Page 1

keller-druck.com

OPERATING INSTRUCTIONSOPERATING INSTRUCTIONS

DCX DATA LOGGERDCX DATA LOGGER

November 2013

1

Page 2

keller-druck.com

Table of contents

Product overview 3

Overview of structural designs, Series DCX 4

Measuring principle for Series DCX 5

General

Level measurement

Relative pressure measurement (VG)

Absolute pressure measurement (SG)

Absolute/absolute pressure measurement (A/A)

Level measurements in closed receptacles

Functionality of the Series DCX data logger 8

Data memory

Installation instructions 9

Important information

Guidelines on safe and efcient use

Warranty conditions

Data for repair and replacement

Disposal of old electrical equipment and batteries / rechargeable batteries

Fitting instructions 11

Requirements for the location

Installation in level tubes

Water level conguration

Installation of relative data logger (-VG versions)

Conguring and reading the DCX

DCX time

Verifying measured data

Device memory

Maintenance 16

Battery

Changing the battery, Series DCX

Watertightness

Rechargeable battery

Ventilation diaphragm

Moisture absorber cartridge

Cleaning 19

Cleaning the level sensor

Cleaning the air pressure sensor (-AA versions)

Calibration 20

Setting the zero point

Testing by the manufacturer

Level measurement with pressure sensors 20

Overview of DCX 22

Accessories 26

2

Page 3

keller-druck.com

Product overview

The data loggers in Series DCX are autonomous, battery-powered data collectors

which can measure the water level (water column, i.e. pressure) and temperature over

lengthy periods.

Series DCX is designed for level measurements and is generally used for long-term

data acquisition in applications with brackish water, salt water or fresh water.

Series DCX is also available with a connecting thread for process applications.

Various versions are available in Series DCX. The standard material is stainless steel,

316L (DIN 1.4435). For added resistance to media, the logger can be manufactured to

order from Hastelloy or titanium as options. The key distinguishing features of products in

Series DCX are their measuring methods and the diameter of the probe.

DCX-22 AA

Probe diameter

16 = Ø 16 mm

18 = Ø 18 mm

22 = Ø 22 mm

25 = Ø 25 mm

38 = Ø 38 mm

Version

.... Absolute pressure measurement / without cable

VG Relative pressure measurement / with cable

SG Absolute pressure measurement / with cable

AA Absolute pressure measurement with 2 sensors / with cable

PVDF For use in aggressive media.

Special housing made of polyvinylidene uoride (PVDF) with high

resistance to chemicals / Available for probe diameter of 25 mm,

without cable only

Maximum pressure ranges and cable lengths

Designation

DCX-16 absolute 0,8…11 bar abs.

DCX-16 VG relative 0…10 bar rel.

DCX-16 SG absolute 0,8…11 bar abs.

DCX-18 absolute 0,8…11 bar abs.

DCX-18 VG relative 0…10 bar rel.

DCX-18 SG absolute 0,8…11 bar abs.

DCX-22 absolute 0,8…11 bar abs.

DCX-22 Baro absolute 0,8…1.3 bar abs.

DCX-22 VG relative 0…10 bar rel.

DCX-22 SG absolute 0,8…11 bar abs.

DCX-22 AA

DCX-25 PVDF absolute 0,8…11 bar abs.

DCX-38 VG relative 0…

Measuring

principle

absolute/absolute

Max.

pressure range

0,8…11 bar abs.

