Page 1

Gas Continuous Flow Hot Water System

Installation Manual

Page 2

environmental tips

environmental tips

Congratulations Contents

Congratulations and thank you for choosing our gas

continuous flow hot water system. Before you install the hot

water system, we recommend that you read through the

entire installation manual, which provides the description

of the hot water system, its functions and how to install it

correctly. To avoid the risks that are always present when you

install an appliance, it is important that the hot water system

is installed correctly and that you read the safety instructions

carefully to avoid misuse and hazards.

After unpacking the hot water system please check it is not

damaged. If in doubt, do not use the hot water system but

contact your local Electrolux Customer Care Centre using the

number located at the back of this installation guide.

NOTE: The actual gas heating appliance that is part of this

gas continuous flow hot water system will here after be

refered to as "water heater" for the purposes of this manual.

The gas continuous flow hot water system as a whole may

also be refered to as "hot water system" for simplicity.

Meanings of symbols used in this manual are shown below:

warning

This symbol indicates information concerning your

personal safety

Important .......................................................................... 3

Important safety instructions ........................................... 4

For the plumber ................................................................ 5

Dimensions and connection points ................................... 6

Installation ......................................................................... 8

Clearances ......................................................................... 9

Gas connection ................................................................ 10

Water connection ............................................................ 11

Electrical connection ....................................................... 12

Remote controller .......................................................... 13

Remote controller Installation ........................................ 14

Commissioning Instructions ............................................ 16

Troubleshooting .............................................................. 18

Remote controller and PCB error codes ......................... 19

Warranty .......................................................................... 23

caution

This symbol indicates information on how to avoid

damaging the hot water system

This symbol indicates tips and information about

economical and ecological use of the hot water system

Information on disposal for users

• Most of the packing materials are recyclable.

Please dispose of those materials through your local

recycling depot or by placing them in appropriate

collection containers.

• If you wish to discard this gas continuous hot water

system, please contact your local authorities and ask for

the correct method of disposal.

warning

• Contact an authorised installer for installation of this

hot water system.

• Contact an authorised service technician for repair

or maintenance of this hot water system.

• If a power cord is to be replaced, replacement work

must be performed by authorised personnel only.

• Installation work must be performed in accordance

with the national standards by authorised personnel

only. Wrong connection can cause over heating or fire.

• This hot water system should be installed in accordance

with AS/NZS 3000 and your local electrical wiring rules.

Conditions of use

This hot water system is intended to be used in household

and similar applications such as :

• staff kitchen areas in shops, ofces and other working

environments.

• farm houses.

• by clients in hotels, motels and other residential type

environments.

• bed and breakfast type environments

2 contents Kelvinator Gas Continuous Flow hot water system

Page 3

Important

This Installation Manual has been prepared for the installers

of the gas continuous flow hot water system.

For the installer

The installation must be completed in accordance with the

information supplied in this Installation Manual.

All other relevant National, State or Local regulations must

also be conformed with and these include (but are not

limited to):

• Australian Standard AS3500.1 – Water Supply

• Australian Standard AS3500.4 – Hot Water Supply

• Australian Standard AS3000 – Electrical Installation

• Australian Gas Association Code AS5601 –

Gas Appliance Installation

• Local Water, Gas & Electrical Authority Regulations

Municipal Building Codes

warning

Installation must be performed by a qualied installer (for

example, a licensed plumber or gas tter).

This gas continuous flow hot water system is not intended

for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of

experience or knowledge, unless they have been given

supervision or instruction concerning use by a person

responsible for their safety. Children should be supervised

to ensure that they do not play with the gas continuous flow

hot water system.

This symbol indicates never to do this

This symbol indicates always do this

warning

Connect with power properly.

Otherwise, it may cause electric shock or re due to

excess heat generation.

Always ensure effective earthing.

No earthing may cause electric shock.

Disconnect the power and turn off the gas inlet

valve to the water heater if strange sounds, smell, or

smoke comes from it.

It may cause re and electric shock.

Do not operate or stop the water heater by switching

on or off the power.

It may cause electric shock or re due to heat generation.

Do not damage or use an unspecified power cord.

It may cause elec tric shock or re.

If the power cord is damaged, it must be replaced by

the manufacturer or an authorised ser vice centre or a

similarly qualied person in order to avoid a hazard.

Do not modify power cord length or share the outlet

with other appliances.

It may cause electric shock or re due to heat generation.

Do not operate with wet hands or in damp environment.

It may cause elec tric shock.

Do not allow water to run into electric parts.

It may cause failure of machine or electric shock.

Do not use the socket if it is loose or damaged.

It may cause re and electric shock.

Do not open the water heater during operation.

It may cause elec tric shock.

Do not allow the power cord to rest close to hot

surfaces.

It may cause re and electric shock.

Do not disassemble or modify the water heater.

It may cause failure and electric shock.

Kelvinator Gas Continuous Flow hot water system important 3

Page 4

Important safety instructions

Ensure the following safety instructions are read and

understood before commencing installation.

warning

For the continued safety of this appliance it must be

installed, operated and maintained in accordance with the

manufacturer's instructions.

warning

If you do not follow these instructions exactly, a re or

explosion may result causing property damage, personal

injury or loss of life.

1. The gas continuous ow hot water system does not have

a pilot. It is equipped with an internal ignition device that

automatically lights the burner. Do not try and light the

burner by hand.

2. BEFORE OPERATING use a suitable gas detector to

check all around the hot water system for evidence of

leaking gas. Be sure to check close to the ground if you

are using LP gas as it is heavier than air and may settle on

the ground.

WHAT TO DO IF YOU SMELL GAS.

• Do not try to light the water heater.

• Do not touch any electrical switch

• Do not use any phone in your building

• Check and isolate the main gas valve

• Immediately call your gas supplier from a neighbour's

phone. Follow the gas supplier's instructions

• If you cannot reach your gas supplier, call the re

department

3. When turning the gas valve knob, do so only by hand,

never use tools. If you can not do this, do not try and

repair it.

4. Do not use the water heater if any part has been under

water. Immediately call a qualied service technician

to inspect the water heater and to replace any

damaged parts.

