Page 1

Solar Hot Water Systems

Installation Manual

Page 2

2 contents Kelvinator solar hot water systems

Congratulations and thank you for choosing our solar hot

water system. Before you install the hot water system, we

recommend that you read through the entire installation

manual, which provides instructions on the safe installation

of the hot water system.

To avoid the risks that are always present when you install

a hot water system, it is important that you read the safety

instructions carefully to ensure that the hot water system is

installed correctly and safely.

After unpacking the hot water system please check that it is

not damaged. If in doubt, do not install the hot water system

but contact your local Electrolux Customer Care Centre.

Meanings of symbols used in this manual are shown below:

warning

This symbol indicates information concerning your

personal safety

caution

This symbol indicates information on how to avoid

damaging the hot water system

environmental tips

This symbol indicates tips and information about

economical and ecological use of the hot water system

environmental tips

Information on disposal for users

• Most of the packing materials are recyclable.

Please dispose of those materials through your local

recycling depot or by placing them in appropriate

collection containers.

• If you wish to discard this hot water system or an old one

that has been replaced, please contact your local

authorities for the correct method of disposal.

warning

• Contact an authorised installer for installation of this

hot water system.

• Contact an authorised service technician for repair

or maintenance of this hot water system.

• If a power cord is to be replaced, replacement work

must be performed by authorised personnel only.

• Installation work must be performed in accordance

with the national standards by authorised personnel

only. Wrong connection can cause over heating or fire.

• This hot water system should be installed in accordance

with AS/NZS 3000 and your local electrical wiring rules.

Important safety instructions ........................................... 3

Specifications .................................................................... 4

General installation ........................................................... 6

General installation of solar collectors ............................. 8

Components list ................................................................ 9

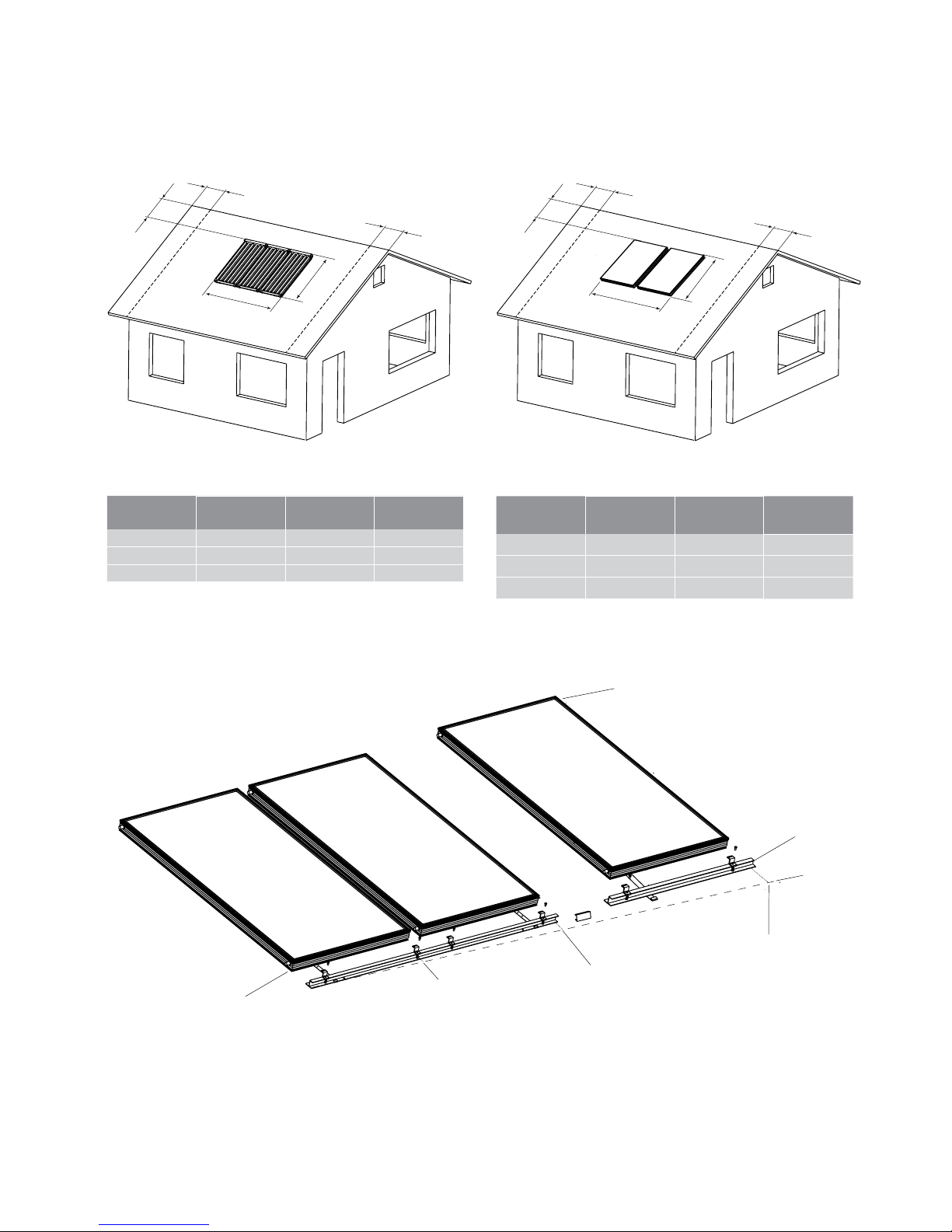

Roof installation – flat panel collectors........................... 10

Installation diagram –

electric boosted flat panel collectors ............................ 12

Installation diagram –

gas boosted flat panel collectors ................................... 13

Roof installation – evacuated tube collectors ................. 14

Installation diagram –

electric boosted evacuated tube collectors .................. 17

Installation diagram –

gas boosted evacuated tube collectors ......................... 18

Installation – storage tank and solar controller .............. 19

Electrical installation ....................................................... 23

Commissioning ................................................................ 25

Troubleshooting .............................................................. 28

Notes ............................................................................... 29

Warranty .......................................................................... 31

Conditions of use

This appliance is intended to be used in household and

similar applications such as:

• staff kitchen areas in shops, ofces and other working

environments.

• farm houses.

• by clients in hotels, motels and other residential type

environments.

• bed and breakfast type environments

Congratulations Contents

Page 3

This Installation Manual has been prepared for qualied

installers of the hot water system. Please keep in a safe place for

future reference. Installation must be performed by a qualied

installer (for example, a licensed plumber or gas tter).

warning

For continued safety of this appliance it must be installed,

operated and maintained in accordance with the

manufacturers instructions.

For the installer

The installation must be done in accordance with the

information supplied in this Installation Manual.

For gas boosted installations, please refer to Warnings and

Cautions in the Gas Continuous Flow installation manual

supplied with the unit. All other relevant National, State or

Local regulations must also be conformed with and these

include (but are not limited to):

• Australian Standard AS3500.1 – Water Supply

• Australian Standard AS3500.4 – Hot Water Supply

• Australian Standard AS3000 – Electrical Installation

• Australian Gas Association Code AS5601 –

Gas Appliance Installation

• Local Water, Gas & Electrical Authority Regulations

Municipal Building Codes

Important safety instructions

Ensure the following safety instructions are read and

understood before commencing installation.

warning

If you do not follow these instructions exactly, a re or

explosion may result causing property damage, personal

injury or loss of life.

• This appliance is not intended for use by persons (including

children) with reduced physical, sensor y or mental

capabilities or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not

play with the appliance.

• If the solar hot water system is gas boosted and you smell

gas or smoke coming from the system:

– Do not try to light the hot water system.

– Do not touch any electrical switch

– Do not use any phone in your building

– Isolate the power at the main switchboard

– Check and isolate the main gas valve

– Immediately call your gas supplier from a neighbour's

phone. Follow the gas supplier's instructions

– If you cannot reach the gas supplier, call the

re department

• The piping system of the solar circuit is to be electrically

connected in the lower part of the building according to

local standards. The connection of the solar system to

an existing or to be created lightning protection system

or potential equalization may be implemented only by

authorised specialists.

• If the solar hot water system is gas boosted, ensure there

is proper ventilation to avoid oxygen deciency.

• Ensure that any water drained during installation does

not cause damage to the building or property.

• Be sure that the hot water system is well earthed in

order to avoid electric shock.

• The solar hot and solar cold pipes between the hot water

storage tank and solar collectors MUST BE copper

and fully insulated with closed cell polymer insulation

or similar (minimum thickness of 20mm). Thicker insulation

may be required to comply with the requirements of

AS/NZS 3500.4. Plastic pipe MUST NOT be used, as it

will not withstand the temperature and pressure of the

water generated by the solar collectors under stagnation

conditions. The solar collectors can generate extremely

high water temperatures of up to 272°C. Plastic pipe can

not withstand these temperatures. Failure of plastic pipes

can lead to the release of high temperature water

and cause severe water damage and flooding.

• The insulation must be weatherproof and UV resistant if

exposed to sunlight.

• All compression ttings must use brass or copper olives.

• The collectors must be lled with water before the

protective cover is removed to prevent damage to the

hot water system and harm to the installer.

• Ensure that the roof has the load bearing capacity

to withstand the weight of installation, including the

installers and the full collectors.