300 mbar rel. 0…3 mH2O

Max. mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

0…100 mH2O

** For other system lengths, please contact our sales staff

3

Max. cable length**

–

500 meters

500 meters

–

500 meters

500 meters

–

–

500 meters

500 meters

80 meters

–

500 meters

Page 4

keller-druck.com

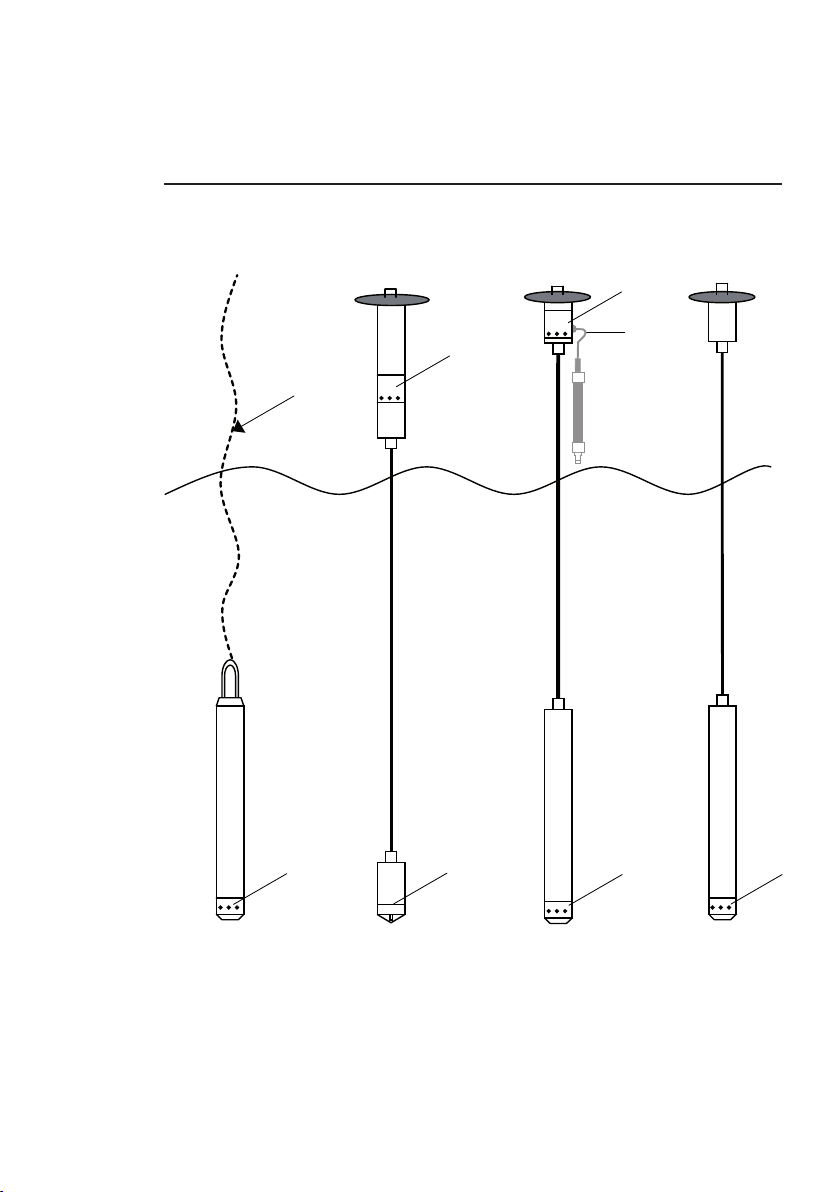

Overview of structural designs, Series DCX

Different versions of the autonomous data loggers in Series DCX are available from

KELLER in order to meet the requirements for the measuring point, the on-site environ-

mental conditions and the uid to be measured:

Series DCX-16

- probe diameter 16 mm

-VG -SG

Series DCX-18

- probe diameter 18 mm

- powered by rechargeable battery

- completely welded in

- screw-on cable

-VG -SG

Series DCX-22

- probe diameter 22 mm

- AA version

- high-accuracy version

- customized versions

-VG -SG -AA

on request

Series DCX-25 PVDF

- probe diameter 25 mm

- for use in aggressive media

Special housing made of polyvinylidene uoride (PVDF)

with high resistance to chemicals. Pressure sensor in

Hastelloy or titanium, according to choice

Series DCX-38 VG

- probe diameter 38 mm

- to measure low pressures or

levels (measuring ranges: 0,5 / 1 / 3 mWS)

- capacitive measuring cell with gold-plated

ceramic diaphragm

- Moisture absorber cartridge included in scope of delivery

4

Page 5

Measuring principle for Series DCX

keller-druck.com

Surface of

water

DCX-

-AA version -VG version -SG version

③

optional

②

Cable

capillary tube

Cable with integrated

①Level sensor

P1 = medium pressure [bar]

TOB1 = medium temperature [°C]

①

① ① ①

②Air pressure sensor

P2 = air pressure [bar]

TOB2 = air temperature [°C]

5

③Reference aperture

For physical compensation

of the ambient pressure (air pressure)

Page 6

keller-druck.com

Ambient pressure (Air pressure)

General information

Fluctuations in the groundwater level (or the levels of other uids) can be determined

and located precisely by measuring the prevailing (hydrostatic) pressure at a dened

depth below the surface of the water. To convert the pressure [bar] into the water

column level [mWS], it is only necessary to know the density of the uid.

Example pure water (H2O): 100 mbar ≈ 1,02 mWS

p = N/m2 =

h =

ρ

*

g kg/m3 *

m/s

mWS

2

p = hydrostatic pressure (0,1 bar = 10,000 N/m2)

ρ = density (kg/m3)

g = gravitational acceleration (m/s2)

h = height of water column (m)

Level measurement

In open systems, i.e. with the classical method of measuring

the lling level, the difference between the pressure acting

on the level sensor (total pressure) and the ambient pressure

acting on the water (air/atmospheric pressure in most cases) is

always measured. The pressure difference determined in this

Hydrostatic pressure

of the water

Total pressure

way corresponds to the hydrostatic water pressure.

As a result of this measurement method, the level measurement becomes independent

of weather-induced uctuations in air pressure that act on the surface of the uid. The

following methods of compensating for air pressure are available:

Relative measurement method (VG)

In the relative measurement method, the sensor cable has an integrated capillary tube

which provides the reference to the ambient air pressure directly on the level sensor.

The sensor pressure measured in this way is therefore physically compensated for air

pressure.

Advantage: high accuracy and resolution

Disadvantage: high ambient humidity at the measuring point may disrupt or interrupt

compensation for air pressure and, in extreme cases, may even damage

the level sensor (→ use moisture absorber cartridges)

6

Page 7

keller-druck.com

Air pressure

Absolute measurement method (SG)

With the absolute measurement method, the prevailing total pressure on the level sen-

sor is determined (= air pressure + hydrostatic water pressure). To compensate for

the inuence of uctuations in air pressure, a second data logger is positioned on the

surface as a barometer.

Advantage: very robust, impervious to ambient humidity

Disadvantage: no integrated air pressure compensation

Absolute/absolute measurement method (A/A)

Total pressure and air pressure are each determined by means of a pressure sensor

(A/A technology) and are calculated mathematically in the device by subtracting the two

measured values. A sensor cable without a capillary tube is used for this measurement

method, and this is why AA systems are highly resistant to the ambient humidity prevailing at the measuring point.

