Page 1

KELLER

M

ANO

G

AUGE

/ M

ANO

R

ECORD

RANGE SERIAL-NO. PROGRAM-VERSION DATE

Page 2

GENERAL DESCRIPTION PAGE 1

OPERATION PAGE 2

MEASURING MODE /C

OMMAND STRUCTURE

MANO-MODE P

AGE 3

S

ETTING NEW ZERO

REFERENCE

ZERO-MODE PAGE 4

ADJUSTING THE MEASURING CYCLE

MECY-MODE PAGE 5

SELECTION OF DISPLAY

DISE-MODE*PAGE 6*

SELECTION OF VALUES TO BE MEASURED

SAVS-MODE*PAGE 8*

PREPARING THE STORAGE PARAMETERS

REC-SEL-MODE*PAGE 9*

STARTING THE RECORDING

REC-MODE*PAGE 10 *

READ-OUT OF THE STORED VALUES PAGE 11

NOTES PAGE 12

INSTRUMENTS WITH ANALOG OUTPUT PAGE 13

TECHNICAL DATA PAGE 14

PRESSURE GENERATION OPTIONS PAGE 15

DECLARATION OF CONFORMITY PAGE 16

*= Mano Record only

LIST OF CONTENTS

Page 3

GENERAL DESCRIPTION

1

The KELLER Intelligent Manometer is a precise

pressure measuring instrument. Its high accuracy, solid construction and its long battery life

make it to an ideal measuring instrument, especially for measuring tasks where independence

and flexibility are required.

In its standard version, the pressure transducer

is built into the housing as shown below. The

transducer is retained with a counternut.

Mounting:

Screw the male port of the Intelligent Mano-

meter into the female pressure port and tighten

using the lower hexagon of the transducer.

Adjusting the face:

Loosen the upper hexagon of the counternut

and rotate the Intelligent Manometer to the desired position. Retighten.

The face of the Intelligent Manometer can be

rotated through 355°. This feature allows the

Intelligent Manometer to be mounted in all possible positions; vertical, horizontal or upside

down.

The splash-proof cover of the Intelligent Mano-

meter is sealed with an O-ring and may easily

be removed by hand by turning the display ring

beyond the limit stop (see “ Battery Change” in

Chapter “Notes” ” on page 12).

KELLER

KELLER

Page 4

OPERATION

Depressing the front key ( marked by a pointed

triangle) sets the Intelligent Manometer into

operation.

After turning on the instrument, all segments of

the display flash three times for operational test.

Between the segment tests, the Intelligent

Manometer displays:

- the measuring range on the upper display

(i.e. 20.00)

- the software program number on the middle

display (MR01 )

- the year and calendar week of the program

version (94:23) on the lower right display

2

KELLER

After this test, the instrument will lead into the

function from which the instrument was previously turned off.

All commands are selected with the front key.

When the front key is depressed and held, all

commands appear in succession. Releasing

the front key executes the displayed command.

This cycle ( constantly depressing the front key

and letting go the key at a desired command) is

subsequently called activation.

Page 5

MANO-MODE / COMMAND STRUCTURE

3

The Mano-Mode is the standard mode of the

Intelligent Manometer. Since the function of

secondary displays can be selected (see Dise-

Mode), the individual segments are described

with the peak- and trough pressure display:

The arrow with a flashing minus sign re-

presents a “1”, i.e. at 10bar in the overpressure range (here 10.034bar).

The two lower displays can also show the temperature or the time since turn on ( more information see “Dise-Mode” on page 6/7).

The following commands, appearing in the shown

order, can be activated from the Mano-Mode:

Mano-Mode

EXE resets the peak- and

trough values

OFF turns off the instrument

EXE resets the peak- and

trough values

STEP* leads into the Record-Mode

OFF turns off the instrument

10 / 11 / 12 / 13 (not programmed / no function)

DISE* DIsplay SElect*

16 / 17 (not programmed / no function)

ZERO Permanent Zero Adjust

20 / 21 (not programmed / no function)

RECS* RECord Select*

24 / 25 (not programmed / no function)

SAVS* SAVe Select*

28 / 29 (not programmed / no function)

MECY MEsure CYcle (Adjusting

the measuring cycle)

32 / 33 / 34 … (not programmed / no function)

(The numbers shown are home positions. Activating these numbers will not execute any command.)