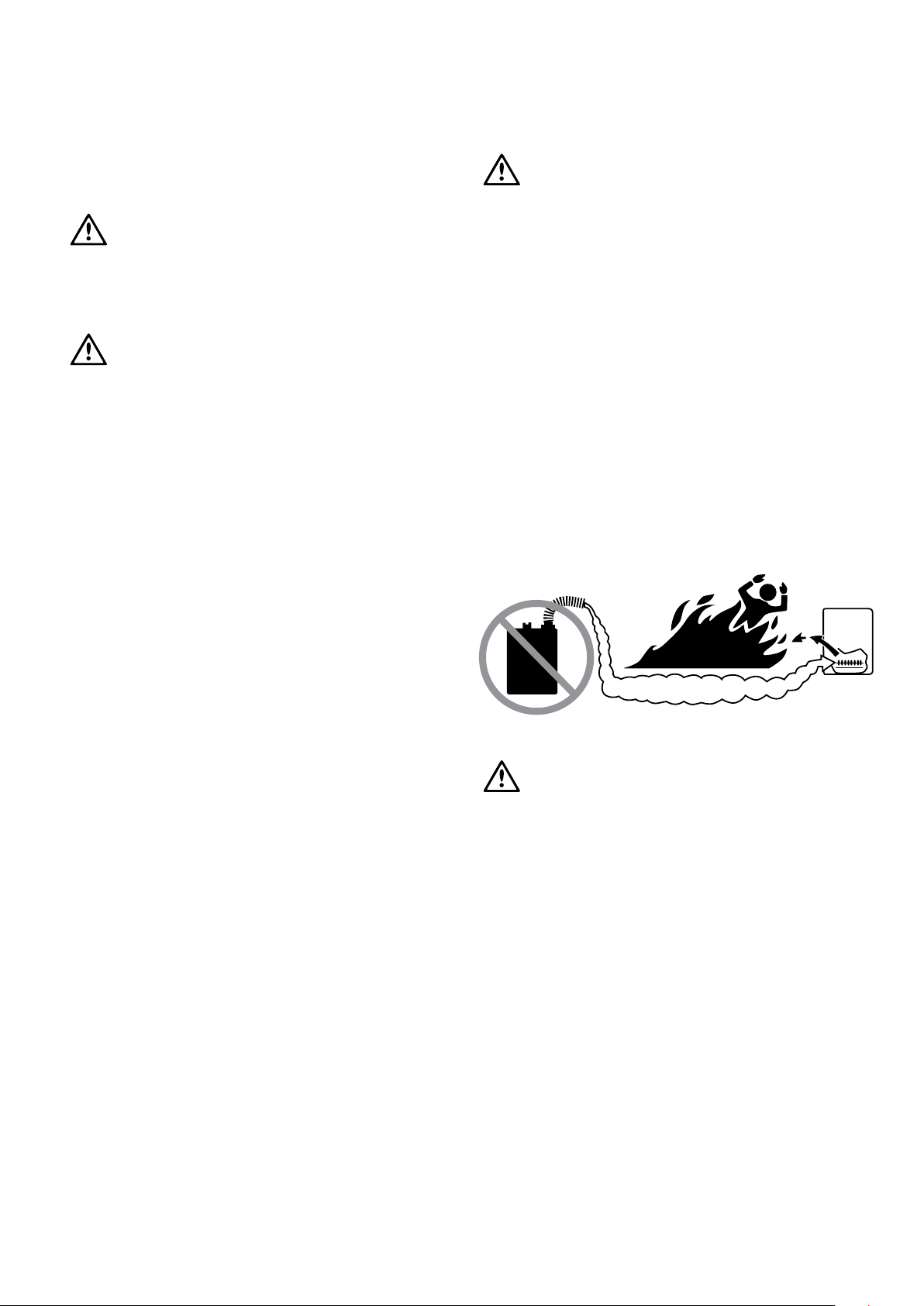

warning

Vapours from ammable liquids will explode and catch re

causing death or severe burns.

Do not use or store flammable products such as gasoline,

solvents or adhesives near the water heater.

Keep flammable products:

1. Far away from the water heater

2. In approved containers

3. Tightly closed

4. Out of children's reach

Vapours:

1. Cannot be seen

2. Vapours are heavier than air

3. Go a long way on the oor

4. Can be carried from other rooms to the main burner by

air currents

FLAMMABLES

warning

The water heater shall be installed so as to be permanently

connected to the water mains with rigid copper piping and

must not be connected by a flexible hose-set or similar

FLAMMABLE VAPOURS

4 impor tant safety instructions Kelvinator Gas Continuous Flow hot water system

Page 5

For the plumber

PLEASE NOTE this water heater is supplied factory set to

comply with the requirements of AS 3498.

If you are installing a 60°C or 70°C preset water heater, a

tempering valve is to be installed for the hot water supplying

sanitary xtures primarily used for the purpose of personal

hygiene.

Please follow all the installation instructions in this manual

including the following instructions regarding the water

heater outlet connection:

1. When connecting the hot water supply to the xtures in

the property, a minimum of three (3) metres of pipework

must be used between the outlet of the water heater and

the rst tap or outlet. If you are installing a 60°C or 70°C

model, only a minimum of one (1) meter of pipework is

necessary. See diagram to the right.

2. The hot water outlet line from the water heater should

be covered with 20mm thick pipe insulation or similar to

prevent heat loss and persons coming in contact with it.

3. When the installation is completed, the temperature of

the hot water supplying sanitary xtures primarily used

for the purpose of personal hygiene, for example the

bathroom shower/taps, shall be checked to ensure it does

not exceed 50°C. If a 50°C model gas continuous ow hot

water system has been installed, all hot water taps and

xtures need to be checked to ensure they do not

exceed 50°C.

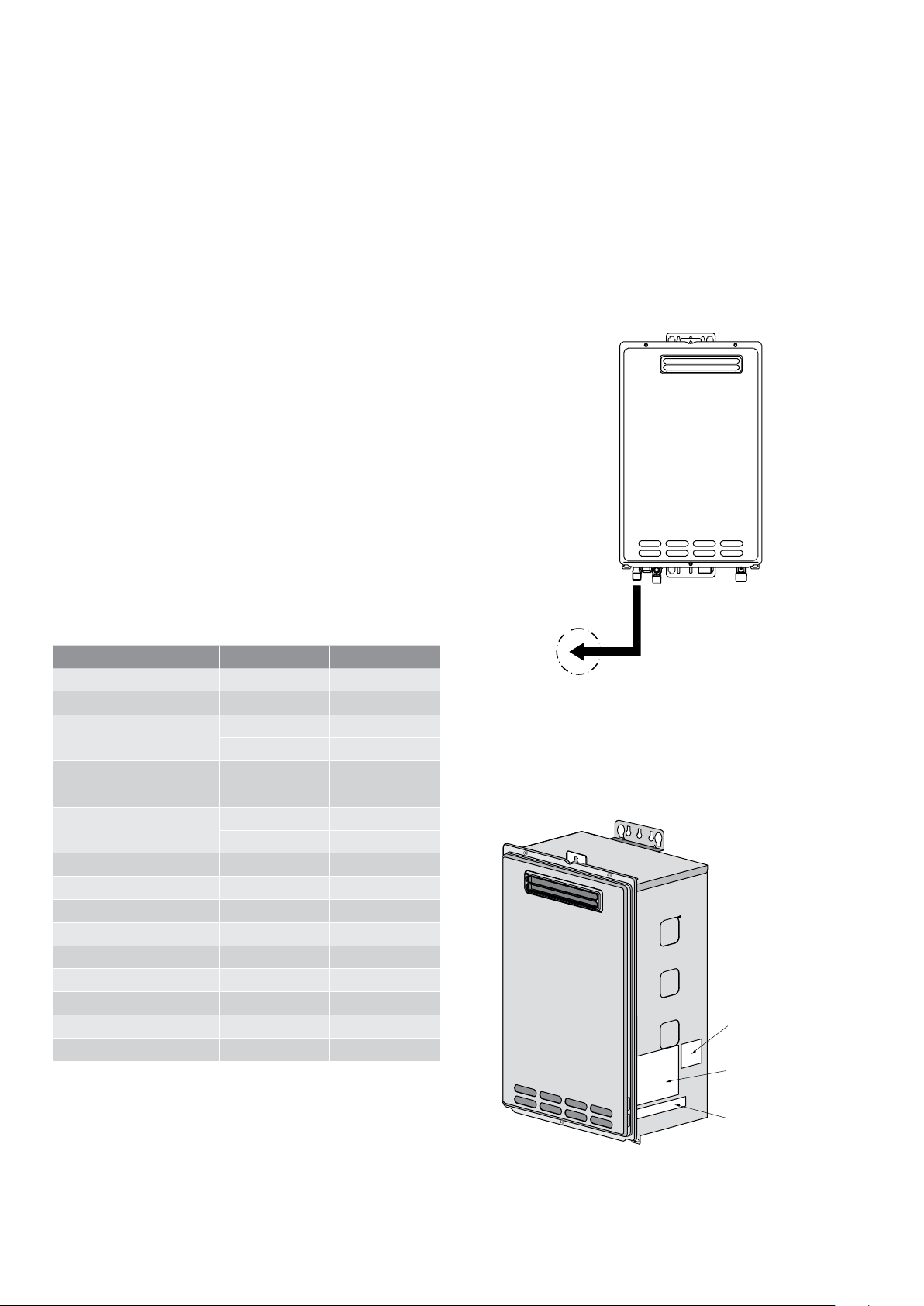

MODELS KGC20*** KGC26***

Capacity L/min 20L/min 26L /min

Gas Input MJ/h 160 195

Supply Inlet Pressure

kPa – Nat. Gas

Supply Inlet Pressure

kPa - LPG

Water Supply

Pressure kPa

1.13 m in. 1.13 m in.