Advantage: very robust, impervious to humidity or ooding

Disadvantage: slight reduction in measurement accuracy because of measurements

by two sensors

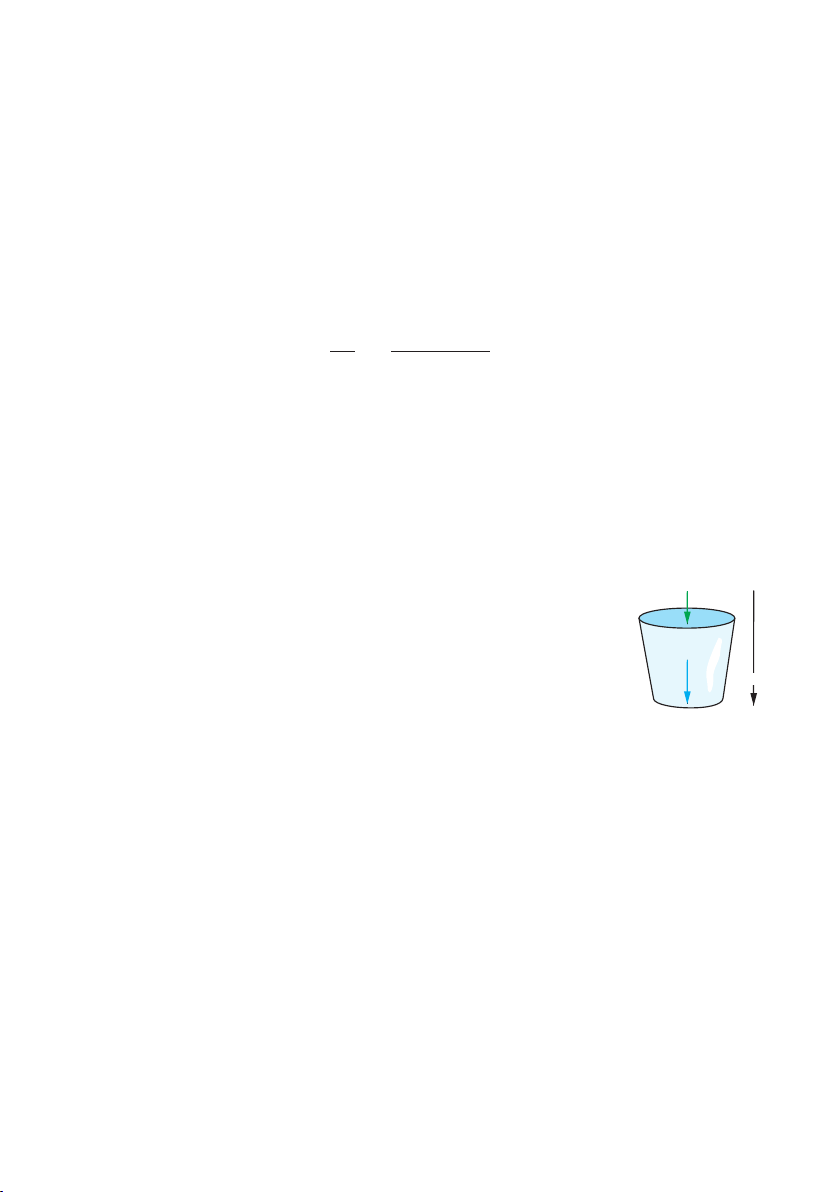

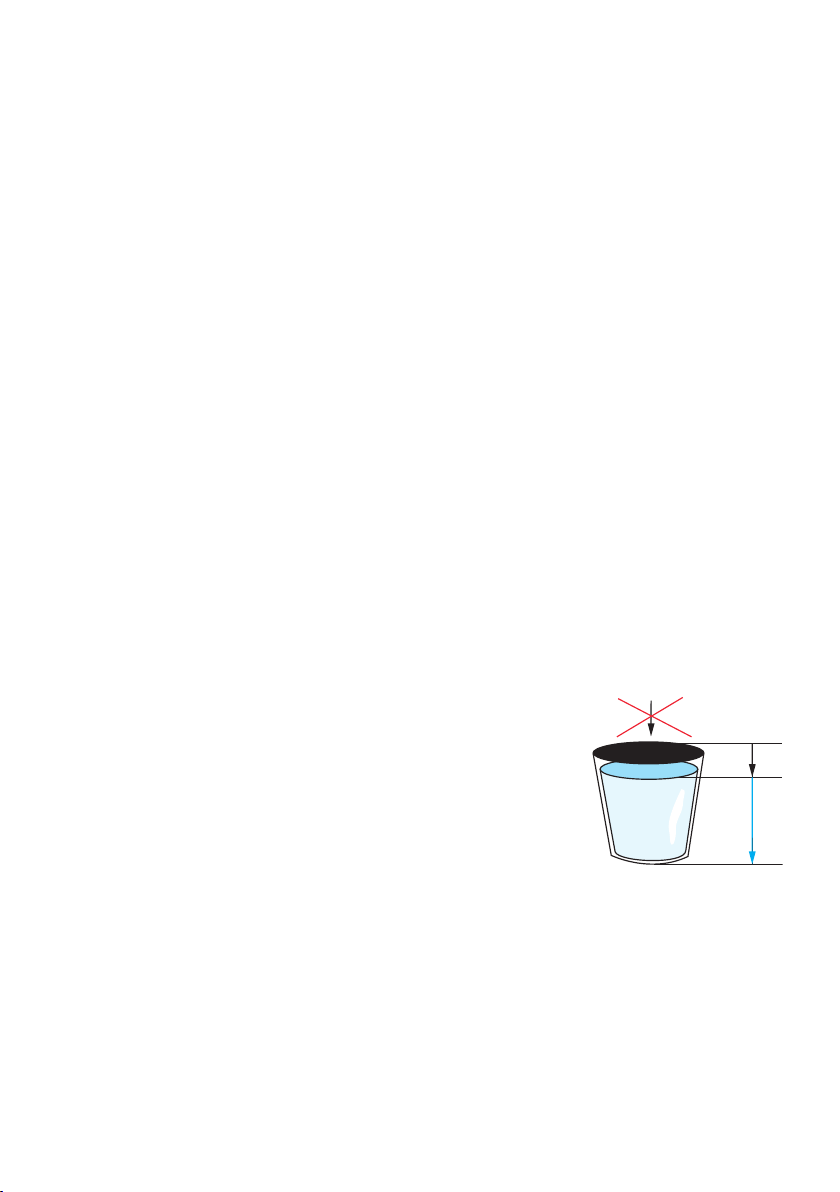

Level measurements in closed receptacles

For level measurement in closed receptacles/vessels,

the internal pressure in the vessel is measured instead of

the air pressure. The A/A measurement method is usually

selected on account of the humidity prevailing inside the

vessel.

