Page 1

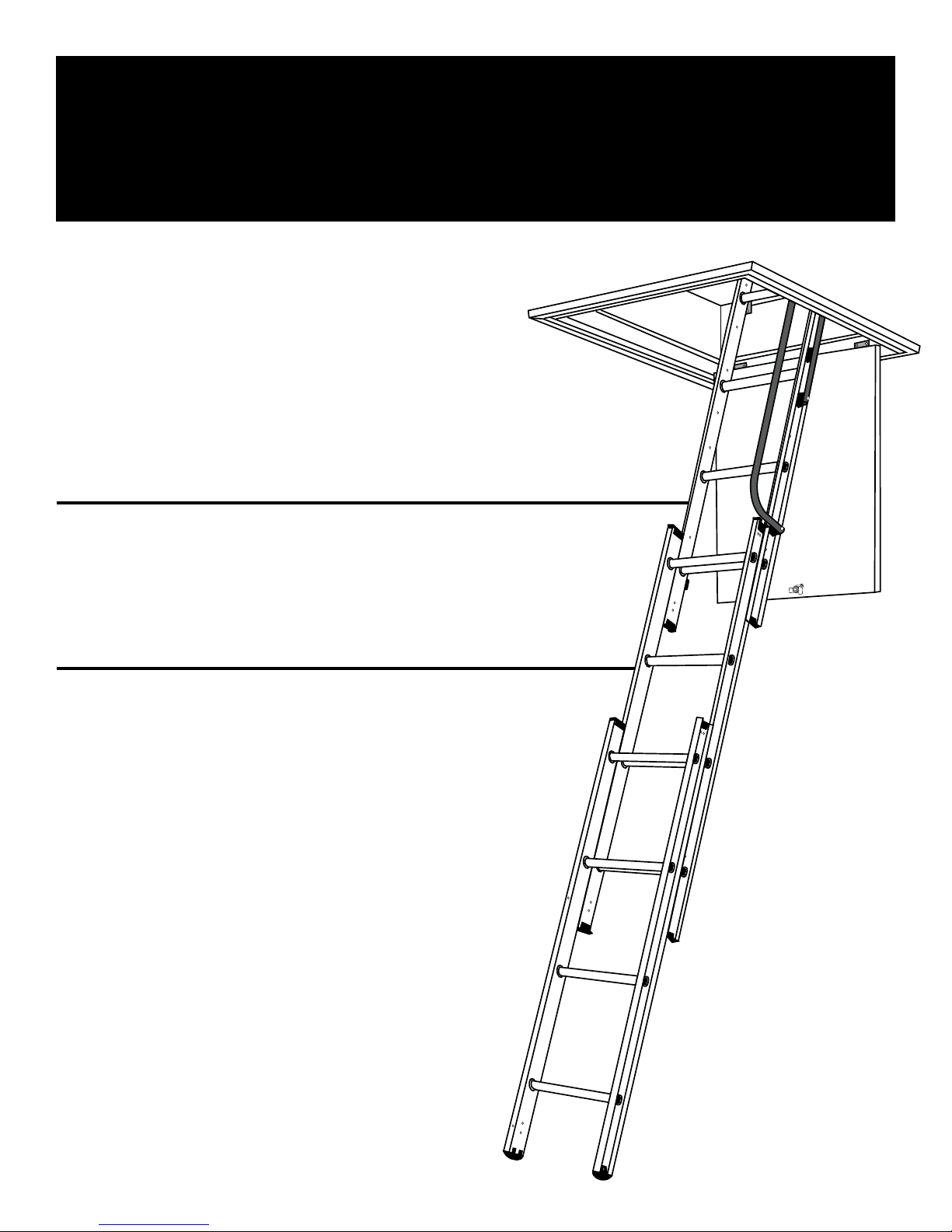

AA1510 / AA1510CA

Installation Instructions

FAILURE TO COMPLY WITH ALL INSTRUCTIONS MAY RESULT IN SERIOUS INJURY

Instrucciones de instalación

NO CUMPLIR TODAS LAS INSTRUCCIONES PODRÍA RESULTAR

EN LESIONES GRAVES

Instructions d’installation

LE NON-RESPECT DE CES INSTRUCTIONS PEUT ENTRAÎNER

UNE BLESSURE GRAVE

Page 2

Compact Attic Ladder

ALUMINUM

BUILT FOR SMALL ATTIC OPENINGS

Table of Contents

Before you begin 2

Important questions 3

Step 1 Assembling the ladder 3

Step 2 Fitting additional top stops 4

Step 3 Fitting bottom stops 5

Step 4 Installing the ladder 5

Page

Step 5 Installing the assist arm 6

Step 6 Handrail assembly 7

Step 7 Finishing opening for door 7

Step 8 Hanging the door 8

Step 9

Step 10 Attaching the location bracket 9

Step 11 Operating the ladder 10

Appendix Creating a rough opening 11

Section 1.1 Important questions 11

Section 1.2 Tools and materials needed 12

Section 1.3 Finding a suitable location 13

Section 1.4 Cutting a hole in the ceiling 14-16

Locating the hole for the door

latch

8-9

Section 1.5 Framing the rough opening 16-19

Page 3

Before you begin

TOOLS REQUIRED

STEPLADDER

AWL

SAW

DRILL PLUS 1/2" & 1/16" BIT

LARGE FLAT SCREWDRIVER

PHILLIPS SCREWDRIVER

(small and medium)

ADJUSTABLE WRENCH/PLIERS

TAPE MEASURE/RULER

HAMMER

PENCIL

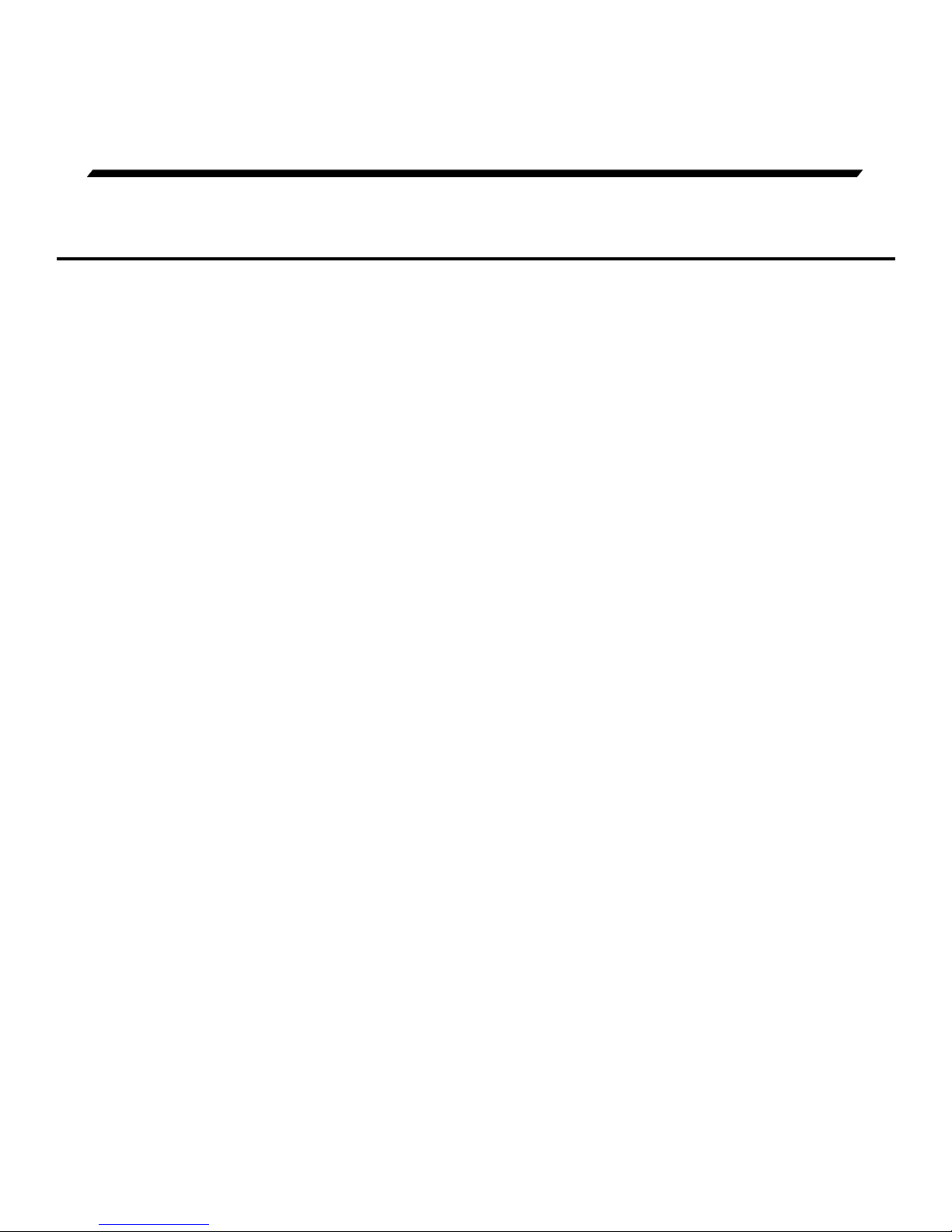

A Minimum Finished Opening (Length) 21"

B Minimum Finished Opening (Width) 15"

DOOR MATERIAL REQUIRED

BE SURE TO USE 3/4" CABINET GRADE PLYWOOD.

1 x 3 SOLID WOOD BOARD REQUIRED FOR DOOR FRAME

1 X 2 SOLID WOOD BOARD REQUIRED FOR DOOR JAM

AT THE BEGINNING OF EACH STEP THROUGHOUT

THIS INSTRUCTION MANUAL, FASTENERS AND

COMPONENTS THAT ARE NEEDED WILL BE LISTED.

IF ANY PARTS ARE MISSING OR BROKEN,

PLEASE CALL CUSTOMER SERVICE AT 1-888-523-3370.

Compact Attic Ladder

C

D* Minimum Stowing Height Required In Attic 28"

E**

Maximum Height 9' 10"

Minimum Height 7'

Minimum Length Required

Behind Rough Opening

44"

Closed Requirements Opened Requirements

D*

B

E**A

68°- 80°

C

*At handrail low position - 28"

At handrail top position - 38"

**At handrail low position - 44"

At handrail top position - 54"

2

Page 4

Important Questions

Read instructions completely before beginning. This is necessary to ensure that you have a suitable location for the attic

ladder and the ability to safely and properly install it.

Are you capable of installing this attic ladder?

To install this attic ladder you should have sawing, squaring, and aligning skills similar to those required to install a

window or a door frame. If you do not have these skills you should hire a professional carpenter to install this unit

(see the Yellow Pages under “Building Contractors, Carpenters, Home Builders, Home Improvements, or

Contractors-General”).

Does this attic ladder meet your needs?

This attic ladder is for residential use only. Installing this attic ladder in commercial buildings and apartments may violate

building codes that require re-rated ceilings and prohibit storing materials in the overhead space! Check with your local

re marshal or building department before installing the attic ladder.

The capacity of the attic ladder (person plus materials being carried) is 250 pounds.

This attic ladder is made for the range of ceiling heights shown on the packaging. Do not install the attic ladder

in a ceiling that has a height outside of this range. Altering the attic ladder to accommodate other heights

is unsafe and should never be attempted.

THIS ATTIC LADDER COMES WITH HINGES AND LATCH TO INSTALL A DOOR (NOT

INCLUDED). TO MODIFY OR CREATE A NEW OPENING, PLEASE REFER

TO THE APPENDIX (PAGE 11).

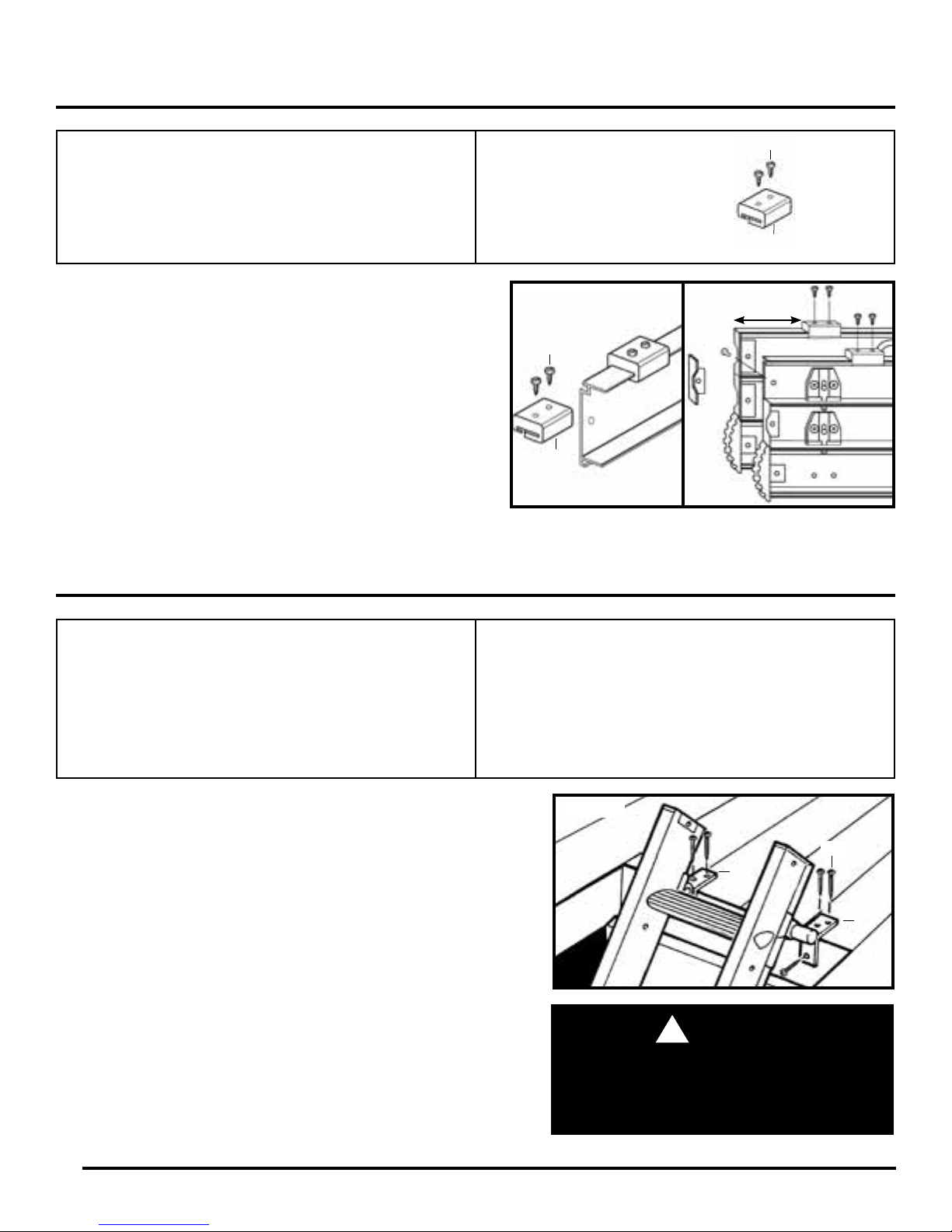

Step 1

Assembling the Ladder

TOOLS REQUIRED

HAMMER

For correct identication, the front section of the ladder can be identied by its rounded feet.

1. Carefully push out the tacks (lightly tap with a hammer if necessary) and remove the plastic end caps from the bottom

of the REAR section of the ladder (See Figure A).

2. Slide the hinge guides (B1 & B2) onto the uppermost frame section. The brackets should be positioned outwards with

the double holed half uppermost (See Figure B).

