each tube (both liquid and gas side tubes) between the

indoor and outdoor units have been properly connected and all

wiring for the test has been completed. Remove the service valve

caps from both gas and liquid sides on the outdoor unit.

For detailed data of pipe length and refrigerant amount, please

refer to page 6.

caution

Both liquid and gas side service valves on the outdoor unit are

kept closed at this stage.

When relocating the unit, perform evacuation using a vacuum

pump. Make sure the refrigerant added into the air conditioner is

in liquid form.

Handling the stop valve

Opening the stop valve:

Open the valve stem until it hits against the stopper. Do not try to

open it further.

Closing the stop valve:

Securely tighten the valve stem with a special tool. Then securely

tighten the valve stem cap with a spanner or the like.

21Installation

Page 22

outdoor unit

WARNING

B

D

C

A

hi stop valve

(2-way valve)

gas side

liquid side

indoor unit

half union

caution

A: Low pressure valve (3-way) - gas side.

B: High pressure valve (2-way) - liquid side.

C and D: they are the ends of indoor unit connection

valve body

charge port

valve stem

stopper

flare nut

cap

5 Keep vacuuming for more than 15 minutes and make sure

the reading of multimeter is -1.0 x 10 Pa (-76cmHg). Then fully

close the low handle of manifold valve and stop the operation

of the vacuum pump.

6 Turn the stem of the stop valve B (2-way valve) about 45

counterclockwise for 6~7 seconds after the gas coming out,

then tighten the flare nut again. Make sure the pressure display

in the pressure indicator is a little higher than the atmosphere

pressure.

7 Remove the charge hose from the low pressure charge port.

8 Fully open the valve stems of A (3-way valve) and B (2-way

valve).

9 Securely tighten the stem cap.

outdoor unit

low handle

changing hose

low pressure

valve

multimeter

-76cmHg

vacuum pump

manifold valve

high handle

charging hose

Make sure to follow the torque table value as below:

Outer diameter (mm) Torque (N.m)

6.35 (1/4”)

9.52 (3/8”)

12.70 (1/2”)

15.88 (5/8”)

19.05 (3/4”

15-20

35-40

50-55

60-65

70-75

Using the vacuum pump

1 Completely tighten the flare nuts on A, B, C and D, connect

the manifold valve charge hose (blue) to the charge port of the

low pressure valve (3-way valve) on the gas pipe side.

2 Connect the other charge hose (yellow) of the manifold to the

vacuum pump.

3 Fully open the low handle of the manifold valve.

4 Open the vacuum pump for vacuumisation. At the beginning,

slightly loosen the flare nut of the low pressure valve to check

if there is air coming inside (if operation noise of the vacuum

pump has been changed, the reading of multimeter is 0

instead of minus). Then tighten the flare nut.

22 Installation

Page 23

Testing the air conditioner

Soapy water method

Apply soapy water or liquid neutral detergent on all valves and

pipe connections (A, B, C and D, refer to the figure below) involved

in installation by a soft brush to check for leakage. If bubbles come

out, the pipes have leakage.

indoor check points

D

discharge pipe

(suction pipe for

KSV52HRF)

C

suction pipe

(discharge pipe

for KSV52HRF)

B

outdoor

unit

2-way

valve

3-way

valve

A

outdoor check points

Leak detector

Use the leak detector to check for leakage.

Electrical safety check

Perform the electric safety check after completing the installation:

1. Earthing work

After finishing earthing work, measure the earthing

resistance by visual detection and earthing

resistance tester.

2. Electrical leakage check (perform while the test is running)

During test operation after finishing the installation, the service

person can use the electric probe and multimeter to perform

the electrical leakage check. Turn off the unit immediately if

refrigerant leakage happens. Check and find out the solution

ways until the unit operates properly.

Operation test

1. Before operation test

• Do not switch on power before installation is finished

completely.

• Electric wiring must be connected correctly and securely.

• Stop valves of the connection pipes should be

fully opened.

• All the impurities such as scraps and waste must be

cleared from the unit.

Operation test method

• Switch on power and press “ON/OFF” button on the remote

controller to start the operation. Press MODE button to

select the COOL, HEAT (if applicable), FAN to check if all the

functions work well.

• When the ambient temperature is lower than 16°C), the unit

can not be set on the remote control to work in COOL mode.

Please use the Emergency Operation mode which is used only

when the remote is unavailable or in case of maintenance.

manual control

button

manual control button

Pump down

When relocating or disposing of the air conditioner, pump down

the system following the procedure below so that no refrigerant is

released into the atmosphere.

• Connect the hose of manifold valve to the charge port of stop

valve on the gas pipe side of the outdoor unit.

• Close the stop valve on the gas pipe side almost completely.

• Fully close the stop valve on the liquid pipe side.

• Turn on the unit in COOL mode.

• Fully close the stop valve on the gas pipe side when the

pressure gauge shows 1 - 0.5 kgf/cm (100 ~ 50 kPa).

• Stop the test run operation by turning the unit off and

all the refrigerant gases have been collected in the

outdoor unit.

