Page 1

KELTEC CNC INDUSTRIES INC

PO BOX 236009

COCOA FL 32923

321-631-0068

www.Kel-Tec.com

SU-16 RIFLE

Owned

Made

Parts

c

SAFETY, INSTRUCTION, AND PARTS MANUAL

Page 2

KEL-TEC SU-16 RIFLE

SAFETY, INSTRUCTION & PARTS MANUAL

STATEMENT OF LIABILITY

This rifle may be classified as a dangerous

weapon and is surrendered by KEL- TEC CNC

INDUSTRIES INC. with the understanding that

the purchaser assumes all liability resulting

from unsafe handling or any action that

constitutes a violation of any applicable laws or

regulations. Firearms can cause serious injury

and death. Safety must be the prime consideration of anyone who handles firearms. Always

treat a firearm as though it were loaded. Always

keep the muzzle pointed in a safe direction.

In owning a firearm, you are responsible for the

firearm’s safety and security. Always secure

firearms from children.

READ THESE INSTRUCTIONS AND

WARNINGS CAREFULLY, BE SURE

YOU UNDERSTAND THESE INSTRUCTIONS AND WARNINGS BEFORE

USING THIS FIREARM

This SAFETY, INSTRUCTION & PARTS

MANUAL should always accompany this

firearm and be transferred with it upon change

of ownership or when the firearm is loaned or

presented to another person. A copy of the

SAFETY, INSTRUCTION & PARTS MANUAL is

available FREE upon request and can also be

downloaded from the internet at http://www.KelTec.com.

.

Page 3

READ AND CAREFULLY FOLLOW THESE

WARNINGS AND INSTRUCTIONS

Make sure your “audience” is always 5 feet in

back of you, not next to you when firing.

Keep your firearm unloaded when not in use.

These warnings and instructions are provided

to assure the safe functioning of the rifle.

Failure to heed them may result in improper

functioning and serious injury.

Kel-Tec firearms are designed to function

reliably with proper care and knowledgeable

use. Do not use your firearm unless you fully

understand these instructions, and the safe

operation of your firearm.

Only safe gun-handling habits will ensure the

safe use of your firearm. This is your responsibility. Accidents are the result of violating the

rules of safe gun handling and common sense.

Before handling a firearm, understand its

operation.

Never accept or pickup a firearm without

checking the magazine and the chamber to

assure the weapon is empty. Do not trust the

extractor to clear the chamber, look and feel.

Always make sure the muzzle is pointed in a

safe direction at all times.

Never point a firearm at anyone or anything you

do not intend to shoot.

Never keep a loaded firearm in the home or

vehicle. Never store a firearm with a cartridge in

the chamber.

Never store firearms and ammunition together,

keep them locked up and away from children.

Never touch the trigger when working the

action. Never alter any components of your

firearm.

Never take medications, drugs, or alcohol when

handling firearms

Never load or unload a firearm without assuring

the muzzle is pointed in a safe direction.

Never load a firearm except immediately before

shooting.

Page 4

SAFE GUN HANDLING IS YOUR

RESPONSIBILITY

Never shoot until you are sure of your backstop

and what lies beyond it.

The SU-16 rifle is designed and chambered for

the .223 Remington cartridge. The type of

ammunition is also stated on the right side of

the receiver. Do not use any other ammunition.

Only use commercially manufactured ammunition, clean, dry, and in good condition. Never

use non-standard, reloaded or damaged

cartridges.

Never use ammunition where the pressure

levels exceed industry standards. Kel-Tec guns

are manufactured from high quality materials.

They will provide extended service life.

However, all warranties, expressed or implied,

are voided and Kel- Tec will not be liable for

property damage or personal injury and

consequential damages, if faulty ammunition is

used in Kel- Tec centerfire firearms.

Discharging firearms in poorly ventilated areas,

cleaning firearms, or handling ammunition may

result in exposure to lead and other substances

known to cause birth defects, reproductive

harm, and other serious physical injury. Have

adequate ventilation at all times. Wash hands

thoroughly after exposure.

Never discharge a firearm without proper

shooting glasses and ear protection. Never

shoot at any water surface or any surface

where a ricochet can occur.

If the gun does not discharge after pulling the

trigger, do not change its direction for at least

30 seconds, you could be having a “hang fire”.

Do not allow a firearm to be used by individuals

who do not understand its safe operation and

the rules of safe gun handling.

CAUTION: After firing several rounds the

forward, exterior metal parts of the SU-16 rifle

get hot and can cause severe burns.

Be sure all accessories are compatible with the

firearm and that the accessories do not

interfere with safe operation.