• Installation must be carried out in accordance with

local Occupational Health and Safety laws.

• Ensure that appropriate safety measures are taken to

prevent objects falling from the roof during installation.

• The standard roof mounting kit for the collectors supplied

with this unit is NOT suitable for cyclone prone areas.

If you are installing in a cyclone prone area, please

consult your local building authority for advice regarding

appropriate mounting requirements.

• The minimum inlet water pressure must be 150kPa.

• If the hot water system supply pressure exceeds 600kPa, a

pressure limiting valve must be tted to limit the pressure

to 600kPa. A cold water 700kPa pressure relief valve may

also need to be installed in the water inlet to the storage

tank according to local regulations.

• A 99°C/850kPa temperature and pressure relief valve

(supplied) must be installed near the top of the storage tank.

• Ensure that the discharge pipes of the pressure relief

valves are left open to the atmosphere at all times.

• The pressure-relief devices are to be operated regularly to

remove lime deposits and to verify that they are not blocked.

• If a supply cord is damaged, it must be replaced by the

manufac turer, its service agent or qualied persons in

order to avoid a hazard.

• The operation of the thermal cut-out on the hot water

storage tank indicates a possibly dangerous situation

(electric boosted installations only). Do not reset the

thermal cut-out until the hot water system has been

serviced by a qualied person.

• Solar hot water systems with at panel type collectors

are not designed to be installed in heavy frost or high

altitude areas 400m above sea level.

• This hot water system delivers water above 50°C

and a tempering valve must be installed to limit the

temperature of hot water to sanitary xtures primarily

used for the purpose of personal hygiene as per the

AS 3500 requirements.

• The temperature settings for the hot water system are

factory pre-set to ensure optimum energy efciency

whilst providing Legionella bacteria protection. The

temperature settings are therefore not adjustable by

the customer or installer.

Important Important safety instructions

Kelvinator solar hot water systems impor tant safety instruc tions 3

Page 4

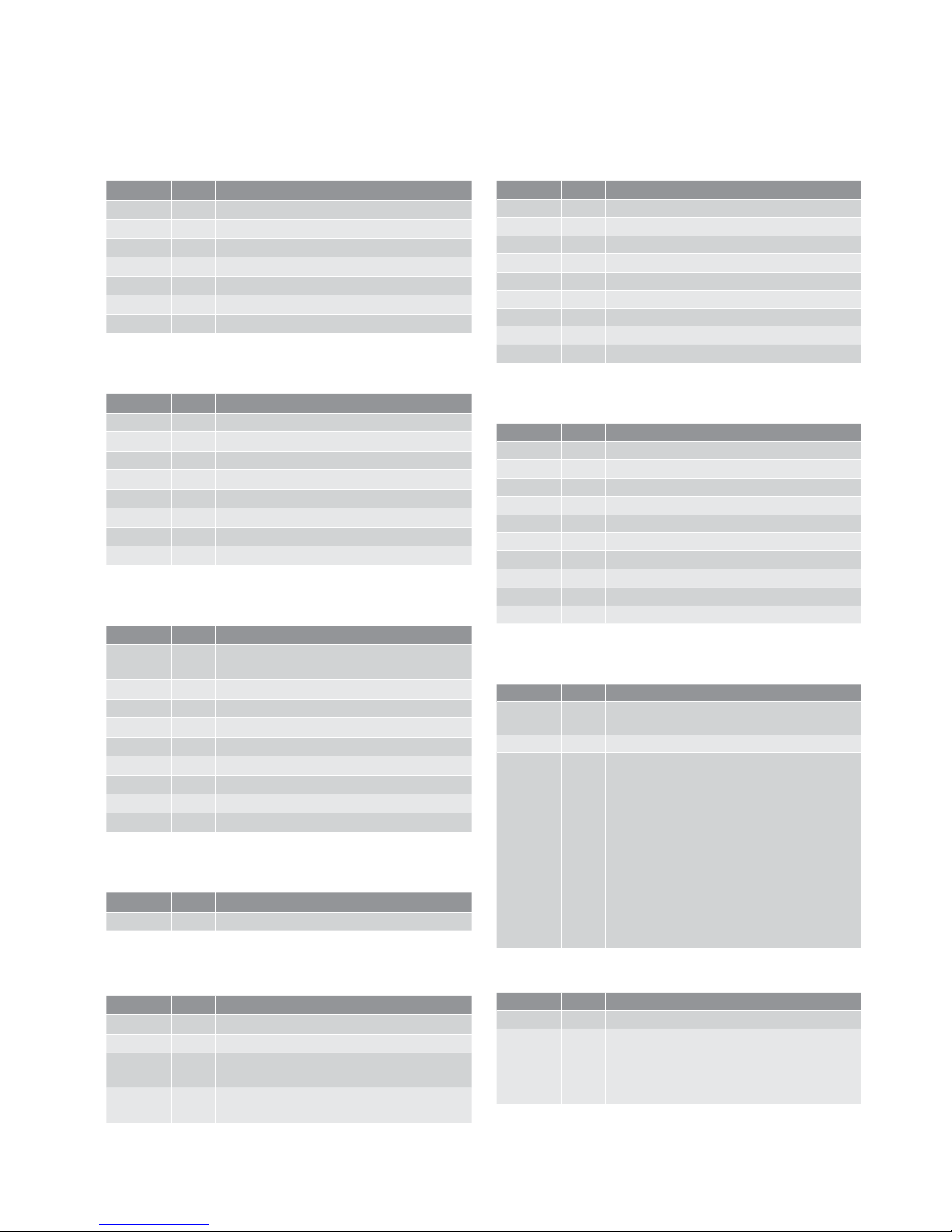

4 specications Kelvinator solar hot water systems

Specifications

Collector Flat panel (KCPF20A)

Collector dimensions per panel (mm) length 2002 x width 1025 x depth 80

Gross surface area 2.05m

2

Aperture surface 1.81m

2

Net weight 34.5kg

Operating positive pressure. max. 1000kPa

Stagnation maximum temperature 199 °C

Header pipe outer diameter 22mm

Collector frame material Aluminium

Absorber material 0.12mm copper n with TiNOx selective coating

Glazing 4mm low iron tempered patterned glass

Insulation material 40mm glass wool

Collector Evacuated tube (KCPE12A)

Number of evacuated tubes per collector panel 12

Collector dimensions (mm) length 1390 x width 1640 x depth 100

Gross surface area 2.28m

2

Aperture surface 2.0m

2

Collector capacity 1.6L

Net weight 37kg

Operating positive pressure. max. 1000kPa

Stagnation maximum temperature 272°C

Collector header pipe outer diameter 15.0 mm

Collector piping connections 1/2"

Collector frame material Anodised aluminium

Material selective absorber layer Aluminium nitrite

Page 5

Kelvinator solar hot water systems specications 5

Specifications

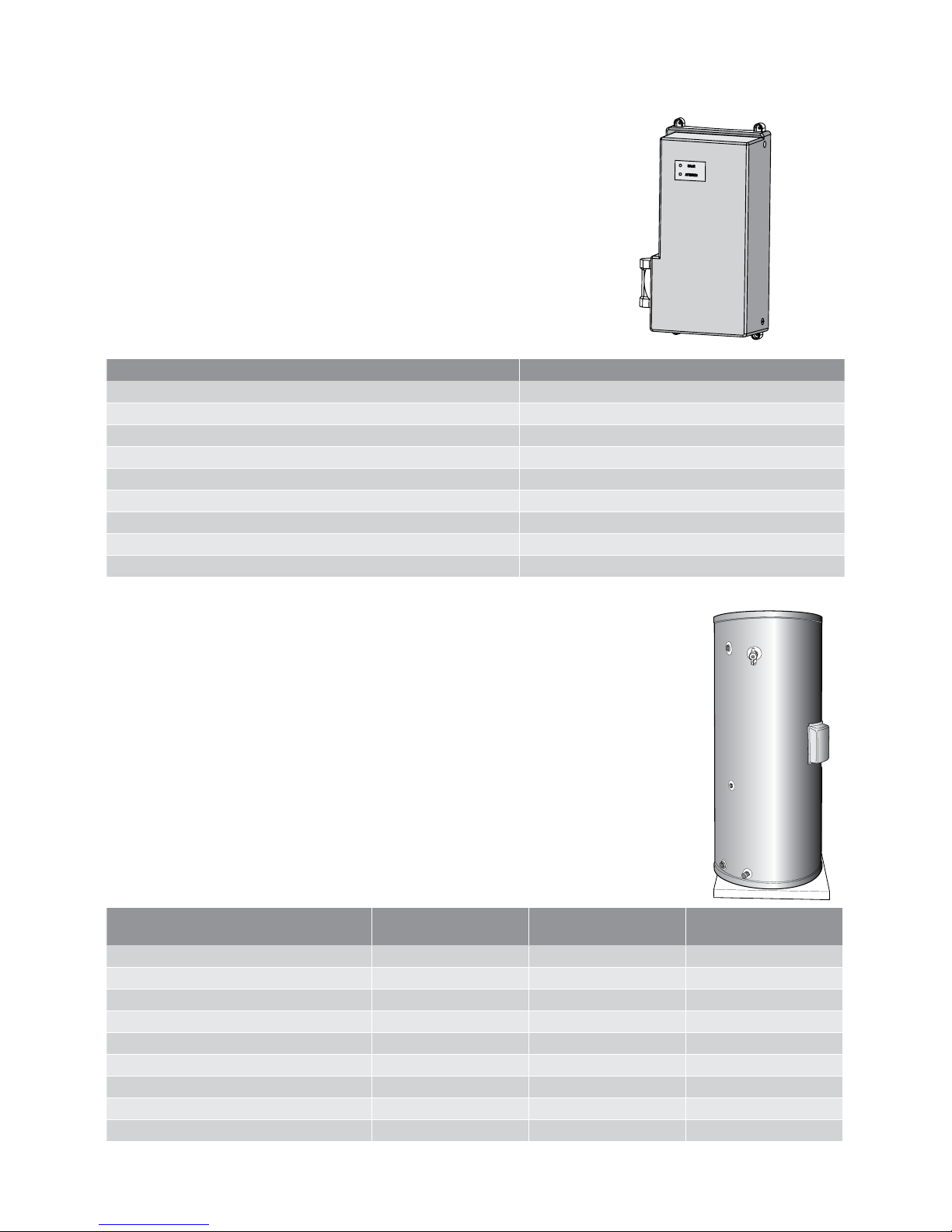

Solar controller (KKSSUA)