3. Slide all the way up to the installed permanent top stops at other end of section.

4. Do not replace the plastic end caps (see later at Step 3 - Fitting Bottom Stops).

Rear

PARTS REQUIRED

B1. (1) HINGE GUIDE - LEFT

B2. (1) HINGE GUIDE - RIGHT

B2

Right side

Front

Figure A Figure B

3

Left side

B1

Page 5

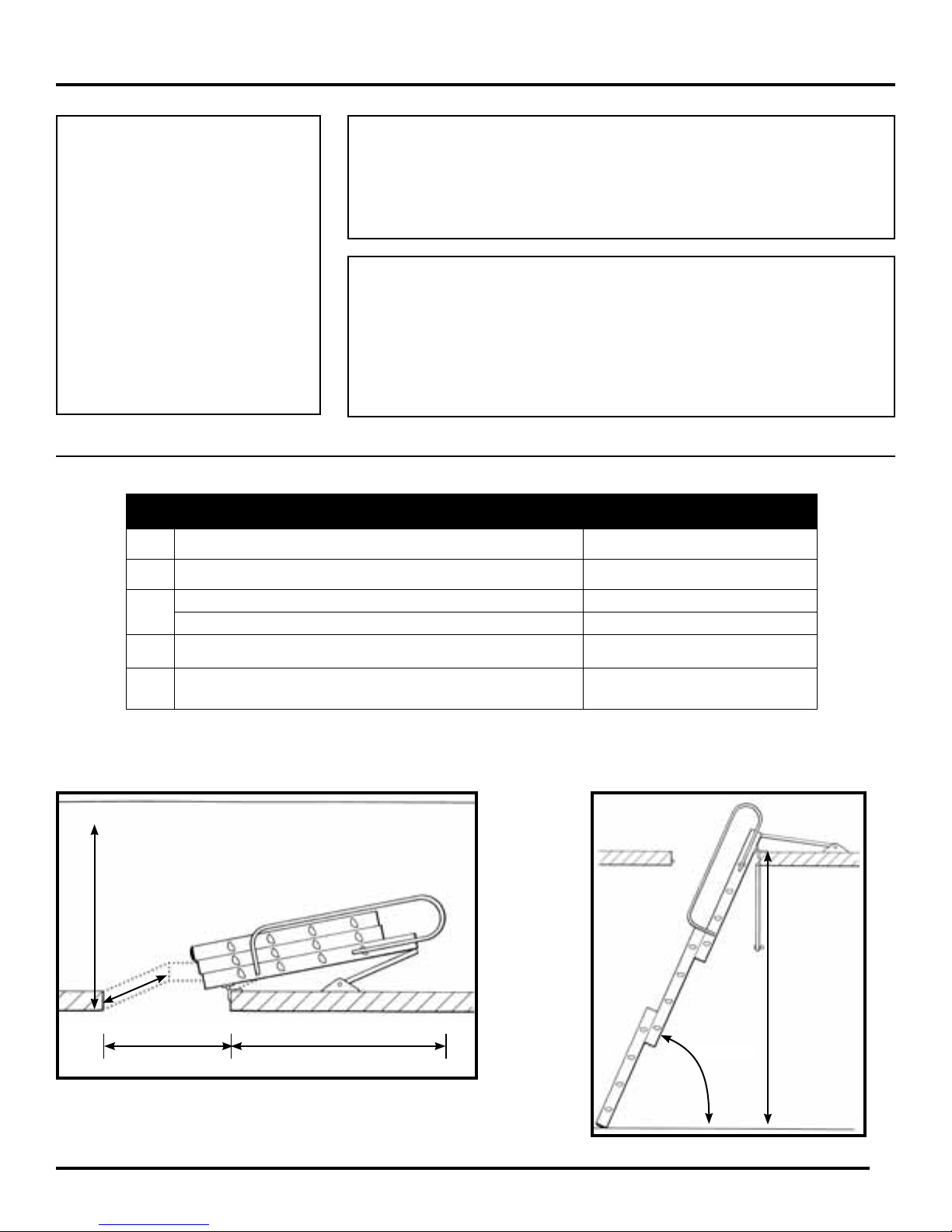

Step 2

Fitting Additional Top Stops

TOOLS REQUIRED

ADJUSTABLE WRENCH/PLIERS

Opened Requirements

PARTS REQUIRED

C1. (2) M4 X 8MM TOP STOP BOLTS

C2. (2) ADDITIONAL TOP STOPS

C3. (2) M4 LOCKING NUTS

Permanent top stop

B2

B1

C1

C2

C3

C1

C2

C3

68°- 80°

Floor to

oor height

Figure C

Depending on the oor to oor height (see Opened Requirements

left), you may need to add the additional top stops provided (C2)

(see table below).

1. If required, locate the additional top stops over the holes

approximately 6" below the permanent top stops on the rear

section of the ladder (See Figure C).

2. Ensure the hinge guides (B1 & B2) are already in place and

below the additional top stops when assembled.

3. Fix the additional top stops using two M4 bolts and nuts

supplied (C1 & C3).

Operating Heights

Feet & Inches Top Stops Required

7' 0" to 7' 6" YES

7' 6" to 7' 11" NO

7' 11" to 8' 5" YES

8' 5" to 8' 10-1/2" NO

8' 10-1/2" to 9' 4" YES

9' 4" to 9' 10" NO

4

Page 6

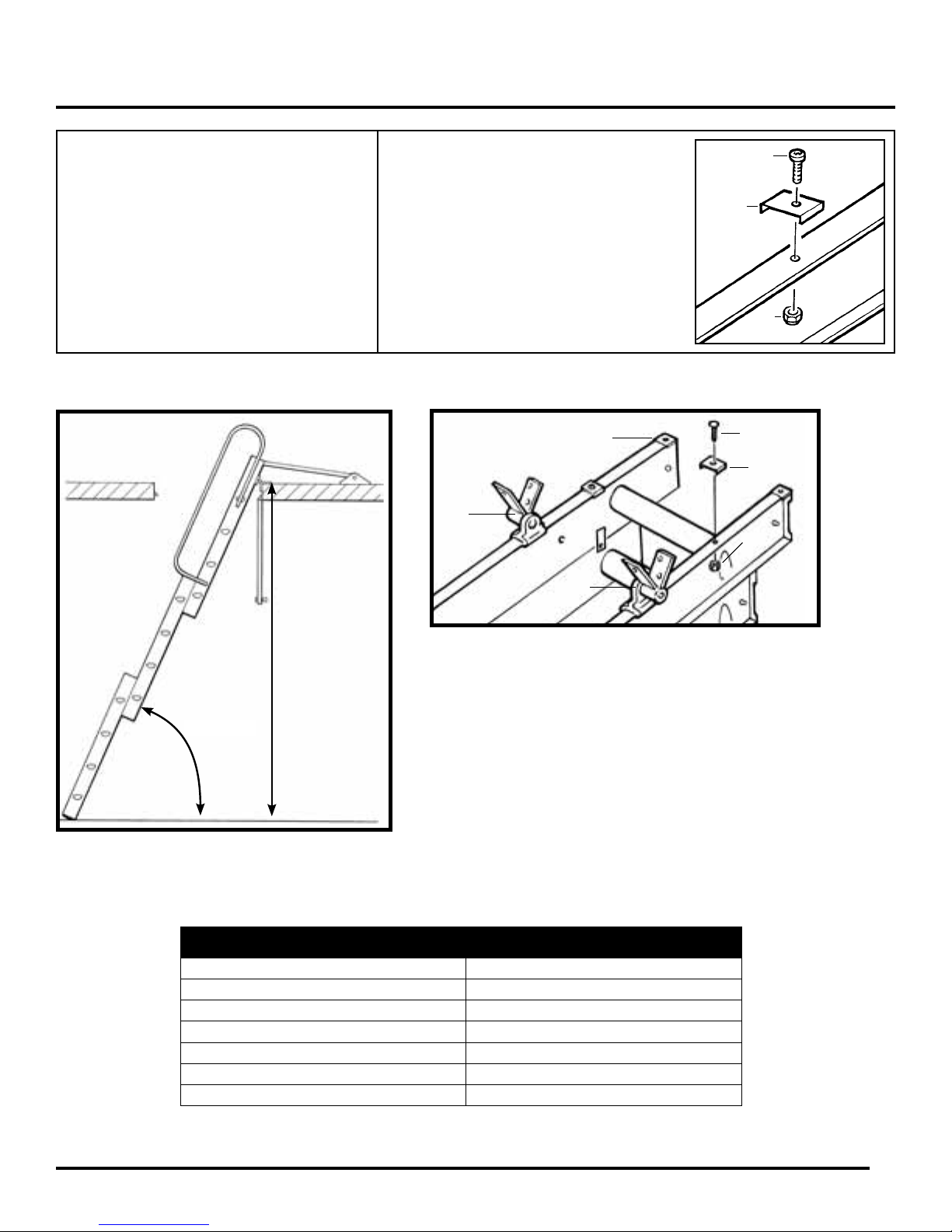

Step 3

Fitting Bottom Stops

TOOLS REQUIRED

LARGE FLAT SCREWDRIVER

PHILLIPS SCREWDRIVER

(small and medium)

HAMMER

1. Both end caps should now have been removed from the

rear section during previous Step 1. Remove end cap

from the rear section rail (on the same side as it is

intended to t the assist arm).

2. Slide the bottom stops (D1) onto the rear rails.

3. Position the bottom stops 6" from the end of

the rails (See Figure D).

4. Secure with screws (D2).

5. Replace the plastic end caps removed previously and

secure with tacks.

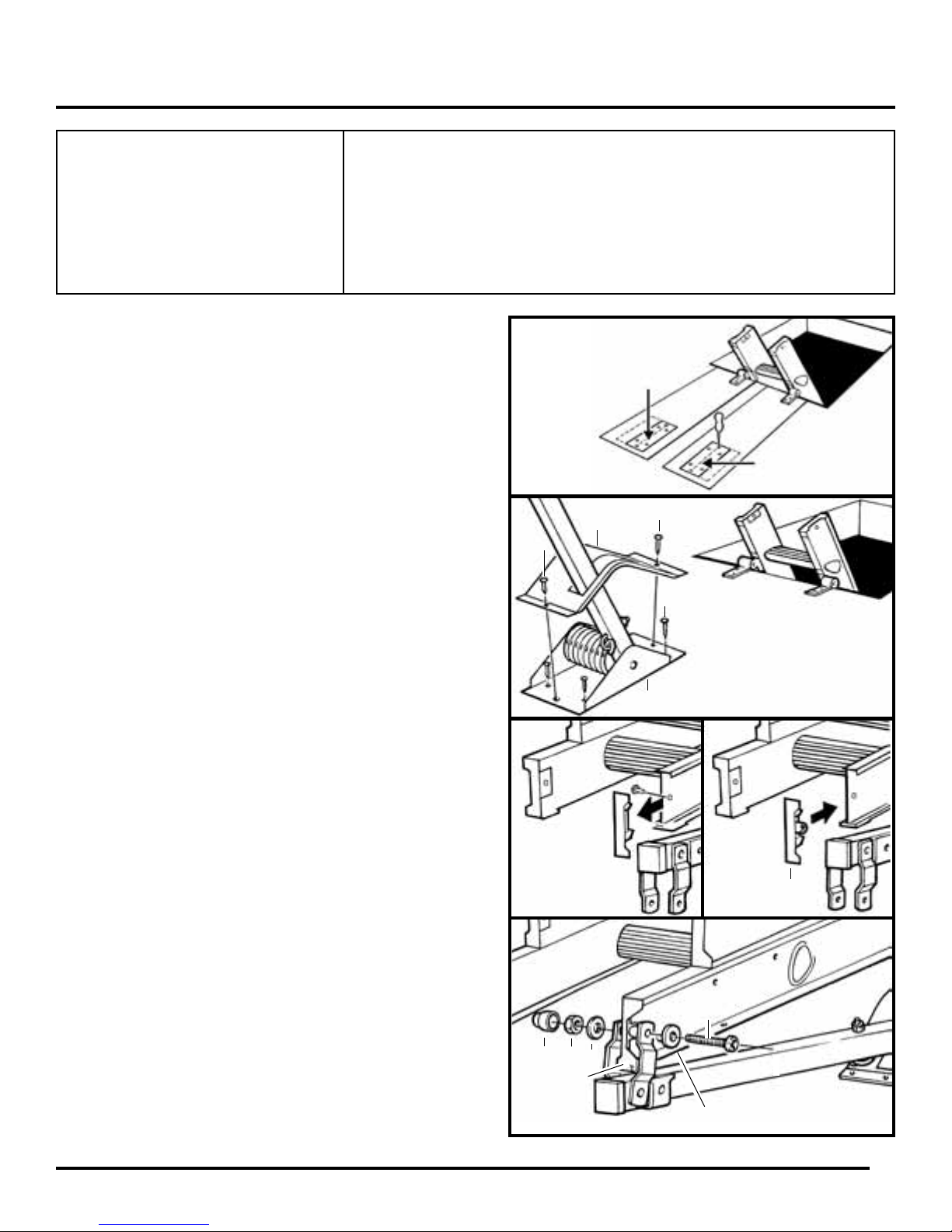

Step 4

Installing the Ladder

PARTS REQUIRED

D1. (2) BOTTOM STOPS

D2. (4) 12MM SCREWS

D2

D1

Figure D

D2

D1

6"

TOOLS REQUIRED

STEPLADDER

DRILL PLUS 1/16" BIT

LARGE FLAT SCREWDRIVER

PHILLIPS SCREWDRIVER (small and medium)

PENCIL

Minimum 3/4" ooring required to support Compact Attic Ladder (See

Appendix, Page 19, Figure 18). The ladder should be installed on the

same side of the opening as where the door hinges will be located.

1. With the ladder centered in the opening, locate the hinge guide

bracket arms (B1 & B2) on the top edge of the opening frame

(See Figure E).

2. Mark guide holes with a pencil and then predrill pilot holes

(1/16" diameter) for all screws.

3. Attach using 35mm screws (B3).

The bracket arms with two screw holes should be on top.

If ooring material covers the top edge of the opening be certain that

the ladder is completely stable. If necessary use longer screws to

penetrate the frame itself.

The ladder should now be free to swing from the hinges and slide

freely up and down the guides.

PARTS REQUIRED

B1. (1) HINGE GUIDE - LEFT

B2. (1) HINGE GUIDE - RIGHT

B3. (6) 35mm SCREWS

Figure E

B3

B1

B2

WARNING:

!

DO NOT stand on the ladder to do this. Either

using a second ladder, or from inside the attic

space, secure the hinges using six 35mm

screws supplied.

5

Page 7

Step 5

Installing the Assist Arm

TOOLS REQUIRED

AWL

LARGE FLAT SCREWDRIVER

PHILLIPS SCREWDRIVER

(small and medium)

ADJUSTABLE WRENCH/PLIERS

1. Position the template cut (from the back of the packaging

card) against either the left or right hand hinge guide

bracket (depending on which chosen side the power pivot

system is to be installed).

2. Using an awl or pencil mark the 6 applicable holes through

the template on to the attic oor (See Figure F).

3. Place the spring housing (F1) in position over the holes

ensuring the arm points AWAY from the rough opening

(with slot in cover on the left-hand side) (See Figure G).

4. Secure the spring housing to the attic oor with 20mm

screws (F3) through the 4 inner holes (See Figure G).

5. Place the housing cover (F2) over the spring housing and

attach using 20mm screws (F3) through the 2 remaining

outer holes (See Figure G)

PARTS REQUIRED

F1. (1) POWER PIVOT UNIT

F2. (1) HOUSING COVER

F3. (6) 20mm SCREWS

F4. (1) PIVOT TIP

F5. (1) M6 x 40mm BOLT

Figure F

F3

F6. (2) PLASTIC WASHERS

F7. (1) M6 LOCKING NUT

F8. (1) NUT CAP

F9. (1) BASE DRILL HOLE TEMPLATE

[ON BACK OF PACKAGING CARD]

For Right

Hand

Installation

For Left Hand

Installation

F2

F3

F3

6. Position the ladder in its fully stowed (closed) position

carefully in the opening.

7. Remove the tack and plastic top cap from the top of the

required side rail of the rear ladder section and discard

(See Figure H).

8. In their place attach Pivot Tip (F4) (See Figure H).

9. Locate the power arm linkage plates on either side of pivot

tip (F4)/ladder rail and align all holes.

10. Secure the rail to the linkage plates using bolt (F5),

washers (F6), nut and nut cap (F7 & F8) (See Figure I).