2.75 max. 2.75 max.

2.61 min 2.61 min

2.89 max 2.89 max

150* min 150* min.

1200 max 1200 max

Height mm 542 542

Depth mm 170 215

Width mm 350 350

Weight kg 15.7 17. 2

Gas Connection mm 20 BSP 20 BSP

Water Connections 15 BSP 15 BSP

Ignition Electronic Electronic

Electrical Supply Voltage 240 AC 240 AC

Operating Current 0.8A 0.8A

*The water heater will operate at reduced performance if inlet water supply

pressure is below 340 kPa.

• For information relating to burner test point pressures

and injector sizes refer to the rating plate located on the

right hand side of the cabinet for each model (please

refer to the diagram at the bottom of this page showing

the locations of the labels on the water heater).

• For information relating to overall dimensions and

connection points refer to diagrams on pages 6 & 7.

• Before installing in areas over 1500 m above sea level,

contact the manufacturer for instructions.

minimum length of 3

meters (1 meter for 60°C

and 70°C models)

• Pipe size is nominal 1/2" from hot water outlet to the rst

tap or outlet.

Accessories

4 tapping screws are included with the water heater.

Serial number

label position

Rating label

position

Note: If the gas supply pressure exceeds the maximum

value in the above table for the respective gas type, fit an

appropriate pressure limiting valve at the inlet to the gas inlet

of the water heater.