Dimensions (mm) length 365mm x width 205mm x depth 100mm

Protection rating IPX4

Net weight 2.3kg

Operating positive pressure. max. 850kPa

Maximum water temperature 95°C

Circulation pump type UP15 – 14B

Circulation pump power 25W

Rated voltage of circulation pump AC 220-240V

Frequency 50Hz

Model number

KCT27000A

KCT27036A

KCT34000A

KCT34 036A

KC T4 5 036A

Diameter (mm) 648 648 730

Height (mm) 139 0 1690 1715

Tank capacity (L) 270 340 450

Net Weight (kg) 95 110 140

Tank wall thickness (mm) 2.5 3 3

Element rating (if installed) 3.6kW 3.6kW 3.6kW

PTR valve pressure limit (kPa) 850 850 850

PTR valve temperature limit (°C) 99 99 99

PTR max energy release rate (kW) 10 10 10

Page 6

6 gener al installation Kelvinator solar hot water systems

General installation

The collec tor rails, unions, straps, clamps, bolts, nuts and

washers required for the installation are included in the

collector kit(s). Suitable screws will be required to x the

collectors to the roof.

The collec tors and mounting kit are not designed to be

installed in cyclone prone areas. If installing in these areas or

other areas where a high level of windy and stormy conditions

exist, the collectors will need to be xed accordingly. Consult

the local authorities for advice regarding any additional

mounting instructions.

Use an appropriate amount of thread sealing tape or an

approved thread sealant in between all ttings.

Solar collector location

Consideration must be given to the position of the solar

collectors in relation to the hot water storage tank. The

maximum length of the solar hot and solar cold pipes must

be 10 metres one way (20 metres total) or less to full energy

efciency rating requirements.

• The solar collectors should be installed in a shade

free position.

• The solar collectors are to be installed facing toward

the equator (i.e. North). Where this orientation is not

practical, a system facing up to 45° from the equator will

have its efciency reduced by approximately 4%.

• Inclination of the solar collectors should be approximately

equal to 90% of the local latitude angle. Solar collectors

may be installed at the roof angle for simplicity of

installation and appearance, but must never be less than

10°. If the roof angle varies by 15° from the correct angle,

efciency will be reduced by 10%.

Latitudes of some Australian cities

Adelaide 35°S Port Hedland 20°S

Mildura 34°S Canberra 35°S

Brisbane 27°S Broken Hill 31°S

Darwin 12°S Geraldton 28°S

Rockhampton 24°S Cairns 17°S

Alice Springs 24°S Hobart 42°S

Melbourne 38°S Sydney 34°S

Townsville 19°S Perth 32°S

If the roof is flat or has a pitch less than or greater than the

recommended angle, a pitch stand may need to be installed

to allow the collectors to be mounted correctly. This stand

may need to be purchased from a local store or made

especially for the installation.

warning

PLUMBER BE AWARE!

• Water temperatures above 50°C can cause severe burns.

• All plumbing work must be carried out by a qualied

person and in accordance with the National Plumbing

Standard AS/NZS 3500.4 and local authority

requirements.

• Ensure the roof structure is suitable to carry the full

weight of the solar collectors. Each flat panel solar

collector and its ttings weigh approximately 45kg

when full of water. Each evacuated tube solar collector

and its ttings weigh approximately 47kg when full of

water. If in doubt the roof structure should be suitably

strengthened. Consult a structural engineer.

• Do not remove the solar collector packaging

completely, prior to the installation. Remove only

sufcient packaging material to enable the installation.

Upon completion of the installation it is necessary to

leave the solar collector packaging covering the glass

on the solar collector. The packaging should not be

removed until the solar hot water system has been

commissioned and is ready for use.

• Plastic pipe MUST NOT be used, as it will not withstand

the temperature and pressure of the water generated

by the solar collectors under stagnation conditions.

The solar collectors can generate extremely high

water temperatures up to 272°C. Plastic pipe cannot

withstand these temperatures and MUST NOT be used.

Failure of plastic pipe can lead to the release of high

temperature water and cause severe water damage

and flooding.

• There must be a continuous fall in the pipe work

between the solar collectors and the solar storage tank.

The highest point of the solar cold pipe and solar hot

pipe must be where they connect to the solar collectors,

to avoid the possibility of air locks occurring in the

system.

• Safety harnesses must be used when working at heights

and on the roof. If the roof is wet or dewy it will be very

slippery and installation work should not be carried out

until it has become dry.

The solar hot and solar cold pipes between the storage

tank and solar collectors MUST BE copper only and fully

insulated with closed cell polymer insulation or similar

(minimum thickness 20mm). Thicker insulation may be

required to comply with the requirements of AS/NZS 3500.4.

The insulation must be weatherproof and UV resistant. All

compression ttings must use brass or copper olives.

Note: Failure to observe this requirement may void the

warranty for freeze damage.

The insulation is essential to assist in providing freeze

protection. When installed on a metal roof, insulation will

ensure corrosion protection against water runoff over the

copper pipe, assist in avoiding accidental contact with the

pipe work and also reduce pipe heat loss.

Page 7

Kelvinator solar hot water systems general installation 7

General installation

Pipe lengths

The solar hot and solar cold pipes between the hot water

storage tank and the solar collectors must:

• have a continuous fall from the solar collectors to the hot

water storage tank of 5 (1 in 10 grade).

• not exceed the maximum recommended length of 10

meters (20 meters total).

Notes:

• It is important not to cross connect the solar cold and

solar hot pipes to the incorrect connec tions.

• In the at panel solar hot water system, the solar cold

pipes connect to the bottom of the solar collectors

and the solar hot pipe connects to the top of the solar

collectors diagonally opposite to the solar cold pipe

connection.

• In the evacuated tube hot water system, both connections

are located at the top of the collector.

• The collector sensor must be located in the same end as

the collector array outlet connection on both flat panel

and evacuated tube collectors.

It is essential for these requirements to be followed for the

system to operate correc tly and efciently. Solar pipe work that

is undersized, does not have the correct fall or is too long can

result in the solar hot water system not operating effectively.

Maximum height to collectors

The solar collectors must be the highest point of the system.

The maximum height of the solar installation, from the

base of the hot water storage tank to the top of the solar

collectors, is 9m. The pump supplied will not circulate closed

circuit uid through heights greater than 9m and solar gain

will not be achieved.

For heights greater than 9m, an auxiliary pump must be

installed above and within 1 m of the hot water storage tank.

Water quality

Water quality can vary in different locations and affect the

performance and safe operation of the hot water system.

If the water supply is not within the acceptable limits as

indicated below, the hot water system should not be

installed, and will not be covered by warranty from the

manufac turer. A suitable solution is to implement a water

pre-treatment process to bring the water quality to within

acceptable limits to support the installation.

The saturation index (SI) is a measure of the corrosive or

scaling properties of the water supply. Corrosive water (SI<-

1.0) can corrode copper components. In these conditions

warranty will not apply. Scaling water (SI>0.5) can cause

build up of CaCO3 (Calcium carbonate) which can impact

to the correct operation of moving parts within the system,

including the temperature and pressure relief valve. In these

conditions warranty will not apply.

Total Dissolved Solids (TDS) and water hardness can also

impact the life of the hot water system, and warranty does

not apply outside the following limits:

• TDS exceeding 600 p.p.m

• Electrical conductivity exceeding 850us/cm

• Total hardness exceeding 200 p.p.m

• Chloride exceeding 250 p.p.m

• Magnesium exceeding 10 p.p.m

• Sodium exceeding 150 p.p.m

• Acidity/Alkalinity must also be within the limits of

pH 6.5 - 8.5

Protecting the solar collectors

The solar collectors are designed to withstand impact and

be hail resistant, so it is not necessar y to install any special

hail guards to protect these collectors. However, if it is

possible that the collectors could be damaged due to falling

branches, vandalism etc. it is recommended that guards are

made and installed to prevent damage to the collectors.

Note: The installation of protective guards will impact on the

performance of the collectors.