Ensure bolt (F5) and nut (F7) are tightened sufficiently to

allow the linkage to freely rotate without any looseness.

DO NOT over-tighten the nut as this will restrict smooth

operation of the ladder system.

Figure H

F8

F7

F4

F6

F1

Figure G

F4

F5

Figure I

F6

6

Page 8

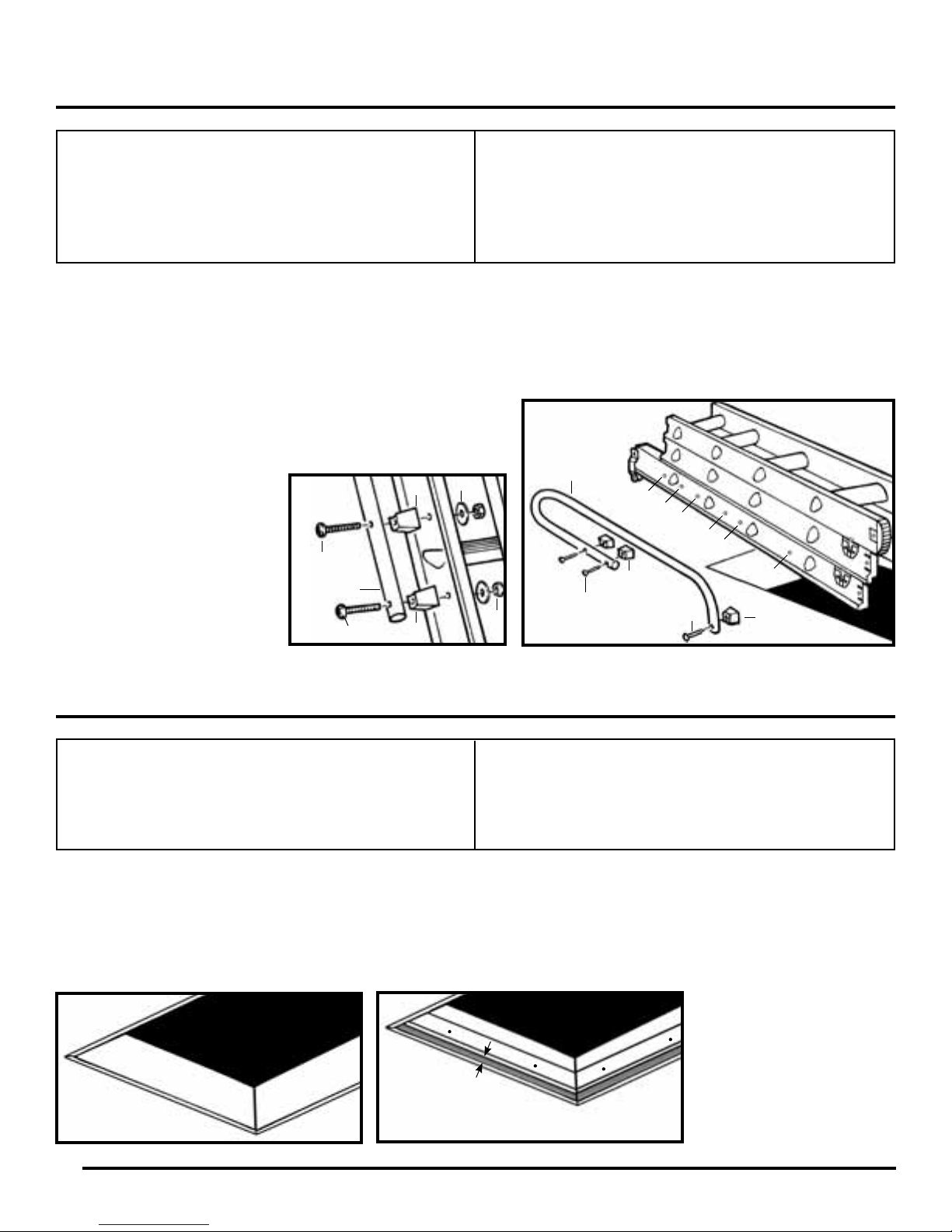

Step 6

Handrail Assembly

TOOLS REQUIRED

ADJUSTABLE WRENCH/PLIERS

The handrail can be attached to either side of the ladder. It is advisable to attach the handle only after attaching the power

pivot arm.

1. Attach the handrail to your chosen side of the rear frame (See Figure J).

2. Use 3 spacers (E1), 60mm bolts (E2), washers and nuts (E3 & E4) supplied.

3. You have a choice of 2 different handrail heights which will be

dependent on the amount of “in-attic” handrail you require (See

Figure J).

Check that all components of the whole assembly are fully secure.

E3

*Position 1 attaches handrail

in top position.

**Position 2 attaches handrail

in low position.

Note: Position of the handrail

will affect the amount of space

needed in the attic.

E2

Handrail

E2

E1

E1

PARTS REQUIRED

E1. (3) HANDRAIL SPACERS

E2. (3) M5 x 60mm BOLTS

E3. (3) 25mm DIAMETER WASHERS

E4. (3) M5 LOCKING NUT

Handrail

1*

1*

2**

2**

E1

E2

E4

Figure J

E2

1*

2**

E1

Step 7

Finishing Opening for Door

TOOLS REQUIRED

SAW

SCREWS / NAILS

PHILLIPS SCREWDRIVER (small and medium)

Use a standard 1 x 3 solid wood plank for the door frame and a standard 1 x 2 solid wood board for the door jam.

1. Measure the width of the opening and cut the 1 x 3 wood board. Nail the trimmed 1 x 3 wood board to the header.

The bottom of the wood door frame should be ush with drywall on ceiling. Repeat for length of opening. (Figure K)

2. Measure inside width of frame and cut the 1 x 2 wood board. Nail the trimmed 1 x 2 wood board to the wood door

frame recessed the thickness of the door to create the door jam. Repeat for length of frame. (Figure L)

Jam should be recessed

Figure K

the thickness of door

PARTS REQUIRED

Standard 1 x 3 solid wood board (Door Frame)

Standard 1 x 2 solid wood board (Door Jam)

Your choice of nishing wood

Caution: Use of

materials greater than the

recommended thickness

may make the opening too

small to be usable.

Figure L

7

Page 9

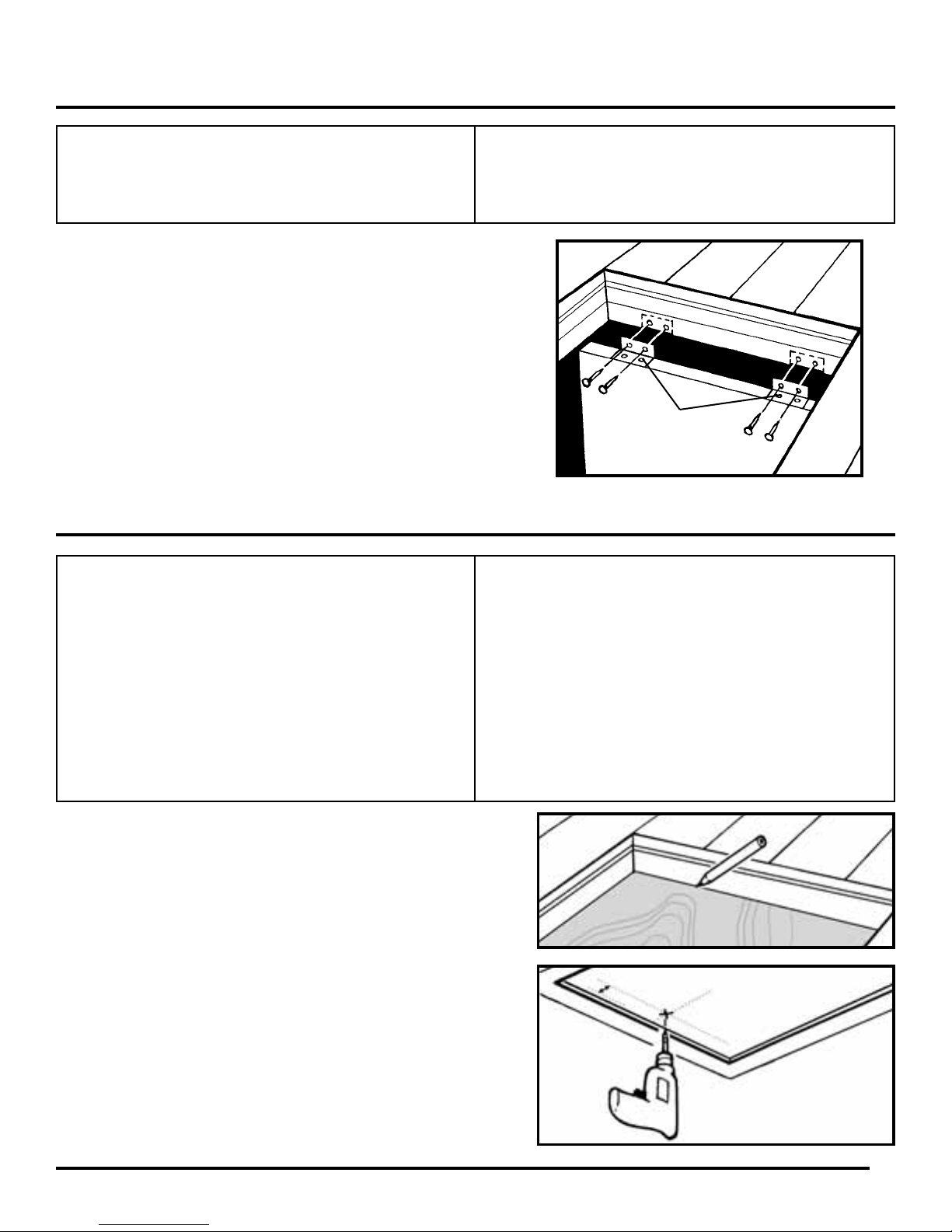

Step 8

Hanging the Door

TOOLS REQUIRED

LARGE FLAT SCREWDRIVER

PHILLIPS SCREWDRIVER (small and medium)

The door thickness should be 3/4" cabinet grade

plywood cut 1/8" smaller than wood door frame

opening (from Step 7 - Finishing Opening for Door)

1. Screw hinges (G5) to one edge of the door using

3/4" wood screws.

2. Attach the hinges to the face of the frame on the

same end as you installed the ladder using 3/4"

wood screws (See Figure M).

PARTS REQUIRED

G5. (2) DOOR HINGES

(8) 3/4" WOOD SCREWS

Step 9

Locating the Hole for the Door Latch

TOOLS REQUIRED

PARTS REQUIRED

G5

Figure M

STEPLADDER

DRILL

1/2" DRILL BIT

SANDPAPER

LARGE FLAT SCREWDRIVER

PHILLIPS SCREWDRIVER (small and medium)

ADJUSTABLE WRENCH/PLIERS

TAPE MEASURE/RULER

PENCIL

1. From inside attic, with door fully closed, mark the edge of the

jam on the door with a pencil. Measure back and transfer line to

opposite side of door.

2. Find the mid-point of the door edge opposite the hinged side.

This will give you your center line (See Figure N). Mark with a

pencil.

3. Measure exactly 1" in from the mark that was transferred, mark

with a pencil.

4. Drill a 1/2" hole in the center and sand off any rough edges.

A1. (1) LATCH

A2. (1) TRAVEL STOP RING

A3. (1) LATCH LEVER

A4. (1) M12 NUT

A7. (1) 12mm SCREW

1"

Door Center Line

1/2" hole

(STEP 9 CONTINUED ON NEXT PAGE)

Drill hole in the center

inside of door frame

Figure N

8

Page 10

(STEP 9 CONTINUED FROM PREVIOUS PAGE)

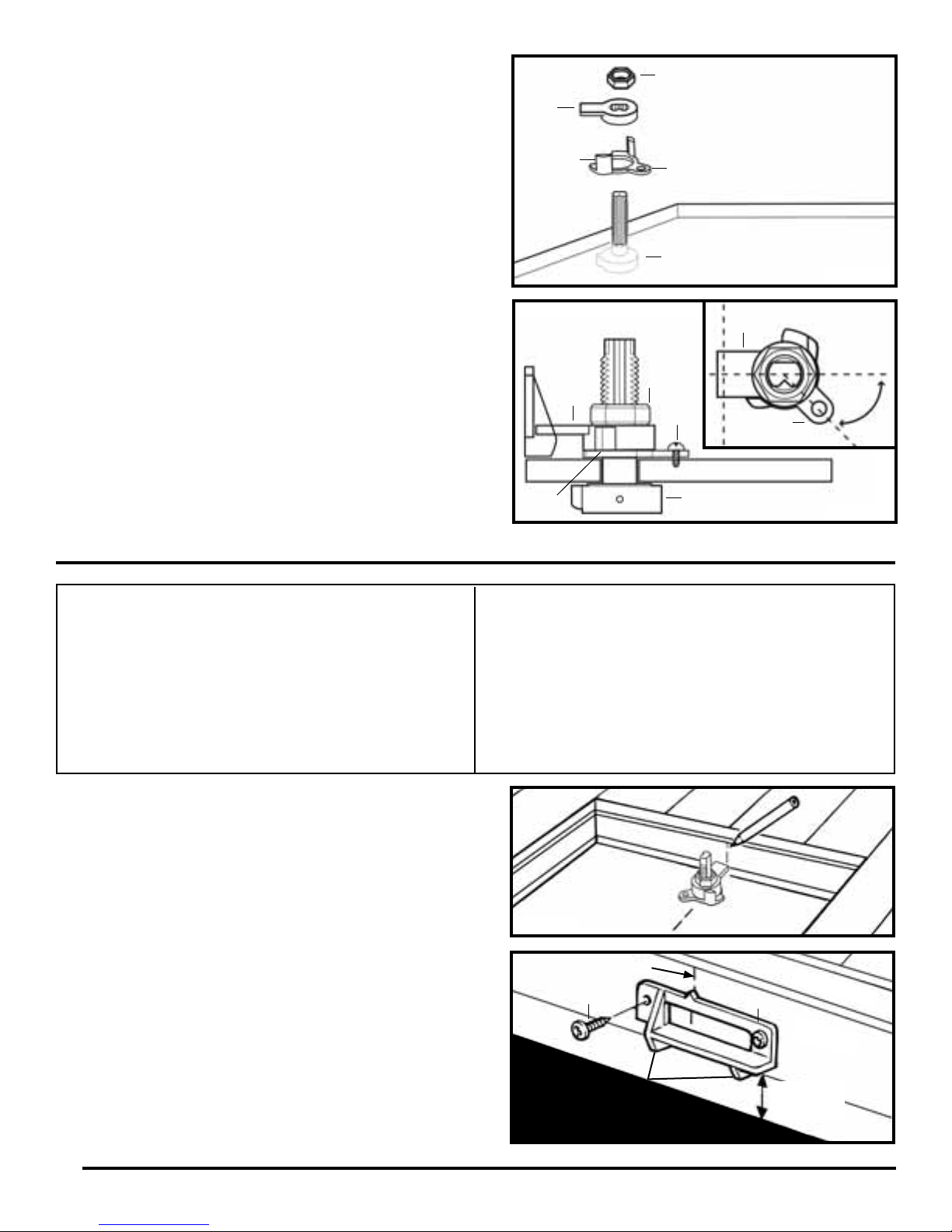

5. Pass the latch (A1) through the door hole from the

underside such that the position pointer points toward

the door edge (See Figure O).

A4

A3

6. Place the travel stop ring (A2) over the latch (A1) such

that the screw hole is at 45 degrees to the door center

line (See Figures O and P).

7. Place the latch catch (A3) over the latch (A1) and locate

into the latch groove such that the latch catch points

toward the door near edge and fully locates within the

travel stop ring (A2) (See Figures O and P).

8. Secure the travel stop ring (A2) using 12mm screw (A7).

9. Secure the catch assembly with M12 nut (A4) ensuring

the nut is tightened sufficiently to allow the catch to

rotate freely without any looseness (See Figure P).