When transporting your firearm, be sure your

firearm is unloaded.

If you do not understand how to operate any of

our products or have any questions about their

safe handling, please write or email us.

Always be aware of other people so that they

cannot accidentally walk into the line of fire.

When firing on a target range, be alert and

follow the range officer’s commands. Never

cross obstacles such as fences or streams with

a loaded firearm.

Page 5

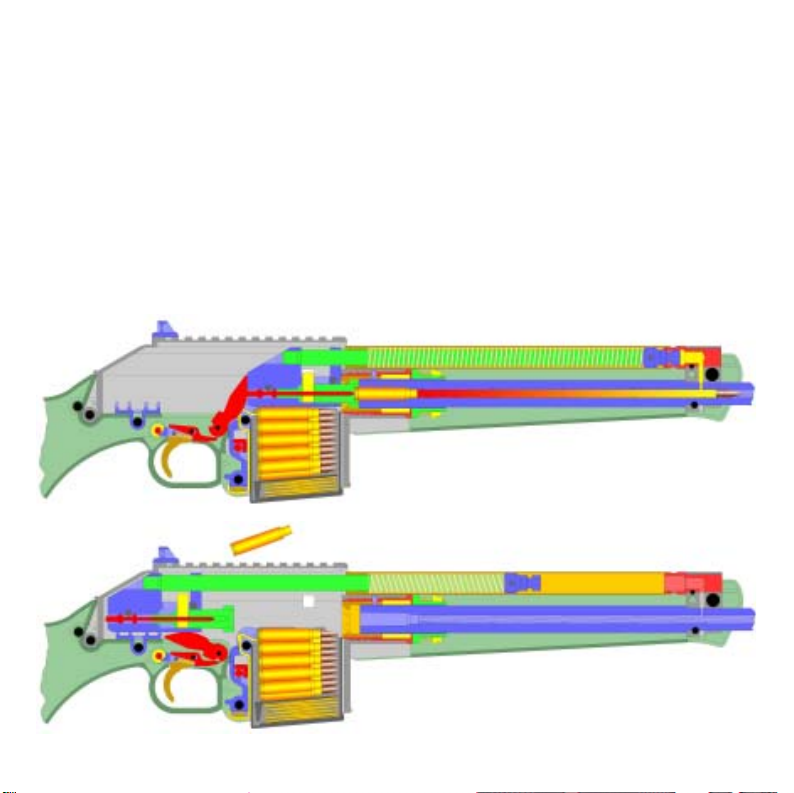

INTRODUCTION

The SU-16 is a semi-automatic rifle chambered

for the .223 Remington (5.56mm) cartridge.

The SU-16 rifle will accept most standard M-16

type magazines. The forend can be unfolded to

form a bi-pod for more accurate shooting. The

stock has storage space for two 10 round KelTec magazines or one 20 or 30 round magazine. By rotating the stock down and forward,

the SU-16 rifle can be reduced to a size of

27x7.5 inches (680x190mm) to facilitate

storage.

The stock houses the firing mechanism and

has storage for two 10 round magazines. It is

ended with a soft rubber butt plate.

The firing mechanism is of conventional single

action type. It has a push bolt safety that blocks

the trigger.

