Page 1

Pyrometer

CellaTemp PX 21 / 31 / 36

Ident.-Nr.: 1102807 09/2019

Page 2

Operating instructions CellaTemp PX 21 / 31 / 36

Content

11 General ��������������������������������������������������������������������������������������������������������������4

1�1 Information about the manual ���������������������������������������������������������������������4

1�2 Explanation of the symbols �������������������������������������������������������������������������4

1�3 Liability and Warranty ����������������������������������������������������������������������������������4

1�4 Copyright �����������������������������������������������������������������������������������������������������5

12 Safety �����������������������������������������������������������������������������������������������������������������5

2�1 Intended use �����������������������������������������������������������������������������������������������5

2�2 User´s responsibility ������������������������������������������������������������������������������������5

2�3 Safety requirements ������������������������������������������������������������������������������������5

2�4 Laser Radiation Hazard ������������������������������������������������������������������������������6

13 Shipping, packaging and disposal ���������������������������������������������������������������������7

3�1 Inspection after shipping �����������������������������������������������������������������������������7

3�2 Packging �����������������������������������������������������������������������������������������������������7

3�3 Disposal oft he old devices �������������������������������������������������������������������������7

14 Theory of Non-Contact Temperature Measurements�����������������������������������������8

4�1 Advantages of Non-Contact Temperature Mesasurement ��������������������������8

4�2 Measurements at Black Bodies (Cavity Radiators) �������������������������������������8

4�3 Measurements of Real Radiators ���������������������������������������������������������������9

4�4 Measurements errors ����������������������������������������������������������������������������������9

15 Ways to determine emissivity ��������������������������������������������������������������������������10

16 Function �����������������������������������������������������������������������������������������������������������10

17 Installation ��������������������������������������������������������������������������������������������������������11

7�1 Assembly ��������������������������������������������������������������������������������������������������� 11

7�2 Assembly fibre optic cable ������������������������������������������������������������������������11

7�3 Aiming the pyrometer ��������������������������������������������������������������������������������12

7�3 Focussing ��������������������������������������������������������������������������������������������������12

18 Electrical connection ����������������������������������������������������������������������������������������14

19 Setup ���������������������������������������������������������������������������������������������������������������15

10 Shielding and Grounding ���������������������������������������������������������������������������������16

11 Operating control and display ��������������������������������������������������������������������������17

11�1 Processing of measuring signals�������������������������������������������������������������18

11�2 Analogue output ��������������������������������������������������������������������������������������18

11�3 Switching threshold OUT 1 ����������������������������������������������������������������������19

11�4 Output signal �������������������������������������������������������������������������������������������19

11�5 Switch on delay ���������������������������������������������������������������������������������������19

11�6 Switch off delay ���������������������������������������������������������������������������������������19

Page 3

Operating instructions CellaTemp PX 21 / 31 / 36

11�7 Hysteresis function ����������������������������������������������������������������������������������20

11�8 Window function ������������������������������������������������������������������������������������21

11�9 Switching output OUT 2 ������������������������������������������������������������������������22

11�10 Damping function ����������������������������������������������������������������������������������22

11�11 Peak hold function ���������������������������������������������������������������������������������23

11�12 ATD function ������������������������������������������������������������������������������������������23

11�13 IO-Link ���������������������������������������������������������������������������������������������������27

12 Menu ����������������������������������������������������������������������������������������������������������������27

12�1 Analogouge output Ao �����������������������������������������������������������������������������27

12�2 Switching output OUT 1 ��������������������������������������������������������������������������28

12�3 Switching output OUT 2 ��������������������������������������������������������������������������29

12�4 Spectral channel �������������������������������������������������������������������������������������30

12�5 Advanced Features ���������������������������������������������������������������������������������31

13 Menu explanation ��������������������������������������������������������������������������������������������32

13�1 Analogue output ��������������������������������������������������������������������������������������32

13�2 OUT 1 (dI) ������������������������������������������������������������������������������������������32

13�3 OUT 2 (d2) �������������������������������������������������������������������������������������������33

13�4 Spectral channel (S) �������������������������������������������������������������������������������33

13�5 Advanced Features (EF) �������������������������������������������������������������������������36

14 Parameterizing �������������������������������������������������������������������������������������������������36

14�1 Setting parameters – general information �����������������������������������������������36

15 Error indications �����������������������������������������������������������������������������������������������38

16 Service functions ���������������������������������������������������������������������������������������������38

16�1 Reset all parameters to factory settings ��������������������������������������������������38

16�2 Simulate a desired temperature ��������������������������������������������������������������39

17 Maintenace ������������������������������������������������������������������������������������������������������39

17�1 Cleaning the pyrometer lens �������������������������������������������������������������������39

17�2 Replacing the protective screen ��������������������������������������������������������������40

18 Models �������������������������������������������������������������������������������������������������������������40

19 Field of view �����������������������������������������������������������������������������������������������������41

20 General technical data �������������������������������������������������������������������������������������42

21 Device-specific technical data �������������������������������������������������������������������������44

23 Accessories �����������������������������������������������������������������������������������������������������47

24 Default settings ������������������������������������������������������������������������������������������������47

25 Copyright ���������������������������������������������������������������������������������������������������������47

EN

Page 4

Operating instructions CellaTemp PX 21 / 31 / 36

1 General

1.1 Information about the manual

The Operating Manual shall enable the user to properly install the pyrometer

and the required accessories� Before starting installation, be sure to read and

understand this entire manual, in particular the chapter on safety! The instruc

tions contained in this manual, especially those concerning safety, as well as site

specific regulations governing UV radiation must be complied with at all times� It

is imperative to comply with the safety instructions and the accident protection

regulations valid for the area of application!

1.2 Explanation of the symbols

Important safety-related references in this manual are marked with a symbol�

ATTENTION

This symbol points out guidelines� If you do not observe them, the device might

be damaged, malfunctioning or even fail to operate�

CAUTION

This symbol points out hints and information which should be heeded for

efficient and trouble-free operation�

►

Action

This symbol instructs the operator to take action�

>

Reaction, result

This symbol indicates the result of the action taken�

1.3 Liability and Warranty

All information compiled in this manual is in accordance with applicable regula

tions� The statements made are based on state-of-the-art technology and reflect

our extensive knowledge and many years of experience�

Always carefully read this Operating Manual before beginning any work

on or with the instrument, especially prior to installation and initial setup!