Frost protection and damage due to freezing

The solar hot water system has been approved to level 2 frost

protection and can therefore withstand frosty conditions.

However, it is not recommended to install at panel type

collectors in areas 400m above sea level. It is recommended

that evacuated tube type collectors are installed in high altitude

and frost prone areas. The warranty for frost damage will not

apply if the hot water system is damaged due to freezing when

using flat panel type collectors in high altitude areas. The

warranty for frost damage will also not apply to solar hot water

systems with either type of collectors installed if the pipe work

between the collectors and the hot water storage tank has

insufcient piping insulation.

Page 8

8 gener al installation of solar collectors Kelvinator solar hot water systems

10 -15 mm

from horizontal

inlet

20-30mm

from horizontal

30-45mm

from horizontal

horizontal

collector rail

outlet

Note: The solar collectors (both flat panel and evacuated

tube) must be installed at an angle from the horizontal.

This is to ensure that any air in the system will travel to

the air vent valve located on the outlet connection of the

collectors.

The distance between the end of the collector rail at the

outlet side of the solar collectors and the horizontal must be:

10 - 15 mm (for one solar collector)

20 - 30 mm (for two solar collectors)

30 - 45 mm (for three solar collectors)

If the roof material is uneven where the collectors are to be

installed, then it may be necessary to add an additional 10

mm to the above distances for each collector.

Space requirements

A

B

C

C

D

Space and load bearing requirements for evacuated

tube collectors

No. of

collectors

Dimension

A (mm)

Dimension

B (mm)

Weight when

full (approx.)

1 14 0 0 164 0 47kg

2 2800 1640 94kg

3 4200 1640 141kg

Dimensions C and D

• when determining the location for the collector ensure

that there is adequate space available for the water

connections and the xing of the mounting kit.

A

B

C

C

D

Space and load bearing requirements for flat

panel collectors

No. of

collectors

Dimension

A (mm)

Dimension

B (mm)

Weight when

full (approx.)

1 1025 2050 45kg

2 2050 2050 90kg

3 3075 2050 135kg

General installation of solar collectors

Page 9

components list Kelvinator solar hot water systems 9

Components list

Supplied in kit: KKSSF2MA –

flat panel double roof mounting kit

Item No. Qty. Description

1 1 rail bottom for 2x flat panel collector

2 2 strap rail bottom

3 4 clamp flat panel collector

4 4 bolt, nut and washer assembly

5 2 strap top flat panel collector

6 2 self tapping screw

7 2 connector flat panel collector

Supplied in kit: KKSSF1MA –

flat panel single roof mounting kit

Item No. Qty. Description

8 1 rail bottom for 1x at panel collector

9 1 rail joiner

2 2 strap rail bottom

3 2 clamp flat panel collector

4 2 bolt, nut and washer assembly

5 1 strap top flat panel collector

6 1 self tapping screw

7 2 connector flat panel collector

Supplied in kit: KKSSE1MA –

evacuated tube single roof mounting kit

Item No. Qty. Description

10 1 rail bottom for 1x evacuated tube

collector

2 2 strap rail bottom

11 2 clamp evacuated tube collector

4 2 bolt, nut and washer assembly

12 1 strap top left evacuated tube collector

13 1 strap top right evacuated tube collector

14 2 bracket top evacuated tube collector

6 2 self tapping screw

9 1 rail joiner

Supplied in kit: KCPF20A –

flat panel solar collector

Item No. Qty. Description

15 1 flat panel collector

Supplied in kit: KCPE12A –

evacuated tube solar collector

Item No. Qty. Description

16 1 evacuated tube collector

17 1 connector evacuated tube collector

18 2 connector sleeve support evacuated

tube collector

19 2 connector to 1/2" male for evacuated

tube collector

Supplied in kit: KKSSURA –

roof fittings kit

Item No. Qty. Description

20 2 connector to 1/2" male for at panel collector

21 2 stopper flat panel collec tor

22 2 union 1/2" female to copper

23 2 t-piece 1/2" female

24 2 nipple 1/2" to 1/2" male

25 1 bush 1/2" male to 3/8" female

26 1 air vent valve 3/8" male

27 1 sensor pocket 1/2" male

28 1 sensor collector with wire 15m

Supplied in kit: KKSSUGA –

ground fittings kit

Item No. Qty. Description

29 1 solar controller

30 4 screw xing solar controller

31 2 bush 3/4" male to 1/2" female

24 5 nipple 1/2" to 1/2" male

23 1 t-piece 1/2" Female

27 1 sensor pocket 1/2" male

32 1 exible tube 1/2" female to 1/2" female

33 1 check valve 1/2" male to 1/2" female

22 2 union 1/2" female to copper

34 1 tempering valve 50°C

Supplied with tank: KCT*****A –

tank and TP&R valve assembly

Item No. Qty. Description

35 1 temperature and pressure relief valve

1/2" male

31 1 bush 3/4" male to 1/2" female

36 1 of

KCT27036A -

270L tank with 3.6kW element

KCT34036A -

340L tank with 3.6kW element

KCT45036A -

450L tank with 3.6kW element

KCT27000A -

270L tank without element

KCT340 00A -

340L tank without element

Supplied with gas booster: KGC26S*A – gas booster

Item No. Qty. Description

37 4 screw gas booster xing

38 1 of

KGC26SNA -

26L/min solar gas booster - natural gas

KGC26SLA -

26L/min solar gas booster - LP gas

Page 10

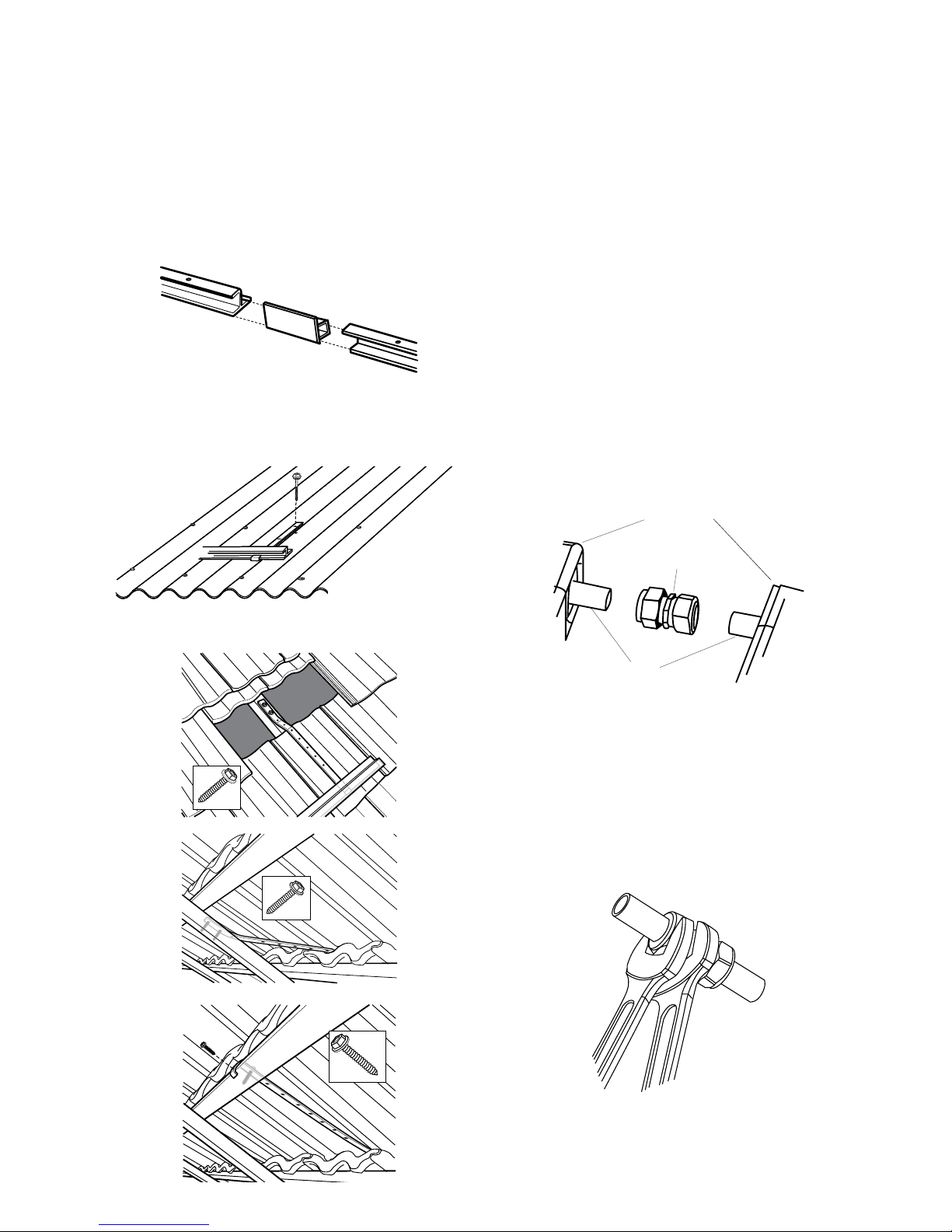

10 roof installation – at panel collectors Kelvinator solar hot water systems

Roof installation –

flat panel collectors

Fix the bottom straps using appropriate screws into the

roof struts or trusses making sure the bottom rail is inclining

towards the proposed outlet end of the collectors.