Gas type label

position

Kelvinator Gas Continuous Flow hot water system for the plumber 5

Page 6

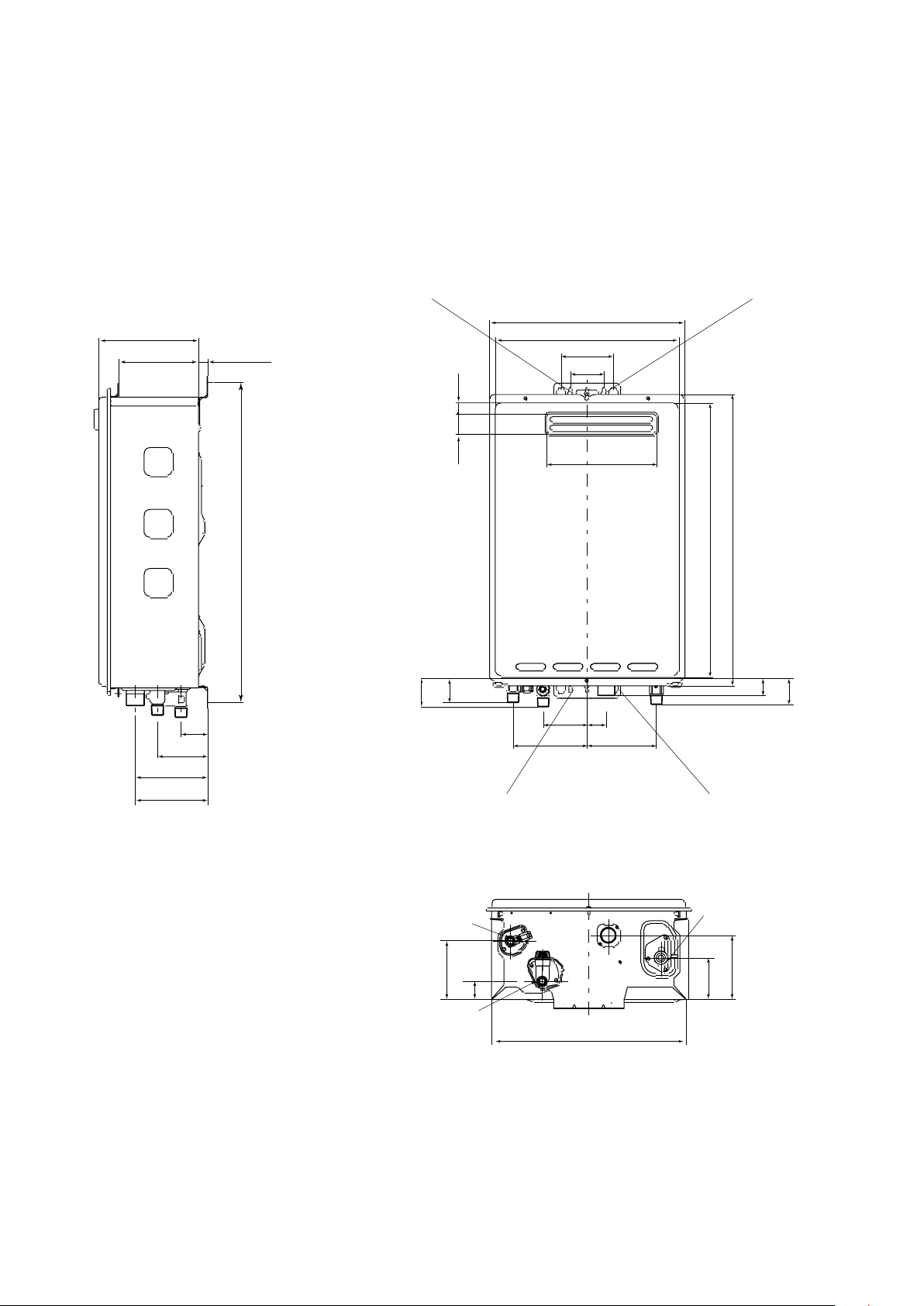

Exterior view –

KGC20***

170mm

137mm

16mm

top xing positions top xing positions

350mm

330mm

94mm

60mm

19mm

542mm

46mm cold

86mm gas

114mm hot

124mm power

37mm

49mm cold

41mm hot

hot

bottom xing positions

hot

198mm

cold

79mm

133mm

Power cable length: 1.5m

power

34mm

124mm

490mm

520mm

31mm power

gas

bottom xing positions

gas

47mm gas

98mm

cold

6 dimensions - KGC20*** Kelvinator Gas Continuous Flow hot water system

30mm

335mm

108mm

70mm

Page 7

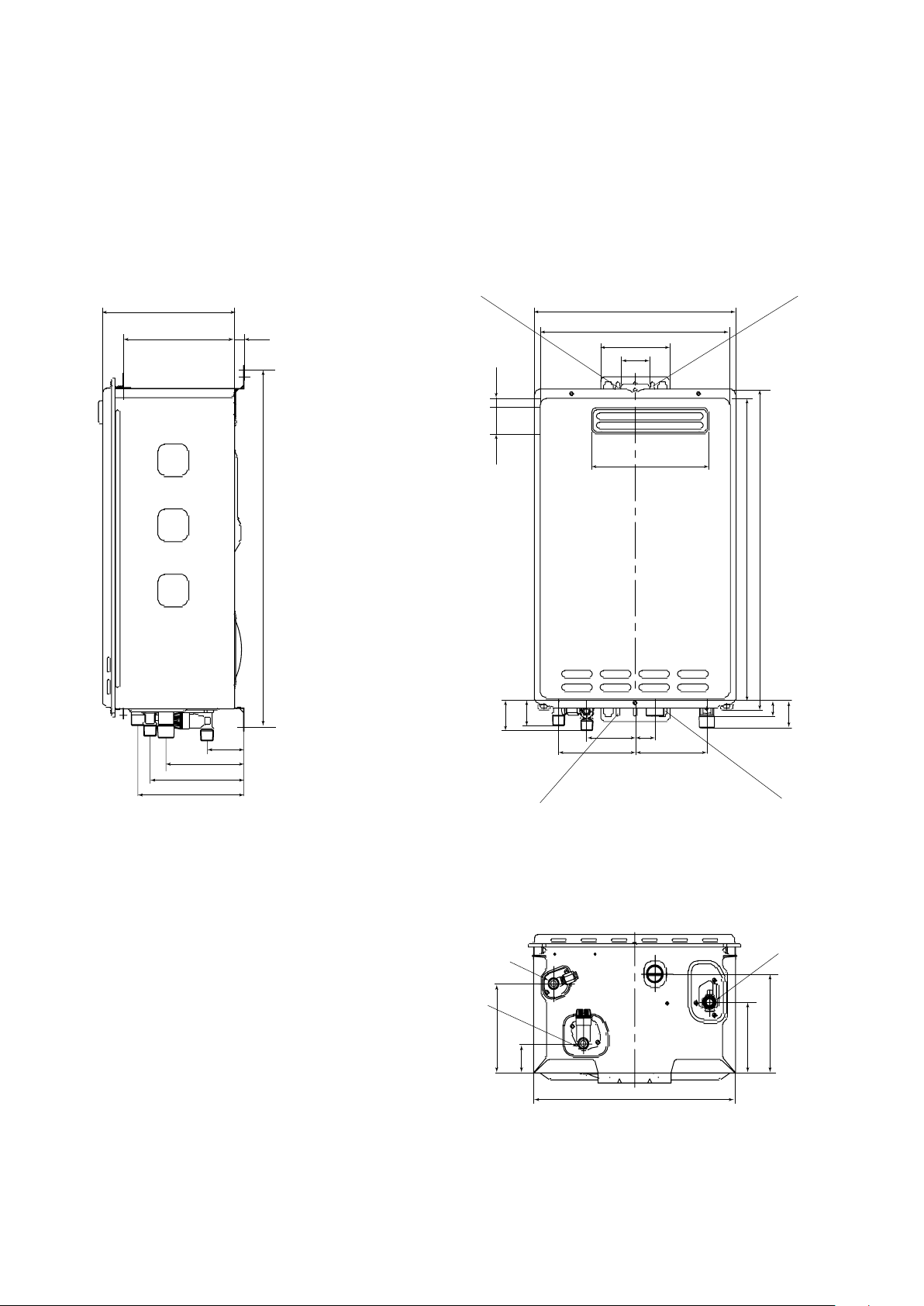

Exterior view –

KGC26***

215mm

182mm

16mm

top xing positions top xing positions

350mm

330mm

94mm

60mm

19mm

542mm

61mm cold

125mm gas

154mm hot

169mm power

37mm

41mm hot

49mm cold

hot

bottom xing positions

198mm

cold

84mm

133mm

Power cable length: 1.5m

power

34mm

124mm

520mm

490mm

25mm power

45mm gas

bottom xing positions

hot

cold

45mm

138 mm

335mm

Kelvinator Gas Continuous Flow hot water system dimensions – KGC26*** 7

gas

109mm

153mm

Page 8

Installation

The water heater requires careful and correct installation

to ensure safe and efcient operation. This manual must be

followed exactly. Read the SAFETY GUIDELINES and the

IMPORTANT sections at the beginning of this manual.

Conrm the water heater suitability

Check the gas type label and the rating plate for the correct

gas type, gas pressure, water pressure and electrical rating

for your application. Do not install this water heater if these

requirements can’t be met.

If this water heater is to be installed in a recess box,

please refer to the installation instructions supplied with

the recess box for specic instructions regarding this type

of installation.

caution

• The water heater must be installed outdoors only. Do not

install the water heater indoors.

• This equipment is not suitable for pool or spa heating.

• Water hardness may affect the water heater. It may be

damaged. It is important that the water heater is installed

in water conditions that are suitable for its efcient,

long term use.

• This is a water heating apparatus only and the nal tness

of water delivered is dependent upon the quality of water

supplied to this system.

• The connection, attachment, integration or general

association of other equipment or parts not specied by

the water heater which either directly or indirectly affect

the operation or performance of this equipment – could

void the warranty.

• Before making connections to the water heater, remove

any transit protection designed to prevent dirt and debris

from entering the water heater.

• The manifold pressure is preset at the factory. It is

computer controlled and does not need adjustment.

• Occupants are to be advised of any inconveniences which

could occur such as disconnection of services.

• Please follow the electrical earthing procedure outlined in

AS3500.4 before cutting or uncoupling existing metallic

pipework.

• To ensure the optimal performance of the water heater, it

should be installed as close as practical to the most used

hot water xtures and have 20mm thick insulation covering

the hot water piping. This will minimise heat loss, water

usage and cost to the customer. Keep in mind that the

minimum distance from the outlet of the water heater to

the rst xture is three metres for 50C models, and one

metre for 60C or 70C models.

• The water heater does not require a reproof back plate

when installed on a timber wall.

• Before connecting the water heater to the power supply

ensure that all air has been bled out of the hot water

system and that water is running freely from a hot tap for a

period of time. If air has not been properly bled from the

hot water system and the water heater begins operating, it

may become severely damaged.

caution

• Although the water heater is designed to operate with

minimal noise, it is recommended that you do not install

the water heater adjacent to bedrooms or other areas

designed to be quiet.

• Locate your water heater close to a drain where leakage

will not damage surrounding areas. As with any water

heating appliance, the potential for leakage at some time

during the life of the product does exist.

• The water heater shall be installed far away from any

flammable or combustible materials including wood and

cardboard. It must also have adequate ventilation to allow

the proper combustion of the gas inside the heater to

take place.

warning

• Ensure every care is taken to warn occupants of the

building and the public of any injury that may occur from

falling tools, open trenches, water connections or any

other general hazard.

• Make sure the water heater will have enough

combustion air and proper ventilation.

• Keep the area around the water heater clean. Particles

may clog the air vent, reduce fan function, or cause

improper combustion.

• Do not locate your water heater in a pit or any location

where gas and water can accumulate.

Selecting an installation location

Carefully read this section before selecting the installation

location and installing the water heater. The installer must

follow these precautions exactly.

• Locate the water heater to allow for easy access for service

and maintenance. Install the water heater so that it can be

connected or removed easily.

• Check the proximity of gas and electrical lines so as not

to create a hazard and avoid access problems for other

services.

• It must be located in accordance with the requirements

of AS5601 and have sufcient clearances from eaves,

windows, vents etc. – see the diagram on p.9.

• Exemption from Prescribed Statutory Requirement:

AS5601-2000 Clause 5.13.6.5, This relates to the physical

separation distance specication where multiple

appliances are employed. That equates to a minimum

150mm horizontal ue separation distance allowing

appliances to be placed side by side in the same

vertical plane

• Most load bearing walls such as brick, brick/veneer,

weatherboard and stud-frames are suitable locations.

• Securely fasten the water heater to the wall with a xing

solution suitable to the type of material the wall is made

from. A minimum of two screws or bolts at the top and

two screws or bolts at the bottom must be used.

Note: Refer to pages 6 & 7 for fixing positions.