The Manufacturer shall not be held liable for any damages or malfunctions

arising from a disregard of the warnings and instructions contained herein�

-

-

4

Page 5

Operating instructions CellaTemp PX 21 / 31 / 36

1.4 Copyright

This Operating Manual should be treated as confidential� It is solely intended for

the use by persons involved with the instrument� This manual may not be made

available to a third party without prior Manufacturer’s consent� Please contact the

Manufacturer if the need should arise�

2 Safety

This chapter outlines all important safety aspects to be considered for optimum

employee protection and to ensure safe and reliable operations�

2.1 Intended use

The pyrometer is solely intended for use as described in this manual� Operational

safety can only be ensured when the instrument is used for its intended purpose�

The use of the pyrometer for any other purpose beyond what is specified

in this manual is prohibited� Using the instrument in any other manner will

be considered as improper� The Manufacturer/Authorised Agent shall not

be held liable for any damages or loss resulting from such unintended or

improper use; in this case the risk is solely borne by the user�

2.2 User´s responsibility

The pyrometer may only be used when it is in perfect working condition�

2.3 Safety requirements

The instrument operates at low voltage (18 – 34 V DC)� The power supply unit

must conform to directiv EN 50178, SELV, PELV entsprechen�

EN

5

Page 6

Operating instructions CellaTemp PX 21 / 31 / 36

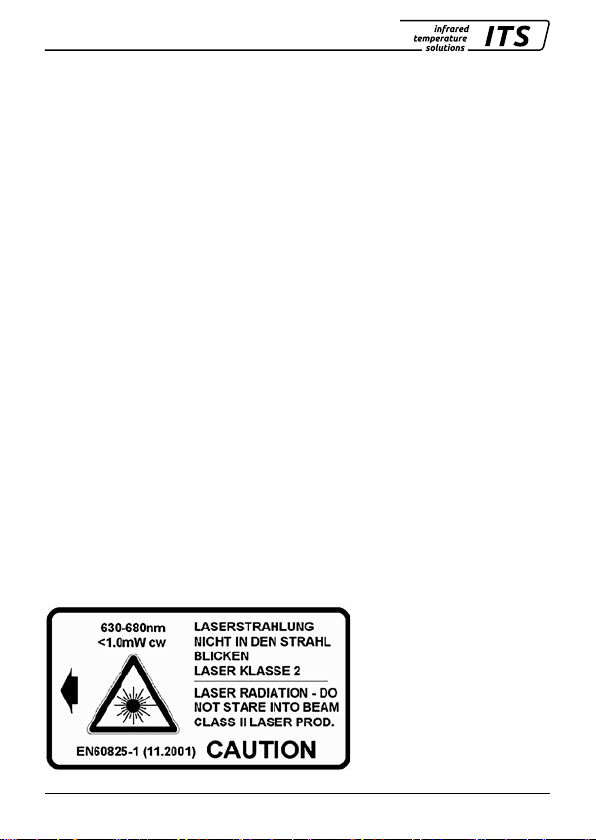

2.4 Laser Radiation Hazard

Laser radiation can be harmful to eyey!

The CellaTemp PX with laser operates with a class 2 red light laser� Direct prolonged viewing of a laser beam can injure the retina� Therefore, the following safety precautions must be strictly observed, otherwise the laser may not be operated!

• Only use the laser to align and focus the pyrometer� Deactivate the laser

immediatley afterwardsAlternatively, the laser will automatically switch off after

2 minutes�

• Never look directly into the laser beam path

• Do not leave the instrument unattended when the laser is activated�

• Do not point th elaser beam at any person

• During pyrometer installation and aligment, make sure to avoid the possibility of

laser reflections caused by reflective surfaces�

• All currently valid laser safety standards must be observed�

Laser power

The laser operates at a wavelength of 630 - 680 nm (visible red light)� The emitted

power of the laser beam at the lens opening is max� 1�0 mW� Under normal operat

ing conditions, the emitted radiation does not present a danger to human skin� This

laser product is classified according to laser class 2, EN60825-1, IEC60825-1�

Laser Warning Label

The black and yellow laser warning label is affixed next to nameplate of the instru

ment� An arrow indicates the laser emission path (lens opening)�

-

-

6

Page 7

Operating instructions CellaTemp PX 21 / 31 / 36

If the pyrometer is installed within, a machine or equipment in such a

way that the instrument’s warning label is visibly blocked, additional laser

warning labels (not included in scope of delivery) must be affixed to the

equipment or accessory in immediate vicinity to the laser beam emission

path opening�

3 Shipping, packaging and disposal

3.1 Inspection after shipping

Unpack and inspect the entire shipment immediately upon receipt to make sure

it is complete and undamaged� If the container/package shows visible signs of

damage, please refuse the shipment� If this is not possible, accept the shipment on

the condition that the freight carrier’s delivery record is noted with the extent of the

damage in order to file a claim� Should you discover a concealed loss or damage,

report it to the shipper or freight carrier immediately� If the period for filing claims

has expired, you will no longer be able to make any claims for compensation of

damage or loss�

3.2 Packging

The packages used are made of carefully selected, environmentally compatible

materials and are thus recyclable� Please ensure that they are disposed of in an

ecologically sound manner�

3.3 Disposal oft he old devices

Old electrical and electronic devices frequently still contain

valuable materials� These devices can be returned for disposal to

the manufacturer or they must be disposed properly by the user�

For the improper disposal of the device by the user, the company

KELLER HCW is not responsible�

EN

7

Page 8

Operating instructions CellaTemp PX 21 / 31 / 36

4 Theory of Non-Contact Temperature Measurements

All materials radiate thermal energy in all states of aggregation above absolute

zero� This radiation is mainly caused by atomic or molecular oscillations�

This temperature radiation is only a limited sector within the total electromagnetic

radiation spectrum� It extends from the visible range starting at wavelengths of ap

prox. 0.5 μm to the infrared range with wavelenghs of more than 40 μm. Radiation

pyrometers detect infrared radiation for non-contact temperature measurement�

4.1 Advantages of Non-Contact Temperature Mesasurement

• Non-contact temperature detection means cost-effective temperature

measurement because this technique only requires a single in-vestment in an

instrument without any follow-up costs for consumables such as thermocou

ples

• This method enables temperature detection of moving objects - quick temper

ature measurements within milliseconds - for example at automatic welding

processes

• Small objects with medium and high temperatures can also be easily and

accurately measured

• When measuring materials with low specific heat, a non-contact method does

not induce heat loss which would distort the temperature reading (as is the

case with contact temperature probes)� Non-contact temperature detection

is ideal with corrosive molten materials for which the use of thermocouples is

hardly feasible

• Last but not least it is also possible to measure the temperature of volt

age-carrying objects�

4.2 Measurements at Black Bodies (Cavity Radiators)

A black body or a black radiator is used to calibrate radiation pyrometers� This

black body is designed in a way that its radiation does not depend on material

characteristics, but only on its temperature� A black body emits at any wavelength

the maximum energy possible for the specific temperature� Real bodies do not

have this ability� In other words, a black body completely absorbs the radiation

without reflection or transmission losses. The spectral emissivity coefficient ε(λ) of

a black body is equal to 1 or 100 %�

-

-

-

-

8

Page 9

Operating instructions CellaTemp PX 21 / 31 / 36

The emissivity coefficient indicates the ratio of radiation of a real body (target) to

the radiation of an ideal black body (target) to the radiation of an ideal black body�

ε(λ): Emissivity coefficient of the object’s surface (targeted spot) at wavelengh λ

M: Emissivity coefficient of the object’s surface (targeted spot) at wavelength

MS: radiant energy emitted by a black body (perfect radiator)

Most burning, annealing and hardening furnaces emit a radiation of nearly ‚1‘

which corresponds to the conditions of a black body if the aperture through which

the measurement is made is relatively small�

4.3 Measurements of Real Radiators

Real radiation sources are characterized by the relation of the emitted radiation to

the radiation of a black body with the same temperature� Measurements outside a

furnace - which applies to all other self-contained targets - always show a reading

which is too low� Considerable errors can occur at targets with reflecting, polished

or bright surfaces, e�g� molten steel and metal without oxide layer and ceramic

materials� Exact results can only be obtained when the emissivity coefficient is

correctly adjusted on the pyrometer� The spectral emissivity coefficient of a body

does not represent an exact material constant, but is also largely dependent on the

surface properties (→ Ways to determine emissivity).

4.4 Measurements errors

The cause of measurement errors in the use of pyrometers is often an incorrectly

determined or wrong emissivity� Another source of error is the reflected „back

ground radiation“� If the measurement object has a low emissivity and there are

hotter objects in the surrounding area, measurement results can be affected�

These objects then have to be shaded� This effect is particularly to be observed in

the measurement of a colder object within a hot oven�

EN

-

9

Page 10

Operating instructions CellaTemp PX 21 / 31 / 36

5 Ways to determine emissivity

Technical literature or operating manuals often contain data on the emissivity of

various materials� This information should be used with caution, however� It is

important to know for which temperature and which wavelength the emissivity

value is applicable� Furthermore, the stated emissivity values were obtained under

ideal conditions� In actual practice, the total emissivity of the target object will vary,

depending on the amount of extraneous radiation transmitted through the object

from the background or reflected onto the object from the foreground� The emissiv

ity can be determined using one of the following methods:

Contact measurements

Measure the temperature with a contact thermocouple and measure the surface

temperature with a pyrometer� Adjust the emissivity coefficient on the pyrometer

until both devices show the same temperature� When measuring with the thermo

couple, make sure to have good thermal contact and low heat dissipation�

Using a reference emissivity coefficient

Apply matte black colour to a part of the surface to be measured� This part has an

emissivity of 94 %� At first, measure the temperature of the coloured part� Then

make a comparative measurement right next to the coloured part and adjust the

emissivity on the pyrometer until it displays the previous measurement reading

again�

-

-

6 Function

The pyrometer detects the radiated infrared radiation of objects without contact

and converts them into an electrical switching signal and an analogue output

signal�

10

Page 11

Operating instructions CellaTemp PX 21 / 31 / 36

7 Installation

7.1 Assembly basic unit

The basic unit should be mounted where it is not unnecessarily exposed smoke,

heat or vapour�

ATTENTION

At ambient temperature > 65 °C, the basic unit must be cooled or protected

against radiation by shielding plate�

7.2 Assembly fibre optic cable

One end of the optical fibre has a nameplate showing the serial number of the

corresponding basic pyrometer� This is the end which must be screwed onto the

pyrometer� For proper connection, the arrow on the name plate of the fibre optic

cable and the arrow on the pyrometer should point toward each other�

The serial number of the measuring head should also correspond to the pyrometer�

EN

ATTENTION

The fibre optic cable must not be exposed to tensile load and must not be

twisted� The minimum bending radius is 125 mm�

11

Page 12

Operating instructions CellaTemp PX 21 / 31 / 36

7.3 Aiming the pyrometer

Point the measuring head at the object to be measured� If possible, the pyrometer

should be installed at an angle of 90° to the object to be measured� The angle

should not be less than 45° from the vertical� The spot must be completely filled by

the measured object�

1 Best - Target larger than the spot size

2 Good - Target equal to spot size

3 Incorrect - Target smaller than spot size

Contamination of lens can lead to measure measurement errors� Therefore, always make sure that the lens is clean� The pyrometer field of view

must remain unobstructed� Any interferences from objects must be avoid�

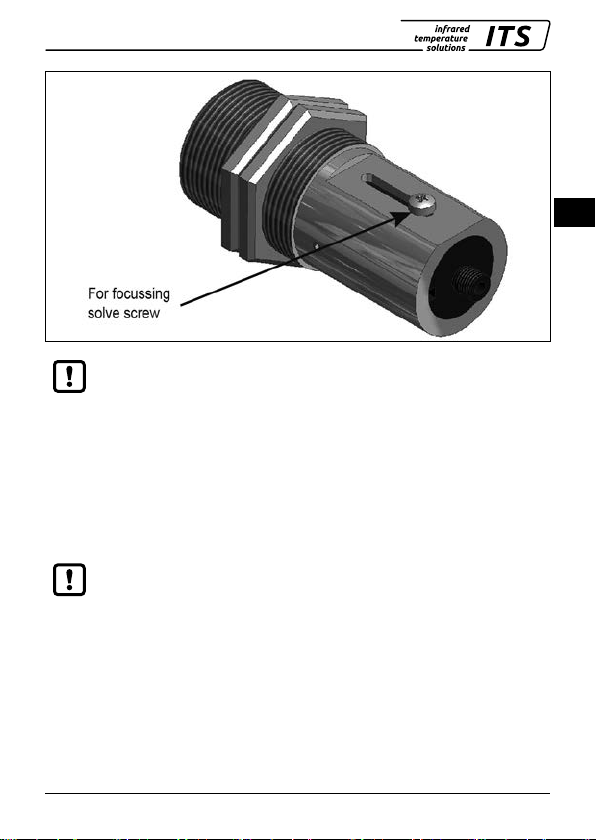

7.4 Focussing

The pyrometers have a laser that can be activated to align the sensing head to

the target spot� To activate the laser, press the MODE button in the real panel for