*= Mano Record only

= Sensor 1 is active

= HIGH flashes, when maximum pressure

is displayed

= Peak pressure

= Actual pressure

= LOW flashes, when minimum pressure

is displayed

= Trough pressure

Page 6

4

ZERO-MODE

The zero of the system can be adjusted with the

command ZERO.

Activate ZERO.

The display shows:

- Upper display: Actual pressure

- Lower left: ZEro

- Lower right: The actual zero

The zero is now ready to be reset. Activate

ZERO once more for permanent zero reset.

After setting the new zero, the Intelligent Mano-

meter returns to the mode it was prior to activating the ZERO-command.

Note:

If the above setting was activated by mistake,

turn off the instrument with the command OFF.

When restarting, the instrument will lead into

the Mano-Mode.

The Intelligent Manometer may be supplied fit-

ted with two sensors. Within ZERO, one has the

possibility to switch back and forth between the

two sensors with the command EXE. The arrow

on the upper left display points upwards if sensor 1 is active, downwards if sensor 2 is active.

After the selection of the desired sensor, the

zero of the corresponding sensor can now be

reset by activating the command ZERO.

Page 7

5

MECY-MODE

The measuring cycle can be adjusted between

once per second up to once per hour ( 59:59).

Longer measuring cycles extend the battery life.

STEP

Activate MECY.

The display indicates CYCL

and the lower right shows

the time in minutes and seconds.

The first digit flashes.

EXE increases the digits

(1, 2,…5).

STEP switches to the next

digit.

The second digit flashes.

EXE increases the digits

(1, 2,…9) etc.

Activating RES programmes the new selected

measuring cycle and switches back to the Mano-

Mode.

If the peak- and trough pressure are displayed,

the time period set here has no meaning. When

set in peak/trough mode, the instrument will

always measure in a 1/2-second interval.

MECY (MEsure CYcle) = Adjusting the measuring cycle.

Page 8

DISE-MODE

6

(MANO RECORD ONLY)

Display Select enables the selection of the display position, and allocates the measured parameter to the chosen display.

There are three selectable display positions:

Upper Display / Lower Left / Lower Right.

These displays can be occupied by the following variables:

Symbol Variable

1 Sensor 1

2 Sensor 2 (only if two sensors

are connected)

1-2 Difference (only if two sensors

are connected)

HIGH Peak Value for Sensor 1*

LOW Trough Value for Sensor 1*

25° Temperature

00:00 Time Meter

*If this variable is selected, the

instrument will always measure

in a 1/2-second interval, indepen-

dent from the set measuring cycle.

The selected configuration is valid for both the

Mano-Mode and the Record-Mode.

Please note that not all possible combinations

are programmable.

DISE (DIsplay SElect) = Selection of Display

Page 9

7

DISE-MODE

(MANO RECORD ONLY)

Programming of the display:

EXE

EXE

EXE

STEP

STEP

After activating DISE, the instrument displays

the actual settings. The display that is now flashing can be changed by activating EXE.

If another display possibility is to be adjusted,

activate STEP.

When all possibilities are defined to your needs,

you may return to the new configured Mano-

Mode from any position within DISE by activating RES.

Page 10

8

SAVS-MODE

(MANO RECORD ONLY)

The settings programmed in DISE, which are

now active, can be selected for storage under

SAVS. Only the variables which are selected

under SAVS will later actually be stored in the

Record-Mode.

Four different combinations of variables are

offered in the Mano Record. One of the following combinations can be selected with the

commmand EXE:

1. Only the variable of the upper display

2. The variable of the upper display and the

lower left display

3. The variable of the upper display and the

lower right display

4. All three variables

Note that the operating hours will never be stored

as an individual variable.

If you have nevertheless selected the operating

hours for storage, they will be neglected during

the storing cycle.

If peak- and trough measurements were selected

for storage, the Record-function will reset the

peak- and trough values after each measurement. Peak- and trough values are monitored

every 1/2 second, the max./min. values occurring during the measurement interval are stored.

RES

RES

RES

RES

EXE

EXE

EXE

EXE

SAVS (SAVe Select ) = Selection of the values to be stored in the Record-Mode.

Attention:

Each selected variable requires one storage place! If, for example, three variables are to be

measured, the available place will only last for 300 measurements (with three variables) instead

of 900 measurements with one variable!

Page 11

REC-SEL-MODE

9

(MANO RECORD ONLY)

RECS (REcord SElect) = Preparing the storage

parameters

Activating RECS leads either to Rec-Sel- or to

the Rec-Cont-Mode. The command STEP swit-

ches between these two modes. EXE initiates the

selected function.