8 installation Kelvinator Gas Continuous Flow hot water system

Page 9

Clearances for outdoor heater locations –

AS5601

This diagram and reference table has been taken from the AS/NZS 5601 standard regarding gas installations. Any references on this page to

clauses or appendix figures are referring directly to this standard.

j

openable

window

f

c

T – Flue terminal

I – Mechanical air inlet

n

k

k

j j

M – Gas meter

P – Electricity meter

or fuse box

h

T

h

h

e e

P

T

g

Shading indicates prohibited

areas for flue terminals

d

see note 2

a

d

g

b

Reference Item Minimum clearances (mm)

a Below eaves, balconies and other projections:

• appliances up to 50MJ/h input 200

• appliances over 50MJ/h input 300

b From the ground above a balcony surface* 300

c From a return wall or external corner* 300

d

From a gas meter (M) (see 4.7.11 for vent terminal location

of regulator)

1000

e From an electricity meter or fuse box (P) 500

f From a drain or soil pipe 75

g

Horizontally from any building structure* or obstruction facing

a terminal

500

h From any other ue terminal, cowl or combustion air intake 300

Horizontally from an openable window, door, non-mechanical

air inlet or any other opening into a building with the exception

of sub-floor ventilation

j

• Appliances up to 150 MJ/h input 300

• Appliances over 150 MJ/h input up to 200 MJ/h input 500

• Appliances over 200 MJ/h input 1500

• All fan-assisted ue appliances in the direction of discharge 1500

k From a mechanical air inlet, including a spa blower 1000

Vertically below an openable window, non-mechanical air

outlet or any other opening into a building with the exception

of sub-floor ventilation

n

• Space heaters up to 50 MJ/h input 150

• Other appliances up to 150 MJ/h input 500

• Appliances over 50 MJ/h input up to 150 MJ/h input 1500

• Appliances over 150 MJ/h input 1500

*unles s appliance is cer tied for closer installation.

NOTES:

1. All distances are measured to the nearest part of the

terminal.

2. Prohibited area below electricity meter or fuse box

extends to ground level.

3. See clause 15.3.6.6 for restrictions on a ue terminal

under a covered area.

4. See Appendix J, gures J2(a) and J3(a) for clearances

required from a flue terminal to an LP gas cylinder. A flue

terminal is considered to be a source of ignition.

5. For appliances not addressed above, acceptance should

be obtained from the technical regulator.

Exemption from prescribed statuatory requirements

referred to above has been granted to allow multiple series

of the water heaters to be positioned side by side.

c

see note 3

T

Kelvinator Gas Continuous Flow hot water system clearances 9

Page 10

Gas connection

caution

1. Turn off the electrical supply to the water heater and

manual gas valve located on the outside of the water

heater before beginning gas connection.

2. Conrm the position of the gas inlet. Do not connect any

water lines to the gas inlet. It may be critically damaged.

power cord

gas supply inlet

gas valve

Sizing and connection

This water heater requires a 3/4" or 20mm gas supply line

size to operate correctly, check the gas supply pipe size is

suitable before installation.

Check the gas type label to make sure that the water heater

was built for the type of gas you will be using, and that the

gas inlet pressure is within the appropriate range. (Please

refer to page 5)

1. Gas pressure below this specied range for the water

heater and/or insufcient gas volume will adversely affect

performance.

2. Inlet gas pressure must not exceed the above maximum

values; gas pressure above the specied range will cause

dangerous operating conditions and damage to the

water heater.

3. Until testing of the main gas line supply pressure is

completed, ensure the gas line to the water heater is

disconnected to avoid any damage to the water heater.

Purging the gas supply line before connection

Before connecting the gas supply inlet piping to the water

heater it must be purged of foreign matter. Before purging

the gas supply line conrm that the electrical supply to the

water heater is turned off, there is adequate ventilation

available and that no ignition sources are present. Follow the

purging instructions detailed in AS5601 and then close the

gas isolation valve.

warning

After purging the gas supply line allow sufficient time for

escaped gas to disperse before operating the water heater

or any potential ignition source.

Measuring inlet gas pressure and testing gas leakage

The inlet gas pressure to the water heater should be checked

and leak tested before operating for the rst time. This is

only to be done by a licensed professional.

1. Shut off the manual gas valve on the supply gas line.

2. Open a faucet. The water heater should turn on and the

gas in the gas pipe line should purge. Leave the faucet on

to keep the water heater running until it shuts down due

to lack of gas supply. Then shut the faucet off.

3. Remove the screw for the pressure port located on the

gas inlet of the water heater shown in the diagram below.

4. Connect the manometer to the pressure port.

5. Re-open the manual gas valve. Check to see that there

are no gas leaks.

6. Open some of the xtures that use the highest ow rate

to turn on the water heater.

7. When the water heater is on at maximum burn, the inlet

gas pressure must be within the appropriate range

(please refer to page 5).

caution

Conversion of this water heater from natural gas to

propane or propane to natural gas cannot be done in the

eld. Contact your local retailer or distributor to get the

correct water heater for your gas type.

• Size the gas piping according to AS5601 installation code

for the correct pipe sizing for the water heater.

• Always use approved connectors to connect the water

heater to the gas line. The service technician should

purge the gas line of any debris before connecting to the

water heater.

• Install a manual gas shut-off valve between the water

heater and the gas supply line.

• The regulator is preset at the factory. It is computer

controlled and is not to be adjusted by any person other

than a qualied Service Provider.

• When the gas connections are completed, it is necessary

to perform a gas leak test either by applying soapy water

to all gas ttings and observing for bubbles or by using a

gas leak detection device.

10 gas connection Kelvinator Gas Continuous Flow hot water system

This water heater and its individual shut-off valve must be

isolated from the gas supply piping system by unplugging

the water heater and turning off the main gas valve during

any pressure testing of the gas supply piping system at test

pressures above 3kPa.

Page 11

Water connection

warning

Do not reverse the hot outlet and cold supply line

connections to the water heater as this will cause your

heater to operate improperly.

drain plug

lter

hot water

outlet

cold water

intlet

• All pipes, pipe ttings, valves and other components,

including soldering materials, must be suitable for

potable water systems.

• A manual shut off valve must be installed on the cold

water inlet to the water heater between the main water

supply line and the water heater.

• Only a gate valve or a ball valve is to be used on the cold

water supply.

• Check that the cold water pressure is sufcient for the

water heater. If it is above 1000kPa an approved pressure

limiting valve must be tted to the installation.

• Before installing the water heater, ush the water line

to remove all debris, and after installation is complete,

purge the air from the line. Failure to do so may cause

damage to the water heater.

• There is a wire mesh lter on the water heater cold inlet

to prevent debris from entering the water heater. Clean

the lter after initial installation to ensure it has not

been blocked.

gate or ball

valve on inlet

lter

gate or ball

valve on inlet

1. Turn off the water inlet supply valve.

2. Open a hot water tap to release the line pressure.

3. Remove the lter by turning it counterclockwise. Clean

under running water with an old toothbrush then replace.

lter

NOTE: This filter is designed to be cleaned as part of

regular maintenance.

Kelvinator Gas Continuous Flow hot water system water connection 11

Page 12

Electrical connection

1. The water heater must be electrically grounded. Please

Weather-proof power outlet

ensure that the earth on the outlet that the supply cord

connects to is wired correctly. If in doubt check the continuity

of the earth at the outlet to the earth stake on the premises.

2. The water heater requires an AC 240V 50Hz

electrical power supply and draws a current of 0.8A.

3. The water heater must be connected to a weather-proof

power outlet. This outlet shall be no more than 1 meter

from the base of the water heater for easy access.

4. Means for disconnection must be incorporated in the

xed wiring in accordance with the wiring rules.

5. The insulation of the xed wiring must be protected by

insulating sleeving having an appropriate temperature rating.

6. If the supply cord is to be replaced, this must be done

by a service technician, electrician or similarly qualied

person in accordance with the wiring rules.

caution

To prevent damage to the water heater leave it

disconnected from the power supply until the

commissioning process has begun and has reached step 9

(see page 16).