Step 10

Attaching the Location Bracket

TOOLS REQUIRED

A2

A4

A3

A2

PARTS REQUIRED

Screw hole

A1

A7

A1

Door

Figure O

A3

45°

A2

Figure P

STEPLADDER

AWL

LARGE FLAT SCREWDRIVER

PHILLIPS SCREWDRIVER (small and medium)

TAPE MEASURE/RULER

PENCIL

When turned to the correct position, the catch lever will

engage in the location bracket to hold the door shut. Attach

as follows:

1. Mark a vertical line on the inside of the door jam

corresponding with the center line of the door catch

(See Figure Q).

2. Position the catch location bracket (A5) along the

bottom edge of the wood door jam (See Figure R).

3. Match up the indent mark on the bracket with the

vertical center line.

4. Make guide holes with the awl and attach using 2 of

the 3/4" wood screws supplied (A6).

5. Apply door labels, P/N103552-01 and P/N103553-01,

to the top side of the door, inside the attic.

A5. (1) LOCATION BRACKET

A6. (2) 3/4" WOOD SCREWS

(1) “WARNING” LABEL P/N103552-01

(1) “HOW TO USE” LABEL P/N103553-01

Figure Q

Center line

A6

Tabs ush with

bottom of door jam

Figure R

A5

Door Frame

Door jam

Thickness

of Door

9

Page 11

Step 11

Operating the Ladder

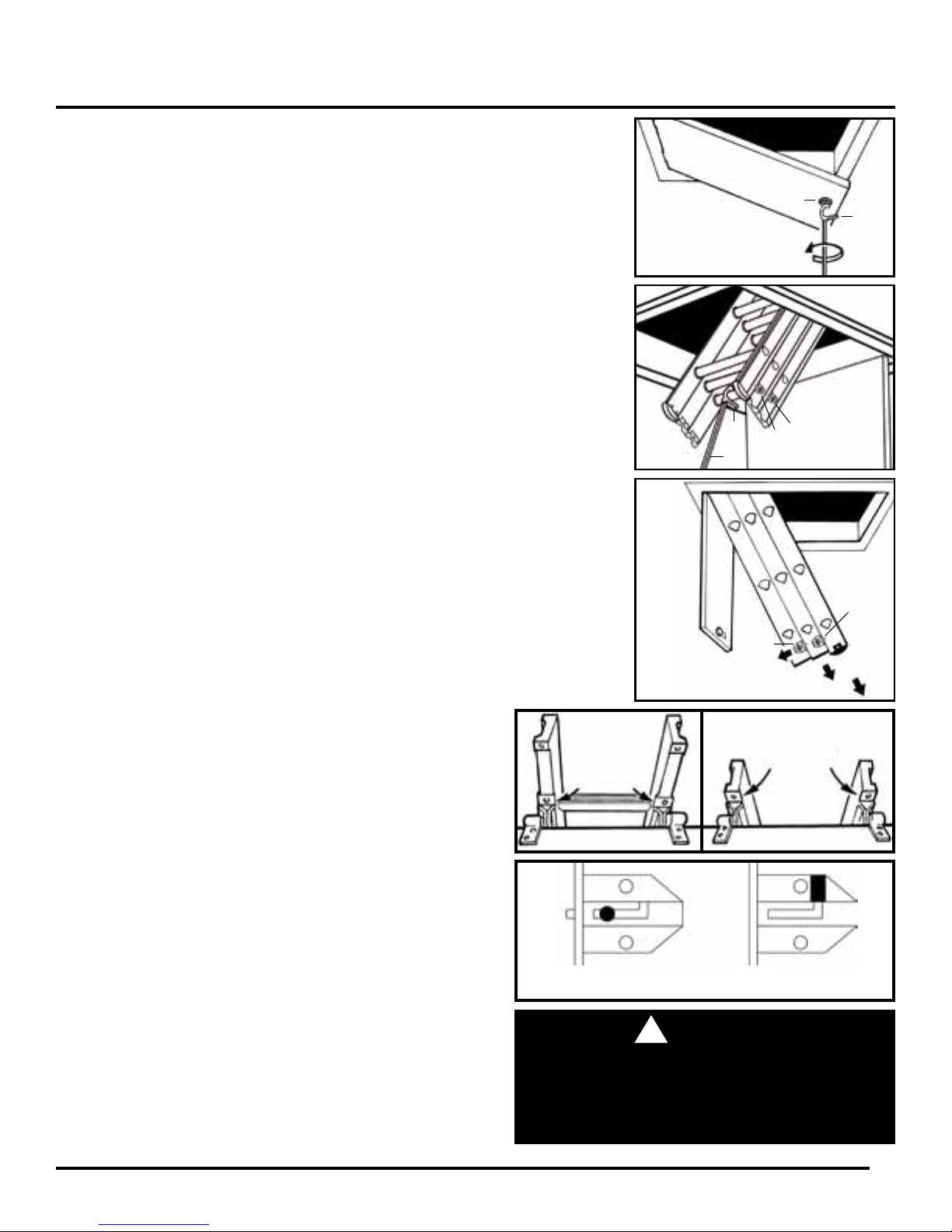

1. Locate the plastic stowing hook (G3) into one end of the assist pole (G2)

and push rmly to ensure the plastic stowing hook (G3) is fully located within the

pole. Secure hook (G3) with self-tapping screw. Push the plastic end plug into

the opposite end of the assist pole (G2).

2. To open the door, locate the hook (G3) into the slot in the latch (A1) and turn

the catch counterclockwise until it reaches the travel stop and then lower the

door (See Figure S).

3. Put the stowing hook (G3) over and at the center of the REAR ladder section

bottom rung and steadily pull the ladder outward and downward until both top

stops reach and make contact with the hinge guides (See Figure T).

4. Retract both right-hand side catches ‘C’ & ‘D’ (blue) and rotate both catch levers

upwards into the locked open position (See Figures T and W).

Figure S

A1

G3

5. To extend the ladder, retract left-hand catch ‘A’ (black) while supporting the front

frame of the ladder. Lower the frame slowly until catch ‘A’ (black) engages again

(Figure U).

6. Then retract catch ‘B’ (black) and lower the middle frame until catch ‘B’ (black) is

engaged in your required position. Extend the ladder until the feet rest rmly on

the oor (Figure U).

7. When the ladder has been fully opened, rotate both right-hand side catch levers

downward to unlock and release both catches ‘C’ and ‘D’ (blue) and ensure both

catches are fully engaged. DO NOT use ladder with any catches (‘A’, ‘B’, ‘C’ or

‘D’) disengaged. Read the safety labels on the product.

8. Ensure the ladder is pulled down so that the top stops (or additional top stops if

installed) rest rmly on the hinge guides. This supports the top section and

prevents it from sliding down when climbed.

9. Check the ladder angle against the safety label or refer back

to opened requirements on page 2.

Stowing the Ladder

10. Retract both right-hand side catches ‘C’ & ‘D’ (blue) and rotate

both catch levers upwards into the locked open position

(Figure W).

11. To stow the ladder, retract catch ‘A’ (black), slide the front

frame fully upwards until catch engages again.

Additional

Top stops

Assembled

Figure V

Figure T

Figure U

Catches

‘C’ & ‘D’

G3

G2

C

B

No Additional

Top stops

Assembled

D

A

12. Repeat step 11 for catch ‘B’ (black) and the middle ladder frame

13. Reverse step 10 and ensure both right-hand side catches ‘C’

and ‘D’ (blue) are fully engaged.

14. Engage the plastic stowing hook (E3) over and at the center

of the REAR ladder section bottom rung. While maintaining

the assist pole in the vertical position, push the ladder

vertically upwards.

15. Continue to slowly push the ladder up and fully into the attic hole.

16. Use the assist pole to raise the door and turn the latch

clockwise to close.

Released/

Figure W

DO NOT attempt to climb your attic ladder until you

have checked that it is pulled down to the stops.

Fully read all safety labels and ensure that it is set

at the correct angle. Ensure that the locking catches

are fully engaged.

engaged

WARNING:

!

Retracted/

locked open

10

Page 12

Appendix

Creating a Rough Opening

Section 1.1

Important Questions

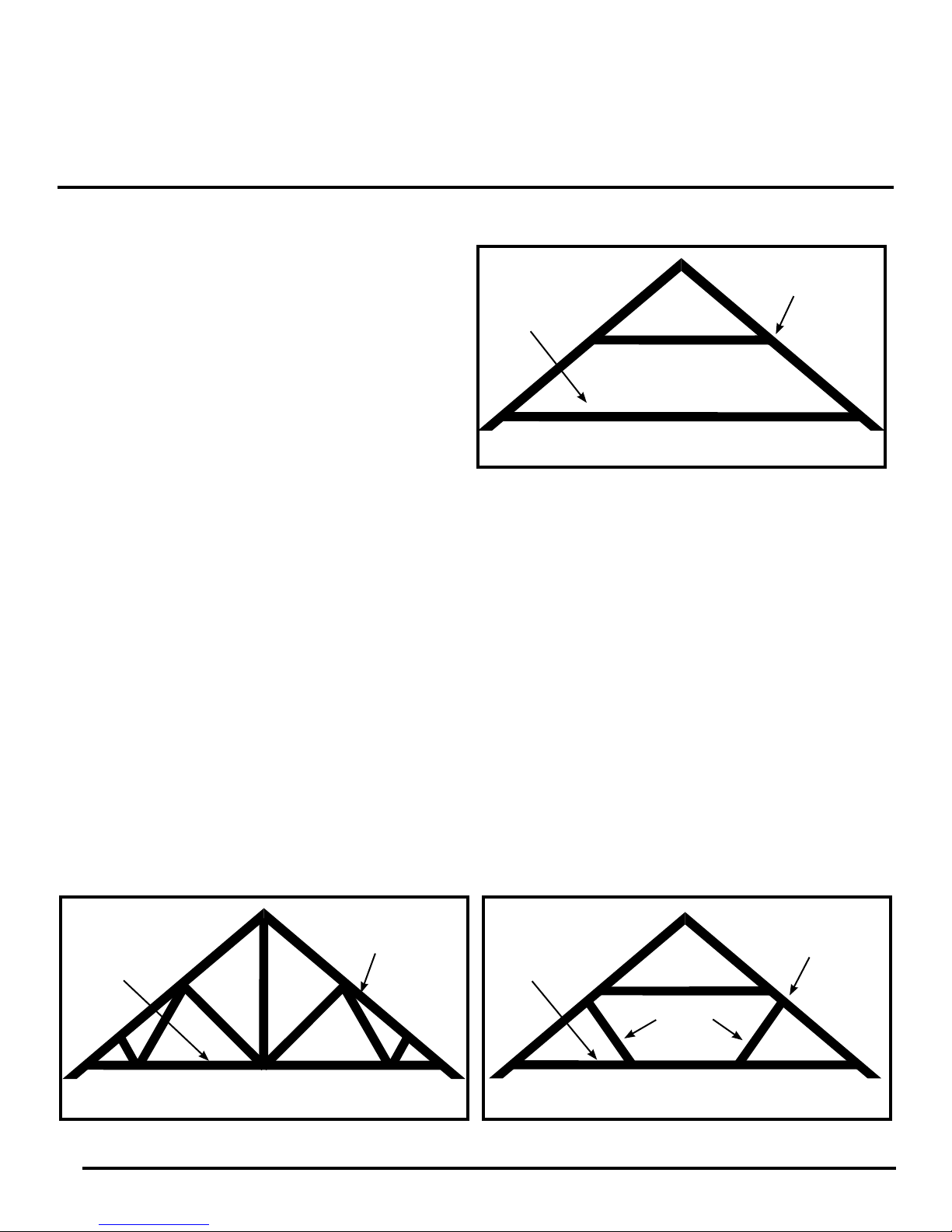

Is your ceiling and joist structure suitable for this installation?

This attic ladder can be installed in structures with

conventional wood roof frames (See Figure 1). If a

ceiling is present, you must have an attic hole in

the ceiling that allows you to enter the overhead

space for a pre-installation inspection.

Roof support structures that have braces connected

to the ceiling joists or which use trusses (See Figure 2)

cannot be cut without destroying the load-bearing

capacity of that section of the roof. Do not cut joists

that are part of a braced conventional frame or

truss without rst consulting an architect or

structural engineer (see the Yellow Pages under

“Architects or Structural Engineers”).

Ceiling Joist

Conventional Roof Frame

Rafter

Figure 1

The attic ladder should not be installed in a ceiling that has any of the following:

– Components of heating/cooling systems embedded in the ceiling

– Joists made of materials other than wood

– Metal reinforced plaster

– Suspended ceilings

If your ceiling contains any of the above, do not attempt to install the attic ladder. Contact a professional for assistance with your specic needs (see the Yellow Pages under “Heating and Cooling Contractors, Building Contractors,

Carpenters, Home Builders, Home Improvements, or Contractors-General”).

Do these instructions meet your needs?

These instructions describe how to install the attic ladder parallel or perpendicular to the ceiling joists. Contact a

professional if you want the attic ladder installed in some other direction relative to the joists.

Is your ceiling and joist structure suitable for this installation?

WARNING: DO NOT CUT THESE TYPES OF STRUCTURES WITHOUT

CONSULTING AN ARCHITECT OR STRUCTURAL ENGINEER.

Ceiling Joist

Rafter

Ceiling Joist

Rafter

Truss Roof Frame

Figure 2

11

Braces

Conventional Roof Frame with Braces

Connected to Ceiling Joists

Page 13

Section 1.2

Tools and Materials Needed

Materials:

– Several pieces of joist-sized lumber (the amount depends on the specic installation)

– 16d sinker nails or screws of equivalent strength (24-60 depending on the specic installation)

– 20d sinker nails or screws of equivalent strength are needed for installations where joists are cut

Stepladder:

– You will need a stepladder that is tall enough so that you can get into the overhead space without

stepping above the working height of the stepladder. The working height of the stepladder is two

steps down from the top.

– Your stepladder must also have a duty rating that is greater than the sum of your weight plus

the weight of the attic ladder and any additional materials used for installation.

CAUTION: Be careful when using a stepladder to climb into and out of the overhead space.

Tools For Creating a Rough Opening:

– Flashlight or extension light

– Claw hammer

– Pencil

– Handsaw/power saw

– Tape measure

– Framing square

– Tools to cut a hole in the existing ceiling

Safety Equipment:

– Gloves

– Safety goggles

– Dust mask

12

Page 14

Section 1.3

Finding a Suitable Location

Before Proceeding: You must have a suitable ceiling and joist structure, tools and materials needed, and a level and

at location in the ceiling.

Goal: To nd a location free of hazards and obstructions that will provide room for the installation and use of the attic ladder.

STEP 1. Pick a potential location for installation. Check for the size of rough opening shown on the box or in in the

pre-installation checklist.

If you are installing the attic ladder in a garage, don’t forget to consider where cars will be parked.

STEP 2. If there is no ceiling and the attic ladder will

t between the joists so that no joists need

to be cut, go to Section 1.5 “FRAMING

THE ROUGH OPENING”.

If there is no ceiling, but one or more

joists need to be cut, go to Section 1.4

“CUTTING THE CEILING JOISTS”.

If there is a ceiling at this location, you

will need to inspect the attic area

above this location as described in

steps 3 and 4.

STEP 3. Go into the overhead space and nd the area above your chosen location.

This area may be located by:

A) Listening for tapping from below

B) Measuring distances from walls or other objects common to the overhead space and the room below

FOR YOUR SAFETY, WATCH OUT FOR OVERHEAD HAZARDS.

DO NOT

stand or sit on the ceiling or insulation covering the ceiling — the ceiling is not made to support your

weight. You can fall through the ceiling even though it

looks solid! Only the joists can support weight.

Watch out for sharp nails sticking through the roof.

WARNING:

!

WARNING: Do not drive metal nails or other conductive objects into the ceiling unless you are sure they will not

contact electric wires. Contact with an electrical wire can be deadly.

STEP 4. At this location in the overhead space:

A) Check that there is enough space for you to safely move around

during installation.

B) Check the overhead space for storage space adjacent to the chosen location. If walking

or crawling in the overhead space is desired, make sure that there is enough room to do so.

C) Check above your chosen location for hazards and obstructions such as:

– Electrical wires

– Pipes

– Heating and cooling ducts

– Furnaces

– Hot water heaters or other obstructions

Note: To check for hazards, you will need to move insulation away from your chosen location.