If installing on a tiled roof, place the tiles back into their

normal positions after xing the straps.

Preparing and xing the collectors

Unpack each collector and cut out the template on the back

of the cardboard packaging. Place the cut out template

on the front of each collector and x it with tape. This is

important as the collector connections will become very

hot once exposed to solar radiation and may cause a safety

hazard or prevent the installation of the pipe work to the

collectors. Carefully lift the collectors onto the roof and

place them in position, resting against the bottom rail of the

collector mounting kit already xed to the roof.

Before the collectors are xed to the roof and mounting kit, they

are to be connected together forming an array (two and three

collector installations only). Two compression union ttings are

used to join two collectors together (one for top and one for the

bottom) and are supplied in the mounting kit(s).

solar collectors

collector

manifold

pipes

compression

union

Slide the ttings onto one side of the collector manifold pipe

to be joined and then push both collec tors together. The

collector manifold pipes should be inserted as far as possible

into both sides of the compression union tting.

Using two spanners, tighten each nut on the compression

union tting one side at a time, with one spanner used to

brace the tting in the middle. Tighten both sides of the

compression union tting until the copper olives are rmly

sealed against both collector manifold pipes.

This standard roof mounting kit is not suitable for cyclone

prone regions. Refer to the warning in the Important Safety

Instructions section.

Unpack the collector mounting kit(s) and check that all

components are included (see mounting kit contents table).

If you are installing three collectors, join the two bottom rails

together using the rail joiner.

Slide the bottom straps onto the bottom rail so that they are

evenly spaced and place the bottom rail assembly on the roof

in the installation location decided. If installing on an iron roof,

line up the bottom straps to the existing roong screws that

are xing the iron roong membrane to the struts.

If installing on a tiled roof lift up the tiles and line up the

bottom straps with the roof struts or trusses.

Page 11

Kelvinator solar hot water systems roof installation – at panel collectors 11

Roof installation –

flat panel collectors

Collector pipe work connections

Open the ttings kit KKSSURA and check that all

components have been supplied (see components list).

Place two 1/2" male to collector compression union ttings

on the manifold pipes of the inlet and outlet of the collector

array (the inlet to the collector array will be at the bottom

and the outlet will be at the diagonally opposite corner at the

top). Tighten the nut using two spanners as before, sealing

the copper olive to the collector manifold pipes.

solar collector

1/2" male

to collecto r

compression union

collector

manifold

pipe

Place the stopper ttings from the kit onto the remaining

collector pipe work (also at diagonally opposite corners of

the collector array) and tighten as before with two spanners.

solar collector

stopper

collector

manifold

pipe

On the collector array outlet, install the two tee pieces, two

nipples, sensor pocket, 1/2" to 3/8" reducing bush, vent valve

and 1/2" female to copper union (see the diagram below).

Between the ttings use an appropriate thread sealant that

is capable of handling the high temperatures created by the

collectors. Ensure the vent valve is installed so that its vent is

pointing directly upwards, perpendicular to the ground (not

the roof).

vent valve

1/2" female to

copper union

sensor pocket

1/2" male to

collector union

1/2" to 3/8"

reducing bush

1/2"nipple

1/2"female T-piece

Once all the collectors are joined together (two or three

collector installations only), they should be correctly

positioned so that they are evenly distributed on the bottom

rail. Place the collector clamps on the bottom rail over the

top of the provided holes and inser t the bolts through the

holes in the clamps and bottom rail. Place the washers

and nuts on the bottom of the bolts and tighten with two

spanners, rmly clamping the collectors to the bottom rail.

If installing on an iron roof, line up a top strap with a

horizontal roof strut (look for where the iron has been xed)

and the top side of the collector. Fix the top strap to the roof

strut by either using an existing roong screw or adding a

new one.

If installing on a tiled roof, lift a tile above the collector and

line up a top strap with a roof strut or truss and the top side

of the collector. Fix the strap to the roof strut or truss and

place the tile back to its normal position (same procedure as

xing the bottom strap).

Fix the top strap to the top side of the collector using a

supplied self tapping screw and repeat for each additional

collector (two or three collector installations only).

Page 12

12 installation diagram – electric boosted at panel collector s Kelvinator solar hot water systems

Installation diagram - electric boosted flat panel collectors

Tiled roof – preferred method: Connect roof straps from bottom rail and top edge

of collectors to vertical roof beams. Secure with 2 screws at top of beams. Connect

roof straps from bottom rail and top of collectors to horizontal beams if vertical

beams are not accessible.

All num bered i tems are supplied with the ho t water s ystem. Pleas e refer to the Com ponents lis t for details. Items w hich ar e not num bered a re not su pplie d and

need to b e supplied by th e inst aller in accordance w ith local plu mbing r equir ement s. Installa tion of t his hot w ater sy stem must be c omple ted by an a uthorised and

licensed per son in accord ance wi th all local reg ulations, in cludi ng AS3500 p lumbi ng and dr ainage requi remen ts and A S3000 el ect rica l wirin g stan dard s.

Bottom rail connection viewed

from above

10 -15 mm

from horizontal

botto m rail

assembly

1.5m

relief valve

uncontrolled

hot water outlet

(kitchen, laundry)

tempered (50°C)

hot water outlet

(bathrooms)

tempering

valve

20-30mm

from horizontal

30-45mm

from horizontal

Connecting strap viewed from

roof cavity

Components shown in grey are only used in 2 and 3 collec tor panel connections

Secure with 2 straps on top and

back edge of beam

Iron roof: Connect bottom rail

and top edge of collectors to

iron roof.

securing top centre

of panel

isolating

and non

return

valve

pressure limiting

valve (600kPa)

may be required

if pressure

exceed s 600kPa

pressure relief

valve (700kPa)

may be required

refer to lo cal

plumbing

guidelines

drain

cold

inlet

flow

relief

valve

from

solar

return

horizontal

outlet

earth terminal

neutral terminal

wiring terminal

block

element

thermostat

active terminal

conduit adaptor

goes in he re and

locking ring holds it

Page 13

Kelvinator solar hot water systems installation diagram - gas boosted at panel collector s 13

Installation diagram - electric boosted flat panel collectors

Tiled roof – preferred method: Connect roof straps from bottom rail and top edge

of collectors to vertical roof beams. Secure with 2 screws at top of beams. Connect

roof straps from bottom rail and top of collectors to horizontal beams if vertical

beams are not accessible.

All num bered items a re supplied w ith the hot wate r system. Ple ase refer to the C omponent s list for det ails. Items wh ich are not num bered are not su pplied and ne ed to be

suppl ied by the inst aller in acco rdance with l ocal plumbi ng requireme nts. Installati on of this hot wat er system mu st be complet ed by an author ised and lice nsed perso n in

accordance wi th all local regul ation s, inclu ding AS 5601 ga s inst allati on requi remen ts, AS350 0 plumbi ng and dra inage re quire ment s a nd AS3 00 0 elec tric al wiring standards .

Bottom rail connection viewed

from above

10 -15 mm

from horizontal

botto m rail

assembly

relief valve

uncontrolled

hot water outlet

(kitchen, laundry)

tempered

(50°C)

hot water

outlet

(bathrooms)

tempering

valve

20-30mm

from horizontal

30-45mm

from horizontal

Connecting strap viewed from

roof cavity

Components shown in grey are only used in 2 and 3 collec tor panel connections

Secure with 2 straps on top and

back edge of beam

Iron roof: Connect bottom rail and

top edge of collectors to iron roof.

securing top centre

of panel

isolating

and non

return valve

pressure limiting

valve (600kPa) may be

required if pressure

exceed s 600kPa

pressure relief valve

(700 kPa) may be

required refer to

local plumbing

guidelines

drain

return

flow

inlet

cold

inlet

flow

relief

valve

from

solar

return

horizontal

outlet

1.5m

inlet

inlet

outlet

outlet

gas

gas

Page 14

14 roof installation – evacuated tube collectors Kelvinator solar hot water systems

Roof installation –

evacuated tube collectors

Fix the bottom straps into the roof struts or trusses using

appropriate screws, making sure the bottom rail is inclining

towards the proposed outlet end of the collectors.

If installing on a tiled roof, place the tiles back into their

normal positions after xing the straps.

Preparing and xing the collectors

Unpack each collector and check the contents against the

components list, being sure to leave the protec tive plastic

cover on each collector. This is important as the collec tor

connections will become very hot once exposed to solar

radiation and may cause a safety hazard or prevent the

installation of the pipe work to the collectors. Carefully lift

the collectors onto the roof and place them in position,

resting against the bottom rail of the collector mounting kit

already xed to the roof.

Before the collectors are xed to the roof and mounting kit,

they are to be connected together forming an array (two and

three collector installations only). The compression union

ttings supplied with the collectors are used to join the

collectors together.

Place the copper sleeve suppor ts into the manifold pipes

of each collector. Slide the ttings onto one side of the

manifold pipe to be joined and then push both collectors

together. The collector manifold pipes shall be inserted as far

as possible into both sides of the compression union tting.

solar collectors

copper sleeve

support

collector

manifold

pipes

compression

union

Using two spanners, tighten each nut on the compression

union tting one side at a time, with one spanner used to

brace the tting in the middle. Tighten both sides of the

compression union tting until the copper olives are rmly

sealed against both collector manifold pipes.