23Testing the conditioner

Page 24

Installation checklist

TIPS & INFORMATION

important

• If your appliance is damaged due to improper installation your warranty may be void.

• Proper installation requires the use of a licensed installer.

• You must keep full details of the installer including the license number and provide those details whenever you

request a service for your appliance.

Question

Does the unit have adequate clearance from walls and ceiling in accordance to installation instructions?

Is the unit mounted to allow condensate to flow freely toward the outside?

Does outdoor section have adequate clearance in accordance to installation instructions?

Is the unit securely mounted?

Is the unit readily accessible without special equipment?

Has the appropriate size circuit and fuse/circuit breaker been fitted?

Has the unit been tested and confirmed to operate correctly?

Has the user of the air conditioner been shown how to use the air conditioner?

CUSTOMER: PLEASE RETAIN WITH YOUR PURCHASE DOCUMENTS IN A SAFE PLACE

Model Number ________________________________________________

Serial Number ___________________________________________________________________________________________________________

Installers name ________________________________________________ Refrigerant handling license no. ______________________________

Installers address ______________________________________________ Phone

Installers signature _____________________________________________ Date of installation

24 Checklist

Page 25

Post installation checks

Items to be checked Possible malfunction

Has the unit been fixed firmly?

Have you done the refrigerant leakage test?

Is thermal insulation sufficient?

Is water drainage satisfactory?

Is the voltage in accordance with the rated voltage

marked on the nameplate?

Is the electric wiring or piping connection installed

correctly and securely?

Has the unit been securely earthed?

Is the power cord specified?

Is the inlet or outlet blocked?

Is the length of connection pipes and refrigerant capacity

recorded?

The unit may drop, shake or emit noise

It may cause insufficient cooling (heating)

It may cause condensation

It may cause water leakage

It may cause electric malfunction or damage the unit

It may cause electric malfunction or damage the parts

It may cause electrical leakage

It may cause electric malfunction or damage the parts

It may cause insufficient cooling (heating)

The refrigerant capacity is not accurate

25Post installation checks

Page 26

Notes

26 Notes

Page 27

Warranty

FOR SALES IN AUSTRALIA AND NEW ZEALAND

APPLIANCE: KELVINATOR SPLIT SYSTEM AIR CONDITIONER

This document sets out the terms and conditions of the product

warranties for Electrolux Appliances. It is an important document.

Please keep it with your proof of purchase documents in a safe place

for future reference should you require service for your Appliance.

1. In this warranty:

(a) ‘acceptable quality’ as referred to in clause 10 of this warranty has the

same meaning referred to in the ACL;

(b) ‘ACL’ means Schedule 2 to the Competition and Consumer

Act 2010;

(c) ‘Appliance’ means any Electrolux product purchased by you and

accompanied by this document;

(d) ‘ASC’ means Electrolux authorised service centres;

(e) ‘Electrolux’ means Electrolux Home Products Pty Ltd of 163

O’Riordan Street, Mascot NSW 2020, ABN 51 004 762 341 in respect

of Appliances purchased in Australia and Electrolux (NZ) Limited

(collectively ‘Electrolux’) of 3-5 Niall Burgess Road, Mount Wellington,

in respect of Appliances purchased in New Zealand;

(f) ‘major failure’ as referred to in clause 10 of this warranty has the same

meaning referred to in the ACL and includes a situation when an

Appliance cannot be repaired or it is uneconomic for Electrolux,

at its discretion, to repair an Appliance during the Warranty Period;

(g) ‘Warranty Period’ means the Appliance is warranted against

manufacturing defects in Australia and New Zealand for the period of

60 months, subject to this warranty and to the customer meeting the

Warranty Condition.

(h) ‘Warranty Condition’ means:

(i) evidence by the customer that the Appliance was installed by a

licensed air conditioner installer in Australia and in accordance with

Electrolux installation guidelines as set out in the installation manual;

(ii) the Appliance rating is correct for the size and thermal

characteristics of the room;

(iii) the Appliance has been regularly maintained in accordance

with Electrolux guidelines set out in the user manual;

(iv) the Appliance is designed for providing human comfort and

should be used under ambient conditions as set out in the

productspecicationsandgeneralairqualityconditions.

(i) ‘you’ means the purchaser of the Appliance not having purchased

the Appliance for re-sale, and ‘your’ has a corresponding meaning.

2. This warranty only applies to Appliances purchased and used in Australia or

New Zealand in normal domestic appliactions and is in addition to (and does

not exclude, restrict, or modify in any way) any non-excludable statutory

warranties in Australia or New Zealand.

3. During the Warranty Period Electrolux or its ASC will, at no extra charge if

your Appliance is readily accessible for service, without special equipment

and subject to these terms and conditions, repair or replace any parts which

it considers to be defective. Electrolux or its ASC may use remanufactured

parts to repair your Appliance. You agree that any replaced Appliances or

parts become the property of Electrolux. This warranty does not apply to

lightglobes,batteries,ltersorsimilarperishableparts.