Functioning

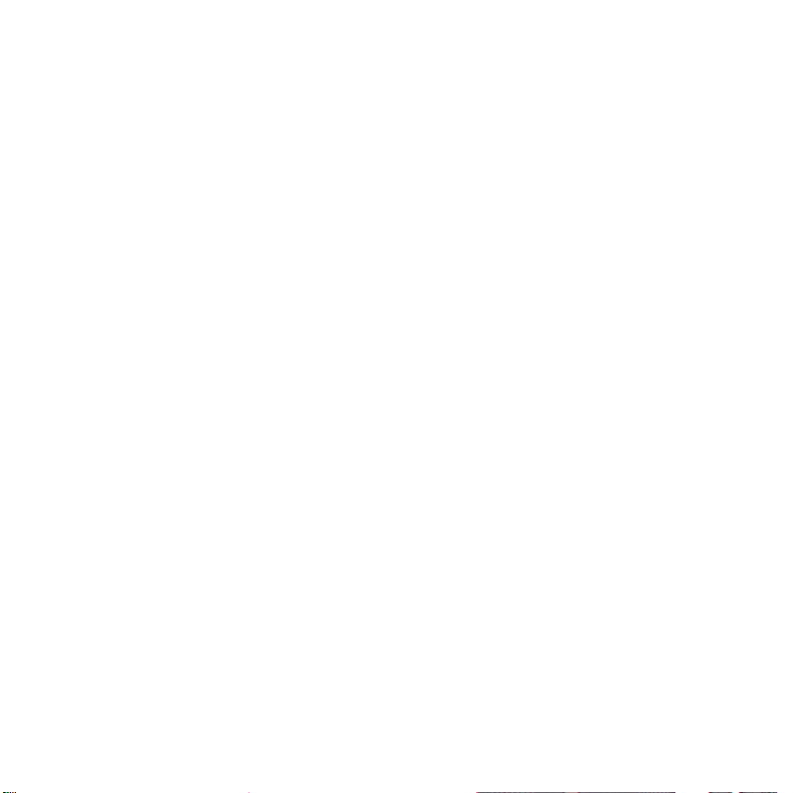

At the start of this cycle the weapon is

assumed already loaded, full magazine

inserted, hammer cocked, the safety disengaged and ready to fire.

CONSTRUCTION

The receiver, stock, and forend are made of an

impact resistant glass reinforced Zytel. The

receiver has an aluminum insert molded into

the front to accept the barrel and the serial

number.

The barrel has a fully adjustable front sight.

When The SU-16 rifle’s trigger is pulled, the

trigger block rotates lifting up the rear of the

sear. This causes the sear to rotate on its axis

disengaging the sear from the hammer. The

hammer rotates forward to strike the firing pin,

which in turn hits the cartridge primer igniting

the powder charge.

Page 6

The hot expanding powder gases drive the

bullet forward through the barrel. After about

.0007 seconds the bullet passes the gas port in

the barrel and some of the powder gases enter

the gas head and press on the piston. The

pressure builds on the piston, which pushes on

the piston rod and the bolt carrier causing the

bolt carrier to move backwards, unlocking the

bolt from the barrel extension. After the bolt

carrier moves about 0.41inches (10.5mm) the

bolt is fully unlocked from the barrel extension

and the bolt and empty case continue to move

backwards with the bolt carrier.

On it’s way backwards, the bolt carrier cocks

the hammer and the empty case ejects. The

bolt carrier is gradually slowed down and

stopped by the recoil spring. The recoil spring

then drives the bolt carrier forward. The top

cartridge in the magazine is picked up by the

bolt and pushed into the barrel. The bolt stops

moving once the round is fully inserted in to the

chamber but the bolt carrier continues to move

forward until it rests on the barrel extension, the

cam path and cam pin cause the bolt to twist

and lock with the barrel extension.

Page 7

The hammer is now resting on the sear which is

pushing back onto the rear of the trigger block.

As the trigger is released the trigger block

rotates, lowering the rear of the trigger block

which allows the sear to move backwards and

rest on the top of the rear of the trigger block.

The SU-16 rifle is now ready for the next shot.

Page 8

INSTRUCTIONS FOR USE

The normal storage condition of the SU-16 rifle

is unloaded with the stock folded underneath

the barrel.

unlatches and then release the bi-pod. Rotate

the bi-pod forward until it is fully extended. If

only one half of the bi-pod opens, squeeze it

closed and try again, being sure to use only two

fingers to unlatch the bipod.