2 seconds�

For focal adjustment loosen the shown socket screw (hexagon socket screw DIN

916) with a wrench (DIN 911) and shift the internal body of the tube towards the

lens tube� Due to the O-ring sealing between the internal body of the tube and the

lens tube the focal adjustment must be carried out very slowly so that the air pres

sure in the space between lens and internal body of the tube can be equalised�

Focus the sensing head until the spot light is shown as a sharp round laser spot in

the target area�

1 2 3

-

12

Page 13

Operating instructions CellaTemp PX 21 / 31 / 36

EN

The activated laser pilot light can influence the measured temperature�

This influence will vary, depending on the instrument model and the

temperature�

To protect the laser against overload, an over temperature is provided� At tempera

tures above 60 °C, the laser switches of an can no longer be activated� To check,

whether the laser is activated, the parameter LED lights up�

In normal operation, the laser is switch off� After activation, the laser switch of

again after 2 – 15 minutes� The operator must be familiar with the pyrometer and

above safety guidelines�

Information on the laser output can be found in chapter 2�4 Laser power

-

13

Page 14

Operating instructions CellaTemp PX 21 / 31 / 36

24 V DC

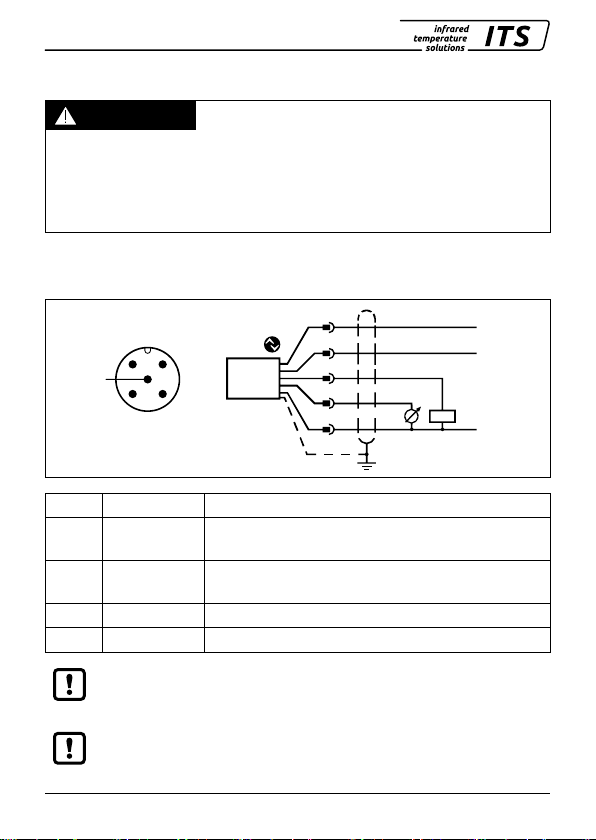

8 Electrical connection

ATTENTION

• The pyrometer may only be installed by a skilled, qualified electrician� Do not

connect the instrument while the voltage supply source is turned on� Please

observe international safety regulations at all times�

• The pyrometer is supplied with low voltage 24V DC� The power supply unit

must conform to directive EN50178, SELV, PELV�

► Switch to neutral and verify absence of voltage

► Connect the instrument according to the following schematic:

1

2

1

5

3

4

4

5

2

3

shielded

Out 2

0/4 - 20 mA

L+

C/Q

L-

Pin 1 BN (brown) L+ (Power supply 24V DC)

Pin 4 BK (black)

Pin 5 GY (grey)

Open Collector switching output; Imax = 150 mA or

IO-Link OUT 1

Open Collector switching output; Imax = 150 mA

OUT2

Pin 2 WH (white) Analogue output; 0/4 - 20mA

Pin 3 BU (blue) L- (GND)

The pyrometer must be protected against high voltage and strong electromagnetic fields� Use a shielded cable, connecting it via connector casing

to the device housing�

Use a flyback diode when switching inductive loads�

14

Page 15

Operating instructions CellaTemp PX 21 / 31 / 36

9 Setup

For non-contact temperature measurement, the pyrometer uses the intensity of the

infrared radiation� In order to obtain accurate measurement results, the respective

emissivity of the measurement object must be set on the pyrometer (→ emissivity

determination)�

An incorrectly set emissivity leads to measurement errors during temperature

measurement� After the supply voltage has been switched on for the first time, the

emissivity must first be set. The emissivity is set as follows:

► Press [˄ or ˅]

> > The value of the selected emissivity is displayed, for example [100.0]

► Press [˄ or ˅] until the desired emissivity will show

► Press [Enter] or wait for 3 seconds

> The current temperature value is displayed and the new emissivity coefficient

is stored�

To compensate for environmental influences, it may be useful to have an

emissivity of > 100 %� A setting of 110 % is possible�

ATTENTION

An incorrectly set emissivity coefficient leads to wrong temperature readings�

EN

15

Page 16

Operating instructions CellaTemp PX 21 / 31 / 36

10 Shielding and Grounding

The pyrometer housing is connected to the shielding via the cable connector!

Differences in ground potentials might cause an equalising current to flow between

devices through a cable shielded at both ends� In this case, be sure to install an

additional equipotential bonding line�

To avoid an equalising current, the pyrometer can be mounted electrically insulat

ed� The shielding must be connected to the plant’s earthing system�

ATTENTION

If the pyrometer is installed without an insulator and without potential equalisation, the interference voltage may not exceed 32V�

-

16

Page 17

Operating instructions CellaTemp PX 21 / 31 / 36

11 Operating control and display

3

4

1

2

6

1 to 4: Indicator-LEDs

LED 1 = Switching state of switching output OUT1

LED 2 = Switching state of switching output OUT2

LED 3 = Laser pilot light active

LED 4 = IO-Link Communication

5: Control key [MODE]

• Selection of parameters

• Reading the set values

• Confirmation of parameter values

6: Control key [˄] and [˅]

• Selection of parameters

• Activation of emissivity quick adjustment

• Confirmation of parameter values

7: Alphanumeric display, 4-digit

• Indicates temperature value

• Indicates parameter and configuration

• Display of errors

7

5

EN

17

Page 18

Operating instructions CellaTemp PX 21 / 31 / 36

Maximum measuring range Measuring range scaled

2 final value of the measuring range

4 Analogue end point

11.1 Processing of measuring signals

The pyrometer disposes of an IO-Link interface�

The generated three output signals correspond to the parameterization:

• Out 1: Switching output/ IO-Link

■ Switch signal: threshold value temperature / status signal

• Out 2: Switching output

■ Switch signal: threshold for temperature / status signal

• • Analouge output: 0/4 -20 mA

■ Analogue output for temperature

11.2 Analogue output

The pyrometer converts the measuring signal into a temperature proportional

analogue signal of 0/4 – 20 mA� The maximum load is 500 Ohm�

[Ao.FN] Changeover 0 -20 mA or 4 -20 mA

[Ao.SP] defines at which measured value the output signal is 0/4 mA.