7

Internal

pressure

Water

pressure

Page 8

keller-druck.com

Functionality of Series DCX

Autonomous data loggers in Series DCX record the values measured for pressure and

temperature together with the time of each measurement.

The following types of recording and initial conditions are supported:

Recording interval Constant

storage interval

Event-controlled

recording

Initial conditions Directly after programming is completed

Specied, user-dened time

Recording starts when a value has been undercut

Recording starts when a value has been exceeded

→ Constant storage interval and event-controlled recording can be used simultaneously

Interval ≥ 1 second

If value is exceeded

If value is undercut

If value changes

Data memory

The following table gives an overview of recording periods for various constant

measurement intervals. (Data memory size: 2 Mbit)

Type Interval Number of

channels

DCX-22 1 sec 1 Total pressure > 15 h 54 min

DCX-22 1 min 1 Total pressure > 21 h 7 h

DCX-22 1 h 1 Total pressure > 3 y 6 m

DCX-22 1 sec 2

DCX-22 1 min 2

DCX-22 1 h 2

DCX-22 1 d 2

DCX-22AA 1 sec 5 Air pressure and air temperature,

DCX-22AA 1 min 5 Air pressure and air temperature,

DCX-22AA 1 h 5 Air pressure and air temperature,

DCX-22AA 1 d 5 Air pressure and air temperature,

Measurement channel Recording period

Total pressure and medium temperature

Total pressure and medium temperature

Total pressure and medium temperature

Total pressure and medium temperature

total pressure and medium tempera-

ture, calculated water column level

total pressure and medium tempera-

ture, calculated water column level

total pressure and medium tempera-

ture, calculated water column level

total pressure and medium tempera-

ture, calculated water column level

> 7 h 57 min

> 14 d 4 h

> 2 y 4 m

> 56 y 9 m

> 3 h 10 min

> 7 d 2 h

> 1 y 2 m

> 28 y 4 m

8

Page 9

keller-druck.com

Installation instructions

Important information

KELLER website

At www.keller-druck.com, you will nd a software section where you can download

all KELLER’s software programs free of charge. The site contains the latest software

versions together with datasheets and operating instructions for the corresponding

products.

Service and Support

For service and support, please contact your local dealer or contact us at www.kellerdruck.com

Guidelines on safe and efcient use

• Treat the product with care and keep it in a clean place that is free of dust.

• This product must only be used within the specied temperature range

(→Product datasheet)

• Do not drop or throw the device

• Do not attempt to modify the device

• The sensor pressure diaphragm is sensitive to contact. Do not press the diaphragm in

by hand or damage it with sharp objects. Do not direct water jets at the diaphragm.

• Only use this device for non-ammable uids with no explosion hazard. KELLER

offers a series of measurement equipment products suitable for use in areas with

explosion hazards (ATEX zones). For more information, please contact our sales

staff.

•

Aggressive media may damage the product. Make sure that the materials in the product

are not attacked by the medium to be measured.

• With relative versions (VG), the end of the cable must be located in a dry environment

in order to prevent condensation forming. If the cable ends in a humid environment, it

is highly advisable to use moisture absorber cartridges.

9

Page 10

keller-druck.com

• The level measurement sensor must not freeze up in the medium

• Do not glue, block or contaminate any ventilation components as this will substantially

impair measurement accuracy.

• Fasten/secure the product so that the logger cannot fall into the measuring point in

case of a handling error.

Warranty conditions

The warranty does not apply to faults on the device caused by normal wear, incorrect

use or misuse, or failure to comply with KELLER’s instructions.

Data security

KELLER assumes no responsibility for data loss of any nature, and shall not pay com-

pensatory damages in case of data loss. Data stored in the product may be lost if the

product is repaired or replaced. You should always create a backup of all data stored in

the product before releasing it for repair or replacement.

Disposal of old electrical equipment and batteries / rechargeable batteries

To prevent possible damage to the environment or to health due to uncontrolled waste

disposal, this product must be separated from other waste and recycled correctly in

order to ensure sustainable use of the raw materials. Remove rechargeable

batteries that have been installed permanently. Permanently installed rechargeable batteries must be removed only by a waste processing facility or a trained service technician.

10

Page 11

keller-druck.com

Fitting instructions

Requirements for the location

The DCX logger unit is installed in a stable position at the measurement location

in order to record a groundwater level.

• If the logger is fully sunk into the ground (e.g. in a sewer shaft), free movement of

the water level in the tube must be ensured by above-ground openings (ventila-

tion apertures)

• Lateral movements of the level sensor may cause measuring errors or cable

breaks. For these reasons, t the level sensor in a calm zone or in a suitable

protective tube

• On VG versions, the sensor cable contains a capillary tube to compensate for

atmospheric pressure. Therefore, position the cable end of VG versions in a dry

area or use moisture absorber cartridges

Installation in level tubes

Place the cap lock in position and screw the two grub screws in to prevent it from

turning (anti-theft protection)

→

requires a slotted screwdriver, size 2 (not included in the scope of delivery)

Guide the sensor with the sensor cable into the level tube by hand. The sensor

cable must be free and extended as it hangs in the level tube; it must not change

its position as this would falsify the measurement results.

→

For system lengths of more than 50 m, cable strain relief is recommended,

e.g. using a straining clamp (see Accessories)

Screw the matching adapter ring onto the read-out unit. After installation, the

adapter ring will lie on the edge of the level cap lock. Secure the logger unit in the

adapter ring using the circlip supplied with the product.

→

requires circlip pliers (not included in the scope of delivery)

11

Page 12

Reference level

Air Gap

System length

Water

surface

Level

Sensor

reference line

keller-druck.com

The DCX logger can be connected locally to a laptop via the interface converter

cable.