Folding and unfolding the rifle

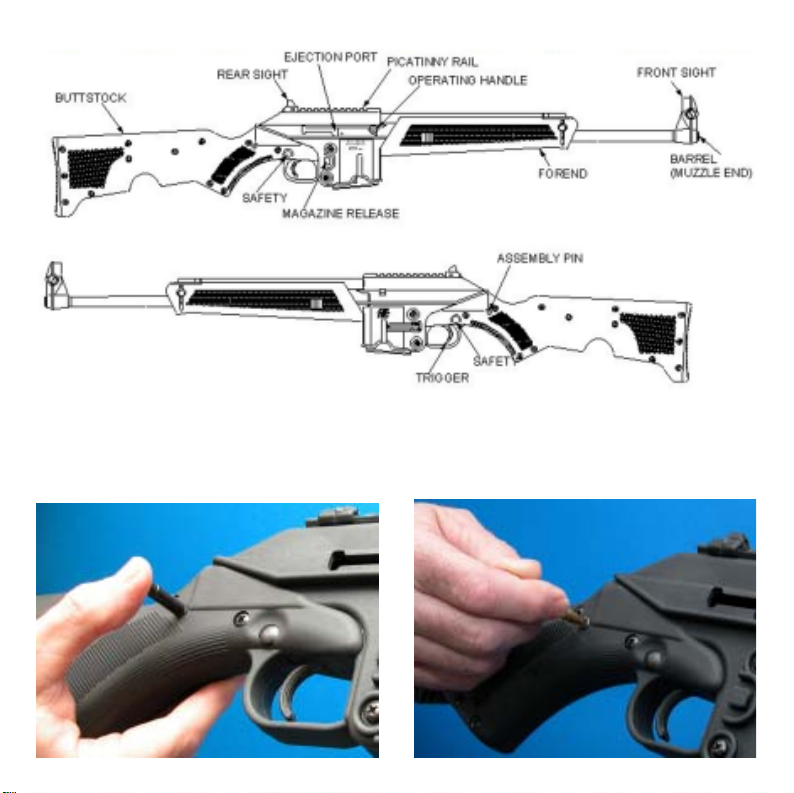

To unfold the rifle remove the assembly pin

from its spring locked hole in the receiver. The

stock is simply latched onto the barrel with

friction and can be unfolded by simply pulling it

apart from the barrel. Fully extend the stock

and line up the assembly pin holes. Press in

the assembly pin until it is flush with the outside

of the stock

To fold the rifle simply press out the assembly

pin with a small tool or the tip of a cartridge,

fold the stock under the barrel, and replace the

assembly pin into the spring locked hole in the

receiver.

Extending and folding the bi-pod

To extend the bi-pod grip the 2 locking tabs on

each side of the forend with your thumb and

middle finger. Pull them back until the bi-pod

To fold up the bi-pod rotate the bi-pod back until

the locking holes are aligned with the locking

tabs. Squeeze the bi-pod together until both

halves snap into place. Be careful not to get

any part of your hand in between the two halves

when you snap it shut.

Safety

To achieve operator safety, combined with ease

of handling, the SU-16 rifle’s manual safety,

when applied, positively blocks the trigger from

rotating the sear. The safety can be applied at

any time, whether the hammer is cocked or not.

Only when the red paint on the safety is fully

obscured is the safety engaged.

Obviously the safest condition of the rifle is

folded and unloaded. Also considering

Page 9

unauthorized operation, other modes of storing

or carrying will gradually improve readiness at

the cost of safety.

Malfunctioning

Proper function of your SU-16 rifle is directly

related to maintenance and care, and to the

ammunition you use. Some of the more

common types of malfunctions which may

occur are as follows:

Misfire: A failure to fire or unusual sound upon

firing is always a signal to cease firing and

immediately examine the bore of the firearm. It

is not sufficient to just pull the operating handle

back and examine the chamber. You must

remove the magazine, clear the chamber, lock

the bolt open and inspect the bore visually and with a rod if necessary - to be certain it is

completely clear of any obstruction. Failure to

detect and remove a bore obstruction can result

in serious injury or death to the shooter and

bystanders, and damage to the firearm.

WARNING: DO NOT ATTEMPT TO

REMOVE A LODGED BULLET OR ANY

OTHER OBSTRUCTION BY USING A

BLANK CARTRIDGE, OR A CARTRIDGE

WITH THE BULLET REMOVED, OR BY

ANY MEANS OTHER THAN THE USE

OF THE PROPER SIZE CLEANING ROD

(WITHOUT A TIP OR BRUSH) AND

REASONABLE FORCE APPLIED TO

THE ROD. BE CERTAIN ALL LOOSE

POWDER HAS BEEN REMOVED FROM

THE BORE AND ACTION BEFORE

INTRODUCING THE ROD INTO THE

BORE.

Failure to Feed: This occurs when a cartridge

has been fed from a magazine but not fully

chambered. If this occurs, keep the firearm

pointed in a safe direction, remove that

cartridge, operate the bolt manually and

continue shooting. If necessary, change the

magazine. The most common causes are dirt

Page 10

or foreign objects impeding the magazine

follower. Improperly crimped cartridges are

another cause.

Failure to Eject or Extract: A fired case is not

fully extracted from the chamber or ejected

from the rifle. Again, keep the firearm pointed in

a safe direction, clear the gun by operating the

bolt, remove the case and continue. If necessary, change the magazine. The most common

causes are a damaged extractor, ejector or

ammunition. Improperly loaded or sized

cartridges can cause this also. If any of the

above problems are not solved by cleaning or

by use of other brands of ammunition, stop

firing, unload and return the SU-16 rifle to our

service department.

Release the trigger and you are ready to fire

another round. Upon firing, the bolt moves

rearward extracting and ejecting the fired round

and returns to the forward position feeding

another round automatically while doing so.