[Ao.EP] defines at which measured value the output signal is 20 mA.

I [mA]

20.5

20

4

3.8

1 2

1 initial value of the measuring range

I [mA]

20.5

20

4

3.8

T [°C/°F]

3 Analogue start point

1 23 4

18

T [°C/°F]

Page 19

Operating instructions CellaTemp PX 21 / 31 / 36

11.3 Switching threshold OUT 1

OUT1 changes its switching status when the configured upper or lower thersholds

[d1.SP,d1.rP] are exceeded. Source d1.S specifies the signal that is

output at OUT1�

• • Spectral channel [dI] → [dI.s] = L1

First, the switching point [d1.SP] is set in °C and °F and then the reset point

[d1.rP]. When changing [d1.SP], the [d1.rP] also changes so that the

difference remains the same� If the [d1.SP] is reduced to such an extent that

the distance can no longer be maintained (as the [d1.rP] would otherwise

move below its minimum), the [d1.rP] is increased to its minimum. If [d1.SP]

is subsequently increased again, [d1.rP] is also increased again immediately.

The minimum distance between [d1.SP] and [d1.rP] is 1 K.

11.4 Output signal

The following output functions can be selected:

• Normally open contact [d1] → [d1.Fn] = hno hysteresis function, nor

mally open or rather Fno window function, normally open

• Normally closed contact [d1] → [d1.Fn] = hnc hysteresis function,

normally open or rather Fnc windows function, normally open

11.5 Switch on delay

Once the sensor has detected a temperature which exceeds the switching thresh

old [d1.SP] the time delay [d1.dS] starts running. When this delay period

has elapsed, the output OUT 1 activates switching� This status is sustained until

the lower threshold [d1.rP] is violated. If this occurs before the time delay has

elapsed, the delay will reset� This function can be used, for example, to supress

spurious impulse signals at the output�

• Switching on delay: [d1] → [d1.dS] = 0...10 sec.

11.6 Switch off delay

To make sure the output is correctly identified, e�g� by downstream control system,

the output can be lengthened�

• Switch off delay: [d1] → [d1.dr] = 0...10 sec.

EN

-

-

19

Page 20

Operating instructions CellaTemp PX 21 / 31 / 36

t

T

11.7 Hysteresis function

SP

rP

1

24V

2

0V

[dr]

[dS]

24V

[dS]

[dS]

[dr]

3

0V

24V

4

0V

[dS]

[dr]

[dS]

[dr]

24V

5

0V

T = temperature rP = rest point

t = time dS = switch on delay

SP = set point dR = switch off delay

1 Temperature

2

Switch signal hno

3

Switch signal hno with switch on delay and switch off delay

4

Switch signal hnc

5

Switch signal hnc with switch on delay and switch off delay

t

t

[dS]

[dr]

[dr]

[dS]

t

[dS]

t

[dS][dr]

20

Page 21

Operating instructions CellaTemp PX 21 / 31 / 36

T

t

]

11.8 Window function

SP

rP

1

t

24V

2

0V

[dS]

[dr]

24V

[dr]

[dS]

[dr]

[dS]

[dr]

[dr]

3

0V

24V

4

0V

[dr]

[dS]

24V

[dS]

[dS]

[dr]

[dS]

5

0V

T = temperature rP = lower limit value

t = time dS = switch on delay

SP = upper limit value dR = switch off delay

1 Temperature

2

Switch signal Fno

3

Switch signal Fno with switch on delay and switch off delay

4

Switch signal Fnc

5

Switch signal Fnc with switch on delay and switch off delay

The switching thresholds of the window function have a hysteresis of

0�25% of the measuring range�

EN

t

t

t

21

Page 22

Operating instructions CellaTemp PX 21 / 31 / 36

t

Ao

[mA]

11.9 Switching output OUT 2

OUT2 changes its switching state according to the adjusted function� The functions

and parameters are the same as OUT 1�

11.10 Damping function

When the target object‘s temperature is erratic, the damping function smoothens

these temperature fluctuations in order to stabilize the measuring signal� The

greater the time constant [S] → [S.FiL], the lower the effect of fluctuations on

the yielded temperature reading�

1

2

1 Output signal without smoothing function

2 Output signal with smoothing function

22

Page 23

Operating instructions CellaTemp PX 21 / 31 / 36

t

A

11.11 Peak hold function

It might often be desirable to determine the peak temperature during a defined

time period, for example when the objects to be measured move past the pyrom

eter, resulting in temperature readings which would appear to be cyclical� In this

mode, the displayed temperature reading will not drop between targeted objects�

The peak temperature reading will be held for a preset time period�

The hold time [S] → [S.Phd] → [t iME] can be set from 0.1 to 999.9 sec.

The maximum temperatures sampled during the defined hold time will be saved� It

EN

make sense to choose a hold time which is approximate 1�5 time as long as cycle

of the moving targets� This avoids temperature drops� Any changes are recognised

at once�

1

o

[mA]

2

4

3

5

1 Measuring object in front of the pyrometer

2 Hold time

3 Second internal hold time

4 Measuring reading with peak hold function

5 Measuring reading without peak hold function

11.12 ATD function

This function is used to automatically measure the temperature of a discontinuous

ly running process� For example, it can be used to determine the temperature of

bolts passing the pyrometer acyclically and which have a variable length�

23

-

Page 24

Operating instructions CellaTemp PX 21 / 31 / 36

The start of a measuring cycle is determined automatically and is dependent on

the following variables:

Limit 1 (LI.1)

Limit 2 (LI.2)

Time delay (T.DEL)

When the conditions are fulfilled, the sampling time can begin� (T�ACT)�

Sampling time

(T.ACT)

The parameter (ANO) defines the temperature emitted during the measuring time�

Display mode (t.Ano)

As an option, the green Status LED can light up or the digital output can be used

to indicate sampling�

When the sampling time has ended, an average value is calculated for recorded

measuring cycles� The temperature reading is weighted with the previously saved

average value and added�

Weighted average

(t.FPr)