Wiring diagram

AC240V

BR

Y&G

BL

Ground

BK

W

BK

W

BK

W

BK

W

7

C

3

9

5

3

7

3

+85-

Dip Switch

743

1

8

1

7

イ

1

0

+

4656

Burning LED

MIN button

MAX button

MV

SV1

SV2

SV3

Hi-

limit

O.H.C.F

Only

Model 26

BL

PK

BLPK

BL

BL

BLBL

BL

LB

G

O

R

F

M

Flow

Sensor

Inlet

thermistor

Mixing

thermistor

B

Y

O

R

W

BK

BK

BK

BK

BK

R

L

W

2 3 4 5 6 7 8

1

OFF

Increase button

Decrease button

MAIN PCB

Fuse

5A

BK

W

P

P

Air-fuel ratio rod

Y

G

O

Flame rod

W

R

BK

R

IG

BK

W

Ground

Proportional

Valve

Flow

Adjust

Valve

Remote

Controller

BK

Transformer

Elect rod

Ground

W

Heater

W

W

Thermostat

BK

BK

W

W

Heater

12 electrical connection Kelvinator Gas Continuous Flow hot water system

Page 13

Remote controller (optional)

The water heater can be installed with up to three remote

controllers (one of each type), a MAIN controller, a SHOWER

controller and an ENSUITE controller.

The primary function of the remote controller is to adjust the

set temperature of the water being delivered by the water

heater (default set temperature on each controller is 40°C).

The set temperature can only be adjusted by the remote

controller that has the priority setting at that time (when

a remote controller has the priority setting, the “Priority”

indicator will be lit). The other remote controllers (if installed)

will simply display the set temperature. If the priority setting

is to be transferred to another controller, it can be transferred

by pressing the “Priority” button on that controller but only

when there is no water flowing through the water heater. This

prevents the water temperature from being changed whilst

someone else is using the hot water e.g. taking a shower.

In addition each remote controller can also display an error

code to indicate when there is a problem with the water

heater. This can be of assistance if there is a problem when

installing the hot water system or for a service person when

a service call is required (see page 19 of this manual for the

error codes and their meaning).

MAIN remote controller KGCMRC*

• The MAIN remote controller must be installed indoors in

areas such as the kitchen as it is NOT water resistant.

• Allows the output temperature from the water heater to

be adjusted within the range of 37°C to 60°C.

• The temperature options are: 37°C, 38°C, 39°C, 40°C,

41°C, 42°C, 43°C, 44°C, 45°C, 46°C, 47°C, 50°C, 55°C

and 60°C.

Note: If you have an "A" series Main remote controller

installed it will not have the 60°C temperature option.

• When the “Burner On” display indicator is lit, the set

temperature cannot be adjusted above 50°C. In order to

set the temperature up to 60°C rst close the hot water

tap or xture, then adjust the temperature.

SHOWER and ENSUITE remote controllers

• The SHOWER and ENSUITE remote controllers are water

resistant and designed to be installed in wet or damp

areas but should be positioned so that they will not come

in direct contact with water.

• The SHOWER controller is designed to be installed in the

main bathroom

shower

• The ENSUITE controller is designed to be installed in the

ensuite bathroom.

ensuite

• Both these remote controllers allow the output

temperature from the water heater to be adjusted within

the range of 37°C to 50°C.

• The temperature options are: 37°C, 38°C, 39°C, 40°C,

41°C, 42°C, 43°C, 44°C, 45°C, 46°C, 47°C, and 50°C.

• When the “Burner On” display indicator is lit, for safety

reasons the set temperature cannot be adjusted above

42°C. If those temperatures are desired, rst close the hot

water tap or xture.

main

NOTE: If the water heater is a 50°C preset model,

it will not be possible to adjust the temperature beyond

50°C.

Kelvinator Gas Continuous Flow hot water system remote controller 1 3

Page 14

Remote controller installation

1. Crimp the lugs provided to the remote controller wiring.

Minimum 18AWG wire (No polarity).・Maximum 100m long

2. If installing the MAIN remote controller, attach the

crimped fork lugs on the end of the wiring to the

terminals on the back of the controller.

fork lugs

25mm

45mm

remote control

wiring

wiring terminals

caution

• TheMAINremotecontrollermustbeinstalledindoors

and in an area that does not have the potential to

become wet or damp as it is NOT water resistant.

In potentially wet areas the SHOWER and ENSUITE

controllers should be used however all controllers

must be positioned so that they will not come into

direct contact with water.

• DONOTpositiontheremotecontrolsinthevicinity

of chemicals.

• DONOTpositiontheremotecontrolsoveracooker,

grill or toaster.

• DONOTpositiontheremotecontrolswherematerials

may spill onto them.

• Pleasenoteifthecontrolsaretobettedtoametal

surface an insulation plate should be provided behind

the mounting position.

3. Install the wiring downward through the cable trench and

out the bottom of the connector base.

4. Fix the remote controller in position using the two screws

provided or alternatively use another xing solution

suitable for the material to be xed to.

84mm

14 remote controller installation Kelvinator Gas Continuous Flow hot water system

Page 15

Connection of remote controller

12345678

wiring to the water heater

1. Turn off the power supply to the water heater.

2. Remove the front cover from the water heater. There are

3 screws on the front cover.

3. Put the remote wires through the hole on the bottom of

the water heater's casing.

Note: If the controller wiring is exposed to sunlight and

is not UV resistant it will need to be protected from UV

damage by conduit or another suitable means.

4. Remove the plastic cover and connect remote control

wires to remote terminals directly. (There is no polarity in

the terminations).

plastic cover

remote control

terminal

12345678

caution

DO NOT jump or short-circuit wires.

Computer will be damaged.

5. Replace the plastic cover and the front cover and connect

the power plug.

remote control

cable

Remove the plastic cover and

connect the terminals directly

behind the cover

Remote control cable connections

SHOWERMAIN ENSUITE

Note: Either each individual controller can be wired to the water

heater separately as pictured above, or alternatively it's acceptable

to have the controllers tapping into a common wire connected to

the water heater. The controllers operate on low voltage, please

ensure suitable and reliable wiring connection is made.

12345678

typical cable layout

Put the remote wires through

the hole on the bottom of the

unit's casing.

Kelvinator Gas Continuous Flow hot water system remote controller installation 15

Page 16

Commissioning instructions

Before commissioning the gas continuous flow hot water

system, please conrm the following:

• Installation location and clearances are correct

as per AS5601

• Gas and water supply lines have been purged

of foreign matter

• Correct gas type has been connected to the

water heater

• There are no gas leaks on the gas pipework

and connections

• A pressure limiting valve is installed (if water

supply pressure is above 1000kPa)

• Hot and cold water connections are correct to

the water heater

• A tempering valve has been installed (60°C

and 70°C preset model installations only)

• Sufcient insulation has been installed on hot

water pipework

• Water heater and pipework has been electrically

grounded

• Power supply to the water heater is 240V AC 50Hz

• Water heater is disconnected from the power

supply or unplugged

These steps are to be followed after the installation of the

gas continuous flow hot water system to ensure its safety

and performance. If the hot water system cannot be setup to

perform correctly as specied in this manual, please call the

service centre for further instructions (number located in the

warranty section of this manual).

caution

Before commissioning the hot water system first ensure

that the water heater is disconnected from the power

supply to protect it from being damaged due to air in

the system. Damage to the water heater due to improper

installation or commissioning may not be covered by the

Electrolux warranty.