This sequence can be repeated until the last

round has been fired. The SU-16 has an

automatic bolt stop so after the last round is

fired the bolt will lock open. Remove the empty

magazine by pressing the magazine catch

located on the right side of the receiver and

pulling out the empty magazine. To continue

shooting simply insert a full magazine into the

magazine well, firmly push it up until it locks,

pull back and release the operating handle to

release the bolt stop and feed the next round,

the rifle is now ready to fire.

Firing

With the muzzle pointed in a safe direction and

your finger outside the trigger guard, take aim

at a safe target, disengage the safety and

squeeze the trigger until a round is fired.

Unloading

To unload the SU-16 rifle engage the safety,

push in the magazine catch, remove the

magazine, and pull the operating handle fully

Page 11

Page 12

back to eject the round in the chamber. Do not

obstruct the ejector port and keep fingers away

from trigger and muzzle. With the operating

handle fully pulled back push up on the bolt

stop and slowly release the operating handle,

the bolt should stay open. Visually inspect the

chamber to make sure it is empty. Pull back on

the operating handle to release the bolt stop

and release the operating handle to close the

chamber. Push the remaining cartridges in the

magazine forward and out.

Loading

To load, fill the magazine by pressing a

cartridge downward on the magazine follower

(or downward on the previously loaded

cartridge). Continue loading until you have

loaded the number of cartridges you wish to

load, up to the magazine capacity of 10 rounds.

Do not attempt to load your magazine with

more than the specified number of rounds.

Doing so can damage the magazine and can

cause a feeding malfunction. Before inserting a

loaded magazine always tap the back of the

magazine against a hard surface two or three

times in order to properly seat all the cartridges

to the rear of the magazine.

With the rifle’s safety engaged, hold the rifle in

one hand with the muzzle pointing in a safe

direction and with your finger off the trigger and

outside the trigger guard. Insert the loaded

magazine into the grip until it is locked in place.

Check to assure that the magazine is secure.

Pull the operating handle back and release.

This strips a round from the magazine and

seats it in the barrel chamber.

Page 13

If you wish to restore the magazine in your rifle

to full capacity, press the magazine catch and

remove the magazine to load the missing

round. Remember to keep the safety engaged

and your rifle pointed in a safe direction under

all conditions and always keep your finger off

the trigger and outside the trigger guard until

ready to fire.

the screws on the rifle should ever need to be

removed for general maintenance.

Rifle disassembly

Unload your SU-16 rifle and cycle the operating

handle to be sure that there is no round in the

chamber. Make sure the bolt is in the forward

position and the safety is engaged.

DISASSEMBLY

NOTE: Disassembly can be performed with

only a cartridge but a few simple tools such as

a small punch and small pliers can make things

much easier. A Phillips head screw driver is not

necessary for general maintenance and none of

CAUTION: some accessories that are

mounted to the picatinny rail on the top of

the receiver may interfere with the disassembly of the SU-16 rifle. It is advisable to

remove any scopes or other devices

mounted to the rail before proceeding with

disassembly.

Page 14

With a cartridge or other pointed object push

out and remove the assembly pin. Fold the

stock down and forward and press it onto the

barrel. Unlatch the bipod. Grip the recoil spring

tube, pull it towards the muzzle and twist it ¼

turn so that the locking tab points towards the

top of the rifle, it should slide into the receiver

about ¼ inch as you release the recoil spring

tube. Slowly pull back on the operating handle,

the recoil spring tube should also move back

and there should not be any spring pressure

felt. Pull the handle all the way back and push it

down into the operating handle removal cutout

in the receiver. The operating handle should

now be able to be pulled straight out of the bolt

carrier. After the operating handle is removed

the bolt carrier assembly can now be guided

out of the bottom of the receiver by holding onto

the recoil spring tube.

Bolt carrier disassembly:

To remove the bolt, cam pin and firing pin

simply press out the firing pin pin from the right

side with a small tool or a cartridge. Remove

the firing pin from the back of the bolt carrier,

you may need to tap the bolt carrier or move

the bolt in and out to get the firing pin to fall out

enough to grip it. With the firing pin removed

the cam pin can now be pulled out and with the

cam pin out the bolt can be removed from the

front of the carrier.

To remove the piston head, recoil spring tube,

Page 15

and recoil spring first align the holes in the

recoil spring tube with the pin in the piston

head. While holding the piston head with one

hand, press out the piston pin with the firing pin

or a small tool.

CAUTION: the piston head is under pressure

from the compressed recoil spring and the

piston head and recoil spring can easily fly

out and injure yourself or bystanders,

always keep a hand on the piston head and

point the piston head in a safe direction

when removing it.

With the piston pin removed the piston head is

now free to be taken off. Slide the recoil spring

tube off the piston rod and remove the recoil

spring from the recoil spring tube.