The smaller you set the F-PR factor, the stronger the weighting will be�

If the parameter T�ACT= 0 automatically the end of the discontinuous

process is detected� At the parameter T�ACT instead of the time „auto“ is

displayed�

Before beginning the measurement, the temperature

reading must have been lower than Limit 1 at least

once�

If Autoreset (A�RST=ON) the limit 1 will be ignored

Limit 2 must be exceeded at least fort he duration of

time delay (T�DEL)�

See above

During the sampling time the temperature is detected

and stored as a temperature value�

t=0“ displays the lower temperature range limit

during the measurement� „T�HLD“ indicates the

previous temperature reading during the current

measurement�

Factor for average weighting� If you choose 100%,

averaging will be off�

24

Page 25

Operating instructions CellaTemp PX 21 / 31 / 36

When the averaging function is activated (F-PR <100%) a plausibility check will

be performed� The difference in temperature between the current reading and

the previously stored average is established� If the difference is higher than the

plausibility threshold TSP, the transmitted data will be „0“ and the average value

will remain unchanged�

Plausibility (t.FAL)

Plausibility (t.riS)

When sampling is completed, the average temperature value or „0“ will be output�

At the same time, an impulse is generated which can be used for the digital out

puts� Enter M�TR�1 as source and set the holt time to 0�5 sec�

A cut-off interval (time lag) begins after the sampling time has ended� This cut-off

interval must expire before the next measurement can start with the cycle starting

conditions described above�

Cut-off interval

(T.DIS)

If a measuring cycle does not start during the period T�OUT, the saved average will

be deleted and reinitialized when the next cycle begins�

Timeout (T.OUT)

Activate auto reset for the ATD function to run cyclically� Limit 1 will then be

ignored� Measurement continues when the Limit 2 is exceeded for the period

configured with T�DEL�

Auto reset (t.AUT)

The parameter Set Li2 checks on T� ACT checks, whether the value falls below

threshold 2 during the measuring time� If the value falls velow the threshold, the

measurement is rejected� The display shows „– – – –“�

Set Li2 check on tAct

(t.L.2)

Threshold for plausibility check: lower limit which is

acceptable for a valid measurement�

Threshold for plausibility check: upper limit which is

acceptable for a valid measurement�

-

The interval between one completed sampling and

the start of a new sampling�

Timeout für Mittelfunktion (in Minuten)

Auto reset on/off

on/off

EN

25

Page 26

Operating instructions CellaTemp PX 21 / 31 / 36

[°C]

1

1500

Li. 2

Li. I

t.dEl

t.Act

t.dis

t.dEl

t.Act

1000

500

3

4

5

4

2

3

5

6

Li. 2 = limit 2 t.dEL = time delay

Li. I = limit 1 t.Act = sampling time

t.diS = cut-off interval

1 Measuring object in front oft he pyrometer

2

Temperature output t.Ano = off

3 Previous reading

4

Lower limit of temperature range

5 New reading

6

Temperature output t.Ano = hold

t.dis

[s]

5

5

26

Page 27

Operating instructions CellaTemp PX 21 / 31 / 36

11.13 IO-Link

This device has an IO-Link communication interface, which requires an IO-Linkcapable module (IO-Link master) for operation� The IO-Link interface allows direct

access to process and diagnostic data and offers the possibility to parameterize

the device during operation� The IODDs required for configuring the IO-Link device

as well as detailed information on process data set-up, diagnostic functions and

parameter addresses are available in the download area at www�keller�de/its�

For IO-Link operation a 3-wire cable port Class A (Type A) must be used�

EN

12 Menu

12.1 Analogouge output Ao

8888

Mode

Ao

dI

d2

S

EF

End

Mode

Run

Mode

Ao

Ao. S

Ao.Fn

Ao.SP

Ao.EP

End

Mode

27

Page 28

Operating instructions CellaTemp PX 21 / 31 / 36

12.2 Switching output OUT 1

8888

Mode

Ao

dI

d2

S

EF

End

Mode

Run

Mode

d1

dI. S

dI.Fn

dI.SP

dI.rP

dI.dS

dI.dr

End

Mode

28

Page 29

Operating instructions CellaTemp PX 21 / 31 / 36

12.3 Switching output OUT 2

8888

Mode

Ao

dI

d2

S

EF

End

Mode

Run

Mode

d2. S

d2.Fn

d2.SP

d2.rP

d2.dS

d2.dr

End

Mode

d2

EN

29

Page 30

Operating instructions CellaTemp PX 21 / 31 / 36

12.4 Spectral channel

Mode

Ao

dI

d2

S

EF

End

Run

E.EPS

S.tAU

S.FiL

S.MEM

S.AtD

P.Phd

S.tMP

End

Mode

S

8888

Mode

TIME

dAP

END

Mode

P.Phd

t.dEL

t.Act

t.diS

Li. I

Li.L2

t.FPr

t.Ano

t.oUT

t.FAL

t.riS

t.L2c

l.Aut

End

Mode

ATD

P�Phd Peak Hold Function

Submenu only available when Peak hold function is active

ADT Function

ATD

Submenu only available when ATD function is active

30

Page 31

Operating instructions CellaTemp PX 21 / 31 / 36

12.5 Advanced Features

8888

Mode

Ao

dI

d2

S

EF

End

Mode

Run

diSP

Unit

t.SiM

rES.

i.t.

End

Mode

EF

EN

31

Page 32

Operating instructions CellaTemp PX 21 / 31 / 36

13 Menu explanation

13.1 Analogue output

Parameter Function Comments

Ao. S

Ao.Fn

Ao.SP

Ao.EP

End

13.2 OUT 1 (dI)

Parameter Function Comments

dI. S

dI.Fn

dI.SP

dI.rP

dI.dS

dI.dr

End

Select source

0/4 – 20 mA

Define lower limit of

temp� span

Define upper limit of

temp� span

End Exit menu

Select source

output function

Lower threshold

Upper thereshold

Switch on delay Value in sec (≤ 10 sec in steps of 0.1)

Switch off delay Value in sec (≤ 10 sec in steps of 0.1)

End Exit menu

LiLambda 1

0 – 20 mA

4 -20 mA

Analogue start value

Analogue end value

LiLambda 1

tU Inner device temperature > 70 ° C *

A.LI.A ATD Trigger *

A.LI.t ATD Tact *

hno hysteresis function normally open

hnc

hysteresis function normally closed

Fnc window function normally closed

Fno window function normally open

* The source is a pure switching signal without the possibility of defining a switch

ing threshold (switch-on/switch-off point)�

32

-

Page 33

Operating instructions CellaTemp PX 21 / 31 / 36

13.3 OUT 2 (d2)

Parameter Function Comments

Li Lambda 1

D2. S

Select source

tU Innentemperatur

A.LI.A ATD Trigger

A.LI.t ATD Tact

hno Hysterese normally open

D2.Fn

Output function

hnc Hysterese normally closed

Fnc Fenster normally closed

Fno Fenster normally open

D2.SP

D2.rP

D2.dS

D2.dr

End

Lower threshold

Upper thereshold

Switch on delay Value in sec (≤ 10 sec in steps of 0.1)

