Page 1

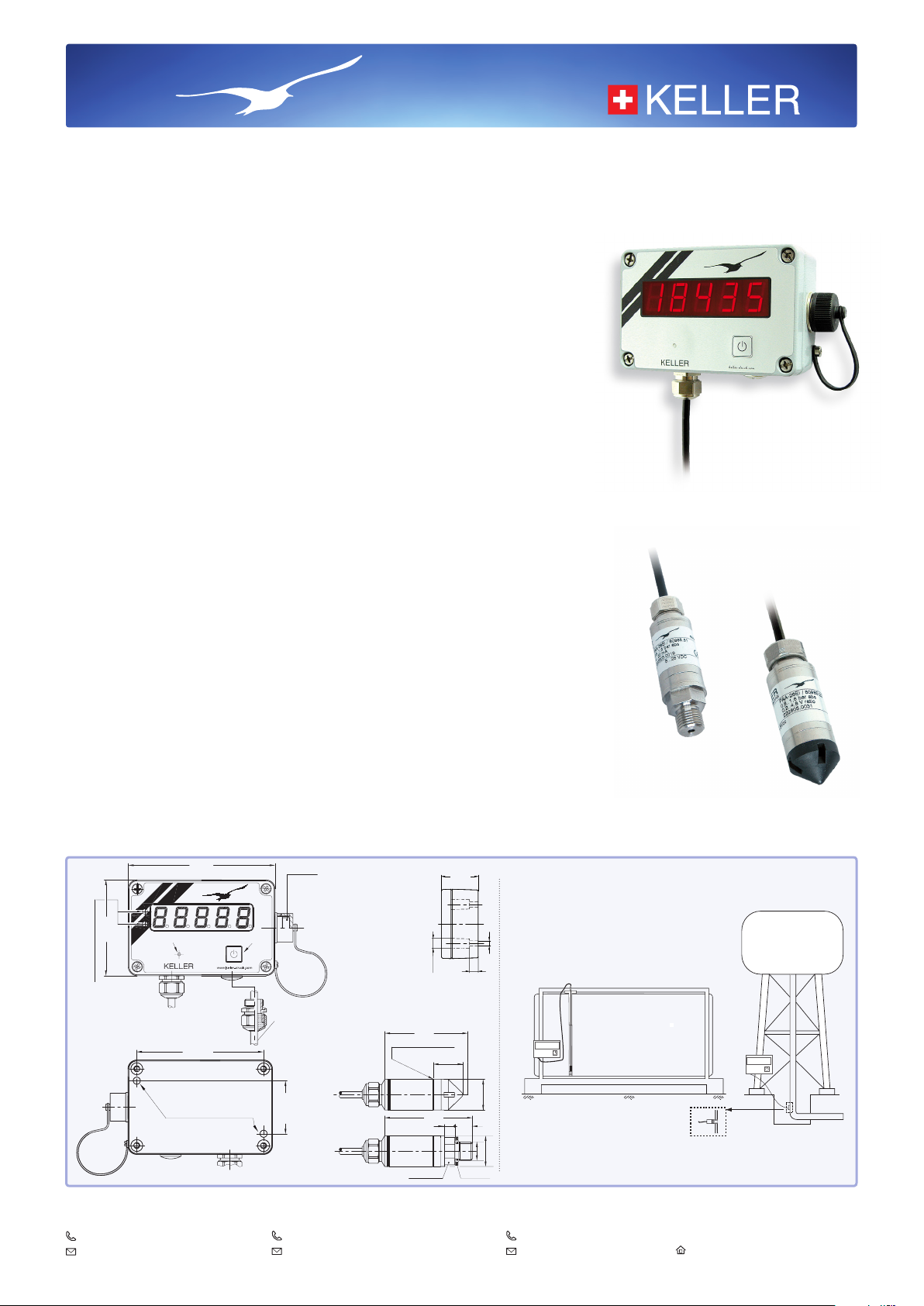

Content MeasureMent systeM

86 mm

53 mm

Ø 21 mm

60 mm

7 mm

12mm

6kt – SW 17

USIT-Ring

G1/4’’

Ø 21 mm

10500

KELLER

98 mm

64 mm

Air-Pressure On-Button

Ø 9,2 mm / Ø 8,6 mm

for ventilated or pressurised tanks

Castello offers a user-friendly way to re present the pressure measurement at the bottom of a

tank as the quantity of remaining liquid. At the push of a button, the micro -controller performs

the calculations using the information of the tank shape and dimen sions and displays the remaining tank content quantity on the clearly legible 5-digit LED display in the desired unit (litres,

gallons etc.).

The unit is congured using a PC and the easy-to-use software so that the lling level, which

determines the pressure, can be converted into an appropriate lling quantity. First the tank

shape is selected, then the tank dimensions and the specic gravity of the liquid are entered. It

contains the most current tank shapes. The program covers the most common tank shapes, but

also enables any shape by entering the parameters into a specied table.