The Logger 5 software can now be used to congure the device or to transmit the

measurement data stored in the DCX to the laptop.

→

Seal the read-out plug with the protective cap

Water level conguration

The surface of the interface plug integrated into the DCX represents the system’s reference level. The measuring system is calibrated during installa-

tion. For this purpose, the run-off distance is measured (reference levelsurface of water, e.g. using a light plummet) and is entered in the water level

conguration in the Logger 5 software together with the density of the medium.

The system length is the sum of the hydrostatic water pressure measured at the

level sensor and the distance from the reference level that is entered.

After completing work on the measuring point, close the level tube seal by screwing in the hexagon socket.

→

Allen wrench, size 5 (not included in the scope of delivery)

Tip:

To give the measuring point better protection against access, the Allen screw head

can be replaced by a screw head that is not available through usual commercial

outlets.

12

Page 13

keller-druck.com

Installation of relative data logger (VG versions)

Ambient pressure is compensated physically on VG versions. The ambient pressure is fed to the back of the pressure sensor on the level sensor, via a capillary

tube integrated into the sensor cable.

If pressure compensation via the capillary tube is impeded or prevented by contamination or moisture inside the capillary tube, the result of the level measure-

ment will be affected.

Standard version

The pressure compensation aperture is located be-

hind the removable protective tube, which is perforated.

This opening for the cable capillary is protected against water

penetration by a Goretex® diaphragm.

A thread to insert moisture absorber cartridges is provided on

the plug component of VG versions (minimum inner diameter

of tube: Ø 35 mm). It is advisable to use moisture absorber

cartridges for measuring points with harsh ambient conditions.

→

section: Maintenance / Moisture absorber cartridge

Moisture absorber cartridge

13

Version with moisture

absorber cartridge

(DCX-38 VG)

Page 14

keller-druck.com

Conguring and reading the data logger

The DCX is congured and read locally. The DCX is tted in the measuring point and is

connected to a laptop via the interface converter cable.

• The Logger 5 Software Manual is available at www.keller-druck.com

Installing the software

Only connect the DCX and the converter cable to your computer after the software has

been installed

• Install the KELLER “Driver K-104 K-114� software

• Install the KELLER “InstallerLogger5� software

→

The connection must not be broken during communication with the DCX (congura tion, data read-out). Always close the software program rst, and only then unplug

the DCX connection.

DCX time

The internal time for the DCX

is set by synchronization with

your computer’s (PC) time. To do this, enable the “Synchronize device time with PC

time“ eld in the Logger 5 software and then register the conguration on the DCX. The

DCX’s internal clock does not take account of summer time/winter time changeovers.

UTC (Universal Time Coordinated)

It is advisable to set the computer’s time zone to UTC.

Since UTC does not implement time corrections, the DCX’s measuring times remain

unchanged throughout the year and they can be converted to local time if necessary.

Time zones

If your computer’s time is assigned to a time zone (e.g. UTC +2), the PC clock will

change over automatically between summer and winter time.

Time corrections / changeovers of the DCX’s internal clock only take place if it is

synchronized with the computer (“Write conguration�).

Tip:

Congurations are only sent to the logger when you press the “Write conguration�

button. You can read the device conguration into the Logger 5 software again to check

the DCX settings.

14

Page 15

Verifying measured data

Ongoing measurements can be read out

with no need to interrupt the measurement

sequence.

As you read ongoing measurements, you

can set a ag (the measurement in progress

will be terminated and a new measurement

will be started immediately) or you can continue the ongoing measurement.

Continue measurement: disable the “Synchronize device time with PC clock� eld and select

“Do not set ag�.

Tip: Verify online measured values directly, e.g. using a light plummet.

Device memory

Storage space management in the DCX is

handled automatically, and the memory can-

not be managed or deleted by the user.

keller-druck.com

Continuous (circular buffer)

The “Continuous� function (circular buffer) releases the data logger’s entire storage

space for the measurement in progress. As soon as the DCX’s storage capacity is

reached, the oldest saved measurement values (for the measurement in progress) are

overwritten by the latest measured values, until recording is stopped by the user.

Linear

The “Linear� function releases the data logger’s entire storage space for the measurement in progress and terminates recording automatically as soon as the entire memory

has been lled with entries.

Data read in

Measured data that are read via the Logger 5 computer software are stored automatically on the computer in a directory that can be freely chosen.

15

Page 16

keller-druck.com

Maintenance

Dry the DCX thoroughly before opening it and make sure that the surrounding area

is dry while handling the device. Check all the sealing rings for signs of wear, dirt and

damage before using the logger unit again.

Battery

The battery status is not measured; instead, it is calculated using the averaged power

consumption. If the battery is changed or in case of a “Power on� reset, the display is

reset to 100%. This also happens if the same battery is inserted again, or if a dis-

charged battery is inserted.

To ensure that the logger operates reliably, it is advisable to replace the battery as soon

as its capacity falls below 30%, or after 5 years of operation.

Changing the battery, Series DCX

Type designation Supply Battery type KELLER product no.

DCX-16 Battery Lithium battery (type AAA) 557005.0017

DCX-22 Battery Lithium battery (type AA) 557005.0006

DCX-25 PVDF Battery Lithium battery (type AA) 557005.0006

DCX-38 VG Battery Lithium battery (type AA) 557005.0006

→

DCX-18: power is supplied by a rechargeable battery (cannot be exchanged)

Battery DCX-16

Lithium battery (type AAA)

KELLER product no. 557005.0017

Battery Series DCX

Lithium battery (type AA)

KELLER product no. 557005.0006

Batteries must never be disposed of in normal household waste. To prevent possible

damage to the environment or to health due to uncontrolled waste disposal, this product

must be separated from other waste and recycled correctly in order to ensure sustainable use of the raw materials.