Switch off delay Value in sec (≤ 10 sec in steps of 0.1)

End Exit menu

13.4 Spectral channel (S)

Parameter Function Comments

E. P. S

Emissivity

Correction of the radiation properties of

the measured object (10���110%)

When using protection shields, the

S.TAU

Transmission factor

value of the transmission of the used

disk can be entered here�

SFIL

Smoothing time time t

in sec�for simple smoothing

98

Off Off

S.MEM

Memory function

S.P.hd Peak-Hold function

s. .Atd ATD function

EN

33

Page 34

Operating instructions CellaTemp PX 21 / 31 / 36

Parameter Function Comments

Opening of the lower

S.Atd******

t.dEL

t.Act

t.diS

Li. I

Li. 2

t.Fpr

t.Ano

t.oUT

t.FAL

t.riS

t.L2c

t.AUt

End

Parameter Function Comments

menu level ATD

Function**

Time delay

Sampling time

Cut-off interval

Limit 1

Limit 2

Weighted average

Display mode

Timeout

Threshold for plau

sibility check: lower

limit

Threshold for plau

sibility check: upper

limit

Check, whether

threshold 2 is fallen

below during the

measuring time

Timeout

Closing of the lower

menu level ATD

Function

-

-

See chapter ATD function

See chapter ATD function

34

Page 35

Operating instructions CellaTemp PX 21 / 31 / 36

Opening of lower

S.P.hd**

tiME

menu level PeakHold Function*

Hold time Peak-Hold

function

Time in sec�

dAP

End

S.tMP

End

** Parameter and lower menu level can only be selected with active Peak-Hold

Function

** Parameter and lower menu level can only be selected with active ATD function

Damping Damping

Closing of lower

menu level PeakHold Function

Actual temperature

reading

End

The display shows the actual

temperatur reading

Exit menu

EN

35

Page 36

Operating instructions CellaTemp PX 21 / 31 / 36

13.5 Advanced Features (EF)

Parameter Function Comments

diSP

Unit

t.SiM

rES.

End

Process value display

Temperature unit

Temperature

Simulation

Factory settings Reset to factory settings

End Exit menu

on current temperature value

off run is shown on the display

Temperature displayed in °Cor °F

A temperature can be simulated

14 Parameterizing

When you reset/adjust the operating parameters, the instrument remains in run

mode� It continues to operate, using the current parameter settings, until you have

finished configuring by pressing [MODE].

14.1 Setting parameters – general information

1 Select main menu

► Press [MODE] to access the main

menu�

2 ► Press [˄ oder ˅] until the required

output function or advanced fea

-

tures is displayed�

3 Select parameter

► Press [MODE].

4 ► Press [˄ or ˅] until the required

parameter is displayed

1

MODE

3

MODE

2

Ao

4

Ao.Fn

36

Page 37

Operating instructions CellaTemp PX 21 / 31 / 36

n

5 Change parameter value

► Press [MODE].

> Current parameter value is

displayed�

6 ► Press [˄ or ˅] for 2 second.

> > Display flashes three times�

7 ► Press [˄ or ˅] to change the

parameter�

► Hold key [˄ or ˅].

> Numerical values scroll

through rapidly�

5

MODE

4-20

6

4-20

7

0-20

8 Confirm parameter value

► Press [MODE].

> The display indicates the parameter�

The new value has been saved and

will take effect�

Exit operating parameter layer

► Wait 30 seconds

or

► Press [˄ or ˅] to change to the parameter End. Then press [MODE] to

change to the functional menu�

► In the functional menu press [˄ or ˅] to change to the parameter End,

then press [MODE].

If you press both keys [˄ ˅] only briefly, you will exit the layer (ESC) func-

tion�

8

Ao.Fn

MODE

Ao.F

EN

37

Page 38

Operating instructions CellaTemp PX 21 / 31 / 36

15 Error indications

Overload switching output

Overtemperature

Incorrect connection of supply voltage The display is turned off

Supply voltage ≤ 16 V The display is turned off

Temperature below mesuring range The display shows UL

Temperature above measuring range The display shows OL

Sc und blinken der LED Out 1/2

Display ot and the process value

change with 0�5 Hz

16 Service functions

16.1 Reset all parameters to factory settings

►

[rES.] Select extended functions [EF] in the menu

►

Press [MODE]

>

RES is shown in the display

►

Press the ˅ key for 2 s

>

RES flashed for 2 s

► Release the key ˅ key and press it again

> – – – – is shown in the display

► Press MODE button

> The current temperature is shown in the display

38

Page 39

Operating instructions CellaTemp PX 21 / 31 / 36

16.2 Simulate a desired temperature

►

[t.SiM] Select extended functions [EF]

►

Press [MODE]

>

The display shows the previously set temperature

►

Press the ˄ key for 2 s

>

Temperature flashes 3 times

► Use the keys ˄ ˅ to set the desired temperature, release the key

>

The display alternately shows t.SiM and the temperature value

► Press MODE button

>

The display shows t.SiM and the simulation is completed

Exit operating parameter layer

► Wait 30 seconds

or

► Press [˄ or ˅] to change to the parameter End. Then press [MODE] to change

to the functional menu�

► In the functional menu press [˄ or ˅] to change to the parameter End,

then press [MODE].

17 Maintenace

17.1 Cleaning the pyrometer lens

A soiled lens leads to wrong display of the measured value�

► Check the lens regularly and clean it, if required.

• Remove dust by blowing or with a soft brush�

• Use clean, soft and lint-free cloths or those offered on the market for lens

cleaning�

• For heavier contamination, use washing-up liquid or liquid soap� Then carful

ly rinse with clear water� Hold the lens downwards�

• Exert only little preasure on the lens during cleaning to avoid scratches�

EN

-

39

Page 40

Operating instructions CellaTemp PX 21 / 31 / 36

17.2 Replacing the protective screen

To protect the pyrometer optics against contamination in harsh industrial environments, an additional protective screen is often used� A contamination of the

protective screen also leads to a reduced indication of the measuring value�

► Check the protective screen regularly and clean it if necessary or replace it in

case of damage�

• Remove dust by blowing or with a soft brush�

• Use clean, soft and lint-free cloths or those offered on the market for lens

cleaning�

• For heavier contamination, use washing-up liquid or liquid soap� Then carful

ly rinse with clear water� Hold the lens downwards�

• Exert only little preasure on the lens during cleaning to avoid scratches�

-

ATTENTION

Replacement of the protection glass only by authorized person� When removing

the protective screen, always wear protective glasses and -gloves.