1. Remove, clean and replace the lter located on the

cold water inlet to the water heater (refer to page 11

of this manual).

lter

2. Open all the hot taps and xtures in the house.

3. Open the cold water isolation valve fully at the inlet to the

water heater

4. Check all pipe work for leaks and stop the leaks as

necessary

5. Once all the air has been forced out of the system and

water is owing freely from every hot tap or xture, close

all hot taps and xtures

6. Open the gas isolation valve fully by hand at the inlet to

the water heater

drain plug

lter

gate or ball

valve on inlet

16 commissioning instruc tions Kelvinator Gas Continuous Flow hot water system

7. Check the gas pipe work for leaks and stop the leaks as

necessary

warning

If there is a gas leak that cannot be stopped, do not try to

start the water heater. Do not touch any electrical switches,

use a mobile phone or any other ignition source. Close the

main gas isolating valve to the premises and walk a safe

distance away. Call the gas supplier and follow the gas

supplier’s instructions.

Page 17

Commissioning instructions

(continued)

8. Check the inlet gas pressure (refer page 10 of this

manual).

9. Plug the power cord into the socket outlet and switch on

the electrical supply.

10. If remote controllers are installed turn on the MAIN

remote controller by pressing the "On/Off" button on

that controller. Press the "Priority" button once then set

the temperature as high as possible by pressing the "+"

button multiple times (refer to page 13 of this manual).

Now that commissioning has been completed and the gas

continuous flow hot water system has been set up to operate

correctly, select the correct model number of the water

heater on page 5 of the user manual. Fill out your details, the

serial number, installation date and include any important

notes to the customer. The user manual is then to be handed

to the customer or left in a suitable location on the premises.

If the customer is available they are to be instructed on

the safe and correct operating of the water heater and any

auxiliary equipment.

If the hot water system isn’t going to be used for a long time

and needs to be turned off after commissioning, follow these

instructions:

• Switch off the electrical supply at the power outlet that

the water heater is plugged into

• Close the gas isolation valve located on the inlet to the

water heater

• Close the cold water isolation valve located on the inlet to

the water heater

Note: If there is a risk of freezing conditions, do not switch off

power to the water heater unless it is drained of water first.

Please see the section on freeze prevention on page 9 of the

user manual for more information.

main

11. Open a hot water tap or xture. If there is sufcient water

flow the water heater should start up automatically.

12. Check each hot water tap or xture to ensure that there

is sufcient ow to operate the water heater (minimum 3

litres per minute).

13. Check the temperature of the hot water at each hot tap or

xture intended primarily for personal hygiene to ensure

the temperature is not higher than 50°C.

14. If remote controllers have been installed, check that the

controllers are operating correctlly (refer to page 13 of

this manual).

The gas continuous flow hot water system should now be

operating correctly.

Kelvinator Gas Continuous Flow hot water system commissioning instructions 17

Page 18

Troubleshooting

Temperature and amount of hot water

Problem Possible solutions

It takes a long time for hot water to

reach the fixtures.

The water is not hot enough

The water is too hot Is the temperature on the controller with priority set too high?

The hot water is not available when a

fixture is opened.

The hot water gets cold and stays cold

Fluctuation in hot water temperature.

The time it takes to deliver hot water from the water heater to your xtures

depends on the length of piping between the two. The longer the distance or

the bigger the pipes, the longer it will take to get hot water.

If a tempering valve is installed, is it set too low or malfunctioning?

Are the cold water and hot water lines cross connected?

Is the gas supply valve fully open?

Is the gas line sized properly?

Is the gas supply pressure enough?

Is the set temperature set too low?

Is the combustible air inlet or exhaust outlet blocked?

Is the gas inlet lter in the water heater blocked? Call a service technician to

remove blockage.

Reset power to the water heater to remove a previously set controller

temperature setting

Does the water heater have a 240V 50Hz power supply available?

If you are using the remote controller, is the power button turned on?

Is the gas supply valve fully open?

Is the water supply valve fully open?

Is the lter on cold water inlet clean?

Is the hot water xture sufciently open to draw at least 3.0l/min through the

water heater?

Is the water heater frozen?

Is there gas available to the water heater and (if applicable) does the gas

storage tank have enough gas in it?

Is the ow rate enough to keep the water heater running?

Is the gas supply valve fully open?

Is the lter on the cold water inlet clean?

Are the xtures clean of debris and obstructions?

Is the gas inlet lter in the water heater blocked? Call a service technician to

remove blockage.

Is the lter on the cold water inlet clean?

Is the gas line sized properly?

Is the supply gas pressure enough?

Are the cold water and hot water lines cross connected?

Is the gas inlet lter in the water heater blocked? Call a service technician to

remove blockage.

Water heater

Problem Possible solutions

Is the ow rate over 3.0l/min?

Burner does not ignite when water

goes through the water heater.

The fan motor is still spinning after

operation has stopped.

White vapour clouds are coming from

the hot air outlet of the water heater

Is there a 240V 50Hz power supply available to the water heater?

Are the cold water and hot water lines cross connected or reversed?

If a remote controller is installed press the "On/Off" button.

This is normal. After operation has stopped, the fan motor keeps running for

15 – 75 seconds in order to re-ignite quickly, as well as push all exhaust gas

out of the flue.

It is normal to see water vapour clouds or steam coming from the hot air outlet

of the water heater especially during cold and wet days.

Remote controller (optional)

Problem Possible solutions

Remote controller does not display

anything when the power button is

turned on.

An ERROR code is displayed Check the error code on the PCB (see page 19 for details).

Remote controller can not change

the set temperature.

18 troubleshooting Kelvinator Gas Continuous Flow hot water system

Press the ON/OFF button.

If the lamp does not light:

Make sure the water heater has power supply.

Make sure the connection to the water heater is correct.

Is priority lamp lit? If it is not, press the priority button after closing all hot

water taps.

Page 19

Remote controller and PCB error codes

To assist in the troubleshooting during installation or service the water heater has the added function of being able to

diagnose and report problems. In the rare event that a problem exists, the water heater will communicate the problem

via two methods, an error code on the remote controller or a blinking LED located on the PCB.

When remote controller is not installed When remote controller is installed

The error code will be displayed

on the remote controller.

123 45678

The LED on the PCB

will blink

The PCB is located at the bottom left-hand side of the

cabinet and the error codes can be read from the LED

on the PCB.

Error codes on the remote controller and PCB

LED on the PCB Error code on the controller Problem

LED light blinks once

LED light blinks twice

LED light blinks three times

LED light blinks four times 611 Irregular fan speed

LED light blinks ve times

031 Incorrect dipswitch setting

701 PCB or proportional valve fault

311 Open or short circuit of hot water output thermistor

321 Open or short circuit of cold water inlet thermistor

391 Air-Fuel ratio rod disconnection or failure

111 Ignition failure

121 Loss of ame

510 Main gas solenoid fault

511 Secondary gas solenoids fault

721 False flame detection

991 Imperfect combustion

101 Warning for 991 error code

741 Communication error with “main” controller

751

Communication error with “shower” or “ensuite”

controllers

If an error code is displayed on the PCB or remote controller, contact the Electrolux service centre using the number

shown in the warranty section of this manual (page 23).

Kelvinator Gas Continuous Flow hot water system Remote controller and PCB error codes 19

Page 20

Notes

20 notes Kelvinator Gas Continuous Flow hot water system

Page 21

Notes

Kelvinator Gas Continuous Flow hot water system notes 21

Page 22

Notes

22 notes Kelvinator Gas Continuous Flow hot water system

Page 23

Warranty

FOR SALES IN AUSTRALIA AND NEW ZEALAND

APPLIANCE: HOT WATER SYSTEMS

This document sets out the terms and conditions of the product

warranties for Electrolux Appliances. It is an important document.

Please keep it with your proof of purchase documents in a safe place

for future reference should you require service for your Appliance.