16

Page 17

keller-druck.com

Battery plug Sealing rings

Vor öffnen Datenlogger trocknen! Keep dry before opening!

Battery sleeve Knurled nut

To replace the battery, rst unscrew the knurled nut and then pull off the battery sleeve.

Carefully disconnect the battery from the plug and replace it.

After changing the battery, guide the plug into the opening in the sleeve, push the bat-

tery in and x it in the clip. Check the sealing rings. Re-t the battery sleeve, knurled

nut and xture.

Check the conguration (time, measurement interval, etc.) of the DCX via the Logger 5

software before using the product.

Watertightness

Products in the Series DCX logger are dustproof and are protected against the effects

of immersion in water (according to the pressure range).

The products are also protected against water splashes in the area of the read-out component.

Exceptions: AA products: may be ooded for brief periods

DCX-22: continuous/long-lasting immersion

→

Please consult the datasheet for the precise specications.

Check that all sealing rings are clean and undamaged, and that the battery compartment cover is rmly closed so that the Series DCX device is watertight.

Rechargeable battery

Type DCX-18 is powered by a rechargeable battery which can only be charged using

interface cable K-114M. The rechargeable battery is welded into the device and cannot

be exchanged. The status of the rechargeable battery is determined by measuring its

voltage. Avoid letting it discharge to a value of less than 10%. If the DCX is not being

used, recording should be stopped and the rechargeable battery should be recharged

once per year to prevent total discharge.

Type of

charging

normal USB max. 20 m 90 mA ~ 8.5 h

fast Power unit max. 100 m 790 mA ~ 1 h

Supply System length Charging current

(rechargeable

battery)

17

Charge time (full charging)

Page 18

keller-druck.com

Ventilation diaphragm (for VG versions only)

The diaphragm used for ventilation generally requires no maintenance.

The ventilation function of the diaphragm is impaired by matter adhering to or contami-

nating the ventilation aperture, or by contact between the diaphragm and solvents, to

such an extent that it may be necessary to replace the diaphragm. Test measurements

are carried out to verify the pressure compensation function.

Tip:

If blowing into the ventilation element during online measurements causes the value to

change visibly, the ventilation diaphragm is in proper working order.

Moisture absorber cartridges (optional)

The condition of the moisture absorber cartridge can be determined from the coloration

of the granulate. Blue = granulate is dry, pink = granulate is moist.

The granulate can be regenerated for re-use. To do this, pour the granulate from the

cartridge into a suitable container and dry it for 1 hour at 210 °C. The granulate releases

moisture into the surrounding environment and takes on a blue color again. After drying,

the granulate should be poured back into the absorber cartridge while it is still warm.

Note: The color of the granulate is less marked after regeneration than before because

the indicator inside the granulate particles migrates.

Input

ambient pressure

Moist granulate = pink Dry granulate = blue

18

Ventilation-DCX

Page 19

keller-druck.com

Cleaning

If the data logger is used in severely contaminated media, the pressure sensor

must be checked for contamination from time to time, and must be cleaned as

necessary. Never use sharp-edged tools such as screwdrivers, and never apply

pressure at any point on the diaphragm.

Cleaning the level sensor

The protective cap over the pressure sensor on the level sensor can be removed

by hand. Then rinse the sensor in owing lukewarm water.

The pressure sensor diaphragm is very sensitive.

Do not touch the diaphragm!

Cleaning the air pressure sensor (-AA versions)

To clean the pressure sensor as thoroughly as possible, remove the knurled nut,

battery sleeve and the protective sleeve of the sensor, and then re-install the bat-

tery sleeve, the protective cap for the interface plug and the knurled nut (without

the protective sleeve for the sensor) so that the electronics are protected against

water and moisture.

Rinse the sensor with clean lukewarm water. After cleaning and before tting the

sleeves, make sure that all parts are dry.

The pressure sensor diaphragm is very sensitive.

Do not touch the diaphragm!

19

Page 20

Calibration

Plug for converter

cable

keller-druck.com

Setting the zero point

The pressure sensors built into the logger unit can be calibrated by the user. It may

be necessary to recalibrate the pressure sensors, for example after maintenance

work, if the measurement set-up is changed, or after the measuring station has

been operated for a year or more.

Calibration is carried out with the Logger 5 software.

Recommended interval between calibrations: 1–2 years.

When carrying out a calibration, note that the sensors must be checked/calibrated

in the same positions as they occupy in the measuring point (usually upright) and

they must be positioned next to each other at the same level.

Testing by the manufacturer

The DCX may also be sent to KELLER AG für Druckmesstechnik in order to

verify its measurement accuracy or for calibration. The following test options may

be chosen: simple check on the DCX without documentation, internal check with

documentation (5- or 11-point test protocol) or an internal check followed by external certication (DKD [German Calibration Service] or SCS [Swiss Calibration

Service] calibration certicate).

Data logger

(Charges are payable for checks/verications, calibrations, protocols and certicates)

Level measurement with pressure sensors

Series DCX devices measure and store the hydrostatic pressure of a uid in bar.

The density of the medium has a decisive inuence on the conversion of the pressure [bar] to the water column level [mWS]. The height of the water column is

calculated with the following formula in the Logger 5 software:

p = 10000 N/m2 =

h =

ρ

*

g 998,207 kg/m3 *

9,80 m/s

2

1,021 mWS

P = hydrostatic pressure (0,1 bar = 10’000 N/m2)

ρ = water density (kg/m3) = 998,207 kg/m3 @ 20°C

g = gravitational acceleration (= 9,80665 m/s2)

h = height of water column (m)

20

Page 21

Density [ρ] of the measured medium

keller-druck.com

The density of uids is temperature dependent. The density of most uids decreases in

linear proportion to the temperature. However,

water reaches its highest density at 3.98 °C;

above and below this temperature, the density

of water decreases. This phenomenon is also

referred to as the “density anomaly of water�.