In the Rec-Cont-Mode, continuous, endless storage can be activated (ON) and deactivated

(OFF). Record Continuous=ON means, that the

once started recording can only be interrupted

manually. Record Continuous=OFF means, that

only the specified number of values will be stored.

The Rec-Sel-Mode sets up the number of mea-

surements to be stored and to adjust the recording interval. The lower left display indicates the

number of measurements, the lower right display the recording interval in minutes and

seconds.

The value of the flashing digit can be increased

with the command EXE.

STEP switches to the next digit which may be

increased with the command EXE, and so on.

When continuous, endless storage is active

(Rec-Cont=ON), only the measuring cycle can

be adjusted. The lower left display therefore

indicates the message “cont” (for “continuous”)

instead of the numbers of values to be stored.

The command RES leads back to the Mano-

Mode, both from the Rec-Cont-Mode and from

the Rec-Sel-Mode. The new settings are now

made and are active in the Record-Mode.

RECS

EXE

EXE

RES

RES

RES

STEP

EXE

RES

Rec-Sel-Mode

Rec-Cont-Mode

EXE

EXE

Page 12

RECORD-MODE

10

(MANO RECORD ONLY)

In the Record-Mode, the measured values can

be stored. The measured parameters (see

SAVS-Mode), the number of measurements

and the interval ( in minutes and seconds ) are

programmable (see Rec-Sel-Mode).

Recording of measuring values:

Activating STEP during the Mano-Mode first

leads into the Prep-Mode (preparation mode)

showing the actual pressure, on the lower left

display the number of the values to be stored

and on the lower right display the measuring

cycle in minutes and seconds.

Activating EXE starts the recording of the measured values. During the recording, the lower

left display indicates the number of values yet to

be measured, the lower right display shows the

time remaining to the next recording.

The actual measured values are not shown between two recordings. They can be displayed by

activating EXE, without interrupting the recording.

The recording can be ended at any time by activating RES.

The display END indicates the end of the recording. Activate EXE to return to the Prep-Mode

or RES to directly access the Mano-Mode.

The starting and ending of the continuous, endless recording (see Rec-Sel and Rec-Cont)

takes place the same way. Except that such a

recording can only be ended with the command

RES.

STEP

EXE

RES RES

RES

EXE

EXE

Record-Mode

in action

Mano-Mode

REC finished

Prepare-Mode

Page 13

READ-OUT OF THE STORED VALUES

11

DATA TRANSFER TO

PC

(only with Logger-Option):

In order to transfer the data from the Intelligent

Manometer into the PC, the special cable K101

and special software is required. The transfer of

data is accomplished over the RS232 serial

interface connected to rear socket of the

Intelligent Manometer.

L

OGGER-SOFTWARE

This software serves to transfer the data to a

PC, offering many further processing possibilities of the read-out data.

The LOGGER-Software meets all the requirements of modern Windows-Software:

- Graphical Display

- Tabulated Display

- Export into other Windows-Programs

The transfer of the data always starts at the last

recording and can be extended to read out the

entire memory . The memory may be read out as

many times as needed. A detailed manual for

the LOGGER-Software is included when ordering with Logger-Option.

TIME ALLOCATION

After each recording the Intelligent Manometer

writes the status of the Manometer’s time meter

into the memory. When transferring, the absolute time-axis is calculated from the time set in

the PC, the time meter of the Manometer and

the recorded time. The Manometer should therefore not be turned off between the recording

and the transfer.

During the recording process, five additional

recording locations for the storage of time are

used for each complete recording cycle.

(MANO RECORD ONLY)

Page 14

12

NOTES

MEMORY

The function REC saves measured values into

the memory of the Intelligent Manometer. New

data is always archived after the last recorded

value, continuously filling the memory. Since

these instruments feature a ring-memory, new

data will only overwrite the oldest data. This

ensures that the maximum amount of most

recent data is always at your disposal when the

memory is full.

TOTAL STORAGE LOCATIONS

Standard: 900

Extended: 8000 (only with memory option)

RESTARTING THE INTELLIGENT MANOMETER

If the Intelligent Manometer program appears to

be locked (the instrument will not respond to

front key operations). This can be rectified by

disconnecting the battery for a period of longer

than 20 seconds. Follow the procedure for

changing the battery. Then restart the instrument.