1. In this warranty

(a) ‘acceptable quality’ as referred to in clause 10 of this warranty has

the same meaning referred to in the ACL;

(b) ‘ACL’ means Trade Practices Amendment (Australian Consumer

Law) Act (No.2) 2010;

(c) ‘Appliance’ means any Electrolux product purchased by you

accompanied by this document;

(d) ‘ASC’ means Electrolux’ authorised serviced centres;

(e) ‘Electrolux’ means Electrolux Home Products Pty Ltd of 163

O’Riordan Street, Mascot, NSW 2020, ABN 51 004 762 341 in

respect of Appliances purchased in Australia and Electrolux (NZ)

Limited of 3-5 Niall Burgess Road, Mount Wellington, in respect of

Appliances purchased in New Zealand;

(f) ‘major failure’ as referred to in clause 10 of this warranty has the

same meaning referred to in the ACL and includes a situation when

an Appliance cannot be repaired or it is uneconomic for Electrolux, at

its discretion, to repair an Appliance during the Warranty Period;

(g) ‘Warranty Period’ means:

(i) where the Appliance is used for personal, domestic or household

use (i.e. normal single family use) as set out in the instruction

manual, the Appliance is warranted against manufacturing

defects in Australia and in New Zealand for the period of 1 year,

following the date of original purchase of the Appliance. Specic

components are warranted against manufacturing defects in

Australia for the periods listed below if there is evidence provided

to Electrolux that the Appliance was installed by a licensed

plumber; and in New Zealand if there is evidence that the

Appliance was installed according to the Electrolux installation

guidelines which can be inspected on the Kelvinator website;

• Hot water tank cylinders - parts 5 years , labour 3 years

• Continuous Gas

- Heat Exchanger – parts 10 years, labour 3 years

- all others components - parts 3 years, labour 3 years

• Heat Pump Refrigerant Sealed System - 2 years parts and labour

• Solar Collectors - parts 5 years, labour 3 years, 1 year for all

other parts (mounting and connection sets)

(ii) where the Appliance is used for commercial purposes (including

being used to directly assist a business or where the Appliance is

used in a multi-family communal or share type environment), the

Appliance will then be warranted against manufacturing defects

in Australia for 0 years and in New Zealand for 0 years, following

the date of original purchase of the Appliance.

(h) ‘you’ means the purchaser of the Appliance not having purchased

the Appliance for re-sale, and ‘your’ has a corresponding meaning.

2. This warranty only applies to Appliances purchased and used in Australia

or New Zealand and is in addition to (and does not exclude, restrict, or

modify in any way) any non-excludable statutory warranties in Australia

or New Zealand.

3. During the Warranty Period Electrolux or its ASC will, at no extra charge

if your Appliance is readily accessible for service, without special

equipment and subject to these terms and conditions, repair or replace

any parts which it considers to be defective. Electrolux or its ASC may

use remanufactured parts to repair your Appliance. You agree that

any replaced Appliances or parts become the property of Electrolux.

This warranty does not apply to light globes, batteries, lters or similar

perishable parts.

4. Parts and Appliances not supplied by Electrolux are not covered by this

warranty.

5. You will bear the cost of transportation, travel and delivery of the

Appliance to and from Electrolux or its ASC. If you reside outside of the

Important Notice

Before calling for service, please ensure that the steps listed in point 13 above have been followed.

service area, you will bear the cost of:

(a) travel of an authorised representative;

(b) transportation and delivery of the Appliance to and from Electrolux or

its ASC,

In all instances, unless the Appliance is transported by Electrolux or an

Electrolux authorised representative, the Appliance is transported at the

owner’s cost and risk while in transit to and from Electrolux or its ASC.

6. Proof of purchase is required before you can make a claim under this

warranty.

7. You may not make a claim under this warranty unless the defect claimed

is due to faulty or defective parts or workmanship. Electrolux is not liable

in the following situations (which are not exhaustive):

(a) the Appliance is damaged by:

(i) accident

(ii) misuse or abuse, including failure to properly maintain or service

(iii) normal wear and tear

(iv) power surges, electrical storm damage, excessive water pressure,

excessive inlet water temperature or incorrect power supply

(v) incomplete or improper installation

(vi) incorrect, improper or inappropriate operation

(vii) insect or vermin infestation

(viii) failure to comply with any additional instructions supplied with

the Appliance;

(ix) quality of water that is not in accordance with the “Water Quality”

guidelines in the installation instructions;

(b) the Appliance is modied without authority from Electrolux in writing;

(c) the Appliance’s serial number or warranty seal has been removed or

defaced;

(d) the Appliance was serviced or repaired by anyone other than

Electrolux, an authorised repairer or ASC.

8. This warranty, the contract to which it relates and the relationship

between you and Electrolux are governed by the law applicable where

the Appliance was purchased. Where the Appliance was purchased in

New Zealand for business purposes the Consumer Guarantee Act does

not apply.

9. To the extent permitted by law, Electrolux excludes all warranties and

liabilities (other than as contained in this document) including liability for

any loss or damage whether direct or indirect arising from your purchase,

use or non use of the Appliance.

10. For Appliances and services provided by Electrolux in Australia, the

Appliances come with a guarantee that cannot be excluded under the

ACL. You are entitled to a replacement or refund for a major failure and

for compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the Appliance repaired or replaced if the

Appliance fails to be of acceptable quality and the failure does not

amount to a major failure. The benets to you given by this warranty are

in addition to your other rights and remedies under a law in relation to

the Appliances or services to which the warranty relates.

11. At all times during the Warranty Period, Electrolux shall, at its discretion,

determine whether repair, replacement or refund will apply if an

Appliance has a valid warranty claim applicable to it.

12. For Appliances and services provided by Electrolux in New Zealand,

the Appliances come with a guarantee by Electrolux pursuant to the

provisions of the Consumer Guarantees Act, the Sale of Goods Act and

the Fair Trading Act.

13. To enquire about claiming under this warranty, please follow these steps:

(a) carefully check the operating instructions, user manual and the terms

of this warranty;

(b) have the model and serial number of the Appliance available;

(c) have the proof of purchase (eg an invoice) available;

(d) telephone the numbers shown below.

14. You accept that if you make a warranty claim, Electrolux and its ASC

may exchange information in relation to you to enable Electrolux to meet

its obligations under this warranty.

or to nd the address of your nearest

FOR SERVICE

state service centre in Australia

PLEASE CALL 13 62 26

For the cost of a local call (Australia only)

FOR SERVICE

or to nd the address of your nearest

authorised service centre in New Zealand

FREE CALL 0800 10 66 10

(New Zealand only)

KHWS_Warr_Oct11

SERVICE AUSTRALIA

ELECTROLUX HOME PRODUCTS

www.electrolux.com.au

SERVICE NEW ZEALAND

ELECTROLUX HOME PRODUCTS

www.electrolux.co.nz

Kelvinator Gas Continuous Flow hot water system warranty 23

FOR SPARE PARTS

or to nd the address of your nearest

state spare parts centre in Australia

PLEASE CALL 1300 666 019

For the cost of a local call (Australia only)

FOR SPARE PARTS

or to nd the address of your nearest

state spare parts centre in New Zealand

FREE CALL 0800 10 66 20

(New Zealand only)

Page 24

If you’d like further information about Kelvinator

appliances,pleasevisityourretailer,phoneoremail

our Customer Care team or visit our website.

telephone: 1300 363 640

fax: 1800 350 067

email: customercare@electrolux.com.au

web: www.kelvinator.com.au

Kelvinator. We are part of the Electrolux family.

Share more of our thinking at www.electrolux.com.au

P/No. KHWGCFI/2

© Copyr ight 2 012 Elect rolu x Home Produc ts Pty Ltd ABN 51 00 4 762 341

Print code: KMAN_KHW GCFI_ Dec12

Loading...

Loading...