NOTE: It is not recommended that you

disassemble the stock of the SU-16 rifle; the

hammer spring is constantly under tension

and can easily injure you or others.

ASSEMBLY

Bolt carrier assembly:

To install the piston head, recoil spring tube,

and recoil spring insert the recoil spring into the

recoil spring tube. Slide the recoil spring tube

with recoil spring onto the piston rod. Align the

holes in the recoil spring tube with the hole in

the piston rod. Push the piston head onto the

recoil spring and onto the piston rod. Insert the

firing pin or similar tool into the piston head

hole to temporarily hold the piston head in

place. While slowly pulling out the firing pin

push in the piston pin from the other side until it

is flush with the piston head. Twist the recoil

Page 16

spring tube so that the locking tab points

towards the top of the bolt carrier. Check the

operation of the recoil spring by lightly pulling

on the recoil spring tube to compress the

spring.

To install the bolt, cam pin, firing pin, and firing

pin pin insert the bolt into the front of the bolt

carrier. Twist the bolt so that the extractor is on

the right side of the carrier and the cam pin

hole in the bolt lines up with the cam pin slot in

the bolt carrier. Insert the cam pin into the hole

in the bolt, be sure that the tab on the cam pin

is pointing straight out the left side of the bolt

carrier. Insert the firing pin into the back of the

bolt carrier, if it does not go in all the way the

cam pin or the bolt may not be inserted

correctly. Push the bolt assembly into the

carrier as far as it will go and then insert the

firing pin pin into the bolt carrier from the left

side. DO NOT FORCE THE FIRING PIN PIN. If

it does not go in easily check that the firing pin

is installed correctly. Check the operation of the

bolt and firing pin to be sure that they move

freely.

Page 17

Rifle assembly

With the rifle stock folded and the bipod

unlatched rest the rifle on its left side. Take the

bolt carrier assembly, pull the bolt out as far as

it will go and twist the recoil spring tube so that

the lock tab is at the top of the bolt carrier.

Insert the carrier from the rear of the receiver,

be sure not to twist the bolt tube or push in the

bolt as you insert it. Align the operating hole in

the carrier with the cut-out in the receiver and

insert the operating handle. Push the carrier up

slightly so that the operating handle aligns with

the slot for it and the recoil spring tube is

parallel with the barrel of the rifle.

WARNING: if the recoil spring tube is not

parallel with the barrel of the rifle the bolt

carrier assembly is not installed correctly.

Remove the carrier assembly and install it

again paying close attention to the alignment of the lock tab on the recoil spring

tube as you insert the carrier and also be

sure that the bolt itself is always in the

forward most position as you insert the

carrier assembly into the receiver.

Check that the forend lock ring is aligned

correctly and push the operating handle all the

way forward, be sure that the piston head lines

up and goes into the gas head. Grip the recoil

spring tube, pull it forward and twist it ¼ turn so

that the locking tab on the recoil spring tube

goes into the receptacle on the left side of the

receiver. Pull the operating handle back and

forth to check that it moves freely, if it does not

take out the bolt carrier and check to make sure

everything is installed correctly and nothing is

damaged. Close the bipod and unfold the

stock. Insert the assembly pin into the hole and

press it in until it is flush with the outside of the

stock.

Changing the safety operation direction:

The safety button on the SU-16 rifle can be

reversed so that the safety can be engaged by

either pressing on the right side, or the left side

of the safety button, depending on your

preferences. You will need a few tools to flip

the safety button including a Philips head screw

driver, a small flat head screw driver or other

thin tool for prying, and a small paper clip.

Bend the paper clip out so that it has a small

hook on one end and a handle shape on the

other as shown in the figure below.

Unload your SU-16 rifle and cycle the operating

handle to be sure that there is no round in the

chamber. Make sure the bolt is in the forward

Page 18

position and the safety is engaged. Put the rifle

on one of its sides and loosen the four screws

on the sock that are closest to the muzzle end

of the rifle as shown in the figure. Do not loosen

screws that are screwed into the receiver. Flip

the rifle over and loosen the four screws that

were in the same position as the previous four

you just loosened. Hold the rifle so that it is

upside down and resting on it’s top, you may

need to remove the sight and any other

accessories that are mounted to the picatinny

rail. Push your small screwdriver or prying tool

into the gap in the bottom rear of the trigger

guard so that there is enough of a gap to get

your paper clip tool in between the two stock

halves at the back of the base of the trigger

guard. You may need another prying tool to

help enlarge the gap. Put your paper clip hook

into the gap you just pried open starting from

the butt end and move the hook towards the

trigger, you should be able to hook onto the

back of the trigger spring. Lift up on your tool

to raise the trigger spring. While holding the

spring up push out the safety, flip it around, and

put it back. Release the pressure on the trigger

spring and remove the paper clip hook. Check

to be sure that the safety moves back and forth

correctly. Remove the pry tool from the trigger

guard. Tighten all the screws that you loosened

on both sides of the stock. Check the operation

of the safety before loading the rifle.