Wear a dust mask, safety goggles, and gloves and keep your body covered to prevent ne cuts

from berglass. Gently push aside insulation to avoid stirring up dust that may be harmful to your

eyes and lungs.

STEP 5. If any hazards or obstructions are present at your chosen location, look for another location or have

the hazards or obstructions moved by professionals (see the Yellow Pages under “Electrical

Contractors, Heating and Cooling Contractors, and Plumbing Contractors”).

13

Page 15

Section 1.4

Cutting a Hole in the Ceiling

Before Proceeding: You must have a location that:

A) Is free of hazards and obstructions in the overhead space.

B) Is free of hazards in the ceiling.

C) Provides enough room for installation.

D) Provides enough room to use the attic ladder.

Goal: To cut a hole, that is the correct size, in the ceiling at the desired location.

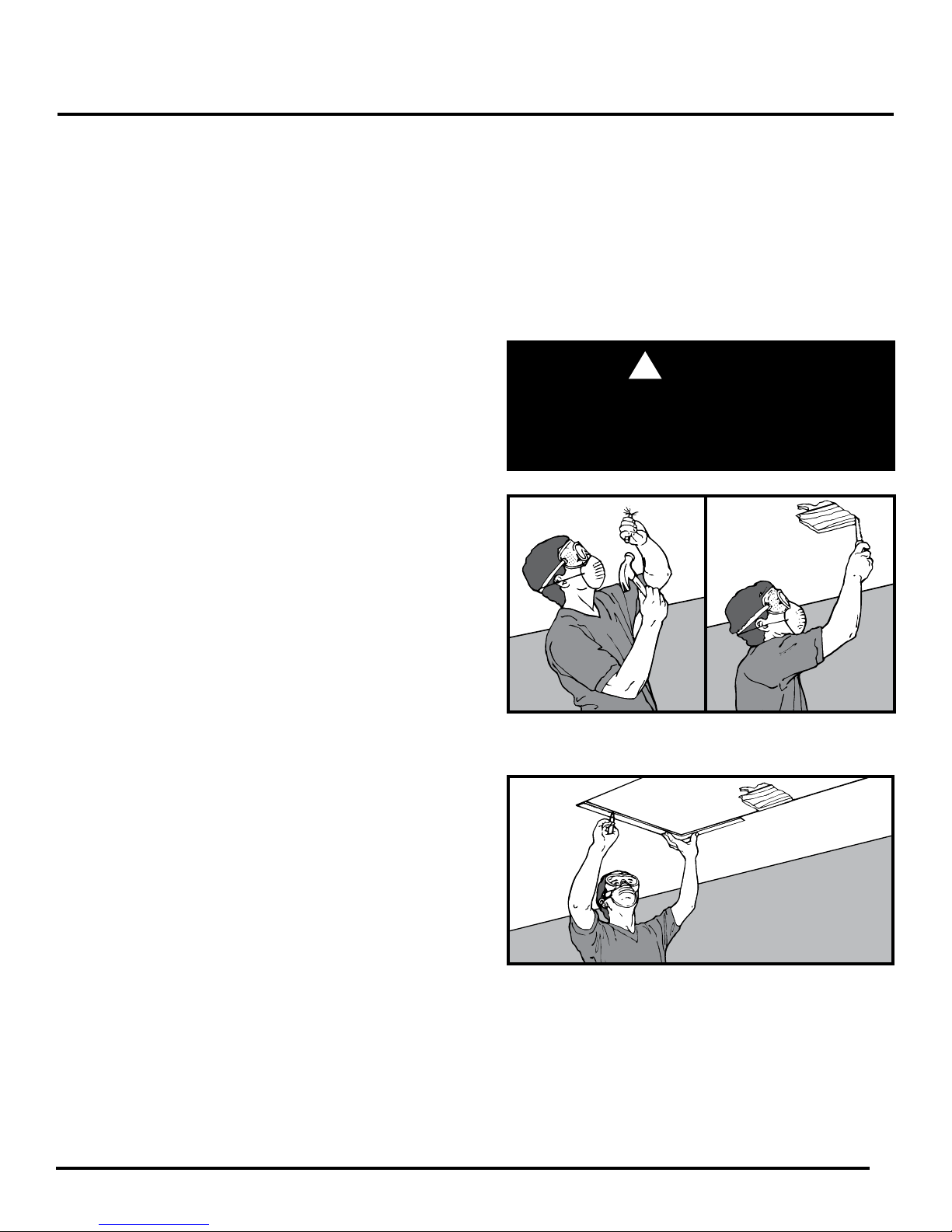

STEP 1. Prepare the room by moving furniture,

covering ooring with a drop cloth and

removing children and pets to a safe

distance.

STEP 2. Put on safety goggles and a dust mask.

These will keep pieces of ceiling particles

and dust from falling into your eyes, mouth

or nose as you make a starter hole and cut

into the ceiling.

STEP 3. With a hammer and chisel, make a starter

hole near the center of the chosen location

(See Figure 4).

STEP 4. Enlarge the opening with a saw until you

can see a joist (See Figure 5).

STEP 5. Draw a rectangle the size of the rough

opening on the ceiling, with one edge

parallel to a joist (See Figure 6). You may do

this by sawing until you reach a joist and use

it as a frame of reference. (The size of the

rough opening must be at least 18" x 24".)

Note: Locating at least one edge of the

opening along a ceiling joist will allow the

joist to be used as a side of the frame you

will build. This will simplify framing the

rough opening.

STEP 6. Cut out the rest of the ceiling within the

marked outline following these instructions:

A) Do not cut any joists at this

time. Cut through the ceiling only.

B) Remove the ceiling in small pieces

because ceiling material can be

very heavy.

STEP 7. If no joists span the hole in the ceiling, go

to Section 1.5 “FRAMING THE ROUGH

OPENING”.

If any joists span the hole, go to Section 1.4

“CUTTING THE CEILING JOISTS”.

DO NOT stand saw, cut, or hammer into the ceiling

until you are sure that the location is free of hazards

and obstructions in the ceiling and attic. Contact with

an electrical wire can be deadly.

Figure 4 Figure 5

Figure 6

WARNING:

!

14

Page 16

Section 1.4

Cutting a Hole in the Ceiling

Before Proceeding: You must have either exposed joists or a correctly sized hole at the desired ceiling location.

Goal: To cut out any joists that are in the way of your chosen location. Before cutting the joists, you must attach

them to other joists in the overhead attic to keep the ceiling from sagging or completely collapsing.

STEP 1. If the room has a ceiling and you have cut

the required hole, go to Step 2.

If the room has no ceiling, you will need to

mark the joists according to (A) or (B) below.

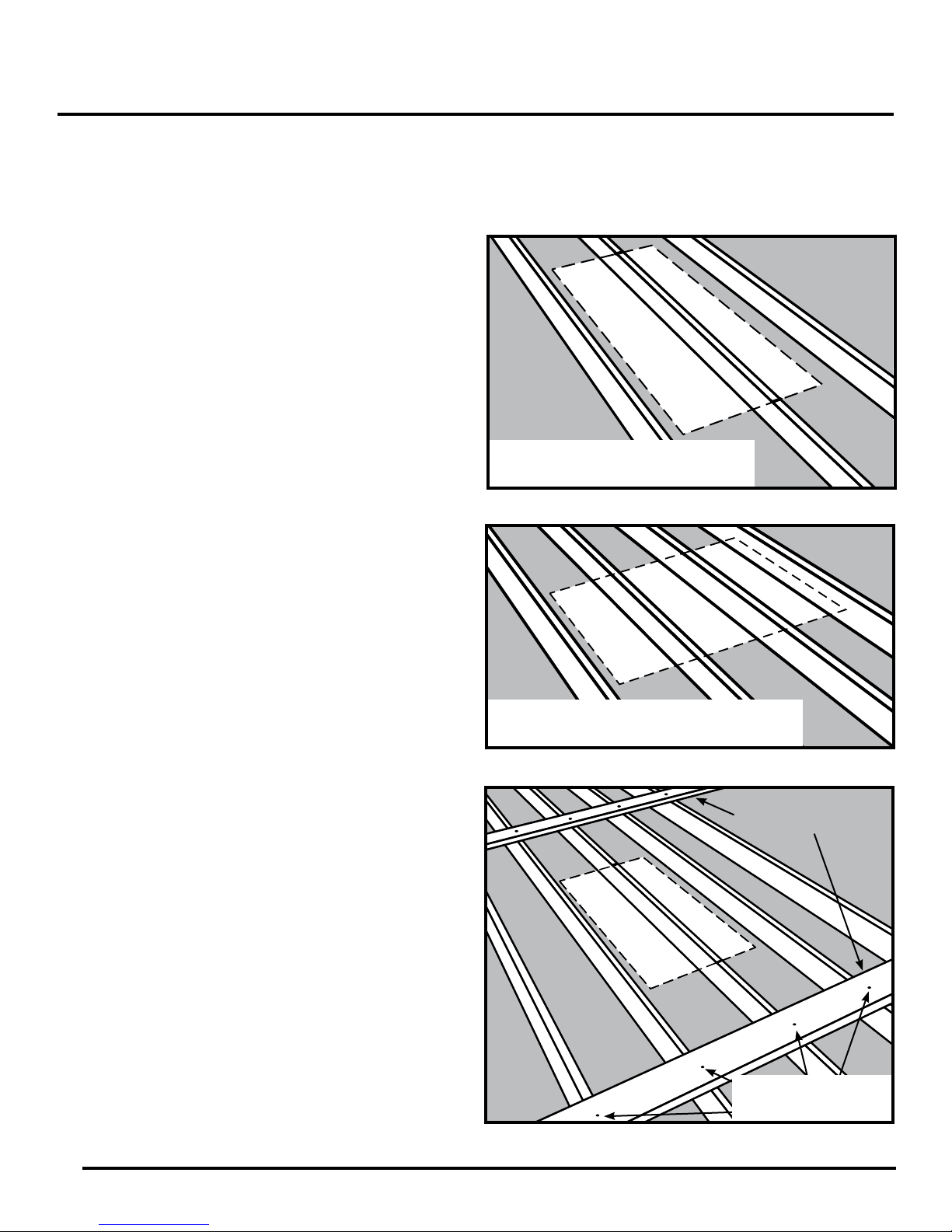

(A) If the chosen location is parallel to the

joists, mark the rough opening length on

top of the joists (See Figure 7).

Do not cut the joist at this mark.

(B) If the chosen location is perpendicular to

the joists, mark the rough opening width on

top of the joists (See Figure 8).

Do not cut the joist at this mark.

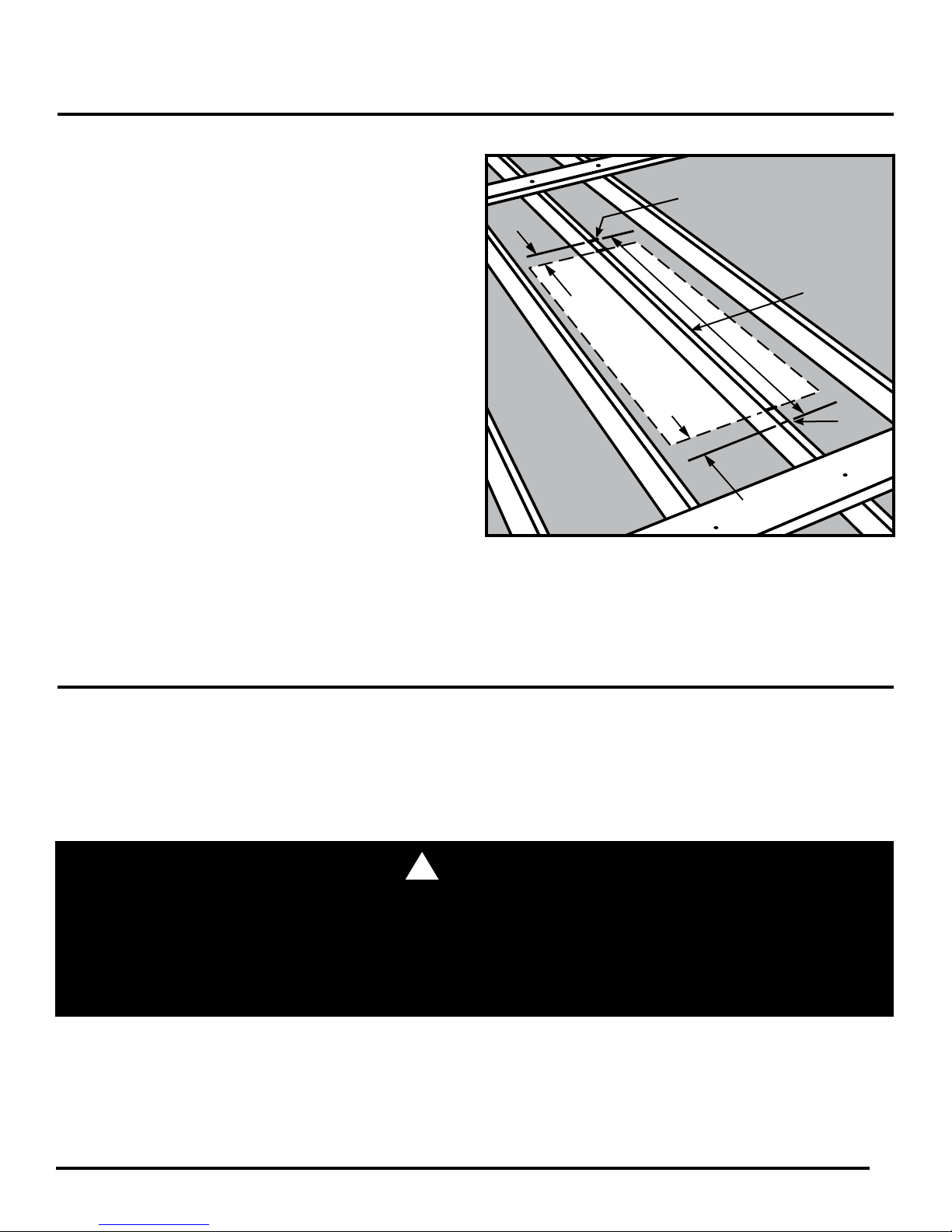

STEP 2. Cut 2 joist-sized boards long enough to

span 2 joists on each side of your chosen

location (See Figure 9). These boards will

support the joists that will be cut and help

keep the ceiling from sagging or completely

collapsing while you are working in the

overhead space.

STEP 3. Place these boards approximately 24"

from the edge of your chosen location and

nail (See Figure 9).

Note: The 24" distance is needed to

give you room to hammer nails into the

frame that you will build in the next section.

Dotted Line Indicates Your Chosen

Location (Location Parallel to Joist).

Figure 7

Dotted Line Indicates Your Chosen

Location (Location Perpendicular to Joist).

Figure 8

15

Joist Support

Boards

Nail or Screw

Boards to Each Joist

Figure 9

Page 17

Section 1.4 (Continued)

Cutting the Ceiling Joists

STEP 4. Next, determine where the joist(s) should

be cut. Figure 10 shows where to mark the

joist(s) that span your chosen location. Note

that the joist(s) should be marked back

from the edge of your location a distance of

2 times the joist thickness (usually three

inches). This leaves room for two joist-sized

headers to be placed against each end of

the cut joist(s) (See Figure 16 on page 18).

Note: In some homes, especially older

ones, the joists may be slightly thicker than

the lumber you can currently buy. If your

joists have a different thickness than the

lumber you will be using for the headers,

you will need to mark the joists back from

the edge of your location a distance of two

times the header thickness instead of the

joist thickness.

STEP 5. Saw through the joist(s) being careful not to

cut through the ceiling and making sure the

cut ends of the joist(s) are at and vertical.

2 x Joist

Thickness

Dotted

Line Indicates

Your Chosen

Location

Cut

Here

Section of Joist

to be Removed

Cut

Here

2 x Joist

Thickness

Figure 10

Section 1.5

Framing the Rough Opening

Before Proceeding: You should have a space between the joists at least 18". Any cut joists must be attached to uncut

joists.