This standard roof mounting kit is not suitable for cyclone

prone regions. Refer to the warning in the Important Safety

Instructions section.

Preparing the mounting kit

Unpack the collector mounting kit(s) and check that all

components are included.

Slide the bottom straps onto the bottom rail and join the

bottom rails together using the rail joiner(s) if you are

installing two or three collectors.

Adjust the straps on the bottom rail so that they are evenly

spaced and place the bottom rail assembly on the roof in the

installation location decided. If installing on an iron roof, line

up the bottom straps to the existing roong screws that are

xing the iron roong membrane to the struts.

If installing on a tiled roof lift up the tiles and line up the

bottom straps with the roof struts or trusses.

Page 15

Kelvinator solar hot water systems roof installation – evacuated tube collectors 15

Once all of the collectors are joined together (two or

three collector installations only), they should be correctly

positioned so that they are evenly distributed on the bottom

rail. Place the collector clamps on the bottom rail over the

top of the provided holes and inser t the bolts through the

holes in the clamps and bottom rail. Place the washers

and nuts on the bottom of the bolts and tighten with two

spanners, rmly clamping the collectors to the bottom rail.

If installing on an iron roof, two top brackets supplied in the

mounting kit are to be used to x the collectors to the roof.

Line up the top brackets with a horizontal roof strut (look for

where the iron is xed) and the side of the collector array. Fix

the top brackets to the roof strut by either using an existing

roong screw or adding a new one.

Fix the top brackets to each side of the collector array with

the supplied self tapping screws.

If installing on a tiled roof, two twisted straps are to be xed

to the roof and each side of the collector array. The twisted

straps are to be xed so that the twisted ends are ush with

the sides of the collector array. It is important to determine

which strap is for the left hand side and which one is for the

right, before xing the strap to the roof. Lift the tiles above

each edge of the collector array and line up the appropriate

top twisted strap with a roof strut or truss and each side of

the collector array. Fix the flat end of the twisted strap to

the roof strut or truss and place the tile back to its normal

position. Fix the twisted end of the twisted strap to each side

of the collector array using the self tapping screws supplied

with the mounting kit.

Roof installation –

evacuated tube collectors

Page 16

16 roof inst allation – evac uated tube collectors Kelvinator solar hot water systems

Roof installation –

evacuated tube collectors

On the collector array inlet install a 1/2” to copper union

onto the 1/2” male compression union tting making sure to

use a thread sealant.

1/2" female to

copper union

1/2" male to

collector union

copper support

sleeve

Collector pipe work connections

Place the copper sleeve suppor t into the inlet and outlet

manifold pipes of the collector array. Install a 1/2" male

compression union tting (supplied with the collectors) and

tighten the nut using two spanners as before, sealing the

copper olive to the collector manifold pipes.

collector

1/2" male

compression

union

Open the ttings kit KKSSURA and check that all

components have been supplied (see components list). Since

this kit is also used for flat panel type collectors there will be

some pieces which will not be used.

On the collector array outlet install a tee piece, 1/2" to 3/8"

reducing bush, vent valve, 1/2" nipple and 1/2" female to

copper union (see diagram below). Between the ttings

use a thread sealant that is capable of handling the high

temperatures created by the collectors. Ensure the vent

valve is installed so that its vent is pointing directly upwards,

perpendicular to the ground (not the roof).

vent valve

T-p ie ce

1/2" female to

copper union

1/2" male to

collector union

1/2" to 3/8"

reducing bush

1/2"nipple

Page 17

Kelvinator solar hot water systems installation diagram – elec tric boosted evac uated tube collectors 17

Installation diagram – electric boosted evacuated tube collectors

Tiled roof – preferred method: Connect roof straps from bottom rail and

top edge of collectors to vertical roof beams. Secure with 2 screws at top

of beams. Connect roof straps from bottom rail and top of collectors to

horizontal beams if vertical beams are not accessible.

All num bered i tems are supplied with the ho t water s ystem. Pleas e refer to the Com ponents lis t for details. Items w hich ar e not num bered a re not su pplie d and

need to b e supplied by th e inst aller in accordance w ith local plu mbing r equir ement s. Installa tion of t his hot w ater sy stem must be c omple ted by an a uthorised and

licensed per son in accord ance wi th all local reg ulations, in cludi ng AS3500 p lumbi ng and dr ainage requi remen ts and A S3000 el ect rica l wirin g stan dard s.

Bottom rail connection viewed

from above

10 -15 mm

from horizontal

botto m rail

assembly

1.5m

relief valve

uncontrolled

hot water

outlet

(kitchen,

laundry)

tempered

(50°C) hot

water outlet

(bathrooms)

tempering

valve

20-30mm

from horizontal

30-45mm

from horizontal

Connecting strap viewed from

roof cavity

Components shown in grey are only used in 2 and 3 collec tor panel connections

Secure with screws on top

and back edge of beam

Iron roof: Connect bottom

rail and top edge of

collectors to iron roof.

Connecting top of

collectors to tiled

roof using twisted

metal straps.

isolating

and non

return

valve

pressure limiting

valve (600kPa)

may be required

if pressure

exceed s 600kPa

pressure relief

valve (700kPa)

may be required

refer to lo cal

plumbing

guidelines

drain

cold

inlet

flow

Ø20mm

conduit

relief

valve

from

solar

return

horizontal

insert sensor here then

apply s ilicone to seal .

Cable t ie the senso r

wire to ou tside of the

pipe insulation, ensuring

that th e wire does not

touch t he hot pipe.

outlet

earth terminal

earth

neutral terminal

wiring terminal

block

element

thermostat

active terminal

conduit adaptor

goes in he re and

locking ring holds it

1/2"nipple

Page 18

18 installation diagram – gas boosted evacuated tube collector s Kelvinator solar hot water systems

Installation diagram – gas boosted evacuated tube collectors

Tiled roof – preferred method: Connect roof straps from bottom rail and

top edge of collectors to vertical roof beams. Secure with 2 screws at top

of beams. Connect roof straps from bottom rail and top of collectors to

horizontal beams if vertical beams are not accessible.

All num bered items a re supplied w ith the hot wate r system. Ple ase refer to the C omponent s list for det ails. Items wh ich are not num bered are not su pplied and ne ed to be

suppl ied by the inst aller in acco rdance with l ocal plumbi ng requireme nts. Installati on of this hot wat er system mu st be complet ed by an author ised and lice nsed perso n in

accordance wi th all local regul ation s, inclu ding AS 5601 ga s inst allati on requi remen ts, AS350 0 plumbi ng and dra inage re quire ment s a nd AS3 00 0 elec tric al wiring standards .

Bottom rail connection viewed

from above

10 -15 mm

from horizontal

botto m rail

assembly

relief valve

uncontrolled

hot water outlet

(kitchen,

laundry)

tempered (50°C)

hot water outlet

(bathrooms)

tempering

valve

20-30mm

from horizontal

30-45mm

from horizontal

Connecting strap viewed from

roof cavity

Components shown in grey are only used in 2 and 3 collec tor panel connections

Secure with screws on top

and back edge of beam

Iron roof: Connect bottom

rail and top edge of

collectors to iron roof.

Connect top of

collectors to tiled

roof using twisted

metal straps.

isolating

and non

return valve

pressure limiting

valve (600kPa) may be

required if pressure

exceed s 600kPa

pressure relief valve

(700 kPa) may be

required refer to

local plumbing

guidelines

drain

return

flow

inlet

cold

inlet

flow

relief

valve

from

solar

return

horizontal

outlet

1.5m

inlet

inlet

outlet

outlet

gas

gas

insert sensor here then

apply s ilicone to seal .

Cable t ie the senso r

wire to ou tside of the

pipe insulation, ensuring

that th e wire does not

touch t he hot pipe.

Page 19

Installation – storage tank

and solar controller

Prepare the solar controller by installing a 1/2" nipple and

the flexible tube on the bottom connection of the solar

controller.

solar controller

connection

1/2" nipple

flexible tube

Place the solar controller in position above the “ow”

connection on the storage tank and line up the flexible

tube with the nipple on the “ow” connection. Fix the solar

controller to the storage tank using the screws provided. Do

not use any screws with a length longer than 13mm and if pre

drilling the holes is required, be very careful not to penetrate

too far into the storage tank. Use a spanner to connect the

exible tubing to the nipple of the “ow” connection of the

storage tank.

Install the check valve, nipple and 1/2” copper union to the

top of the solar controller with an appropriate thread sealant.

1/2" female to

copper union

1/2" nipple

check valve

solar controller

connection

Preparing the storage tank location

The storage tank shall be installed on a level surface,

preferably on a concrete platform so that it is elevated

slightly from the ground and has a uniform mounting surface

to spread its load. The storage tank shall be checked with a

spirit level to ensure it is level for a number of reasons:

• to ensure the correct positioning of the anode inside

the tank

• to ensure that any hot water is drawn from the very top

of the tank

• to assist air being dispelled during commissioning

Consideration should be given to any potential damage due

to water drainage or leakage. If leakage of water from the

hot water system has potential to cause property damage, a

properly drained safe tray is to be installed under the storage

tank. The relief valve drainage pipes will be required to be

plumbed to an outside drainage point.