OVERFLOW/OVERPRESSURE LIMIT

The Intelligent Manometer displays the pressure

until 5 to 10% above the rated pressure range.

If this range is being exceeded, the display indicates “OVFL” (overflow). Do not increase the

applied pressure any more!

If the pressure exceeds the indicated pressure range by more than 20%, the sensor

may be destroyed.

BATTERY CHANGE

Turn the display ring beyond the limit stop. It will

detach from the main housing. Disconnect the

battery connections and remove the old battery.

Insert the new battery with the same pin assignment. Set the display ring back in place.

Settings of DISE, ZERO, RECS, SAVS or

MECY will be lost when the battery is disconnected. The Intelligent Manometer will

revert to the original default/factory settings.

This feature can be used to reset the instrument

if necessary.

The Intelligent Manometer will not indicate a

battery low. If the display starts to fade, it’ s an indication that the battery charge is weakening. At

this point, we recommend changing the battery.

The batteries can be acquired from KELLER.

After a battery change, it is possible that the

recorded values cannot be interpreted correctly

by the Logger-Software! We therefore recommend that all data is downloaded and safely

stored on a PC before changing the battery.

Page 15

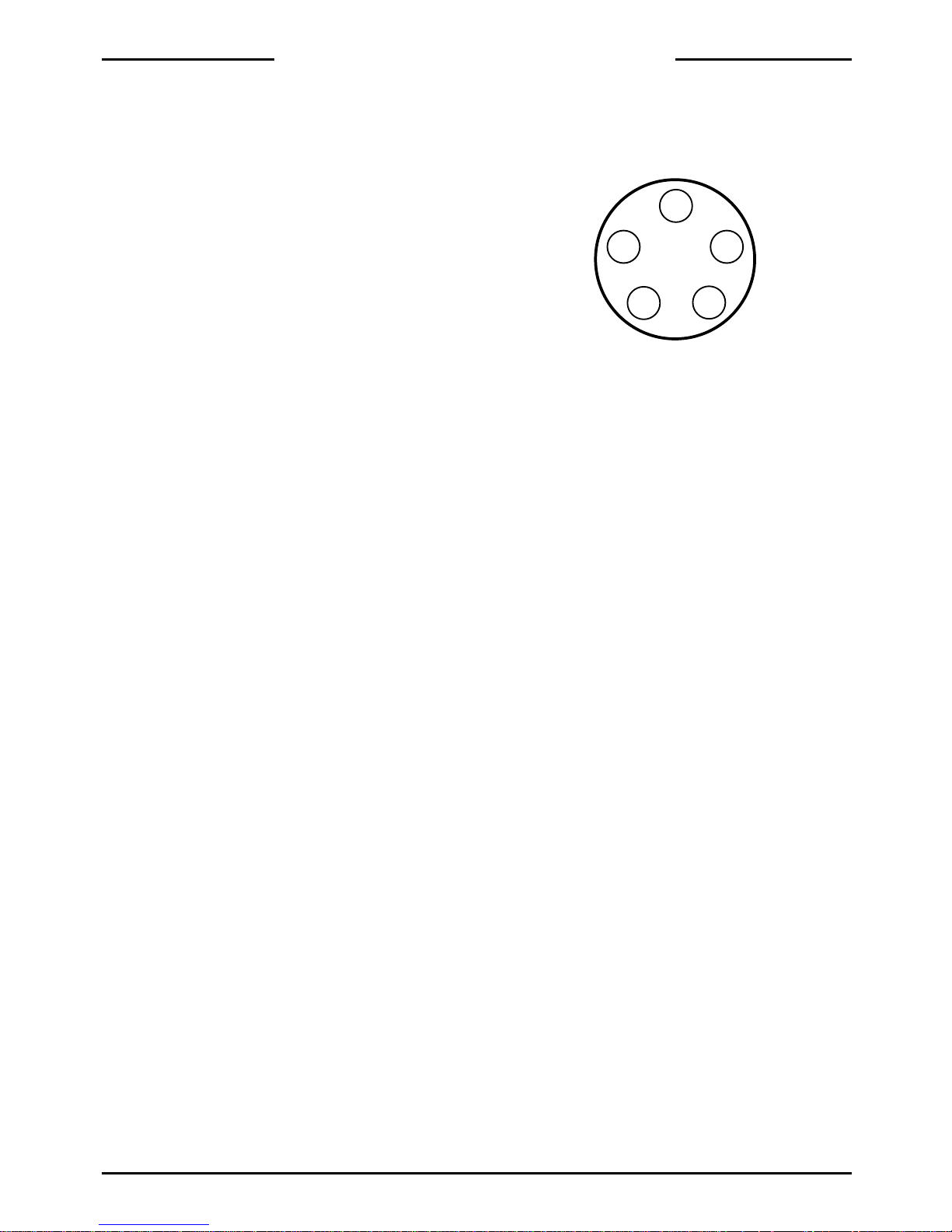

Rear Side:

INSTRUMENTS WITH ANALOG OUTPUT

13

The Intelligent Manometer may be supplied fit-

ted with an optional 0…10V or 4…20 mA analog signal output.

The analog signal output must be powered from

an external DC supply. The signal output will

only function when the supply is connected, it is

completely independent of the Intelligent

Manometer’s battery powered measuring circuits. A battery is still required to power the

instrument.

The connector for the external power supply is

located on the rear side of the Manometer housing. The corresponding 5-pin plug is included

in delivery.

Pin Configuration: 0…10 V

Power Supply: 13…18 VDC

1 = +SUPPLY

2 = +SIGNAL 0…10V

3 = GND

4 = free

5 = free

Pin Configuration: 4…20 mA

Power Supply: 8…28 VDC

1 = +SUPPLY

2 = free

3 = OUT/GND

4 = free

5 = free

1

2

3

4

5

Page 16

TECHNICAL DATA

14

Total Accuracy of displayed Pressure

(1)

Overpressure

Measurement Cycle

Displayed Temperature

Storage Temperature

Operating Temperature

Compensated Temperature Range

Air Humidity

Memory

Power Supply of Electronics

Battery-Life

Total Weight, including Batteries

Media Compatibility

Protection

(1)

Includes linearity, repeatability, hysteresis, temperature

error and resolution of the display

typ. ±0,1% FS, ±1 Digit (at 20° C)

max. ±0,3% FS, ±1 Digit (from 0…50°C)

FS + 20%

1 Measurement per Second

Temperature of Reference Sensor in °C

-20…60°C

0…50°C

0…50°C

5…95% Relative Humidity

900 Storage Places (8’000 optional)

Lithium-Battery 3,6V (not rechargeable)

> 200 Days at Continuous Operation

250g

Pressure Transducer: Stainless Steel Diaphragm.

Electronics sealed with Gel.

IP 65

Page 17

PRESSURE GENERATION OPTIONS

HIGH P

RESSURE-PUMP P12

- Pressure generation up to 700bar

- Pressure media: Hydraulic oil (148cm

3

)

- High volume calibration

- Fine adjustment valve

- Ideal test equipment for manometers

and pressure transmitters

HIGH PRESSURE

-HANDPUMP HTP1

- Pressure generation up to 700bar

- Pressure media: Hydraulic oil or water

(100cm

3

)

- Fine adjustment valve

- Ideal test equipment for manometers

and pressure transmitters

HANDPUMP

K/P

- Pressure generation up to 20bar,

by switch down to -850mbar vacuum

- Fine adjustment valve

- Ideal test equipment for manometers

and pressure transmitters

L

OW PRESSURE BASE

- Pressure generation up to 20bar or

vacuum down to -850mbar

- Fine adjustment valve

- Air pump and vacuum pump included

in delivery

15

Page 18

DECLARATION OF CONFORMITY

Herewith we declare, that the following products or product range

MANO GAUGE / M

ANO RECORD

according to drawing 80124 and 80124.05

meet the basic requirements for the electromagnetic compatibility, which are established in the guidelines of the European Community (89 / 336 / EWG).

This declaration is valid for the products MANO GAUGE

or MANO RECORD, of which a drawing, marked with

the CE sign, exists, and which are produced according to this drawing. This explanation has no validity

without such a drawing.

As criteria for the electromagnetic compatibility, the following norms are applied:

EN - 50081 - 1

EN - 50082 - 1

This declaration is given for the manufacturer

KELLER AG für Druckmesstechnik

St. Gallerstrasse 119

CH - 8404 Winterthur

in full responsibility by

KELLER GmbH

Schwarzwaldstrasse 17

D - 79798 Jestetten

Jestetten / September 19, 1996

H.W. Keller

Geschäftsführer

with legally effective signature

16

Page 19

YOUR NOTES

Loading...

Loading...