Goal: To create a four-sided frame the size of the rough opening using joist-sized lumber. This frame will be made of

single or double thickness headers and stringers depending upon the particular installation. The frame is necessary to

support the attic ladder and to reinforce the roof and ceiling structure.

WARNING:

!

FOR YOUR SAFETY, WATCH OUT FOR OVERHEAD HAZARDS.

DO NOT Do not stand or sit on the ceiling or insulation covering the ceiling — the ceiling is not made to support your

weight. You can fall through the ceiling even though it looks solid! Only the joists can support weight. To avoid falling

through the ceiling, you may want to make a working platform by laying boards across the joist. Watch out for sharp

nails sticking through the roof.

16

Page 18

Section 1.5 (Continued)

Framing the Rough Opening

Installing Headers

If no joists have been cut, go to “Single Headers” below.

If any joists have been cut, go to “Double Headers” on page 18.

Single Headers

STEP 1. Measure the header length “H” between

the joists (See Figure 11).

STEP 2. Cut 2 headers this length. Use

joist-sized lumber.

STEP 3. Place one of these headers at one end of

your chosen location (See Figure 12). The

header must t snugly between the joists.

Hammer it into position if necessary; if it is

more than 1/16" too long, trim it. If it is

more than 1/16" too short, cut another piece.

STEP 4. Square the header to one joist and drive

3 nails (16d) through the joist and into the

header. Check for squareness and drive

3 nails (16d) through the other joist and

into the header (See Figure 12). It is very

important that header board is vertically

square as well as horizontally square to

side joists.

STEP 5. Position the second header at least 24" from

the rst one and repeat Step 4 (See Figure 13).

STEP 6. The frame for the rough opening requires

four sides. The headers make up two of

those sides. If your ceiling joists are spaced

so that they make up the other two sides of

the rough opening, check the opening for

squareness by measuring across the

diagonals. The measurements should be

within 1/8” to be considered square

(See Figure 13).

If your ceiling joists do not make up the

other two sides of the rough opening, you

need to install one or two additional pieces

of lumber to frame the other side(s) of the

rough opening, go to “Installing Stringers”

on page 19.

H

Figure 11

Header

Joists

Nails

Drive 3 Nails (16d) into

each end of the Header

Figure 12

Header

At

least

24"

17

Diagonal

Measurements

Nails

Header

Figure 13 How to check for square

Page 19

Section 1.5 (Continued)

Framing the Rough Opening

Double Headers

STEP 1. Measure the header length “H” between

the uncut joists (See Figure14).

STEP 2. Cut 4 headers this length. Use joist-sized

lumber.

STEP 3. Place one of these headers against the end

of the cut joist(s) (See Figure 15). It must

t snugly between the uncut joists.

Hammer it into position if necessary; if it is

more than 1/16" too long, trim it. If it

is more than 1/16" too short, cut

another piece.

STEP 4. Square the header to the uncut joist and

nail the header to the end of the cut

joist(s) with 3 nails (See Figure 15).

STEP 5. Check header for squareness then drive

3 nails through each joist into each

end of the header (See Figure 15).

STEP 6. Place a second header against the rst

header and nail it to the rst header with

3 nails between each joist (See Figure 16).

STEP 7. Drive 3 nails through the joists into each

end of the second header (See Figure 16).

STEP 8. Repeat steps 3-7 to install headers at the

opposite end of the opening.

STEP 9. To frame the other side(s) of the rough

opening, go to “Installing Stringers” on page 19.

H

Figure 14

Cut Joist

First Header

Nails

Uncut Joists

Figure 15

Nails

Figure 16

Second Header

18

Page 20

Section 1.5 (Continued)

Framing the Rough Opening

Installing Stringers

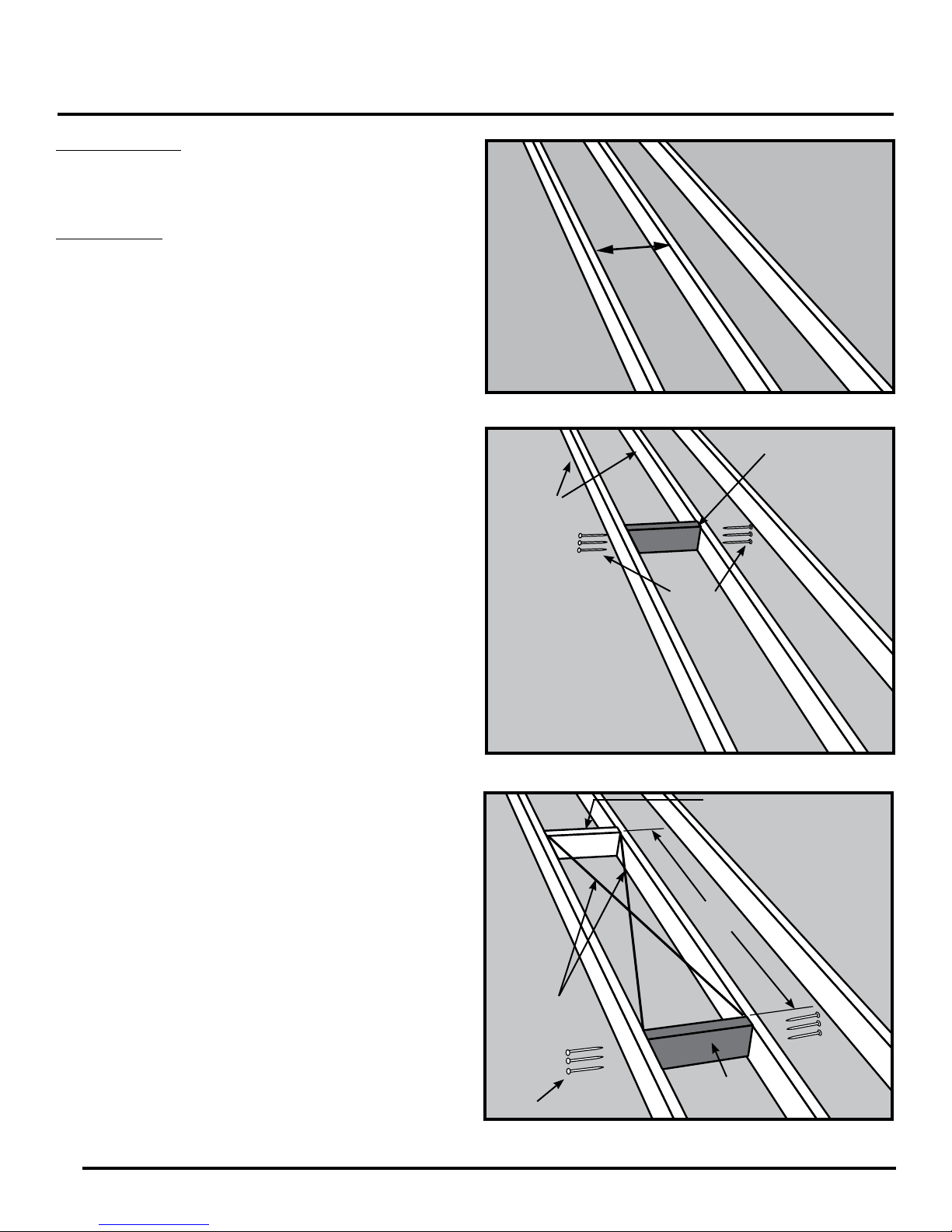

STEP 1. Measure the stringer length “S” between

the headers (See Figure 17).

STEP 2. Cut a stringer to this length. Use

joist-sized lumber.

STEP 3. If the ceiling joist does not provide one side

of the frame, then cut a second stringer the

same length as the rst one. Note that only

one stringer is needed in Figure 17 because

the ceiling joist provides one side of

the frame.

STEP 4. Position the stringer(s) along the unframed

side(s) of your location (See Figure 18).

Check that the inside dimensions of the

frame are at least 18" x 24".

STEP 5. To attach the stringer(s) to the headers, use

nails that are long enough to go through

both headers and into the stringer at least

one inch. In most cases, a 4" nail (20d)

will be long enough. Square the stringer(s)

to the headers at one end and drive 3 nails

through the headers and into the stringer.

Check for squareness, then nail the other

end. Check the rough opening for

squareness by measuring across the

diagonals. The two measurements must

be within 1/8" to be considered square

(See Figure 18).

Headers

S

Headers

Figure 17

Stringer

Note: A 3/4" wood oor 27" min. deep by the full width of

your opening is required for the attachment of the assist

arm. Please refer to Step 5 on page 6 of this manual for

instructions on attaching assist arm.

19

Diagonal

Measurements

Support oor for power

assist arm min. 27" by

full width of opening

Figure 18

Nails

27"

Full Width

of opening

Page 21

Compact Attic Ladder

ALUMINUM

BUILT FOR SMALL ATTIC OPENINGS

Escalera de Compacta Para Ático

ALUMINIO

CONSTRUIDA PARA ABERTURAS DE ÁTICO PEQUEÑAS

-

Índice

Página

Antes de comenzar 2

Preguntas importantes 3

Paso 1 Ensamblaje de la escalera 3

Paso 2

Paso 3 Instalación de topes inferiores 5

Paso 4 Instalación de la escalera 5

Paso 5 Instalación del brazo de ayuda 6

Paso 6 Pasamanos 7

Paso 7

Paso 8 Colgado de la puerta 8

Paso 9

Paso 10

Paso 11 Manejo de la escalera 10

Apéndice Creación de una abertura preliminar 11

Instalación de topes

superiores adicionales

Acabado de la abertura

para la puerta

Ubicación del oricio para la

cerradura de la puerta

Sujeción del soporte para el

pestillo de la cerradura

Sección 1.1 Preguntas importantes 11

4

7

8-9

9

Sección 1.2 Herramientas y materiales necesarios 12

Sección 1.3 Búsqueda de una ubicación adecuada 13

Sección 1.4 Corte de una abertura en el cielo raso 14-16

Sección 1.5 Enmarcado de la abertura preliminar 16-19

Page 22

Antes de comenzar

HERRAMIENTAS

REQUERIDAS

ESCALERA TIPO TIJERA

PUNZÓN

SIERRA

TALADRO MÁS BROCA DE 1/2" y 1/16"

DESTORNILLADOR DE PALA

GRANDE

DESTORNILLADOR PHILLIPS

(pequeño y mediano)

LLAVE AJUSTABLE / ALICATES

CINTA MÉTRICA / REGLA

MARTILLO

LÁPIZ

A Abertura mínima acabada (longitud) 0.53m

B Abertura mínima acabada (ancho) 0.38m

MATERIAL DE PUERTA REQUERIDO

ASEGÚRESE DE UTILIZAR MADERA LAMINADA DE 3/4" PARA ARMARIOS.

TABLA DE MADERA MACIZA DE 1 X 3 REQUERIDA PARA EL MARCO

DE LA PUERTA

TABLA DE MADERA MACIZA DE 1 X 2 REQUERIDA PARA LA

CUÑA DE LA PUERTA

AL COMIENZO DE CADA PASO A LO LARGO DE ESTE

MANUAL DE INSTRUCCIONES, SE ENUMERARÁN LOS

TORNILLOS/CLAVOS Y COMPONENTES NECESARIOS.

SI CUALQUIER PIEZA ESTÁ FALTANDO O ESTÁ ROTA,

POR FAVOR LLAME AL SERVICIO AL CLIENTE AL

1-888-523-3370.

Escalera de ático compacta

C

D* Altura mínima para guardado requerida en el ático 0.72m

E**

Hacia atrás de la apertura preliminar

Altura máxima 3.00m

Altura mínima 2.13m

Longitud mínima requerida

1.12m

Requisitos en la posición cerrada Requisitos en la posición abierta

D*

B

E**A

68°- 80°

C

*En la posición inferior del pasamanos - 0.72m

En la posición superior del pasamanos - 0.97m

2

**En la posición inferior del pasamanos - 1.12m

En la posición superior del pasamanos - 1.37m

Page 23

Preguntas importantes

Lea completamente las instrucciones antes de empezar. Esto es necesario para garantizar que usted tiene una ubicación adecuada

para la escalera de ático y la capacidad para instalarla de manera segura y apropiada.

¿Es usted capaz de instalar esta escalera de ático?

Para instalar esta escalera de ático usted debe tener habilidades para aserrar, escuadrar y alinear, similares a las habilidades

requeridas para instalar un marco de ventana o puerta. Si usted no tiene estas habilidades, usted debería contratar un carpintero

profesional para instalar esta unidad (consulte las Páginas Amarillas bajo los títulos de “Contratistas de Construcción, Carpinteros,

Constructores de Casas, Remodelaciones de Casas, o Contratistas en General”)

¿Satisface esta escalera de ático sus necesidades?

Esta escalera de ático sólo es para uso residencial. La instalación de esta escalera de ático en edicaciones comerciales y

apartamentos podría violar los códigos de construcción que exigen cielos rasos con capacidad de resistencia al fuego y prohíben

almacenar materiales en el espacio superior. Verique con su jefe de bomberos local o con el ministerio de construcciones antes de

instalar la escalera de ático.

La capacidad de la escalera de ático (persona más materiales que se cargan) es de 250 libras.

Esta escalera de ático está hecha para el rango de alturas de cielos rasos mostrado en el embalaje/paquete. No instale la escalera

de ático en un cielo raso que tiene una altura fuera de este rango. Alterar la escalera de ático para acomodarse a otras alturas es

inseguro y nunca debe intentarse.

ESTA ESCALERA DE ÁTICO VIENE CON BISAGRAS Y CERRADURA PARA INSTALAR

UNA PUERTA (NO INCLUIDA). PARA MODIFICAR O CREAR UNA ABERTURA NUEVA, POR

FAVOR CONSULTE EL APÉNDICE (PÁGINA 11).

Paso 1

Ensamblaje de la escalera

HERRAMIENTAS REQUERIDAS

MARTILLO

Para la identicación correcta, la sección delantera de la escalera puede identicarse por sus patas redondeadas.

1. Extraiga cuidadosamente las tachuelas (golpee suavemente con un martillo en caso de ser necesario) y retire las tapas de extremo

plásticas de la parte inferior de la sección TRASERA de la escalera (vea la Figura A).

2. Deslice las guías de bisagra (B1 & B2) sobre la sección más alta del marco. Los soportes deben colocarse hacia afuera con la

mitad de doble oricio más alta (vea la Figura B).

3. Deslice todo el recorrido hasta los topes superiores de instalación permanente en el otro extremo de la sección.

4. No vuelva a colocar las tapas de extremo plásticas (vea más adelante en el Paso 3 - Instalación de los peldaños inferiores).

Parte

trasera

PIEZAS REQUERIDAS

B1. (1) GUÍA DE BISAGRA - IZQUIERDA

B2. (1) GUÍA DE BISAGRA - DERECHA

B2

Lado

derecho

Lado

izquierdo

Parte

delantera

Figura A Figura B

B1

3

Page 24

Paso 2

Instalación de los topes superiores adicionales

HERRAMIENTAS

REQUERIDAS

LLAVE AJUSTABLE / ALICATES

Requisitos en la posición abierta

PIEZAS REQUERIDAS

C1. (2) PERNOS DE TOPES

SUPERIORES M4 X 8MM

C2. (2) TOPES SUPERIORES

ADICIONALES

C3. (2) TUERCAS DE FIJACIÓN M4

Tope superior

permanente

B2

B1

C1

C2

C3

C1

C2

C3

68°- 80°

Altura de

piso a piso

Figura C

Dependiendo de la altura de piso a piso (vea a la izquierda los

Requisitos en la posición abierta), usted podría necesitar agregar los

topes superiores adicionales suministrados (C2) (vea abajo la tabla).

1. En caso de requerirse, coloque los topes superiores adicionales

en los oricios a aproximadamente 6” debajo de los topes

superiores permanentes en la sección trasera de la escalera

(vea la Figura C).

2. Verique que las guías de bisagra (B1 y B2) ya estén en su

sitio y debajo de los topes superiores adicionales cuando están

instalados.

3. Fije los topes superiores adicionales utilizando las dos tuercas y

pernos M4 suministrados (C1 y C3).