SIGHT ADJUSTMENT

Sight adjustment on the SU-16 rifle depends on

the placement of the rear sight, if the sight is

placed farthest forward on the picatinny rail the

rifle will have a different sight radius than if the

sight is placed farthest rearward on the

picatinny rail. The main data below is given for

Page 19

when the rear sight is placed on the farthest

rearward slot on the picatinny rail, the data in

parentheses is for when the rear sight is placed

on the farthest forward slot on the picatinny rail.

Use a coin or large screwdriver to adjust the

windage by the two screws on each side of the

front sight block. Before turning a screw

clockwise (in) the opposite must be backed out

the same amount. 1/4 of a turn changes the

point of impact 1.3"(1.6”) at 100 yards or 1.3

m.o.a. (1.6 m.o.a.). One full turn is 5.2 m.o.a.

(6.4 m.o.a.) By turning the left screw clockwise

(in) the sight moves to the right and the point of

impact to the left.

Before tightening the screws, the post may be

pushed up or down to adjust elevation. .007"

(.005”) will change the impact 1 m.o.a.

DO NOT OVER-TIGHTEN.

MAINTENANCE

Your rifle is a precision instrument and to insure

reliable function, it is necessary to follow a

routine maintenance procedure. After firing your

rifle, be sure to unload it following the procedure outlined in the section entitled “Unloading”

before any cleaning or maintenance procedure.

Routine cleaning, after every shooting

session:

Your rifle should be cleaned by brushing the

barrel bore and chamber with a good powderremoving solvent and bore brush. Wipe the

areas clean with patches or a swab. Using a

small brush dipped in solvent, remove all

deposits from around the breech of the barrel,

and chamber, extractor and adjacent areas

which have been subjected to the action of

powder or primer residue. Remove any residue

on the frame with light brushing and a solvent.

After cleaning the entire gun, use a cloth to

apply a light coating of high quality gun oil to all

external surfaces and wipe clean.

Additional cleaning, after firing 500 rounds:

Remove the bolt carrier assembly and fully

disassemble it as stated in the disassembly

section of this manual. Thoroughly Clean with

solvent and a brush the piston head, piston pin,

piston rod, recoil spring, recoil spring tube, bolt,

cam pin, firing pin, and bolt carrier. Do not

clean the firing pin pin, solvents can damage

the O-ring used to hold it in place. Thoroughly

dry all parts. Apply a light coat of oil to the firing

pin, bolt, cam pin and the surfaces in the bolt

Page 20

carrier where the bolt, cam pin, and firing pin

slide. Apply a light coat of oil on the piston rod

and assemble the bolt carrier assembly and

rifle as stated in the assembly part of this

manual. Manually cycle the bolt back and forth

to check the function of the rifle. If any parts are

damaged or badly worn or the rifle does not

work correctly the rifle should not be fired and

should be returned to Kel-Tec for servicing

immediately.

LUBRICATION WARNING:

Firing a rifle with oil, grease, or any

other material even partially obstructing the bore may damage the rifle and

injure the shooter and those nearby.

Do not spray or apply lubricants

directly on ammunition. If the powder

charge of a cartridge is affected by the

lubricant, it may not be ignited, but the

energy from the primer may be sufficient to push the bullet into the bore

where it may become lodged. Firing a

subsequent bullet into the obstructed

bore will damage the rifle and may

injure the shooter and bystanders. Use

lubricants properly. You are responsible for the proper care and maintenance of your firearm.

WARNING: It is not recommended that

you disassemble the stock of the SU-16

rifle; the hammer spring is constantly

under tension and can easily injure you

or others. If the need arises to lubricate

the trigger assembly do so through the

access slot behind and in front of the

hammer.

Service

Should your SU-16 rifle require adjustment,

refinishing, or repair, it should be returned

unloaded to the factory. In shipping the SU-16

rifle, be sure to adhere to the following rules:

Individuals who wish to return the firearm for

service can do so by shipping via UPS prepaid.

No return authorization number is required.