1000.0

999.0

998.0

997.0

996.0

995.0

Density [kg/m3]

994.0

993.0

992.0

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41

Anomalous density

Temperature [°C]

Make sure that the correct density of the measured medium is entered in the logger

software in order to calculate the level.

The density entered in the logger software is static. Changes in the temperature of the

measured medium and the associated change in density are not taken into account

when calculating the water level because this could result in misinterpretations of the

measurement result on account of the heterogeneous temperature distribution in bodies

of still water.

In normal cases, the temperature distribution is heterogeneous, so the temperature

dependency can be neglected. In case of homogeneous temperature distribution and

major temperature changes, however, a conversion error between pressure [bar] and

level [mWS] occurs due to the density that is stored as a static value.

Temp. [°C] Pressure

[bar]

4 0,5 999,975 5,0987 m 0 cm

10 0,5 999,702 5,1001 m + 0,14 cm

15 0,5 999,103 5,1032 m + 0,45 cm

20 0,5 998,207 5,1077 m + 0,9 cm

25 0,5 997,048 5,1137 m + 1,5 cm

30 0,5 995,65 5,1209 m + 2,22 cm

Density [kg/m3] Calculated water level Error at 5 mWS [cm]

(Water, temperature range 0...30 °C, pn = 1013 kPA).

21

Page 22

DCX overview

keller-druck.com

DCX-16 DCX-16 VG

1

1

2

3

4

5

7

8

9

13

11

Vor öffnen Datenlogger trocknen! Keep dry before opening!

14

3

4

5

7

12

11

Vor öffnen Datenlogger trocknen! Keep dry before opening!

15

DCX-16 SG

1

14

3

4

5

7

12

11

Vor öffnen Datenlogger trocknen! Keep dry before opening!

15

No. Designation

1 interface plug RS485

2 Sealing ring for interface plug

3 Sealing ring for battery compartment

4 DCX-22…38 VG: AA lithium battery

4 DCX-16: AAA lithium battery

5 Battery plug

6 Air pressure sensor

7 Sensor reference line

8 End cap

9 Fixture with hook to secure the suspended cable

8

8

KELLER product numbers are shown in the list of

accessories (starting on page 26).

22

Page 23

keller-druck.com

DCX-18

1

2

7

8

9

DCX-18 VG

1

13

2

7

8

DCX-18 SG

1

12

2

15

7

8

12

15

No. Designation

10 Knurled nut

11 Battery sleeve

12 Cap lock for interface plug

13 Ventilation aperture (only present on VG versions)

14 Screw nut

15 Circlip

16 Sealing ring for battery compartment DCX-25 PVDF, 15,5 x 1,5 NBR

17 Sealing ring for battery compartment DCX-25PVDF, 16 x 2 Viton

®

18 Plastic housing component

19

Humidity absorber cartridge, opt. Included in the scope of delivery for DCX-38

23

KELLER product numbers are shown in the list of

accessories (starting on page 26).

Page 24

keller-druck.com

DCX-22

1

2

3

4

5

3

9

10

11

Vor öffnen Datenlogger trocknen! Keep dry before opening!

DCX-22 AA DCX-22 VG

1

12

10

3

4

5

3

6

11

Vor öffnen Datenlogger trocknen! Keep dry before opening!

15

13

14

3

4

3

1

12

10

11

5

Vor öffnen Datenlogger trocknen! Keep dry before opening!

15

7

8

7

8

7

8

24

Page 25

keller-druck.com

DCX-22 SG

1

14

3

4

5

3

1

12

10

Vor öffnen Datenlogger trocknen! Keep dry before opening!

16

4

5

16

17

11

7

DCX-25 PVDF

18

15

DCX-38 VG

1

13

Vor öffnen Datenlogger trocknen! Keep dry before opening!

11

14

3

4

5

3

12

19

10

11

Vor öffnen Datenlogger trocknen! Keep dry before opening!

8

15

7

7

8

15

25

Page 26

Accessories

DESCRIPTION SCOPE OF DELIVERY PRODUCT NO.

keller-druck.com

Software CD Supplied with product

Contains all KELLER software

including USB driver for

K-114/K-104

Can be downloaded free of

charge at:

www.keller-druck.com

Adapter rings for DCX Optional

(can be supplied as an option)

Suitable for

- DCX-16 SG/VG

- DCX-18 ECO (SG/VG)

- DCX- 22 SG/VG

- DCX-22 AA

- DCX-38 VG

750505.0001

X

9 mm

Y

Dimen-

sions

[mm]

x y Drawing no. Product no.

30

25 33386 pos. 1 506810.0006

40

25 33386 pos. 2 506810.0018

49

39 33386 pos. 3 506810.0015

55

50 33386 pos. 4 506810.0019

60

55 33386 pos. 5 506810.0014

65

55 33386 pos. 6 506810.0020

35

32 33386 pos. 8 506810.0022

37

32 33386 pos. 9 506810.0025

42

32 33386 pos. 10 506810.0026

76

32 33386 pos. 11 506810.0027

125

32 33386 pos. 12 506810.0030

26

Page 27

DESCRIPTION SCOPE OF DELIVERY PRODUCT NO.

Cap lock, DCX Optional

2”

3”

4”

5”

6”

Adapter ring to match Optional

DCX cap lock 3” 506810.0085

4” 506810.0085

5” 506810.0087

6” 506810.0078

→

to install the DCX logger

in the level tube, an adapter

ring (2” pot) is required

506815.0043

506815.0009

506815.0040

506815.0041

506815.0042

keller-druck.com

2“

Adapter ring (2” pot) Optional 506810.0021

A

54 mm 46 mm

27

A: Opening

B

for light plummet

Ø 16 mm

B: Opening

for DCX

M20 x 1,5

Page 28

DESCRIPTION SCOPE OF DELIVERY PRODUCT NO.