18 Models

Pyrometer

Type Temp. range Application

PX 21 250 - 2000 °C Metals, ceramics, molten glass

PX 31 500 - 2500 °C Metals, ceramics at high temperatures

PX 36 650 - 3000 °C Precise measurement of metals, semiconductors

40

Page 41

Operating instructions CellaTemp PX 21 / 31 / 36

d

19 Field of view

With a pyrometer with focusable optics, the size of the measurement field is

determined by the distance ratio D� The measurement field diameter d at the focal

distance is defined by the formula:

EN

a

On our website you will find a measurement field calculator� Select the suitable

pyrometer, enter the measuring distance and the length of the measurement

field and you will get the suitable measurement field courcse and you can see

the size of the measuring spot at the relevant distance�

https://www.keller.de/en/its/tools/field-of-view-calculator.htm

41

Page 42

Operating instructions CellaTemp PX 21 / 31 / 36

20 General technical data

Pyrometer

Analogue output 0(4) -20 mA linear according NAMUR 43,

Switching output OUT1 PNP Open Collector outputs 24 V, ≤ 150 mA

Switching output OUT2 PNP Open Collector outputs 24 V, ≤ 150 mA

Ambient temperature 0 - 65 °C (basic unit)

IO-Link revision V1�1, download compatible to V1�01

SIO mode yes, supported

Transmission rate COM2 (38�400 Baud)

Storage temperature -20 – 80 °C

Permissible humidity 95 % r�H� max� (non condensing)

Power supply 24 V DC +10 % / -20 % ripple ≤ 200 mV

Current consumption ≤ 150 mA

Housing material Stainless steel

Weight Approx� 1 kg

Connectivity 5-pin connection M12 (A coded)

Protection IP 65 according DIN 40050

switchable, scalable load 500 Ω

switch point [°C]/ return switch point [°C],

hysteresis ≥ 1 K, on/switch-off delay, NC/ NO or

IO-Link

switch point [°C]/ return switch point [°C],

hysteresis ≥ 1 K, on/switch-off delay, NC/ NO

0 - 250 °C (measuring head)

with screwed plug

42

Page 43

Operating instructions CellaTemp PX 21 / 31 / 36

Conguration parameter Emissivity ε 10 - 110 %

Sighting device Laser spot light

Dimensions Ø 65 x 187 mm (basic unit without plug)

Transmissions factor τ 10 - 100 %

Smoothing function t98 0�1 – 999�9 s

Peak hold function 0�1 – 999�9 s

ATD function

Ø 30 x 67���86 mm (LWL measuring head M30)

Ø 16 x 33���39 mm (LWL measuring head M16)

EN

43

Page 44

Operating instructions CellaTemp PX 21 / 31 / 36

21 Device-specific technical data

PX 21

Temperature range

Sensor Photodiode

Spectral sensitivity 1�1 -1�7 µm

Focussing range

Distance to target-size ration

Resolution current output 0�2 K + 0�03 % of selected range

Resolution temp� reading 1 K

Response time t

Measurement uncertainty

Repeatability 2 K

Temperature coecient with

reference to 23°C

250 - 2000 °C

(Default setting analog output 300 - 2000 °C)

0.4 m - ∞ optic PA 41.01 M30

0.12 m - ∞ optic PA 41.05 M16

33 - 45 mm optic PZ 41�18 M16

180:1 (PA 41.01)

100:1 (PA 41.05)

50:1 (PZ 41.18)

98

≤ 50 ms (T > 300 °C)

≤ 2 ms (T > 800 °C)

0,75 % of temperature reading, minimum 4 K

(at ɛ =1.0 and Tu = 23 °C)

≤ 0.25 K / K (T < 500 °C)

≤ 0.05 %/K (T ≥ 500 °C)

of temp� reading / K

44

Page 45

Operating instructions CellaTemp PX 21 / 31 / 36

PX 31

Temperature range 500 - 2500 °C

Sensor Photodiode

Spectral sensitivity 0�78 - 1�06 µm

Focussing range

0.4 m - ∞ optic PA 41.01 M30

0.12 m - ∞ optic PA 41.05 M16

33 - 45 mm optic PZ 41�18 M16

Distance to target-size ration

190:1 (PA 41.01)

100:1 (PA 41.05)

50:1 (PZ 41.18)

Resolution current output 0�2 K + 0�03 % of selected range

Resolution temp� reading 1 K

Response time t

98

Measurement uncertainty

≤ 50 ms (T > 600 °C)

≤ 2 ms (T > 800 °C)

0,75 % of temperature reading, minimum 4 K

(at ɛ =1.0 and Tu = 23 °C)

Repeatability 2 K

Temperature coecient with

≤ 0.05 %/K

reference to 23°C

EN

45

Page 46

Operating instructions CellaTemp PX 21 / 31 / 36

PX 36

Temperature range 650 - 3000 °C (AF 2)

Sensor Photodiode

Spectral sensitivity 0�82 - 0�93 µm

Focussing range

0.4 m - ∞ optic PA 41.01 M30

0.12 m - ∞ optic PA 41.05 M16

33 - 45 mm optic PZ 41�18 M16

Distance to target-size ration

190:1 (PA 41.01)

100:1 (PA 41.05)

50:1 (PZ 41.18)

Resolution current output 0�2 K + 0�03 % of selected range

Resolution temp� reading 1 K

Response time t

98

Measurement uncertainty

≤ 50 ms (T > 680 °C)

≤ 2 ms (T > 900 °C)

0�75 % of measuring value

(at ɛ =1.0 and Tu = 23 °C)

Repeatability 2 K

Temperature coecient with

≤ 0.05 %/K

reference to 23°C

46

Page 47

Operating instructions CellaTemp PX 21 / 31 / 36

22 Accessories

A range of mechanical and electrical accessories are available for mounting the

pyrometers in industrial environments�

For the selection of the components use the following link:

https://www.keller.de/en/its/pyrometers/accessories.htm

23 Default settings

The default settings can be found in the description of the IODD� You can find it on

our website www�keller�de/its under Mediathek�

EN

24 Copyright

The licence information of the Open Source libraries used can be found in the

media library on our website www�keller�de/its

47

Page 48

Copyright prohibits the reproduction or distribution of this instruction manual,

including text, photographs or images contained herein, in whole or in part, for

any purpose whatsoever, without prior consent of the author� This applies to

any form of mechanical or electronic reproduction as well as to electronic

transmission in any form through any medium�

Please note:

Unless otherwise stated in this instruction manual, the instruments described

herein are subject to change without prior notice, particularly modifications for

the sake of technological advancement�

© 2019 KELLER HCW GmbH

Carl-Keller-Straße 2-10

D-49479 Ibbenbüren-Laggenbeck

Germany

www�keller�de/its

Loading...

Loading...