Include a letter of instruction, full name,

address, phone number and the gun’s serial

number. This will insure prompt service and

handling. Once your rifle has been received,

anything other than warranty work, will receive

a quotation. You will be notified of full charges

and no work will commence before receiving

your approval of our quotation. Also see

Warranty Page for further instructions.

All quotations are payable by C.O.D., VISA,

M.C. or money orders only. No personal checks

accepted. Please return your SU-16 rifle to:

Kel-Tec CNC, Inc. Service Dept.

1475 Cox Road

Cocoa FL 32926

Page 21

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

This warranty is granted by Kel-Tec CNC

Industries, Inc. P.O. Box 236009, Cocoa, FL

32923. This lifetime warranty is effective from

the date of purchase and applies to the original

owner of a Kel-Tec SU-16 rifle.

Kel-Tec firearms are warranted to be free from

defects in material and workmanship. Any such

defects of which Kel-Tec receives written notice

by the original owner, will be remedied by KelTec without charge within a reasonable time

after such notification and delivery of the

product as provided below.

Warranty claims (in writing) and the gun

concerned should be delivered (transportation

charges pre-paid) to:

Kel-Tec CNC, Inc

Service Department

1475 Cox Road

Cocoa, FL 32926.

No return authorization number is required. In

addition, a copy of a bill of sale in the owner’s

name, or a copy of ATF Form 4473, indicating

date of purchase must be included.

Transportation and insurance charges for return

to owner will be paid by Kel-Tec if the claim is

covered by the warranty.

Under no circumstances shall Kel-Tec be

responsible for incidental or consequential

damages with respect to economic loss or

injury or property damage, whether as a result

of breach of express or implied warranty,

negligence or otherwise. Some states do not

allow the exclusion or limitation or incidental or

consequential damages, so the above limitation

or exclusion may not apply to you.

Kel-Tec will not be responsible for defects

resulting from careless handling, unauthorized

adjustments or modifications, defective or

improper ammunition, corrosion, neglect,

abuse, ordinary wear and tear, or unreasonable

use.

In order to expedite service, warranty claims

should state the model and serial number of the

gun concerned and a description of the difficulty

experienced. It is recommended that shipments

be insured by the owner, since Kel-Tec will

accept no responsibility for loss or damage in

transit.

Page 22

100-BARREL

SU-16 RIFLE PARTS LIST

102-BARREL NUT

104-BARREL EXTENSION

108-BARREL RETAINER

110-BOLT

112-EXTRACTOR

114-EXTRACTOR AXIS

116-EJECTOR

118-FIRING PIN

120-BOLT CARRIER

122-OPERATING HANDLE

124-PISTON ROD

126-CAM PIN

128-RECOIL SPRING CATCH

130-PISTON HEAD

132-RECOIL SPRING TUBE

134-FIRING PIN PIN

136-GAS BLOCK

138-GAS HEAD

140-TRIGGER BLOCK

142-HAMMER

144-SEAR

145-SEAR SPRING PIN

146-SAFETY

148-FOREND AXIS

150-STOCK SPACER-16

154-STOCK SPACER-29

158-ASSEMBLY PIN

159-MAG SNAP PIN

172-FOREND LOCK SPRING

174-RECOIL SPRING

176-MAGAZINE CATCH SPRING

180-SEAR SPRING

182-TRIGGER SPRING

186-STOCK PIN SPRING

188-MAGAZINE SNAP SPRING

190-BOLT STOP SPRING

192-FOREND SPREADER SPRING

194-EXTRACTOR SPRING

196-EJECTOR SPRING

198-MAGAZINE SPRING

202-RECEIVER

204-MAG WELL

206-FRONT SIGHT

208-TRIGGER

212-STOCK-RIGHT

214-STOCK-LEFT

216-RECEIVER SPACER

218-FOREND-RIGHT

220-FOREND-LEFT

226-FOREND LOCK

228-BOLT STOP

230-REAR SIGHT

232- REAR SIGHT LOCK

234-MAG CATCH

236-FRONT SIGHT SCREW

240-FRONT SIGHT POST

244-RECOIL PAD

252-MAGAZINE HOUSING

254-MAGAZINE FOLLOWER

256-MAGAZINE PLATE

258-MAGAZINE BOTTOM

268-SAFETY/OPERATION MANUAL

274-EJECTOR PIN

276-RECEIVER SCREW

278-RECEIVER WASHER

280-TRIGGER AXIS

282-HAMMER AXIS

284-BARREL EXTENSION PIN

286-FOREND PIN

288-F.E. LOCK RETAINING RING

290-MAG SNAP E-RING

292-GAS HEAD PIN

294-O’RING

296-PISTON PIN

298-SEAR PIN

Loading...

Loading...