Alturas de funcionamiento

Pies y pulgadas Topes superiores requeridos

2.13m hasta 2.28m SÍ

2.28m hasta 2.41m NO

2.41m hasta 2.57m SÍ

2.57m hasta 2.71m NO

2.71m hasta 2.84m SÍ

2.84m hasta 3.00m NO

4

Page 25

Paso 3

Instalación de topes inferiores

HERRAMIENTAS REQUERIDAS

DESTORNILLADOR DE PALA GRANDE

DESTORNILLADOR PHILLIPS

(pequeño y mediano)

MARTILLO

1. En este momento, ambas tapas de extremo debieron

haber sido retiradas de la sección trasera durante el

anterior Paso 1. Retire la tapa de extremo del riel de la

sección trasera (en el mismo lado tal como está pensado

para instalar el brazo de ayuda).

2. Deslice los topes inferiores (D1) sobre los rieles traseros.

3. Coloque los topes inferiores a 0.15m del extremo de los

rieles (vea la Figura D).

4. Fije con los tornillos (D2).

5. Coloque nuevamente las tapas de extremo plásticas reti

radas previamente y asegure con tachuelas.

Paso 4

Instalación de la escalera

PIEZAS REQUERIDAS

D1. (2) TOPES INFERIORES

D2. (4) TORNILLOS 12 MM

D2

D1

Figura D

D2

D1

6"

HERRAMIENTAS REQUERIDAS

ESCALERA TIPO TIJERA

TALADRO MÁS BROCA DE 1/16"

DESTORNILLADOR DE PALA GRANDE

DESTORNILLADOR PHILLIPS (pequeño y mediano)

LÁPIZ

Espesor mínimo de piso de 3/4" requerido para soportar la Escalera de

Ático Compacta (vea el Apéndice, Página 19, Figura 18). La escalera debe

instalarse en el mismo lado de la abertura donde se colocarán las bisagras

de la puerta.

1. Con la escalera centrada en la abertura, coloque los brazos de soporte

de las guías de bisagra (B1 y B2) en el borde superior del marco de la

abertura (vea la Figura E).

2. Marque con un lápiz los oricios de guía y luego pretaladre los oricios

piloto (1/16” de diámetro) para todos los tornillos.

3. Sujete utilizando tornillos de 35mm (B3).

Los brazos de soporte con dos oricios para tornillo deben estar en la parte

superior.

Si el material del piso cubre el borde superior de la abertura, verique que la

escalera está completamente estable. Si es necesario, utilice tornillos más

largos para penetrar el marco en sí.

En este momento, la escalera debe estar libre para girar en las bisagras y

deslizarse libremente hacia arriba y abajo por las guías.

PIEZAS REQUERIDAS

B1. (1) GUÍA DE BISAGRA - IZQUIERDA

B2. (1) GUÍA DE BISAGRA - DERECHA

B3. (6) TORNILLOS de 35 MM

Figura E

B1

ADVERTENCIA:

!

NO se pare sobre la escalera para hacer

esto. Utilizando una segunda escalera, o

desde el interior del ático, asegure las

bisagras utilizando seis tornillos de 35mm

suministrados.

B3

B2

5

Page 26

Paso 5

Instalación del brazo de ayuda

HERRAMIENTAS REQUERIDAS

PUNZÓN

DESTORNILLADOR DE PALA GRANDE

DESTORNILLADOR PHILLIPS

(pequeño y mediano)

LLAVE AJUSTABLE / ALICATES

1. Coloque la plantilla cortada (procedente de la parte trasera

de la caja de cartón de embalaje) contra el soporte de la

guía de bisagra izquierda o derecha (dependiendo del lado

elegido donde se instalará el sistema de pivote de fuerza).

2. Utilizando un punzón o lápiz, marque los 6 oricios

respectivos a través de la plantilla sobre el piso del ático

(vea la Figura F).

3. Coloque el alojamiento (F1) del resorte sobre los oricios

asegurándose que el brazo quede dirigido en dirección

contraria de la abertura preliminar (con la ranura de la

cubierta en el lado izquierdo) (vea la Figura G).

4. Fije el alojamiento del resorte al piso del ático mediante los

tornillos de 20 mm (F3) a través de los 4 oricios interiores

(vea la Figura G).

5. Coloque la cubierta (F2) del alojamiento sobre el

alojamiento del resorte y sujete utilizando los tornillos de

20 mm (F3) a través de los 2 oricios exteriores restantes

(vea la Figura G)

6. Coloque cuidadosamente la escalera en su posición

totalmente guardada (cerrada) en la abertura.

PIEZAS REQUERIDAS

F1. (1) UNIDAD DE PIVOTE DE

FUERZA

F2. (1) CUBIERTA DEL ALOJAMIENTO

F3. (6) TORNILLOS de 20 MM

F4. (1) PUNTA DE PIVOTE

F5. (1) PERNO M6 x 40 MM

Para instalación

derecha

Figura F

F2

F3

F6. (2) ARANDELAS PLÁSTICAS

F7. (1) TUERCA DE FIJACIÓN M6

F8. (1) TAPA DE TUERCA

F9. (1) PLANTILLA DE ORIFICIOS PARA

TALADRAR EN LA BASE [EN LA PARTE

TRASERA DE LA CAJA DE CARTÓN DE

EMBALAJE/EMPAQUE]

Para instalación

izquierda

F3

F3

F1

Figura G

7. Retire la tachuela y la tapa superior plástica de la parte

superior del riel lateral requerido de la sección trasera de la

escalera y deséchela (vea la Figura H).

8. En su lugar, sujete la Punta de Pivote (F4)

(vea la Figura H).

9. Coloque las placas de conexión del brazo de fuerza en

cualquier lado de la punta de pivote (F4) / riel de escalera y

alinee todos los oricios.

10. Asegure el riel a las placas de conexión utilizando el perno

(F5), arandelas (F6), tuerca y tapa de tuerca (F7 y F8)

(vea la Figura I).

Verique que el perno (F5) y la tuerca (F7) están apretados

de manera suciente para permitir que el mecanismo gire

libremente sin ninguna soltura.

NO apriete en exceso la tuerca ya que esto restringirá el

funcionamiento suave del sistema de la escalera.

6

Figura H

F8

Figura I

F7

F4

F5

F6

F4

F6

Page 27

Paso 6

Pasamanos

HERRAMIENTAS

REQUERIDAS

LLAVE AJUSTABLE / ALICATES

PIEZAS REQUERIDAS

E1. (3) ESPACIADORES DEL PASAMANOS

E2. (3) PERNOS M5 x 60 MM

E3. (3) ARANDELAS DE 25 MM DE DIÁMETRO

E4. (3) TUERCA DE FIJACIÓN M5

El pasamanos puede sujetarse a cualquier lado de la escalera. Se recomienda sujetar el pasamanos sólo después de sujetar el brazo de

pivote de fuerza.

1. Fije el pasamanos en su lado elegido del marco trasero (vea la Figura J).

2. Utilice 3 espaciadores (E1), pernos de 60mm (E2), arandelas y tuercas (E3 y E4) suministrados.

3. Usted tiene la opción de 2 diferentes alturas de pasamanos que

dependerán de la cantidad de pasamanos “dentro del ático” que

usted requiera (vea la Figura J).

Verique que todos los componentes de todo el conjunto están

totalmente rmes.

*La posición 1 ja el pasamanos

en la posición superior.

**La posición 2 ja el pasamanos

en la posición inferior.

Nota: La posición del pasamanos

afectará la cantidad de espacio

necesario dentro del ático.

E2

Pasamanos

E2

E1

E1

E3

E4

Pasamanos

E2

E1

1*

1*

2**

E2

2**

1*

2**

E1

Figura J

Paso 7

Acabado de la abertura para la puerta

HERRAMIENTAS REQUERIDAS

SIERRA

TORNILLOS / CLAVOS

DESTORNILLADOR PHILLIPS (pequeño y mediano)

Utilice una tabla de madera maciza estándar de 1 x 3 para el marco de la puerta y una tabla de madera maciza estándar de 1 x 2 para

la cuña de la puerta.

1. Mida el ancho de la abertura y corte la tabla de madera de 1 x 3. Sujete con clavos la tabla de madera recortada de 1 x 3 al

travesaño. La parte inferior del marco de madera para la puerta debe quedar a ras con el panel drywall de acabado en el cielo raso.

Repita para el tramo de longitud de la abertura. (Figura K)

2. Mida el ancho interior del marco y corte la tabla de madera de 1 x 2. Sujete con clavos la tabla de madera recortada de 1 x 2 al marco

de madera para la puerta, adentro a una distancia igual al espesor de la puerta para crear la cuña de la puerta. Repita para el tramo

La cuña debe

quedar adentro a

una distancia igual al

Figura K

espesor de la puerta

PIEZAS REQUERIDAS

Tabla de madera maciza estándar de 1 x 3 (marco para la puerta)

Tabla de madera maciza estándar de 1 x 2 (cuña para la puerta)

Su elección de madera de acabado

de longitud del marco. (Figura L)

Precaución: El uso de

materiales con un espesor

superior al espesor

recomendado podría hacer

que la abertura sea demasiado

Figura L

pequeña para ser útil.

7

Page 28

Paso 8

Colgado de la puerta

HERRAMIENTAS REQUERIDAS

DESTORNILLADOR DE PALA GRANDE

DESTORNILLADOR PHILLIPS (pequeño y mediano)

El espesor de la puerta debe ser de 3/4", de madera

laminada para armarios, cortada 3mm más pequeña

que la abertura del marco de madera para la puerta

(del Paso 7 - Acabado de la abertura para la puerta)

1. Atornille las bisagras (G5) a un borde de la

puerta utilizando tornillos para madera de 3/4".

2. Sujete las bisagras a la cara del marco en

el mismo extremo que usted instaló la escalera,

utilizando los tornillos para madera de 3/4"

(vea la Figura M).

PIEZAS REQUERIDAS

G5. (2) BISAGRAS PARA LA PUERTA

(8) TORNILLOS PARA MADERA DE 3/4"

G5

Figura M

Paso 9

Ubicación del oricio para la cerradura de puerta

HERRAMIENTAS REQUERIDAS

PIEZAS REQUERIDAS

ESCALERA TIPO TIJERA

TALADRO

BROCA DE 1/2"

PAPEL DE LIJA

DESTORNILLADOR DE PALA GRANDE

DESTORNILLADOR PHILLIPS (pequeño y mediano)

LLAVE AJUSTABLE / ALICATES

CINTA MÉTRICA / REGLA

LÁPIZ

1. Desde el interior del ático, con la puerta totalmente cerrada,

marque con un lápiz el borde de la cuña en la puerta. Mida

atrás y transera la línea al lado opuesto de la puerta.

2. Encuentre el punto medio del borde de la puerta opuesto al

lado con bisagra. Esto le proporcionará a usted su línea central

(vea la Figura N). Marque con un lápiz.

3. Mida exactamente 25mm hacia adentro desde la marca que fue

transferida, marque con un lápiz.

4. Taladre un oricio de 1/2" en el centro y lije los bordes rugosos.

A1. (1) CERRADURA

A2. (1) ANILLO DE TOPES DE RECORRIDO

A3. (1) PALANCA DE LA CERRADURA

A4. (1) TUERCA M12

A7. (1) TORNILLO de 12 MM

1"

Línea central de la puerta

Oricio de 1/2"

(PASO 9, CONTINÚA EN LA SIGUIENTE PÁGINA)

8

Taladre el oricio en el centro

dentro del marco de la puerta

Figura N

Page 29

(PASO 9, CONTINUACIÓN DE LA PÁGINA ANTERIOR)

5. Pase la cerradura (A1) a través del oricio de la puerta

desde la parte de abajo de modo que el puntero de

posición apunte hacia el borde de la puerta

(vea la Figura O).

6. Coloque el anillo de topes de recorrido (A2) sobre la

cerradura (A1) de modo que el oricio para tornillo esté a

45 grados con respecto a la línea central de la puerta

(vea las Figuras O y P).

7. Coloque el pestillo (A3) de la cerradura sobre la cerradura

(A1) y coloque dentro de la ranura de la cerradura de modo

que el pestillo de la cerradura apunte hacia el borde cerca

de la puerta y se coloque totalmente dentro del anillo de

topes de recorrido (A2) (vea las Figuras O y P).

8. Asegure el anillo de topes de recorrido (A2) utilizando el

tornillo de 12 MM (A7).

9. Asegure el pestillo con una tuerca M12 (A4) vericando que

la tuerca esté apretada de manera suciente para permitir

que el pestillo gire libremente sin ninguna soltura

(vea la Figura P).

A3

A2

A3

A4

Oricio para tornillo

A1

A3

A4

A7

Puerta

Figura O

45°

A2

A2

A1

Paso 10

Sujeción del soporte para el pestillo de la cerradura

HERRAMIENTAS REQUERIDAS

ESCALERA TIPO TIJERA

PUNZÓN

DESTORNILLADOR DE PALA GRANDE

DESTORNILLADOR PHILLIPS (pequeño y mediano)

CINTA MÉTRICA / REGLA

LÁPIZ

Cuando se gira hasta la posición correcta, el pestillo de la

cerradura enganchará en el respectivo soporte para mantener

cerrada la puerta. Sujete de la siguiente manera:

1. Marque una línea vertical en el interior de la cuña de

puerta correspondiente con la línea central de la

cerradura de la puerta (vea la Figura Q).

2. Coloque el soporte (A5) para el pestillo de la cerradura

a lo largo del borde inferior de la cuña de madera de

la puerta (vea la Figura R).

3. Haga coincidir la marca de muesca del soporte con la

línea central vertical.

4. Realice oricios de guía con el punzón y sujete,

utilizando 2 de los tornillos para madera de 3/4"

suministrados (A6).

5. Aplicar las etiquetas de puerta, 103552-01 y

103553-01 a la parte superior de la puerta, dentro del ático.

PIEZAS REQUERIDAS

A5. (1) SOPORTE PARA EL PESTILLO DE

LA CERRADURA

A6. (2) TORNILLOS PARA MADERA DE 3/4"

(1) “ADVERTENCIA” ETIQUETA P/N103552-01

(1) “COMO UTILIZAR” ETIQUETA P/N103553-01

Figura Q

Línea central

A6

Pestañas a ras con

la parte inferior de la

cuña para la puerta

Figura R

Marco de la puerta

A5

Figura P

Cuña de la

puerta

Espesor de la

puerta

9

Page 30

Paso 11

Manejo de la escalera

1. Coloque el gancho de guardado plástico (G3) dentro de un extremo de la barra de ayuda

(G2) y empújela rmemente para garantizar que el gancho de guardado plástico

(G3) quede totalmente colocado dentro de la barra. Asegure el gancho (G3) con el tornillo

autorroscante. Introduzca el tapón de extremo plástico en el extremo opuesto de la barra

de ayuda (G2).

2. Para abrir la puerta, coloque el gancho (G3) dentro de la ranura de la cerradura (A1) y gire

el pestillo en sentido antihorario hasta que éste llegue al tope de recorrido y luego baje la

puerta (vea la Figura S).

3. Coloque el gancho de guardado (G3) sobre y en el centro del peldaño inferior de la

sección TRASERA de la escalera y hale continuamente la escalera hacia afuera y hacia

abajo hasta que ambos topes superiores alcancen y hagan contacto con las guías de

bisagra (vea la Figura T).

4. Retraiga ambos seguros derechos ‘C’ y ‘D’ (azules) y gire las palancas de ambos seguros

hacia arriba dentro de la posición abierta asegurada (vea las Figuras T y W).

5. Para extender la escalera, retraiga el seguro izquierdo ‘A’ (negro) mientras se sostiene

el marco delantero de la escalera. Baje lentamente el marco hasta que el seguro ‘A’

(negro) enganche nuevamente (Figura U).

6. Luego retraiga el seguro ‘B’ (negro) y baje el marco intermedio hasta que el seguro ‘B’

(negro) se enganche en su posición requerida. Extienda la escalera hasta que las patas se

apoyen rmemente en el piso (Figura U).