4. Parts and Appliances not supplied by Electrolux are not covered by

this warranty.

5. To the extent permitted by law, you will bear the cost of transportation,

travel and delivery of the Appliance to and from Electrolux or its ASC. If you

reside outside of the service area, you will bear the cost of:

(a) travel of an authorised representative;

(b) transportation and delivery of the Appliance to and from Electrolux

or its ASC.

Important Notice

Before calling for service, please ensure that the steps listed in clause 13 above have been followed.

In all instances, unless the Appliance is transported by Electrolux or an Electrolux

authorised representative, the Appliance is transported at the owner’s cost and

risk while in transit to and from Electrolux or its ASC.

6. Proof of purchase is required before you can make a claim under

this warranty.

7. You may not make a claim under this warranty unless the defect claimed is

due to faulty or defective parts or workmanship. Electrolux is not liable in the

following situations (which are not exhaustive):

(a) the Appliance is damaged by:

(i) accident

(ii) misuse or abuse, including failure to properly maintain or service

(iii) normal wear and tear

(iv) power surges, electrical storm damage or incorrect power supply

(v) incomplete or improper installation

(vi) incorrect, improper or inappropriate operation

(vii) insect or vermin infestation

(viii) failure to comply with any additional instructions supplied with the

Appliance;

(b) theApplianceismodiedwithoutauthorityfromElectroluxinwriting;

(c) the Appliance’s serial number or warranty seal has been removed

or defaced;

(d) the Appliance was serviced or repaired by anyone other than Electrolux,

an authorised repairer or ASC.

8. This warranty, the contract to which it relates and the relationship between

you and Electrolux are governed by the law applicable where the Appliance

was purchased. Where the Appliance was purchased in New Zealand for

commercial purposes the Consumer Guarantee Act does not apply.

9. To the extent permitted by law and subject to your non-excludable

statutory rights and warranties, Electrolux excludes all warranties and

liabilities (other than as contained in this document) including liability for any

loss or damage whether direct or indirect arising from your purchase, use or

non use of the Appliance.

10. For Appliances and services provided by Electrolux in Australia, the

Appliances come with a guarantee by Electrolux that cannot be excluded

under the ACL. You are entitled to a replacement or refund for a major failure

and for compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the Appliance repaired or replaced if the

Appliance fails to be of acceptable quality and the failure does not amount

toamajorfailure.Thebenetstoyougivenbythiswarrantyareinaddition

to your other rights and remedies under a law in relation to the Appliances or

services to which the warranty relates.

11. At all times during the Warranty Period, Electrolux shall, at its discretion,

determine whether repair, replacement or refund will apply if an Appliance

has a valid warranty claim applicable to it.

12. For Appliances and services provided by Electrolux in New Zealand, the

Appliances come with a guarantee by Electrolux pursuant to the provisions

of the Consumer Guarantees Act, the Sale of Goods Act and the Fair

Trading Act.

13. To enquire about claiming under this warranty, please follow these steps:

(a) carefully check the operating instructions, user manual and the terms of

this warranty;

(b) have the model and serial number of the Appliance available;

(c) have the proof of purchase (e.g. an invoice) available;

(d) telephone the numbers shown below.

14. You accept that if you make a warranty claim, Electrolux and its ASC may

exchange information in relation to you to enable Electrolux to meet its

obligations under this warranty.

ortondtheaddressofyournearest

FOR SERVICE

state service centre in Australia

PLEASE CALL 13 13 49

For the cost of a local call (Australia only)

FOR SERVICE

ortondtheaddressofyournearest

authorised service centre in New Zealand

FREE CALL 0800 10 66 10

(New Zealand only)

KSSAC_Warr_Aug13

SERVICE AUSTRALIA

ELECTROLUX HOME PRODUCTS

www.electrolux.com.au

SERVICE NEW ZEALAND

ELECTROLUX (NZ) Limited

www.electrolux.co.nz

FOR SPARE PARTS

ortondtheaddressofyournearest

state spare parts centre in Australia

PLEASE CALL 13 13 50

For the cost of a local call (Australia only)

FOR SPARE PARTS

ortondtheaddressofyournearest

state spare parts centre in New Zealand

FREE CALL 0800 10 66 20

(New Zealand only)

27Warranty

Page 28

For more information on all Kelvinator

appliances, or for dimension and installation

information, call into your retailer, phone or email

our customer care team or visit our website:

AUSTRALIA

phone: 1300 363 640

fax: 1800 350 067

email: customercare@electrolux.com.au

web: kelvinator.com.au

NEW ZEALAND

phone: 0800 436 245

fax: 0800 225 088

email: customercare@electrolux.co.nz

web: kelvinator.co.nz

Kelvinator. We are part of the Electrolux family.

Share more of our thinking at electrolux.com.au

Part No. 66129913263

© 2015 Electrolux Home Products Pty Ltd.

ABN 51 004 762 341

KMAN_KAIRINV2_IM_Jun15

Loading...

Loading...