End cap for DCX-16 Supplied with product 507205.0033

for DCX-16

End cap for DCX-18 Supplied with product 507220.0109

for DCX-18

End cap for Supplied with product 507220.0001

DCX-22 & DCX-25 PVDF for DCX-22

Protective cap with lter Optional 507220.0002

for DCX-22

Battery Supplied with product 557005.0017

to match: for DCX-16

DCX-16 (AA/SG/VG)

Minamoto brand:

lithium 3,6 V AAA

keller-druck.com

Battery Supplied with product 557005.0010

to match: for DCX-22

DCX-22 (AA/SG/VG)

Tadiran brand:

lithium 3,6 V AA

Type: SL-760

Battery Supplied with product 557005.0006

to match: for DCX-22

DCX-22 (AA/SG/VG)/25/38

Models from 2009 onwards:

with plug cable

Tadiran brand:

Lithium 3,6 V AA

Type: SL-760

Power unit, 15 V Supplied with product 309010.0025

(Europa) for K-114M

DC plug

Input: 230 VAC

Output: 15 VDC, 360 mA

Cable length: 1,8 m

28

Page 29

DESCRIPTION SCOPE OF DELIVERY PRODUCT NO.

Plug-type power unit, 15 V Supplied with product 309010.0087

(U.K.) for K-114M

DC plug

Input: 230 VAC

Output: 15 VDC, 360 mA

Cable length: 2 m

Plug-type power unit, 15 V Supplied with product 309010.0086

(USA) for K-114M

DC plug

Input: 120 VAC

Output: 15 VDC, 360 mA

Cable length: 2 m

keller-druck.com

Auto adapter cable Optional 309010.0051

Connection to converter

K-104M/K-114M (→ DCX-18)

Extension cable Optional 5 meters

“Reference“ 602515.0023

for DCX-18 10 meters

(PE cable, Ø 5,8 mm) 602515.0024

20 meters

602515.0025

50 meters

602515.0026

100 meters

602515.0027

29

Page 30

DESCRIPTION SCOPE OF DELIVERY PRODUCT NO.

keller-druck.com

Flange socket

for connection socket with DCX-16/DCX-22/

hexagon socket screw DCX-38 VG

(Inox/stainless steel M3 x 6)

for securing

Circlip

DIN: 471 (BN: 682)

Ø 18 mm

O-ring, battery compartment Spare part 508610.0007

and interface plug

For type DCX-16

Ø 11 mm x 1,5 mm / Nitrile

O-ring, interface plug Spare part 508610.0055

For type DCX-18

Ø 13,5 mm x 1,5 mm / Nitrile

O-ring, interface plug Spare part 508610.0051

For type DCX-22

Ø 13 mm x 1,5 mm / Nitrile

O-ring, battery compartment Spare part 508610.0024

For type DCX-22/-38

Ø 17 mm x 1,5 mm / Nitrile

Supplied with product for

Supplied with product for

AA/VG/SG versions

508415.0004

508830.0002

O-ring, battery compartment Spare part 508610.0150

For type DCX-25 PVDF

Ø 16 mm x 2 mm / Viton

O-ring, read-out plug Spare part 508610.0144

For type DCX-25 PVDF

Ø 15,5 mm x 1,5 mm / NBR

O-ring, read-out plug Spare part 508610.0159

For type DCX-25 PVDF

Ø 16,5 mm x 1,5 mm / NBR

30

Page 31

DESCRIPTION SCOPE OF DELIVERY PRODUCT NO.

Interface converter Optional 309010.0002

K-103A

(not for DCX-18 ECO)

For communication

between PC and DCX-16/22.

Connection to serial

interface (converter

RS232 – RS485)

Interface converter Optional 309010.0075

K-114A with Fischer plug/

5-pin:

• Supply via USB for

a connected end consumer

(U-Out = 11,8 VDC /

I-Out

= 40 mA)

max

• Optical status and

conguration display (LED)

• Electrical isolation

• Total length: 1,7 m

• Software CD and USB

connection cable included in

scope of delivery

keller-druck.com

Interface converter Optional 309010.0077

K-114M with M12 socket/

5-pin:

• Supply/charge via USB

(U-Out = 5 V /

I-Out

= 100 mA)

max

(fast charging via

external power unit,

12…20 VDC)

• Optical status and

conguration display (LED)

• Electrical isolation

• Total length: 2,3 m

• Software CD, power unit and

USB connection cable

included in scope of delivery

31

Page 32

keller-druck.com

11 Declaration of Conformity

For the following products

DCX-16 / DCX-18 / DCX-22 / DCX-25 / DCX-38

We hereby declare that the product complies with the most important protection

requirements that are dened in the directive of the committee for harmonizing the

legal requirements of the member states with regard to electromagnetic compatibility (2004/108/EC).

This declaration applies to all of the above-mentioned items that are marked with

the CE symbol and are a constituent of this declaration.

The following standards were used to evaluate the products with regard to electromagnetic compatibility:

EN 61000-6-1: 2007

EN 61000-6-2: 2005

EN 61000-6-3: 2007

EN 61000-6-4: 2007

EN 61326-2-3: 2006

This declaration applies to the manufacturer:

Keller AG, St. Gallerstrasse 119, 8404 Winterthur, Switzerland

submitted by:

Keller GmbH, Schwarzwaldstrasse 17, D-79798 Jestetten

Jestetten, November 12, 2013

H.W. Keller, Director

with legally valid signature

KELLER AG für

St. Gallerstrasse 119 • CH-8404 Winterthur

Tel. ++41 (0)52 235 25 25 • Fax ++41 (0)52 235 25 00

www.keller-druck.com

Druckmesstechnik

32

Loading...

Loading...