Solar controller mounting and connections

Open the ttings kit KKSSUGA and check that all

components have been provided (refer to the components

list). It is recommended that the storage tank “ow”

connections be installed rst in order to determine the exact

location to mount the solar controller.

Install the tee piece, sensor pocket, 1/2" nipples and 3/4" to

1/2" reducing bush on the “ow” connec tion of the storage

tank using appropriate thread sealant (see diagram below).

FLOW

storage tank 'ow'

connection

sensor pocket

3/4" to 1/2"

reducing bush

T-p ie ce

1/2" nipple

Kelvinator solar hot water systems installation – storage tank and solar controller 19

Page 20

20 installation- storage tank and solar controller Kelvinator solar hot water systems

Installation – storage tank

and solar controller

20mm thermal

insulation around pipe

The storage tank “ow” connection is to be piped to the

inlet of the collector array. The outlet of the collector array is

to be piped to the “return” connection on the storage tank

and shall have continuous fall back to the storage tank. It

is recommended that the sensor cable be run at the same

time as the collector piping for convenience. Ensure that the

sensor cable is installed neatly, kept out of the way and is not

in contact with any potentially hot surfaces or copper piping.

If the tank is not to be installed until a later date, ensure that

the sensor plug is well protected and waterproofed (e.g. put in

plastic bag and cable tied in a safe location) until nal assembly.

Installation of storage tank inlet and outlet connections

Storage tank inlet connections

isolating

and non

return valve

pressure limiting

valve (60 0kPa)

may be req uired if

pressure exceeds

600 kPa

pressure relief

valve (70 0kPa) may

be required refer

to local plumbing

guidelines

cold

inlet

to storage

tank in let

An isolating and not return valve must be installed on the

inlet to the hot water system. If it is possible that the supply

pressure could exceed 600kPa, a pressure limiting valve shall

also be installed on the inlet piping. A pressure relief valve

may also need to be installed on the inlet to the hot water

system under local plumbing requirements.

If the hot water system is installed in a bad water quality

area where regular flushing is required due to sediment

build-up, a drain cock or valve is also to be installed on the

inlet piping.

On the storage tank return connection install a 1/2" copper

union, 1/2" nipple and 3/4" to 1/2" reducing bush with

appropriate thread sealant.

RETURN

storage tank return

connection

3/4" to 1/2"

reducing bush

1/2"

nipple

1/2"

nipple

Installation of pipe work between the collectors and

storage tank

The pipe work between the collectors and the hot water

storage tank is to be made of copper and be a minimum of

1/2" in diameter. It shall be covered with 20mm thick thermal

insulation to maintain the efciency of the system, prevent heat

loss and to allow the proper operation of the freeze protection.

Any piping insulation that will be exposed to sunlight must

also be UV resistant. The copper pipes shall be supported by

saddles and installed neatly with no sharp bends. The pipes

shall not exceed the recommended length of 10m (20m total)

and the height difference between the storage tank and the

collectors must not be greater than 9 meters. Penetrations

through the roong material must be neat, kept as small

as practical and made at the high point of the roof tile or

metal sheet. Exposed insulated pipe work between the solar

collectors and the penetration through the roong material

should be kept to a minimum to maintain the aesthetics of the

installation. The penetrations are to be waterproofed upon

installation of the pipe work and a boot shall be installed to

prevent any water from leaking into the premises.

Page 21

Storage tank outlet connections

It is recommended that a heat trap be installed on the outlet

piping of the storage tank in order to prevent convective

heat losses and to maintain the efciency of the hot water

system. If your system is gas boosted, the gas continuous

flow water heater supplied with the hot water system is to be

installed and connected to the hot water line after it leaves

the storage tank. Refer to the installation manual supplied

with the gas continuous ow water heater for specications,

dimensions, suitable installation locations and details on how

to install it.

Any pipes delivering hot water to the premises are to be

installed with sufcient piping insulation to maintain the

efciency of the hot water system and to prevent heat loss.

Any piping insulation that may be exposed to sunlight must

also be UV resistant. The tempering valve provided in the

KKSSUGA kit is to be installed in order to temper any water

owing to xtures primarily used for the purposes of personal

hygiene (e.g. bathroom or ensuite xtures). The water

supplying these xtures shall not exceed 50°C as required by

AS 3500.4.

heat trap

uncontrolled hot

water outlet –

kitchen, laundry

tempered hot water

outlet (50°C) –

bathrooms

tempering

valve

Relief valve piping

A temperature and pressure relief valve comes supplied with

the storage tank and must be installed on the relief valve

connection near the top of the tank.

stora ge tank relief

valve connection

temperature and

pressure relief valve

3/4" to 1/2"

reducing bush

RELIEF

VALV E

The drainage piping from the relief valve (and the one on

the inlet if installed) must have a constant downward fall

and must be plumbed to an outside drain. The outlet of

the drainage piping must be left open to the atmosphere at

all times, and installed in a frost free environment.

RELIEF

VALV E

OUTLET

drain

flow

inlet

warning

Failure to operate the relief valve easing gear at least

once every six months may result in the storage tank failing

or in extreme cases, exploding. Continuous leakage of

water from the valve may indicate a problem with the

hot water system.

Kelvinator solar hot water systems installation – storage tank and solar controller 21

Installation – storage tank

and solar controller

Page 22

22 installation – storage tank and solar controller Kelvinator solar hot water systems

Installation – storage tank

and solar controller

Connecting the temperature sensor at the storage tank

The short tank sensor from the solar controller goes inside

the sensor pocket located at the “ow” connection near

the bottom of the storage tank. When inserting the sensor

into the pocket, ensure that it is inserted all the way into the

pocket and reaches the end. Install the sensor pocket plug

and x the clamp to the sensor pocket using the screws

provided. This will prevent the temperature sensor from

being pulled out of the sensor pocket and seals it from the

outside environment.

FLOW

Filling the storage tank

Once all plumbing has been completed, it is necessar y to ll

the storage tank with water in order to allow the hot water

system to be electrically tested. Open the isolation valve on

the inlet piping and activate the temperature and pressure

relief valve on the tank.

drainage pipe

relief valve

activation

lever

Once water begins owing from the relief valve piping de-

activate the lever on the temperature and pressure relief

valve. Close the isolation valve on the inlet piping and repair

any leaks as necessary.

Installation - temperature sensor

The solar controller has two temperature sensors that

are required to be installed. One sensor will measure the

temperature of the water at the collector array. The other

sensor will measure the temperature of the water at the

bottom of the storage tank. Both temperature sensors

should not be run alongside power supply cables as this may

induce a false signal into the sensor cable.

Installing the collector array temperature sensor

The collec tor sensor cable is provided in the kit KKSSURA

and is 15m long. It has a temperature sensor on one end

that is required to be installed in the sensor pocket located

on the outlet to the collector array, and the connector at

the other end inserts into the plug at the solar controller.

It is recommended that this sensor cable be tied neatly to

the insulated pipe work between the storage tank and the

collector array. Any excess cable should be tied neatly in a

loop and kept out of the way. If it is possible that the sensor

cable could become damaged during the life of the hot

water system it is recommended that the sensor cable be

protected by installation in a conduit or by other protective

means. If the solar hot water system has evacuated tube

collector(s), the temperature sensor is to be installed in the

sensor pocket on the side of the collector near the outlet

pipe connections to the collector array. The sensor shall be

inserted all the way in and sealed with silicon to protect it

from the environment and hold it in place.

If the solar hot water system has at panel collector(s), the

temperature sensor is to be installed in the sensor pocket on

the outlet connection of the collector array. When inserting

the sensor into the pocket, ensure that it is inserted all the

way into the pocket and reaches the end. Install the sensor

pocket plug and x the clamp to the sensor pocket using the

screws provided. This will prevent the temperature sensor

from being pulled out of the sensor pocket and seals it from

the outside environment.

Page 23

Kelvinator solar hot water systems electrical installation 23

The current draw is approximately 0.1A for the solar controller

and 0.8A for the gas continuous ow water heater. If a new

power outlet is to be installed and wired to an existing power

circuit, consideration should be given to how many outlets

are already on the circuit and if the existing cable is capable

of handling the added current draw of the hot water system

or any other appliances that may potentially be plugged into

the new outlet. If a new cable supplying the outlet is to be

installed, it shall be protected by a suitably rated and labelled

circuit breaker. It is recommended that the outlet be used by

the hot water system only and not be shared with any other

appliances.

Electrical installation

The solar hot water system is required to be installed in

accordance with the AS/NZS 3000 wiring rules, the local

electrical authority regulations and any other applicable

standards. The pipe work, storage tank and collectors are to

be properly connec ted to the earthing system of the premises

in accordance with AS/NZS 3000.

Means for disconnection must be incorporated in the xed

wiring in accordance with the wiring rules. The insulation of the

xed wiring must be protected by insulating sleeving having

an appropriate temperature rating.

The solar controller and gas continuous flow water heater (if

system is gas boosted) require a weatherproof socket outlet

with a 240 volt alternating current continuous power supply.