The exclusive use of absolute pressure sensors in the Castello system eliminates the use of

capillary vented cables with all the problems associated with a gauge pressure measurement.

The Castello housing integrates an air pressure sensor, ranged between 0,8 bar and 1,2 bar

absolute. The sensors to measure the hydrostatic pressure at the bottom of the tank are calibrated from 0,8 to 1,8 bar abs for tanks up to 5 m in height, and 0,8 to 2,3 bar abs for tanks up to

10 m in height. The pressure difference, calculated by the

static pressure.

The content of a pressurised tank is determined using the difference between the measurements from two absolute pressure sensors located at the top and bottom of the tank.

The overall accuracy of the system of 2 mbar is achieved using a computerised calibration

and compensation procedure for the pressure sensors. The coefcients for this calculation are

stored in EEPROMs in the sensors. These are retrieved by the micro processor at each mea-

surement and employed within the equations to calculate the pressure values. The Castello

housing and hydrostatic sensor can be interchanged at will.

It is also possible to connect a standard 3-wire transmitter or high-precision digital transmitter

(Series 36 X) that can be congured to an accuracy of 0,02 %FS over a range of 0 to 50 °C, a

true representation of which is displayed by the Castello.

The power supply to the system (8 to 28 V) can be provided externally or internally using a

9 V battery. The display is obtained by pressing the button on the front, and the value appears

for a congurable duration. The Castello has two switch outputs with congurable functiona lity

and threshold values. An external power supply must be provided if the switch outputs are used.

micro -controller

, is the relative hydro-

Castello

CA1

Series 23 Q

Series 26 Q

Indication of

switching outputs (LED)

Bottom View

Drill holes for mounting

KELLER AG für Druckmesstechnik

CH-8404 Winterthur

+41 52 235 25 25

info@keller-druck.com

Binder male socket

8 pole / Serie 723

Pin connection

1: +S1 (Relayoutput)

2: -S1 (Relayoutput)

3: +S2 (Relayoutput)

4: + VCC (8…28 VDC)

5: RS 485 A

6: -S2 (Relayoutput)

7: RS 485 B

8: GND

34 mm

Side View

Optional:

second transmitter

Diaphragm’s position

20 mm

36 mm

KELLER Ges. für Druckmesstechnik mbH

DE-79798 Jestetten

+49 7745 9214 0

eurocenter@keller-druck.com

Mounting Options

Ø 4,8 mm

8

KELLER America

Newport News, Virginia

1 877 253 5537

sales@kelleramerica.com

Series 26 Q

10500

KELLER

/ / / / / / / / / / / / / / / / / / / / / / /

Series 23 Q

Edition 04/2018

Subject to alterations

Companies approved to ISO 9001

www.keller-druck.com

Page 2

Installation

There are two holes in the housing for mounting the unit. To install the sensor, unscrew and remove the cover of the unit, lead the cables through

the PG screw connections and attach the wires to the screw terminals. The Castello is programmed via the connector on the side, which is also

the location of the external power supply and switch output connections. Provided that the cover and the cable leadthrough are securely tightened,

the extremely robust housing is watertight in compliance with IP65.

Castello Ordering Information

Castello basic unit + KELLER standard transmitter series 23 Q (with thread) or series 26 Q (for lling level)

+ converter K-107 (serial) or K-104B (USB) for conguration incl. adapter (5-pin --> 8-pin)

or conguration in accordance with customer specications

Specications for Castello

Measuring / Pressure Ranges 5 m tank level (10 m standard cable): Range 0,8…1,8 bar abs.

10 m tank level (15 m standard cable): Range 0,8…2,3 bar abs.

Supply External: 8…28 V

Internal: 9 V battery

Switch outputs 2 pcs. PhotoMOS-Relais 40 V / 0,4 A

Battery Life

4’000 Measurements (display 10 seconds on)

6’000 Measurements (display 5 seconds on)

Interface RS485

Air Pressure Probe Level Probe

Temperature Range -20…+70 °C 0…50 °C

Accuracy (Error Band) max. 0,5 mbar

2 mbar (1,8 bar range)

3 mbar (2,3 bar range)