7. Cuando se haya abierto completamente la escalera, gire hacia abajo ambas palancas de

los seguros derechos para desasegurar y liberar ambos seguros ‘C’ y ‘D’ (azules) y

verique que ambos seguros están totalmente enganchados. NO utilice la escalera

con algún seguro (‘A’, ‘B’, ‘C’ y ‘D’) desenganchado. Lea las etiquetas de seguridad

en el producto.

A

8. Verique que la escalera está halada hacia abajo de modo que los topes superiores (o

topes superiores adicionales, si los tiene) estén apoyados rmemente en las guías de

bisagra. Esto soporta la sección superior y evita que ésta se deslice hacia abajo cuando la

persona sube por ésta.

9. Verique el ángulo de escalera indicado en la etiqueta de seguridad

o consulte nuevamente los requisitos en posición abierta en la

página 2.

Guardado de la escalera

C

10. Retraiga ambos seguros derechos ‘C’ y ‘D’ (azules) y gire las

palancas de ambos seguros hacia arriba dentro de la posición

abierta asegurada (Figura W).

11. Para guardar la escalera, retraiga el seguro ‘A’ (negro), deslice el

marco delantero totalmente hacia arriba hasta que el seguro enganche

nuevamente.

12. Repita el paso 11 para el seguro ‘B’ (negro) y el marco intermedio de la

escalera

13. Invierta el paso 10 y verique que ambos seguros derechos ‘C’ y ‘D’

(azules) están totalmente enganchados.

14. Enganche el gancho de guardado plástico (E3) sobre y en el centro

G3

del peldaño inferior de la sección TRASERA de la escalera mientras

se mantiene la barra de ayuda en la posición vertical, empuje la

escalera verticalmente hacia arriba.

15. Continúe empujando lentamente la escalera hacia arriba y totalmente

dentro de la abertura del ático.

16. Utilice la barra de ayuda para levantar la puerta y gire la cerradura en

sentido horario para cerrar.

D

A1

10

Figura W

NO intente subir por su escalera de ático hasta que

usted haya revisado que ésta está halada hacia

abajo hasta los topes. Lea completamente todas

las etiquetas de seguridad y verique que ésta está

colocada en el ángulo correcto. Verique que los

seguros de jación están totalmente enganchados.

Topes

superiores

adicionales

instalados

Figura V

enganchado

Figura S

G3

Figura T

G2

Figura U

Sin topes superiores

adicionales instalados

Seguros

‘C’ y ‘D’

Liberado /

Retraído / posición

abierta asegurada

ADVERTENCIA:

!

B

Page 31

Apéndice

Creación de una abertura preliminar

Sección 1.1

Preguntas importantes

¿Es adecuado su cielo raso y estructura de vigas para esta instalación?

Esta escalera de ático puede instalarse en estructuras con estructuras de madera convencionales de techos (Vea la Figura 1). Si

existe un cielo raso, usted debe tener una abertura de ático en el

cielo raso que le permita ingresar al espacio superior para una

inspección de pre-instalación.

Las estructuras de soporte de techos que tienen refuerzos diagonales conectados a las vigas del cielo raso o que utilizan celosías

(Vea la Figura 2) no pueden cortarse sin destruir la capacidad de

soporte de carga de esa sección del techo. No corte vigas que

son parte de una celosía o estructura convencional reforzada con

diagonales, sin primero consultar un arquitecto o ingeniero estructural (consulte las Páginas Amarillas bajo los títulos de “Arquitectos

o Ingenieros Estructurales”).

La escalera de ático no debe instalarse en un cielo raso que tenga alguno de los siguientes componentes:

– Componentes de sistemas de calefacción / enfriamiento incrustados en el cielo raso

– Vigas hechas de materiales diferentes a la madera

– Revoque (mortero) reforzado con metal

– Cielos rasos suspendidos

Viga de

cielo raso

Estructura convencional de techos

Alfarda

Figura 1

Si su cielo raso contiene alguno de los anteriores elementos, no intente instalar la escalera de ático. Comuníquese con un profesional para obtener ayuda para sus necesidades especícas (consulte las Páginas Amarillas bajo los títulos “Contratistas de Calefacción

y Enfriamiento, Contratistas de Construcción, Carpinteros, Constructores de Casas, Remodelación de Casas, o Contratistas en

General”).

¿Satisfacen estas instrucciones sus necesidades?

Estas instrucciones describen cómo instalar la escalera de ático de manera paralela o perpendicular a las vigas del cielo raso.

Comuníquese con un profesional si usted quiere instalar la escalera de ático en otra dirección con respecto a las vigas.

¿Es adecuado su cielo raso y estructura de vigas para esta instalación?

ADVERTENCIA: NO CORTE ESTOS TIPOS DE ESTRUCTURAS SIN

CONSULTAR UN ARQUITECTO O INGENIERO ESTRUCTURAL.

Viga de

cielo raso

Alfarda

Viga de

cielo raso

Refuerzos diagonales

Alfarda

Estructura de techo tipo celosía

Figura 2

Estructura convencional de techo con refuerzos

diagonales conectados a las vigas del cielo raso

11

Page 32

Sección 1.2

Herramientas y materiales requeridos

Materiales:

– Varias piezas de madera con tamaño de viga (la cantidad depende de la instalación especíca)

– Clavos perforantes 16d ó tornillos de resistencia equivalente (24-60 dependiendo de la instalación especíca)

– Clavos perforantes 20d ó tornillos de resistencia equivalente son necesarios para instalaciones

donde se cortan vigas

Escalera tipo tijera:

– Usted necesitará una escalera tipo tijera que sea lo sucientemente alta para que usted pueda ingresar al espa

cio superior sin pararse más allá de la altura de trabajo de la escalera tipo tijera. La altura de trabajo de la

escalera tipo tijera es dos peldaños abajo de la meseta (supercie superior de la escalera).

– Su escalera tipo tijera también debe tener una capacidad de servicio superior a la suma de su peso más el peso

de la escalera de ático y cualquier material adicional utilizado para la instalación.

PRECAUCIÓN: Tenga cuidado al utilizar una escalera tipo tijera para ingresar y salir del espacio superior.

Herramientas para crear una abertura preliminar:

– Linterna o lámpara de extensión

– Martillo de uña

– Lápiz

– Serrucho manual / sierra motorizada

– Cinta para medir

– Escuadra para fabricación de marcos

– Herramientas para cortar una abertura en el cielo raso existente

Equipo de seguridad:

– Guantes

– Gafas de seguridad

– Mascarilla contra polvo

12

Page 33

Sección 1.3

Búsqueda de una ubicación adecuada

Antes de proceder: Usted debe tener una estructura apropiada de vigas y cielo raso, herramientas y materiales

requeridos, y una ubicación nivelada y plana en el cielo raso.

Objetivo: Encontrar una ubicación libre de peligros y obstrucciones que proporcione espacio para la instalación y uso de la escalera de

ático.

PASO 1. Elija una posible ubicación para la instalación. Verique el tamaño de la abertura preliminar mostrado en la caja

o en la lista de vericación de pre-instalación.

Si usted está instalando la escalera

de ático en un garaje, no olvide considerar

donde se estacionarán los automóviles.

PASO 2. Si no hay cielo raso y la escalera de ático

encajará entre las vigas de modo que

no se requiere cortar vigas, vaya a la

Sección 1.5 “ENMARCADO DE LA

ABERTURA PRELIMINAR”.

Si no hay cielo raso, pero se requiere cortar

una o más vigas, vaya a la Sección 1.4

“CORTE DE VIGAS DEL CIELO RASO”.

Si hay un cielo raso en esta ubicación, usted

deberá inspeccionar el área de ático sobre esta

ubicación según se describe en los pasos 3 y 4.

PASO 3. Ingrese al espacio superior y encuentre el área sobre su ubicación elegida.

Esta área podría ubicarse:

A) Escuchando al golpear desde abajo

B) Midiendo distancias desde las paredes u otros objetos comunes al espacio superior y al sitio debajo

POR SU SEGURIDAD, TENGA CUIDADO CON LOS PELIGROS

se pare ni siente sobre el cielo raso o el aislamiento

NO

que cubre el cielo raso – el cielo raso no está hecho

para soportar su peso. ¡Usted puede caer a través del

cielo raso aun cuando éste parezca rme! Sólo las

vigas pueden soportar el peso.

Tenga cuidado con clavos losos clavados a

través del techo.

ADVERTENCIA:

!

SOBRE SU CABEZA.

ADVERTENCIA: No clave clavos metálicos u otros objetos conductores de la electricidad en el cielo raso a menos que usted esté

seguro que no harán contacto con cables eléctricos. El contacto con un cable eléctrico puede ser mortal.

PASO 4. En esta ubicación en el espacio superior:

A) Verique que hay suciente espacio para que usted se pueda mover de manera segura

durante la instalación.

B) Revise el espacio superior en cuanto a espacio de almacenamiento adyacente a la ubicación elegida.

Si desea caminar o arrastrarse en el espacio superior, asegúrese que hay suciente espacio para

hacerlo así.

C) Revise el espacio sobre su ubicación elegida en cuanto a peligros y obstrucciones tales como:

– Cables eléctricos

– Tubos

– Ductos de calentamiento y enfriamiento

– Hornos

– Calentadores de agua calientes u otras obstrucciones

Nota: Para revisar en cuanto a peligros, usted deberá mover el aislamiento de su ubicación elegida. Utilice una

mascarilla contra polvo, gafas de seguridad y guantes, y mantenga cubierto su cuerpo para evitar pequeños cortes con

la bra de vidrio. Mueva suavemente a un lado el aislamiento para evitar agitar el polvo que podría ser dañino para sus

ojos y pulmones.

PASO 5. Si existe cualquier peligro u obstrucción en su ubicación elegida, busque otra ubicación o haga mover los peligros u

obstrucciones por parte de profesionales (consulte las Páginas Amarillas bajo los títulos de “Contratistas Eléctricos,

Contratistas de Calefacción y Enfriamiento, y Contratistas de Plomería”).

13

Page 34

Sección 1.4

Corte de una abertura en el cielo raso

Antes de proceder: Usted debe tener una ubicación que:

A) Esté libre de peligros y obstrucciones en el espacio superior.

B) Esté libre de peligros en el cielo raso.

C) Proporcione suciente espacio para la instalación.

D) Proporcione suciente espacio para utilizar la escalera de ático.

Objetivo: Cortar una abertura, que tenga el tamaño correcto, en el cielo raso en la ubicación deseada.

PASO 1. Prepare el sitio moviendo los muebles, cubrien

do el piso con una tela anti-salpicaduras y,

llevando los niños y mascotas a una distancia

segura.

PASO 2. Colóquese gafas de seguridad y una mascarilla

contra polvo. Estos elementos evitarán que

partículas del cielo raso y polvo caigan en sus

ojos, boca o nariz a medida que usted realiza un

oricio de inicio y corte dentro del cielo raso.

PASO 3. Con un martillo y cincel, realice un oricio de ini

cio cerca del centro de la ubicación elegida

(Vea la Figura 4).

PASO 4. Agrande la abertura con una sierra hasta que

usted pueda ver una viga (Vea la Figura 5).

PASO 5. Dibuje sobre el cielo raso un rectángulo del

tamaño de la abertura preliminar, con un borde

paralelo a una viga (Vea la Figura 6). Usted

podría hacer esto aserrando hasta que usted

alcance una viga, y utilícelo como un marco de

referencia. (El tamaño de la abertura preliminar

debe ser de 0.46m x 0.61m como mínimo).

Nota: Ubicar al menos un borde de la abertura a

lo largo de una viga del cielo raso permitirá uti

lizar la viga como un lado del marco que usted

construirá. Esto simplicará la enmarcación de

la abertura preliminar.

PASO 6. Corte el resto del cielo raso dentro del trazo

marcado siguiendo estas instrucciones:

A) No corte ninguna viga en este momento.

Corte únicamente a través del cielo raso.

B) Remueva el cielo raso en pequeños pedazos

ya que el material del cielo raso puede ser

muy pesado.

PASO 7. Si ninguna viga atraviesa la abertura en el

cielo raso, vaya a la Sección 1.5 “ENMARCADO

DE LA ABERTURA PRELIMINAR”.

Si alguna viga atraviesa la abertura, vaya a la

Sección 1.4 “CORTE DE VIGAS DEL

CIELO RASO”.

ADVERTENCIA:

!

NO serruche, corte, ni martille dentro del cielo raso

hasta que usted esté seguro que la ubicación está

libre de peligros y obstrucciones en el cielo raso y

el ático. El contacto con un cable eléctrico puede

ser mortal.

Figura 4 Figura 5

Figura 6

14

Page 35

Sección 1.4

Corte de una abertura en el cielo raso

Antes de proceder: Usted debe tener vigas expuestas o una abertura de dimensión correcta en la ubicación deseada

en el cielo raso.

Objetivo: Cortar cualquier viga que esté en el camino de su ubicación elegida. Antes de cortar las vigas, usted debe

sujetarlas a otras vigas en el ático superior para evitar que el cielo raso se combe o colapse completamente.

PASO 1. Si el sitio tiene un cielo raso y usted ha cortado

la abertura requerida, vaya al Paso 2.

Si el sitio no tiene un cielo raso, usted deberá

marcar las vigas de acuerdo con los literales (A)

o (B) siguientes.

(A) Si la ubicación elegida es paralela a las

vigas, marque la longitud de la abertura prelimi

nar en la parte superior de las vigas

(Vea la Figura 7).

No corte la viga en esta marca.

(B) Si la ubicación elegida es perpendicular a

las vigas, marque el ancho de la apertura pre

liminar en la parte superior de las vigas

(Vea la Figura 8).

No corte la viga en esta marca.

La línea punteada indica su ubicación

elegida (ubicación paralela a la viga).

Figura 7

PASO 2. Corte 2 tablas de tamaño de viga lo

sucientemente largas para abarcar 2 vigas en

cada lado de su ubicación elegida (Vea la

Figura 9). Estas tablas soportarán las vigas que

serán cortadas y ayudarán a evitar que el cielo

raso se combe o colapse completamente

mientras usted está trabajando en el espacio

superior.

PASO 3. Coloque estas tablas a aproximadamente 24

pulgadas del borde de su ubicación elegida y

clávelas (Vea la Figura 9).

Nota: La distancia de 24 pulgadas es necesaria

para darle espacio a usted para martillar los

clavos dentro del marco que usted construirá en

la siguiente sección.

La línea punteada indica su ubicación

elegida (ubicación perpendicular a la viga).

Figura 8

Tablas que soportan

la viga

Clave o atornille las

tablas a cada viga

Figura 9

15

Page 36

Sección 1.4 (Continuación)

Corte de las vigas del techo

PASO 4. Luego, determine dónde debe cortarse la

viga(s). La Figura 10 muestra dónde marcar la

viga(s) que atraviesa su ubicación elegida.

Observe que la viga(s) debe marcarse detrás

del borde de su ubicación a una distancia de 2

veces el espesor de la viga (usualmente 3 pul

gadas). Esto deja espacio para colocar dos

travesaños del tamaño de viga contra cada

extremo de la viga(s) cortada, (Vea la Figura 16

en la página 18).

Nota: En algunas casas, especialmente las

viejas, las vigas pueden ser levemente más

gruesas que la madera que usted puede com

prar actualmente. Si sus vigas tienen un espe

sor diferente que la madera que usted utilizará

para los travesaños, usted deberá marcar las

vigas detrás del borde de su ubicación a una

distancia de dos veces el espesor del travesaño

en vez del espesor de la viga.

PASO 5. Serruche a través de la viga(s) teniendo cui

dado de no cortar a través del cielo raso y

asegurándose que los extremos de corte de la

viga(s) son planos y verticales.

Figura 10

2 x Espesor

de viga

La línea

punteada

indica su

ubicación

elegida

Corte

aquí

Sección de

la viga a ser

removida

2 x Espesor

de viga

Corte

aquí

Sección 1.5

Enmarcado de la abertura preliminar

Antes de proceder: Usted debería tener un espacio entre vigas de al menos 0.46m. Cualquier viga cortada debe sujetarse a las vigas no-cortadas.