This outlet shall be located as close as possible to the hot

water system, ideally within one and a half meters of the solar

controller and gas continuous ow water heater (if installed).

fuse 1

power supply pump

display unit

tank

sensor

collector

sensor

connector

CN1

up low collect

1

2

3

4

on

bw2

fre

ups

N L

3.15A/250VAC

Solar controller wiring diagram

Note: The solar controller contains a 3.15A 250V T3.15AL

20mm glass cylinder type fuse.

Page 24

24 electrical installation Kelvinator solar hot water systems

Electrical installation

If the solar hot water system is electric boosted, the storage

tank will have a heating element installed inside the tank. The

element is required to be installed with a 240 volt alternating

current continuous or off peak power supply. This heating

element is designed to be installed on extended off peak

which is available up to 18 hours of the day compared to the

standard off peak available only 8 hours. If the customer has

only standard off peak available, they should be advised to

call their electrical supplier and get it changed to extended

off peak. If the heater is connected to standard off peak and

not extended off peak power supply against manufacturers

recommendation, complaints from customers about

insufcient hot water being available will be considered an

installation fault and hence not covered under warranty. The

supply cable must be capable of handling the current draw of

the 3.6kW element and be protected by a suitably rated and

labelled circuit breaker. Where the cables are run externally,

they are to be installed in a conduit in order to provide

mechanical protection. The recommended size of the conduit

is 20mm and an entry has been provided for a 20mm conduit

adapter on the terminal box of the storage tank. If xing the

conduit to the storage tank with saddles be sure to use screws

no longer than 13mm in length and if pre drilling of holes is

required, be very careful not to penetrate too far into the

storage tank.

For safety reasons it is recommended that the wiring of the

storage tank be completed rst before the cable is wired to

the switchboard. If you are replacing an existing electric hot

water system and re-using the existing cable, ensure that the

power supply to this cable is isolated or disconnected at the

switchboard.

The 20mm conduit adapter is to be inser ted into the 20mm

cut-out provided and the locking ring screwed down to hold

the conduit rmly in place. The earth wire is to be wired to the

earthing terminal on the bottom left hand side of the terminal

block. The active wire is to be wired to terminal “A1” and the

neutral wire to terminal “N” of the wiring terminal block.

be very careful

not to penetrate

too far into the

storage tank

earth terminal

earth

neutral terminal

wiring terminal block

element

thermostat

active terminal

conduit adaptor goes

in here and locking

ring holds it

Electrical testing of the solar hot water system

Once the hot water system has been wired correctly and

the storage tank lled with water, the following mandatory

tests are required to be completed as per the AS/NZS 3000

Australian Standards:

a) Continuity of the ear thing system

b) Insulation resistance

c) Polarity

d) Correct circuit connections

e) Verication of impedance required for automatic

disconnection of supply

Note: The solar controller and gas continuous flow

water heater (if installed) are required to be electrically

disconnected during the insulation resistance testing to

prevent damage to their electronics.

Refer to the AS/NZS 3000 Australian Standard for specic

details on how to perform these tests and the acceptable

readings that must be obtained. If the electrical installation

fails a test, that test and any preceding tests that may have

been influenced by the fault indicated shall be repeated after

the fault has been rectied.

Page 25

Commissioning

Before commissioning the solar hot water system, please

conrm the following:

• Collector(s) have been installed correctly

• Collector(s) have been covered

• Collector array has been adequately xed to the roof

• Storage tank has been installed correctly

• Storage tank and collector array connections have

been completed

• The solar controller has been installed correctly

• Inlet piping and valves have been installed correctly

• Relief valve(s) have been installed and piped correctly

• Tempering valve has been installed correctly

• Piping between the storage tank and the collectors

has been installed correctly

• Gas continuous ow water heater has been installed

correctly (gas boosted only)

• Sufcient insulation has been installed on all hot

water piping

• The electrical supply is isolated to the hot

water system

• Electrical wiring has been completed and installed

correctly

• Electrical testing has been completed and

satisfactory results obtained

• Temperature sensors have been installed and

connected to the solar controller

The following steps are to be followed af ter the installation

of the solar hot water system to ensure its safety and

performance. If the hot water system cannot be setup to

perform correctly as specied in this manual, please call the

service centre for further instruc tions (number located in the

warranty section of this manual).

Filling the hot water system with water and checking

for leaks

At this stage, the power to the tank element and pump

station should be isolated (off). Fully open the cold water

isolation valve located on the inlet to the storage tank to

allow the system to begin lling with water.

Activate the temperature and pressure relief valve on the

storage tank in order to allow air to bleed out of the tank.

outlet

relief valve

activation

lever

drainage

pipe

Once water begins owing from the relief valve piping de-

activate the lever on the temperature and pressure relief

valve. The automatic air vent valve installed on the collector

array will allow air to bleed out of the solar hot water system.

Loosen the cap on the air vent valve to enable the air venting

function, then leave the cap loose after installation to allow

continued automatic air and steam venting as required. It

should not be necessary to manually bleed air from the top

of the collector (although it may take up to a few hours to

release all the air, depending on the installation). Check for

any water leaks on the storage tank, collector array and pipe

work connections, tightening or sealing as appropriate to

conrm the system is water tight.

In order to bleed air out of the hot water pipes into the

premises, open the nearest hot water tap or xture to the

hot water system.

Once water has begun owing freely from the hot water tap

or xture, indicating that all air has been expelled from the

hot water pipes, close the hot water tap or xture.

Kelvinator solar hot water systems commissioning 25

Page 26

Commissioning the solar controller

A solar monitor is located on the front of the solar controller

and houses a green and a red LED.

Remove the covering on the collector(s) to allow them to

begin receiving solar radiation and heating water in the

system. Plug in and switch on the power supply to the solar

controller. Once the electrical supply is switched on to the

solar controller it will start up and the green and red LED’s

will emit a constant glow for 2 seconds. If the solar hot water

system is operating correctly the green LED marked “solar”

will stay on and emit a constant glow.

SOLAR

ATTENTION

NOTE: The solar controller will monitor the temperatures

at the collector array and the storage tank in order to

determine the correct conditions to begin circulating the

water efficiently. As such it may not begin circulating water

immediately through the collector array.

If power to the solar controller is available and the green LED

is off or the red LED is ashing, this indicates that there may

be a fault with the hot water system. The red LED may emit

up to ve ashes every two seconds indicating the relevant

fault mode. See the chart below for descriptions of the

operating modes:

Flashes Operational modes

green & red constant glow power on initialization

green constant glow

(remains on)

standby mode, or circulating

water through collectors

Flashes Fault modes

4 x red

sensor in storage tank –

open circuit or short circuit

5 x red

sensor in collec tor – open

circuit or short circuit

red rapid flash

temperature difference

between collector and

storage tank higher than 40°C

for more than 10 minutes

during circulating

no green & red

(remains off)

power outage or call for service

If any of the fault modes occur, check that the temperature

sensors are installed correctly, connected to the solar

controller and that the cables have not been damaged. If

the red LED is emitting continuous ashes, this indicates

that water is not circulating through the collectors and the

storage tank correctly and that the temperature difference

between them has been greater than 40°C for ten minutes.

There may be air in the system that still needs to be bled

in order for the water to circulate correctly. Reset the solar

controller by cycling power to the controller at the power

outlet and bleed the air out of the collector array “ow” and

“return” lines.

Optimising circulating water flow through the

collector array

In order to optimise the energy per formance of the hot

water system, it is recommended to check and adjust the

circulating flow rate through the collector array. In order to

achieve this install an appropriate flow restrictor (control

valve or orice plate) and non intrusive ow sensor on the

piping to the collector array. It is recommended that the flow

sensor be installed at the outlet of the check valve connected

to the solar controller. The flow restrictor should be installed

at the outlet to the flow sensor.

The pump should start to circulate automatically if there

is sufcient sunlight, however if not, it may be necessary

to force circulation by articially warming the collector hot

sensor probe. This can be achieved by covering the probe

with a plastic cover and placing it in a cup of hot water

(please do not directly expose the sensor probe to water

ingress). Adjust the valve or ow restrictor until the circulating

flow rate registered on the flow sensor is as per the table

below, depending on the number of collectors installed in

the hot water system:

Number of collectors

installed:

1 2 3

Optimal circulating ow

rate (L/min):

1.0L /min 1.5L/min 2.0L/min

Commissioning

26 commissioning Kelvinator solar hot water systems

Page 27

Checking the hot water delivery temperature,

pressure and flow

Individually open each hot water tap or xture in the house

and check that hot water is available and that there is sufcient

ow or pressure. Ensure that any xtures designed primarily

for the purposes of personal hygiene (e.g. bathroom, ensuite)

do not supply hot water above 50°C and adjust the tempering

valve as necessary. If the hot water system is gas boosted,

check the installation manual supplied with the gas continuous

flow hot water heater to determine if it is operating correctly

and for any other specic commissioning instructions. Clean

any lters installed in the water system of the premises or at

the individual xtures as they may have been become blocked

by debris during the installation and commissioning of the hot

water system.

lter

Now that commissioning has been completed and the

solar hot water system has been setup to operate correctly,

select the specic components of the hot water system in

the user manual. Fill out your details, the serial numbers, the

installation date and any important notes to the customer.

The user manual (and the gas continuous flow user manual if