Indicator 5 digits – 14 mm high

7 segments LED

Resolution Min. 2’000 Points

Indicator Material Aluminium

Level Probe Material Stainless Steel AISI 316L

Cable Type Hytrel, 4,60 mm Ø

Probe Protection IP 68

Indicator Protection IP 65

Probe Certication II 1 G EEx ia IIC T6

LCIE 02 ATEX 6124 X

Indicator Certication In Progress

Overpressure 2 x Nominal Range

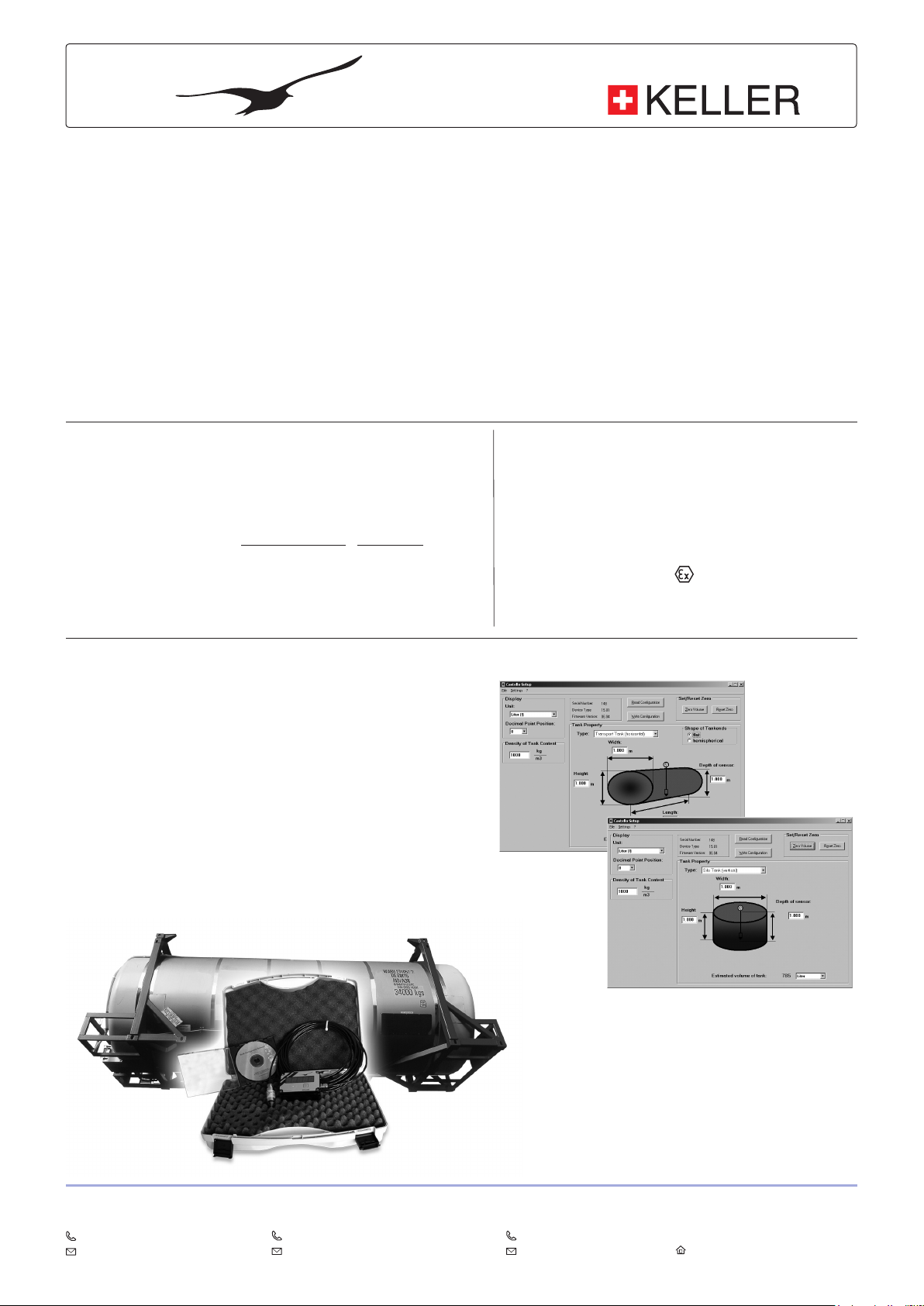

Conguration PC-Software

The software to congure Castello can be downloaded from our website or

ordered on CD for a handling charge. Castello can be connected to the PC

via KELLER converter cable K-107 or K-104B with adapter. Castello can be

congured for standard or EEPROM transmitters.

The software contains the pressure/content curves of the featured tanks.

The dimensions of the tank of a certain shape and the specic gravity of the

liquid is entered and the measurement unit for the display chosen.

The software also foresees the application for free standing water towers,

where the distance of the tank to the position of the transducer can be

chosen.

Options (extra charge):

–

Face plate with various measuring units and

customer’s logo

– Other housing colours (default: grey)

– Carrying case

– Factory conguration: foil strip on rear con-

taining all application-related details

– Wireless transmission via ARC-1

KELLER AG für Druckmesstechnik

CH-8404 Winterthur

+41 52 235 25 25

info@keller-druck.com

KELLER Ges. für Druckmesstechnik mbH

DE-79798 Jestetten

+49 7745 9214 0

eurocenter@keller-druck.com

KELLER America

Newport News, Virginia

1 877 253 5537

sales@kelleramerica.com

Edition 04/2018

Subject to alterations

Companies approved to ISO 9001

www.keller-druck.com

Loading...

Loading...